Tag Archives: laser

Social Distancing Laser Hat Uses Lasers to Stake Your Territory

These days, it’s important that we maintain our distance to prevent the spread of the deadly COVID-19 virus. While the best thing you can do is just stay home, sometimes you have to go out to buy groceries or other essentials. Face masks and gloves can offer some protection, but social distancing still has had the most significant impact on controlling the spread.

One clever geek came up with a great way to help keep people out of his personal space, and it involves lasers!

A maker going by the moniker “StupotMcDoodlepip” created a gadget that shows people how far to stand away by projecting a six foot diameter laser circle. It’s a pretty simple design – basically a laser pointer that sits on a motorized base, and attached to a plastic hat. As it spins around, it paints a virtual boundary on the ground around him.

If you want to build one for yourself, you can check out the full list of materials on Stupot’s YouTube posting. The models for the 3D printed parts can be found on Thingiverse.

I think this is a great idea, though if I made one, I’d use lasers that can actually cut off limbs. That’ll show ’em!

[via KXOJ via Geekologie]

Optoma CinemaX P1 review: A stunning 4K projector with terrible apps

The shiniest new toys in AV land are the short-throw laser projectors you might have seen recently, particularly at CES. They're cool because they give you a huge, bright image for a fraction the price of a comparably sized 4K TV. At the same time, t...

The shiniest new toys in AV land are the short-throw laser projectors you might have seen recently, particularly at CES. They're cool because they give you a huge, bright image for a fraction the price of a comparably sized 4K TV. At the same time, t...

X-ray lasers can spot elusive electron motion

Scientists can track the movements of an atom's nucleus relatively easily, but electrons have proven elusive -- they move so fast that they tend to be reduced to blurs. Now, however, those movements could be crystal clear. Researchers at the SLAC Nat...

Scientists can track the movements of an atom's nucleus relatively easily, but electrons have proven elusive -- they move so fast that they tend to be reduced to blurs. Now, however, those movements could be crystal clear. Researchers at the SLAC Nat...

FLUX Beamo Review: An Easy and Compact CO2 Laser Cutter/Engraver

Ever since I saw a CO2 laser cutter in action at a maker space I visited, I always wanted to have one for my own workshop. The ability to cleanly cut and engrave materials with laser precision has all kinds of uses, from cutting out flat-pack models and puzzles, to adding logos and personalization to objects. But most of the more capable CO2 laser cutters on the market are expensive, difficult to use, and take up a lot of space.

The folks at FLUX aim to change that with their Beamo, a laser cutter/engraver that’s small enough to fit on a desktop, yet is powerful and versatile enough for pro-quality work. It’s also well-priced, with early bird orders on Kickstarter going for as little as $849. FLUX has a strong track record with its crowdfunded projects, having previously delivered on its well-rated Delta+ 3D printer.

Measuring in at 24.21″ (w) x 17.52″ (d) x 6.97″ (h), and weighing 48.5 pounds, the Beamo is equipped with a 30-watt CO2 laser, which basically zaps high voltage across a glass tube filled with CO2 gas, producing a powerful beam from the end of its tube. The beam is then reflected using mirrors, and crisply focused using a lens, which narrows the beam down to about 0.2mm. The Beamo’s resolution is roughly 1000 dpi, and it can engrave at speeds up to 300 mm per second.

I was fortunate enough to get my hands on a pre-production Beamo, and I have to say that I’m very impressed. It took no time to get it set up and connected to my network, and within 10 minutes of opening the box, I had my first completed piece. Everything comes pre-assembled in the box – all you need to do is connect the Wi-Fi antenna (or an Ethernet cable), attach the vent hose to the back of the printer, and plug it in. You’ll definitely want to run that vent hose to a window, as it’s important to keep the fumes in your space to a minimum.

The Beamo can engrave a variety of different materials, including wood, cardboard, fabric, glass, acrylic, leather, stone, tile, and more. Cutting is limited to cardboard, paper, wood, acrylic, and other similar lightweight materials, with maximum thicknesses between 3mm and 5mm. There’s enough room inside the machine to handle objects up to 11.81″ by 8.27″ (300 x 210 mm), and as tall as 1.77″ (45 mm.)

