People today live in the fast lane, for better or for worse. Many change jobs or even careers in a snap; others change residences or living arrangements. A lot of the products today are designed to cater to that kind of lifestyle, from smartphones that put everything under our fingertips, almost literally, to modular and portable equipment that let us pick up and go anywhere we need to be. There are, however, still a few things that are still set in the old ways, so to speak, like how furniture is made or how rooms are built. While there’s nothing terribly wrong with traditional processes, they can sometimes be wasteful, inefficient, and unsustainable. Modularity has started to make inroads in construction and architecture, like this modular block system that empowers people to set up walls, dividers, or even rooms with no tools or knowledge required.

Designer: Stan Spencer (Blokaloks)

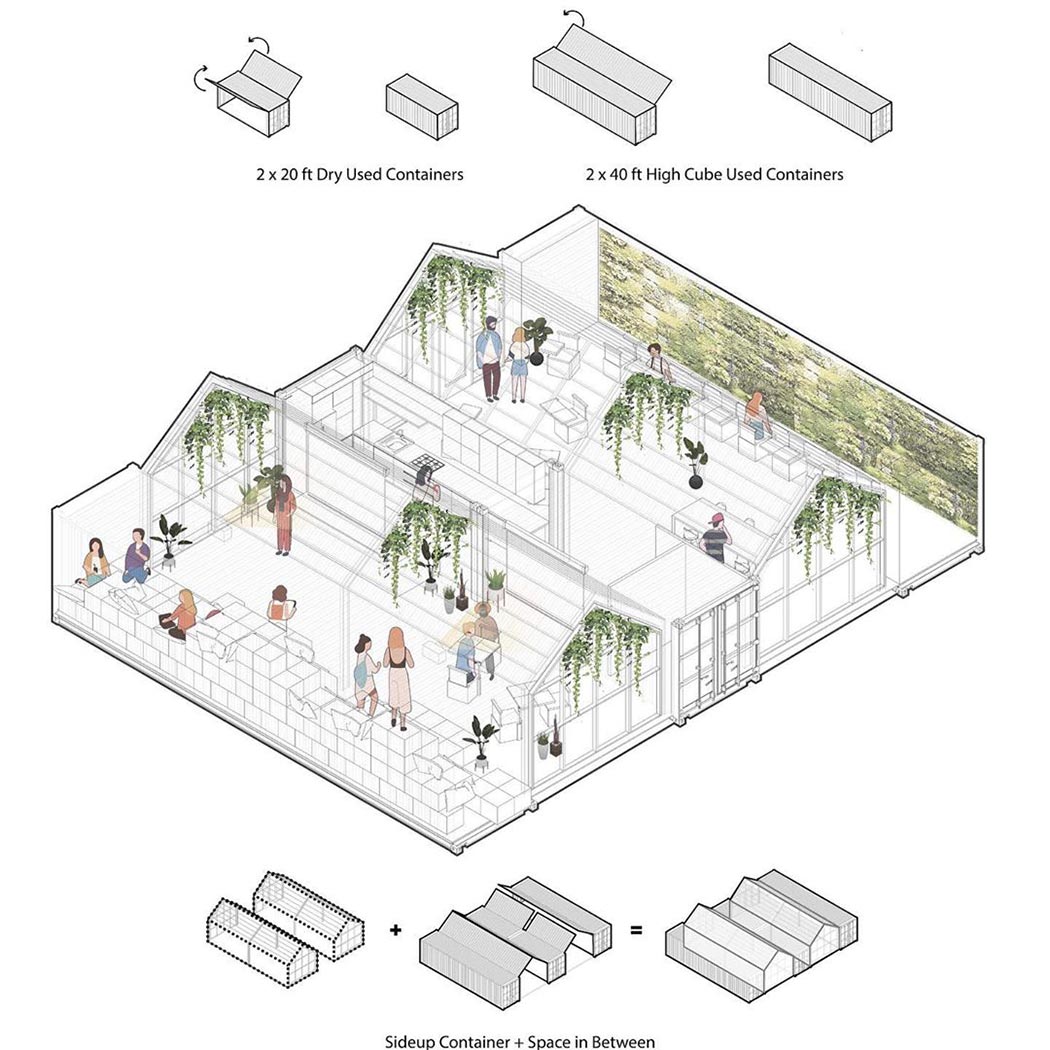

Blocks have become a favorite form when it comes to modular systems. After all, they’re akin to bricks that serve as the foundations of many things that we build, so it’s really no surprise that LEGO chose this metaphor for its now iconic line of construction toys. Some block-inspired systems offer the ability to build simpler pieces of furniture or products without much effort, but Blokaloks really takes it to the next level when it comes to putting up walls.

