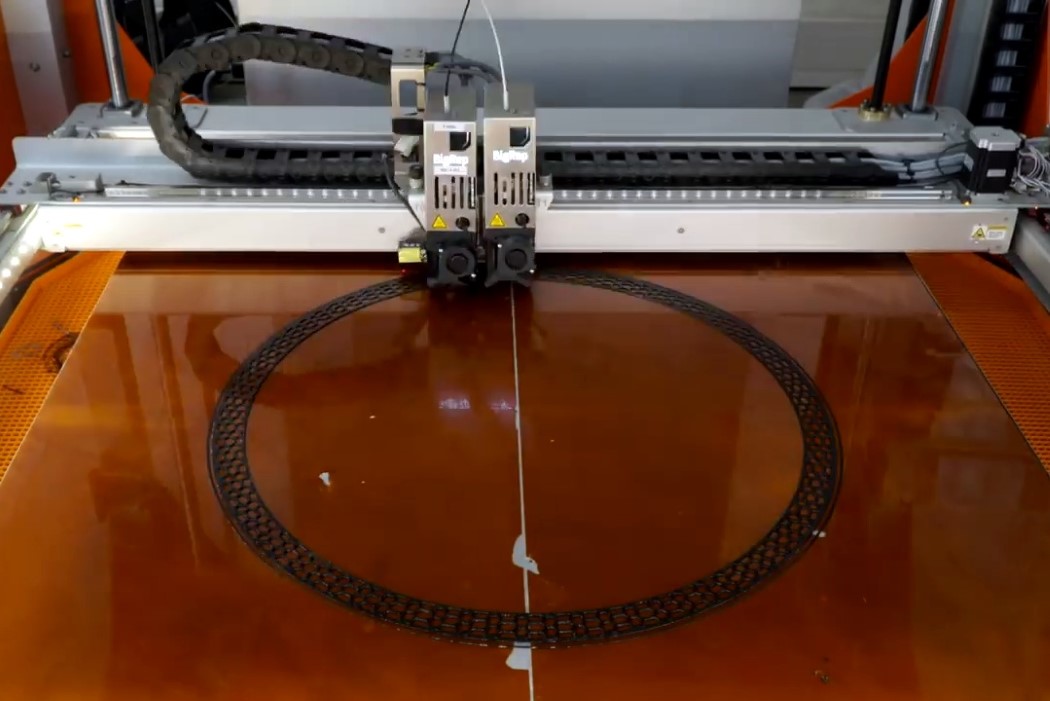

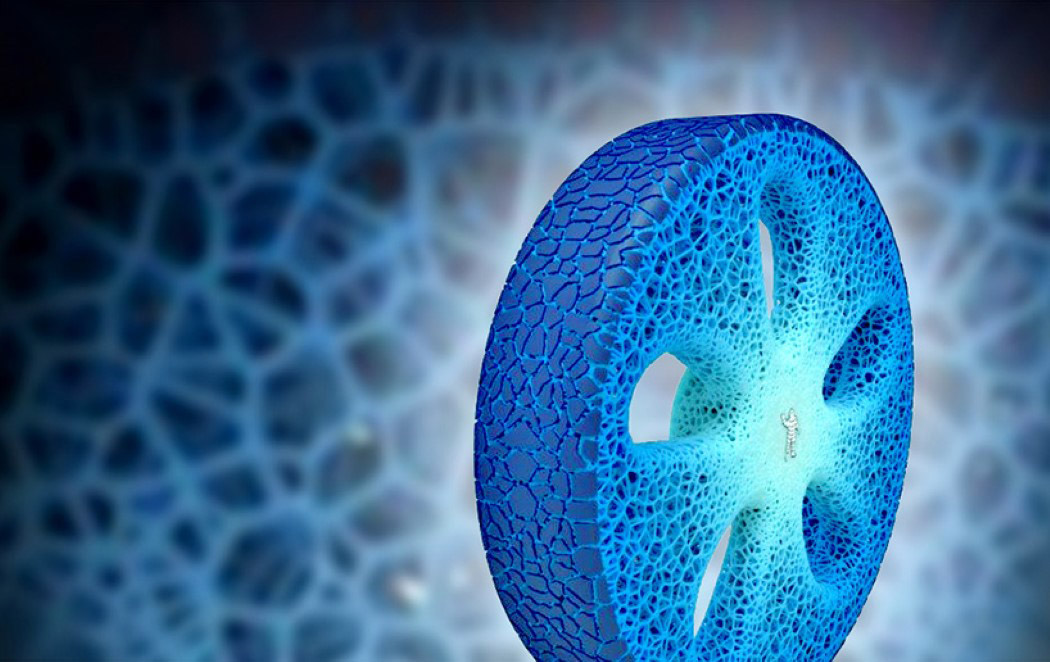

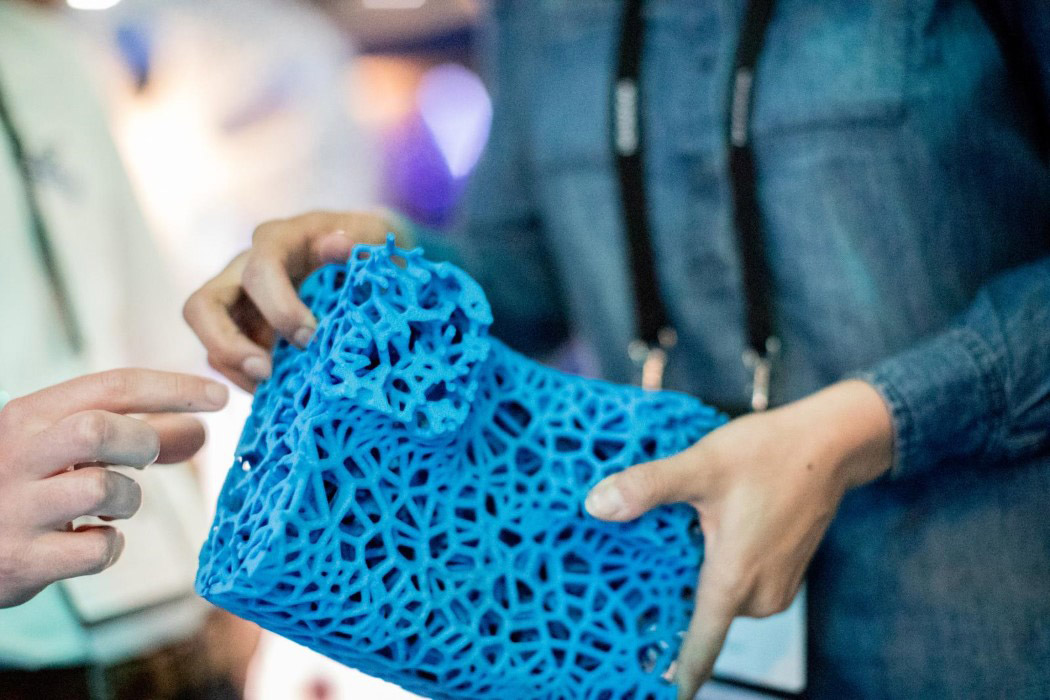

It’s been too long that we’ve stared at these marvelous, promising airless 3D printed tires but with no clear timeline of when they’ll actually make their real-world debut. Channeling that frustration into something productive, BigRep designed a 3D printed airless tire of their own that they then went on to print on their own using their PRO FLEX Filament, a TPU based industrial-grade filament. Flexible enough to easily bend and fit onto your regular tire hub, and durable enough to handle roads with relative ease, the airless tire comes with a honeycomb-style construction that gives it its springiness and shape-memory, and is more of BigRep’s experiment of putting their PRO FLEX filament to the test. The PRO FLEX Filament can be used with the BigRep One industrial 3D-printer and it boasts “high-temperature resistance, low-temperature impact resistance” and durability “with excellent damping behavior and dynamic properties.”

While BigRep doesn’t plan on mass manufacturing tires yet, the printers and the filament are up for purchase, allowing you to experiment on your own designs and even test out treads that allow the 3D printed tires to work on wet roads or terrains. Unlike Bridgestone’s airless tire that is an entire wheel in itself, BigRep’s tires can be retrofitted on any bike by ditching the current tire tube, and can more importantly, be customized to the max!

Designer: BigRep