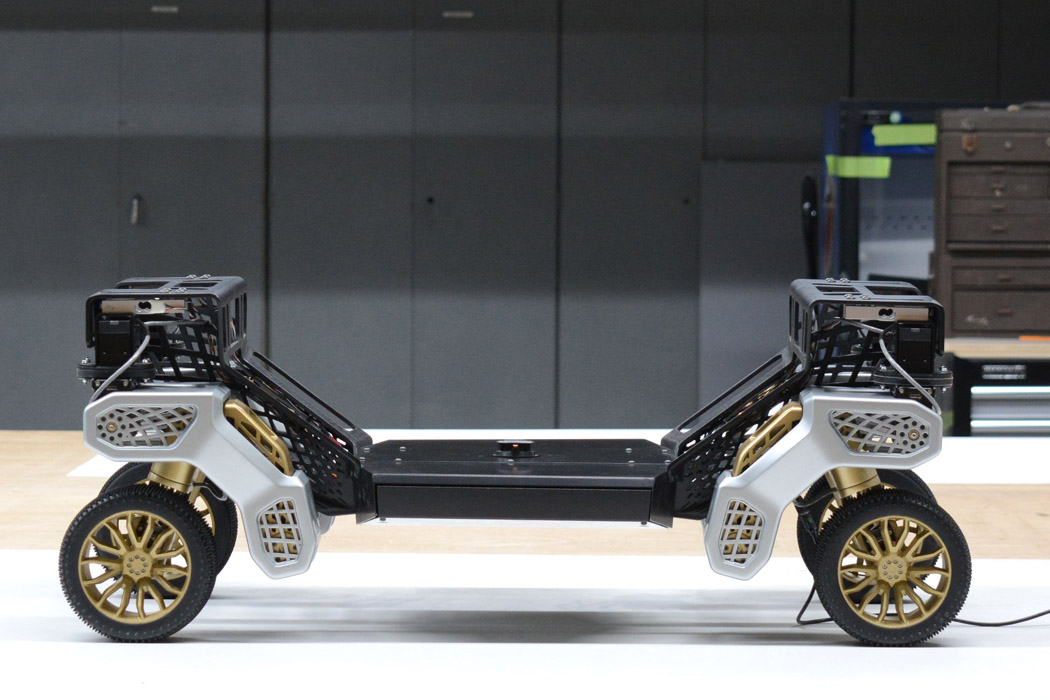

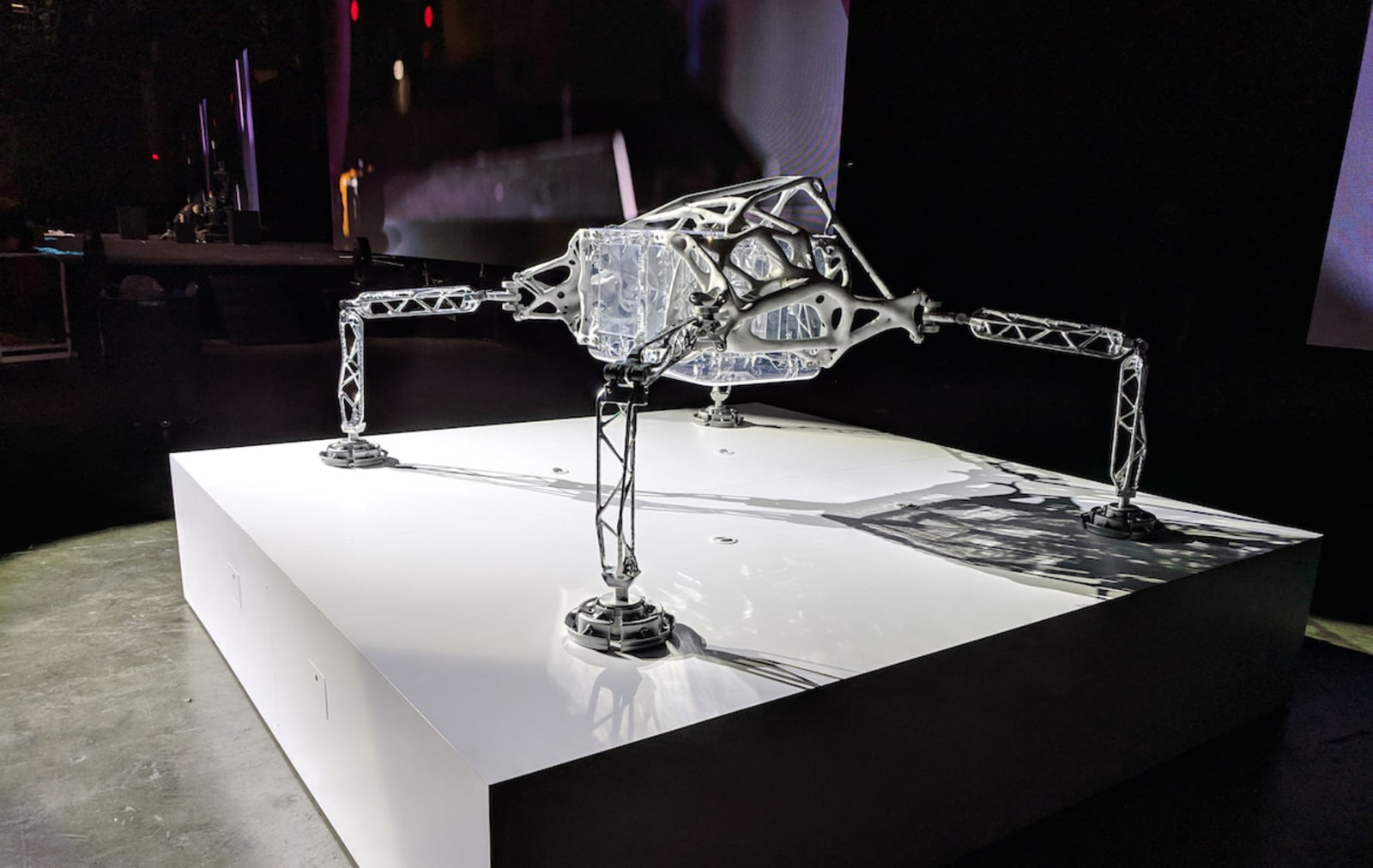

Walking in the footsteps of Elevate – Hyundai’s Ultimate Mobility Vehicle (UMV) shown-off at CES 2019, is the all-new TIGER that the Hyundai Motor Group revealed today. A logical progression in the development of the walking car robot dream that Hyundai has been chasing for quite some time, the TIGER (Transforming Intelligent Ground Excursion Robot) concept is developing under the freshly formed New Horizons Studio in collaboration with Autodesk and Sundberg-Ferar. This will be the company’s first unmanned Ultimate Mobility Vehicle (UMV) with the 360-degree directional control, designed typically to carry payload on challenging terrain in remote locations.

As Dr. John Suh, Head of New Horizons Studio, aptly put forward, the group’s vision to design automated vehicles like TIGER and the associated technologies to push the envelope of imaginations for future UMV’s. He said, “We are constantly looking at ways to rethink vehicle design and development and re-define the future of transportation and mobility.” The vehicle’s size and total weight are kept to the minimum courtesy of the carbon fiber composite additive printing – making it possible to transport TIGER to remote locations via unmanned aerial vehicles (UAV’s) for exploration or delivering emergency payload for rescue missions. Taking the capabilities of any off-road vehicle to the next level, TIGER can transform its locomotion from wheeled mobility to walking abilities instantly. Hyundai Motor Group calls it the Leg-wheel articulation that enables it to deliver payload in inhospitable terrain safely. For the most part, TIGER uses an all-wheel-drive mechanism to get over the landscape, and when things get too tricky for its wheels, it’s time to get walking.

The first prototype version of the TIGER will be X-1 (‘X’ for experimental) – honing strong legs and chassis thanks to the advanced generative design capabilities. Not only will the UMV be ideal for rescue missions and payload delivery, but it will also be perfect for 360-degree surface evaluation for other planetary exploration missions – the likes of the Moon mission or the ongoing Mars missions. As per David Byron, Manager of Design and Innovation Strategy at Sundberg-Ferar. “TIGER is a modular platform design allowing different bodies to be attached to the chassis for unique applications such as cargo delivery or surveillance in locations not suitable for humans.”