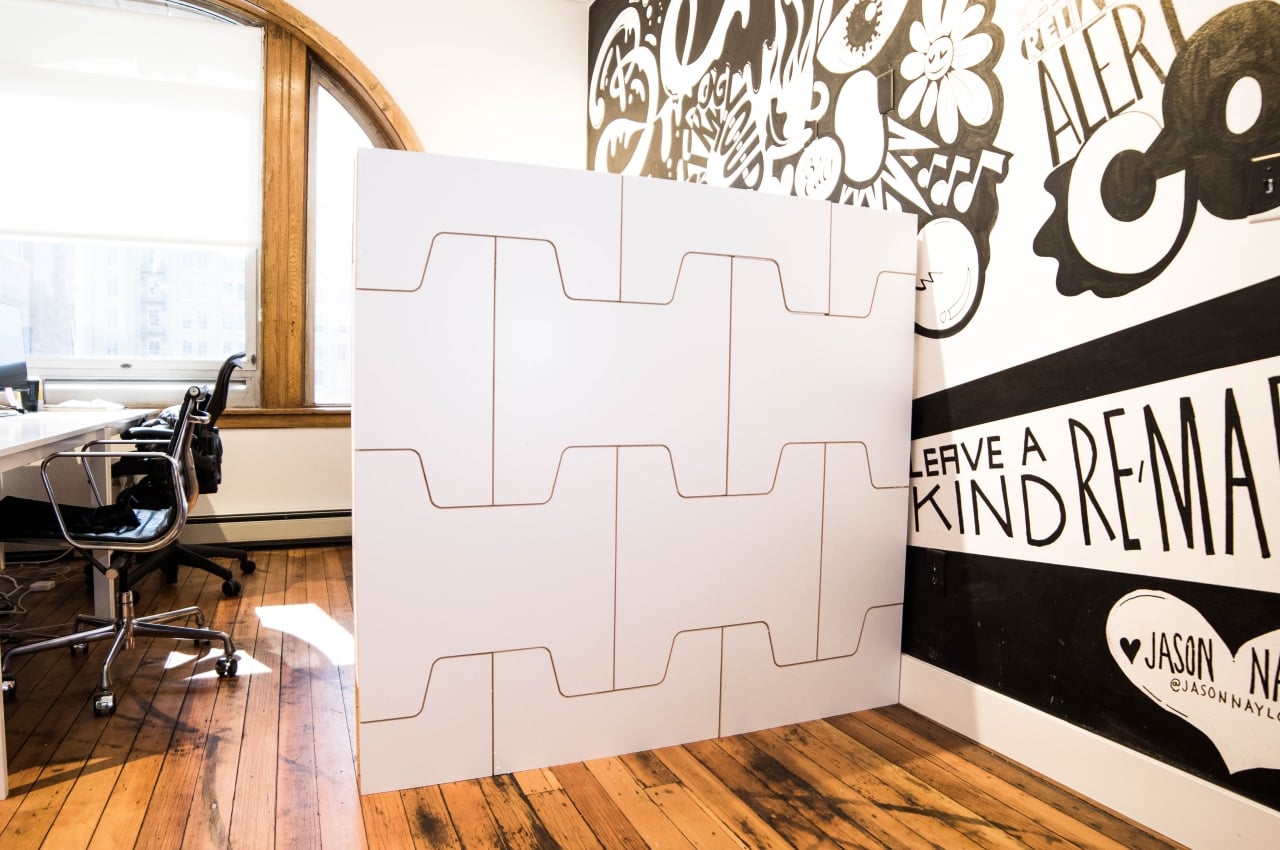

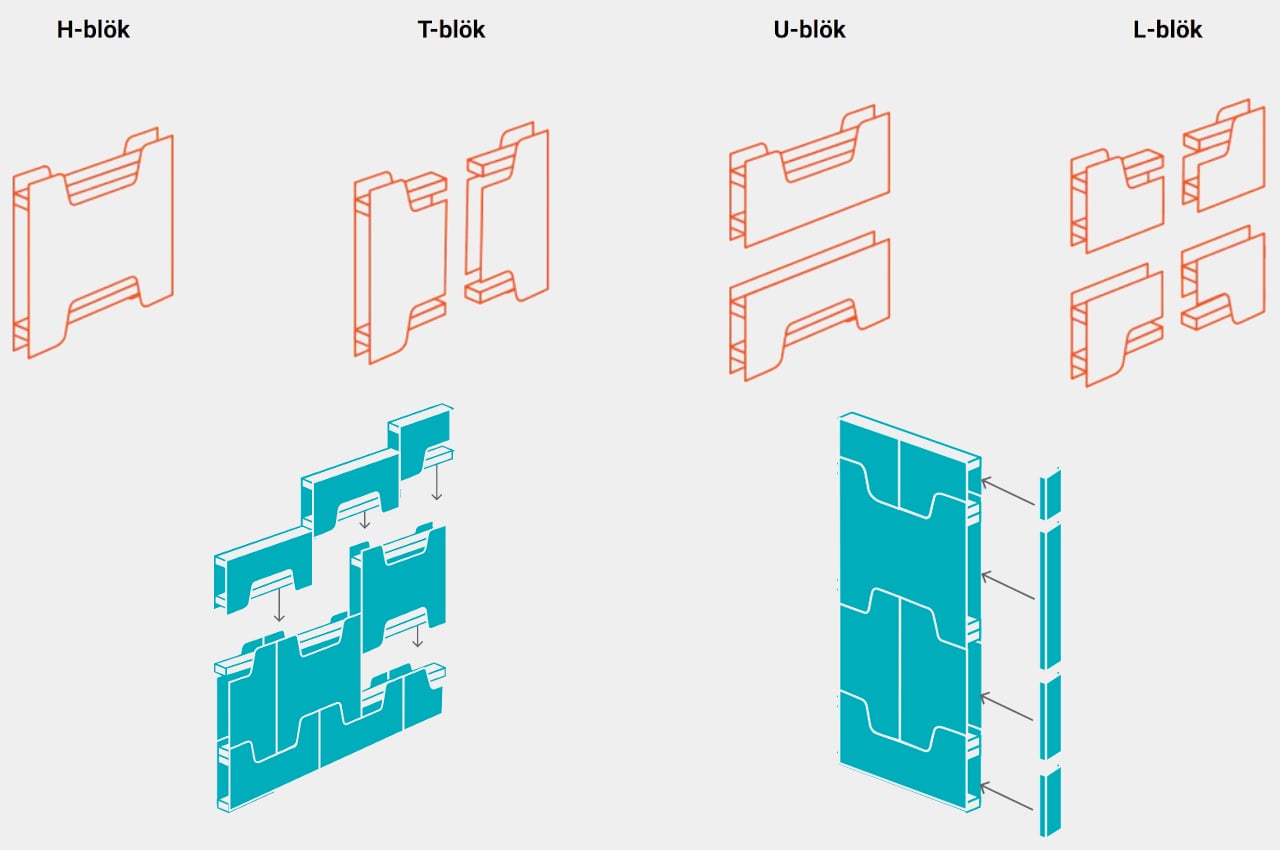

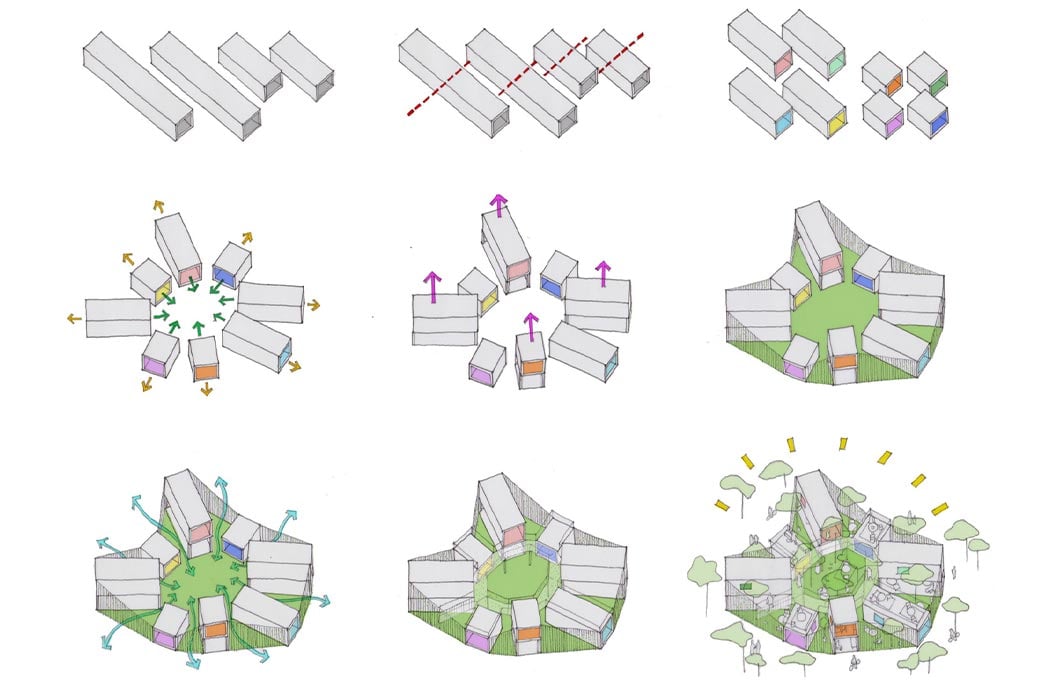

Instead of actual rectangular blocks, though, Blokaloks come in four shapes that you mix and match to create a flat vertical surface like a wall. It doesn’t have to be just a single wall, though, or a floor-to-ceiling wall. It can be as simple as a divider or as big as a full-blown room. The system comes with stands to prevent the wooden walls from tipping as well as trim pieces for edges and corners.