Preparing for a cutting or engraving job is as simple as placing your object on the ventilated surface, flipping down the plastic calibration clip on the head unit, then loosening the knurled knob on the laser head and adjusting it to the height of the object. This ensures a sharp beam focus. This manual adjustment process is easy and takes only a couple of seconds, though buyers can opt for an autofocus module, which also enables slightly deeper cuts in woods (up to 7mm.) That tool is currently bundled with a rotary module, which allows for engraving on curved surfaces, such as drinking glasses.

Working with the Beamo Studio desktop application is quite easy. It works on both Mac OS and Windows (I used the Mac version), and provides an intuitive interface for setting up your artwork. Since the Beamo has a built-in camera, you first use the Camera tool to preview your work piece, then you can start arranging your digital cutting files. The app works with SVG and DXF vector files, as well as JPG and PNG bitmap art. Vector files generally produce sharper images, but with a high enough resolution bitmap, the Beamo does just fine too.

The software comes with presets for a variety of materials and job types, and you can create multi-layered jobs with different settings. For instance, you could import one layer with sharp vector lines, another layer with a bitmap shading, and yet another layer, and set it to cut an outline. This way you can create complicated objects in a single pass. FLUX also plans on releasing a mobile app which will allow users to snap photos, place them using the Beamo’s camera, then send them for output, but it hasn’t been released for review as of yet.

The Beamo made quick and precise work of the wood, paper, mirrored glass, and leather that I tested with, though the irregularities of leather cause some blurring that you don’t get in flatter and smoother materials like wood. For materials not listed, you might have to experiment on some scrap to get the power, speed, and repetition settings right. Be sure to avoid using certain plastics, foams, and adhesives with a laser cutter, as it can create toxic fumes or damage the machine. Render times can vary dramatically depending on the material and complexity of job you’re outputting. Smaller jobs can take as little as a minute, while the most complex images I tested with took 20 minutes or so.

I cannot recommend the FLUX Beamo highly enough. It brings the power of CO2 laser cutting and engraving down to a size and price that many more people can afford, and unlike some crowdfunding projects, the hardware and software is ready for primetime. The Kickstarter campaign for the Beamo is running through Saturday, November 30, 2019 at 11:00 am Central Time, so if you want to get in on one of the earlier units and pre-release pricing as low as $849, now is the time.

For those looking for a larger work area, FLUX is also readying the Beambox, which can work with objects as large as 15.7″ x 14.7″, and cuts material up to 10mm thick. That model is quite a bit more expensive, though, with prices starting at $2499.

The Pentagon has a laser that identifies people by their heartbeat

Biometric identification has become part of everyday life. We've got facial recognition in airports, cars that can be unlocked just by looking at them, technology that detects a person's unique way of walking, and of course the ubiquitous fingerprint...

Biometric identification has become part of everyday life. We've got facial recognition in airports, cars that can be unlocked just by looking at them, technology that detects a person's unique way of walking, and of course the ubiquitous fingerprint...