While Elevate is designed to carry passengers, this one solely targets unscrewed missions with its compact form factor. Now that Hyundai Motor Group has acquired Boston Dynamics, this robotic powerhouse’s characteristics may well come into play for bringing the two walking robots to life. In a way, it looks like the evolved cousin of Spot the dog robot already. We can expect the TIGER X-1 to take shape in the next couple of years, and a buyable version is expected at least five years from now. After all, designing a vehicle like this is no child’s play!

Designer: Hyundai Motor Group

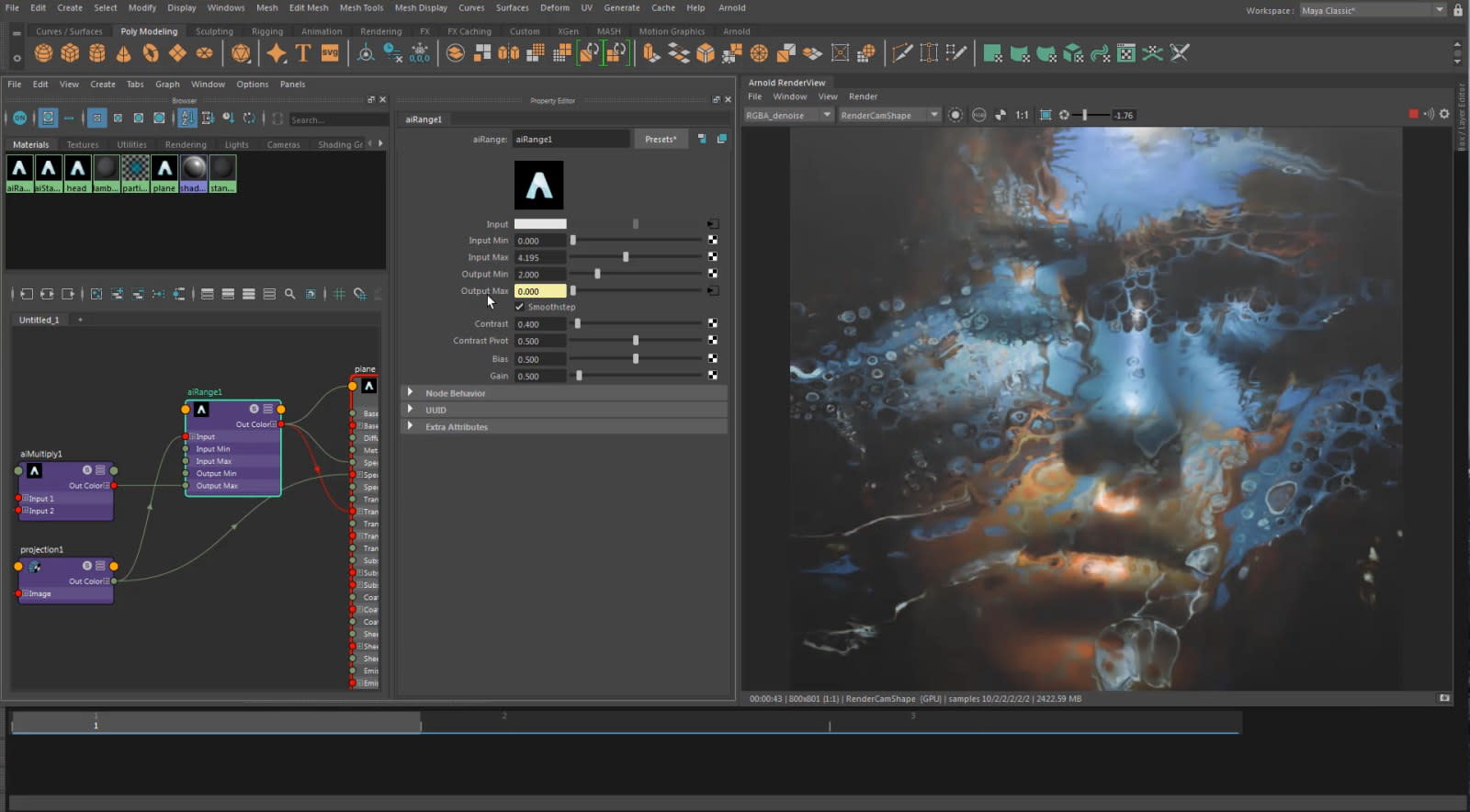

Now that NVIDIA's RTX graphics cards are boosting performance for Adobe's Creative Cloud suite and Blender, it was only a matter of time until Maya, the 3D creation tool widely used for Hollywood films and TV shows, joined the party. NVIDIA announced...

Now that NVIDIA's RTX graphics cards are boosting performance for Adobe's Creative Cloud suite and Blender, it was only a matter of time until Maya, the 3D creation tool widely used for Hollywood films and TV shows, joined the party. NVIDIA announced...

Autodesk, the software company behind AutoCAD, has teamed up with NASA's Jet Propulsion Laboratory (JPL) to look at news ways to create an interplanetary lander that could potentially touch down on the moons of Saturn or Jupiter. When Mark Davis, the...

Autodesk, the software company behind AutoCAD, has teamed up with NASA's Jet Propulsion Laboratory (JPL) to look at news ways to create an interplanetary lander that could potentially touch down on the moons of Saturn or Jupiter. When Mark Davis, the...

The virtues of 3D printing have long been touted by a vast range of manufacturers, so it was only a matter of time before the EV industry got in on the action. General Motors has announced that, alongside design software company Autodesk Inc, it's cr...

The virtues of 3D printing have long been touted by a vast range of manufacturers, so it was only a matter of time before the EV industry got in on the action. General Motors has announced that, alongside design software company Autodesk Inc, it's cr...

Earlier this year, Makerbot announced in its most recent bloodletting that it would focus more on the education market. Today we're seeing some of the fruits of that decision. First up is "My MakerBot," what the outfit describes as a cloud-enabled br...

Earlier this year, Makerbot announced in its most recent bloodletting that it would focus more on the education market. Today we're seeing some of the fruits of that decision. First up is "My MakerBot," what the outfit describes as a cloud-enabled br...

Drones and airports usually go together like oil and water, but you can't say that about Atlanta's air hub. The city has formed a partnership with 3DR, Autodesk and engineering firm Atkins that has drones mapping Hartsfield-Jackson International Air...

Drones and airports usually go together like oil and water, but you can't say that about Atlanta's air hub. The city has formed a partnership with 3DR, Autodesk and engineering firm Atkins that has drones mapping Hartsfield-Jackson International Air...