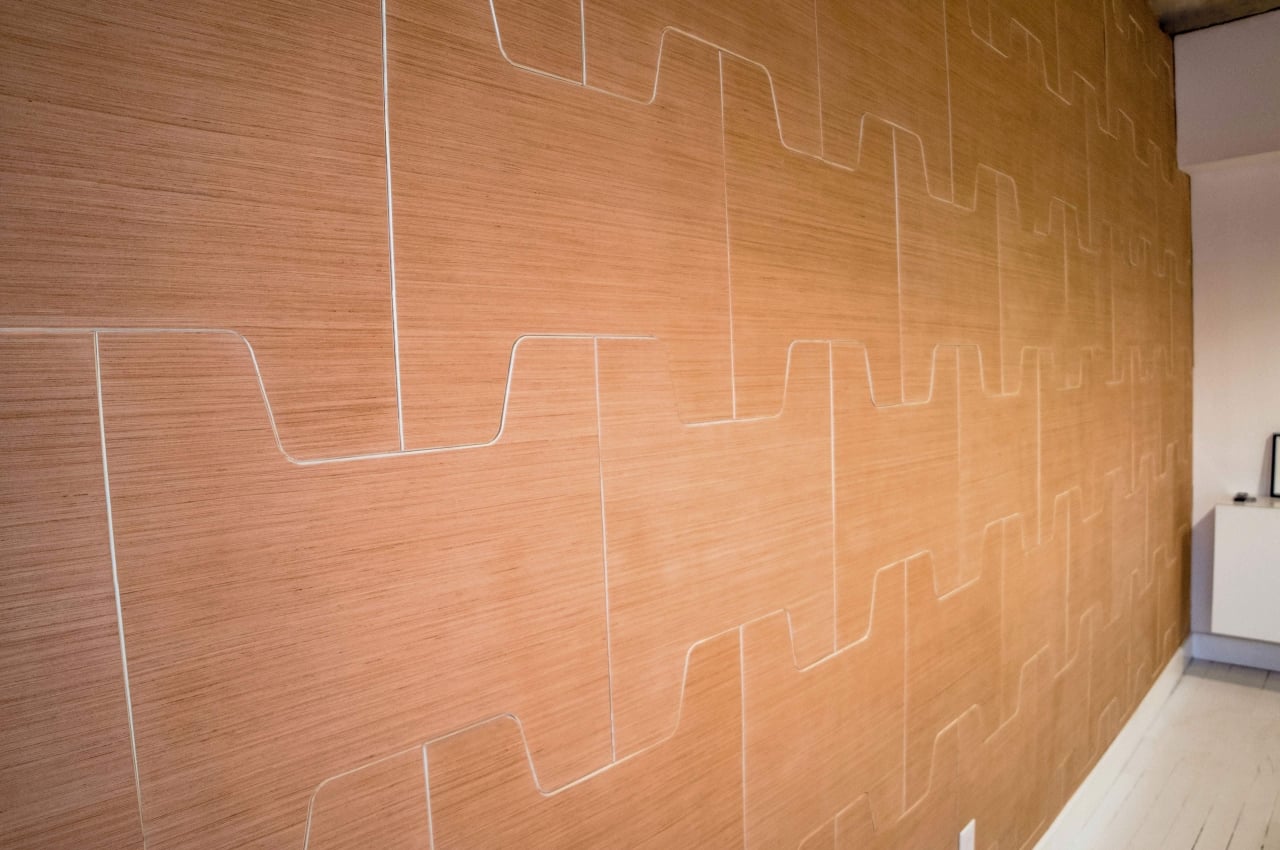

Unlike other modular construction systems, Blokaloks offers something that goes beyond modularity. There is, for example, an eye towards sustainability, with all blocks made from different types of wood such as Bamboo, Beech, Maple, and Walnut, just to name a few. Even the core is made from mineral wool to help dampen sound from the other side. That core is optional, though, in case you actually want chatter to go through.

Blokaloks also give freedom and flexibility in the way you build your structures. You don’t need tools to put things together, nor do you need tools to take them apart. The design makes it easy to redesign walls and rooms as needed. Rather than having to physically expand the room to accommodate new uses, you can simply “tear down” some unused sections to make room for a different one.

With this in mind, Blokaloks seems to be perfectly designed for fast-paced changes that go along with today’s lifestyles. Even the pricing scheme is meant to be scalable, depending on the need at that time rather than being stuck with what you purchased forever. Even if the materials or the manufacturing process isn’t 100% sustainable, the modular system already helps reduce wasted resources and energy by leaving room for growth and change anytime.

The post Blokaloks modular system lets you build walls or even rooms in just minutes first appeared on Yanko Design.