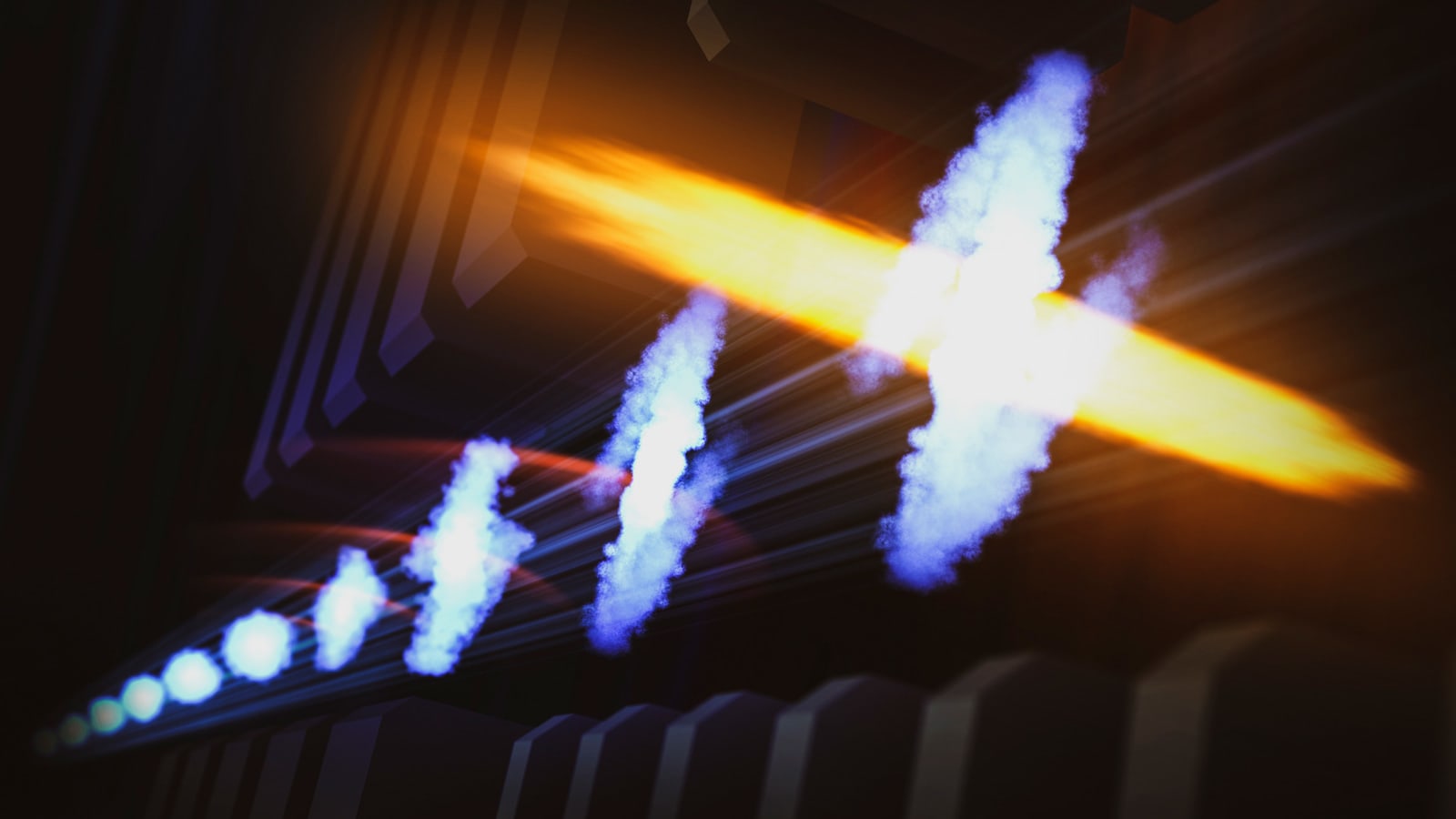

US Air Force successfully shoots down multiple missiles with a laser

The US Air Force just edged closer to its goal of outfitting aircraft with laser weapons. Testers at the White Sands Missile Range have successfully shot down multiple air-launched missiles using the Self-Protect High Energy Laser Demonstrator (SHiE...

The US Air Force just edged closer to its goal of outfitting aircraft with laser weapons. Testers at the White Sands Missile Range have successfully shot down multiple air-launched missiles using the Self-Protect High Energy Laser Demonstrator (SHiE...