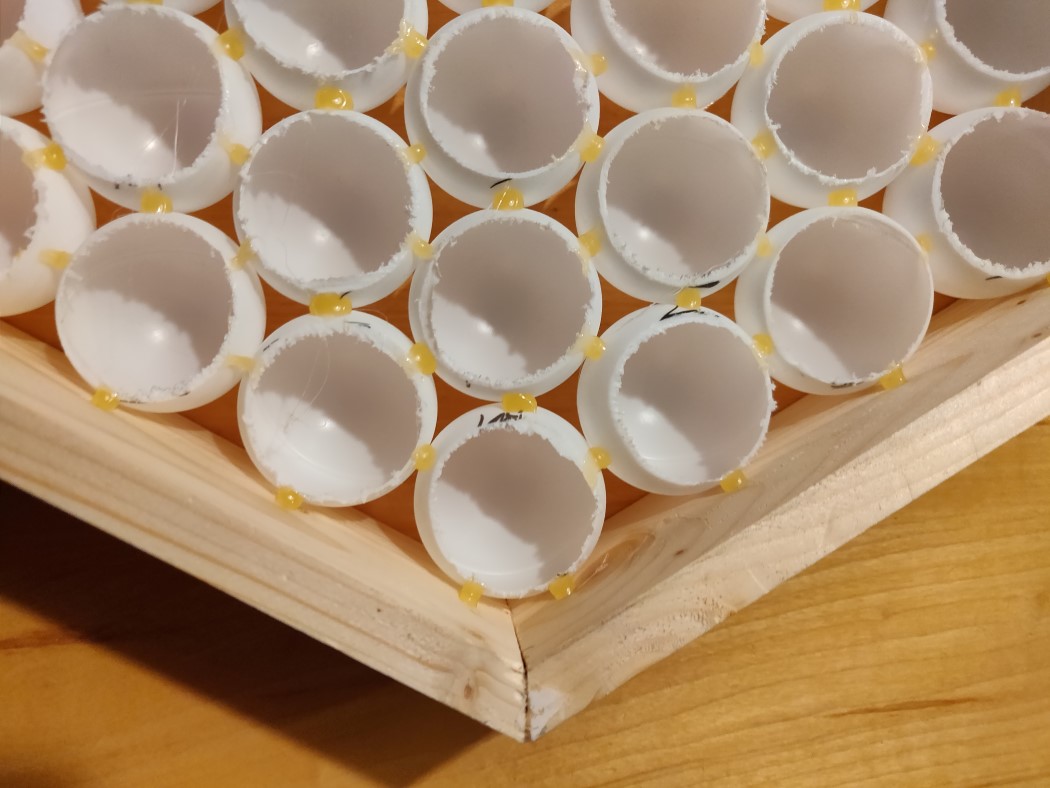

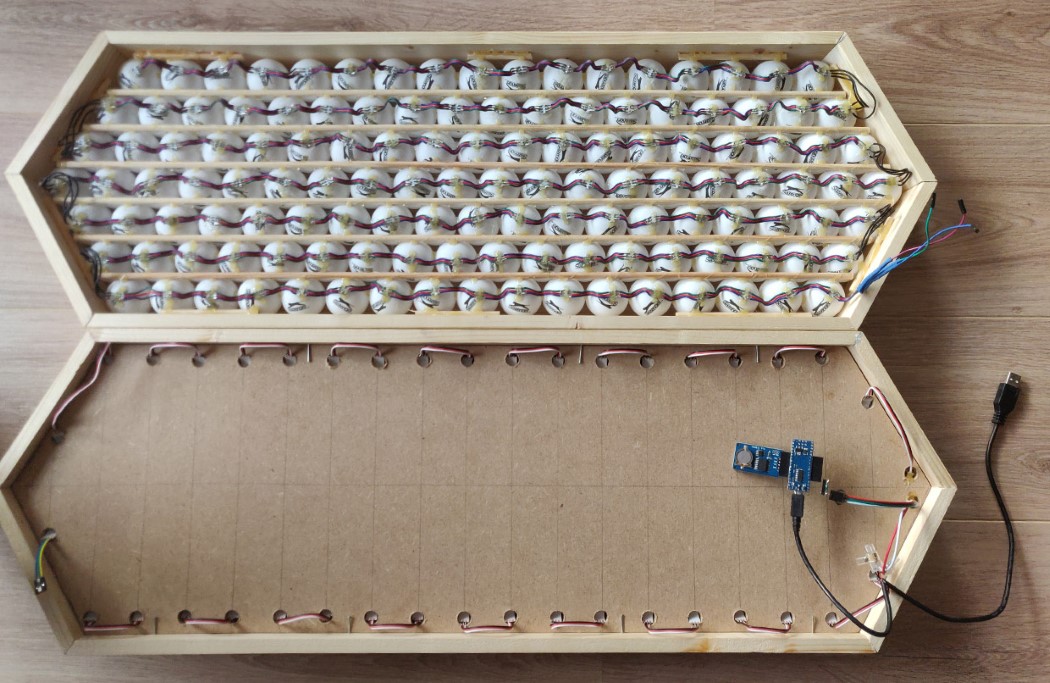

The holidays are a time to forget about your fitness goals and indulge. And what better to stuff your face with than, well, your face? Candy Mechanics is in the business of personalised chocolate, but the company's latest service takes that idea one...

The holidays are a time to forget about your fitness goals and indulge. And what better to stuff your face with than, well, your face? Candy Mechanics is in the business of personalised chocolate, but the company's latest service takes that idea one...