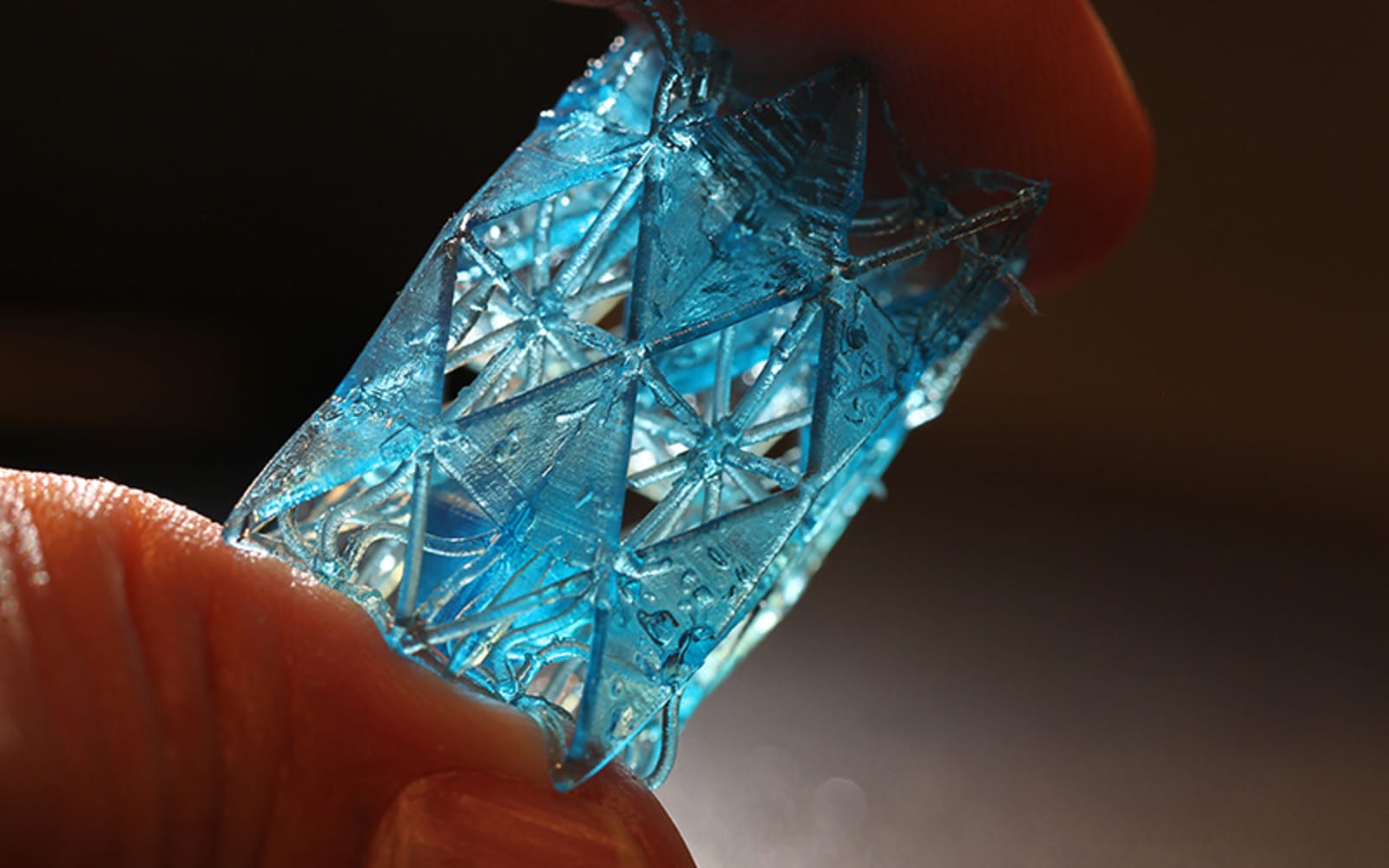

You may not think of your bones as buildings, but researchers do. A team from Cornell University, Purdue University and Case Western Reserve University believes that by studying the internal structure of bones, they may be able to 3D-print stronger c...

You may not think of your bones as buildings, but researchers do. A team from Cornell University, Purdue University and Case Western Reserve University believes that by studying the internal structure of bones, they may be able to 3D-print stronger c...