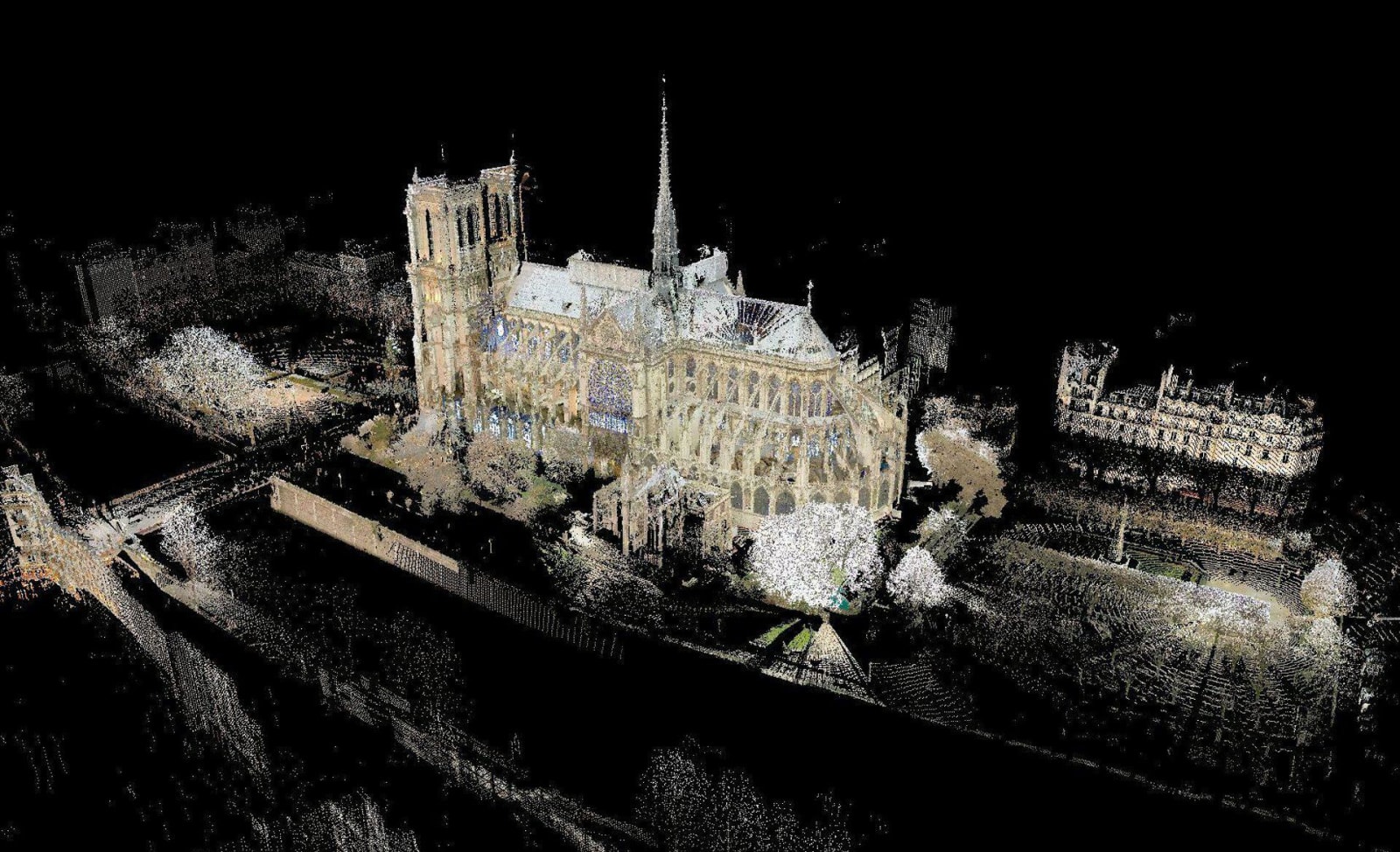

The billion point laser cloud that will help rebuild Notre Dame

On April 15th, 2019 around 6:40 pm, I was walking around the Jardin du Luxembourg park in Paris with some friends when we saw some yellow colored smoke in the sky. We thought nothing of it, but soon discovered, shocked, that one of the most famous la...

On April 15th, 2019 around 6:40 pm, I was walking around the Jardin du Luxembourg park in Paris with some friends when we saw some yellow colored smoke in the sky. We thought nothing of it, but soon discovered, shocked, that one of the most famous la...