Mushroom has recently gained immense popularity as a sustainable and economical material for building almost everything – from housing structures to even lamps! Or more specifically, the vegetative part of mushroom called ‘Mycelium‘ has. It is the thread-like main body of a fungus–of certain mushroom-producing fungi on agricultural wastes, and it’s vegan as well! Biodegradable and low-cost this delightful material can be used to design and produce a whole range of objects! And, we’ve curated a whole collection of these sustainable designs to convert you into ‘Team Mushroom’ for good. From a sustainable DIY helmet built from mushrooms to a mycelium-based grill design – these intriguing designs will have you wondering about the curious world of mushrooms. Can you envision a future where all your everyday objects are built from mushrooms? Can mushrooms have a purpose beyond simply jazzing up your stir fry? I think so.

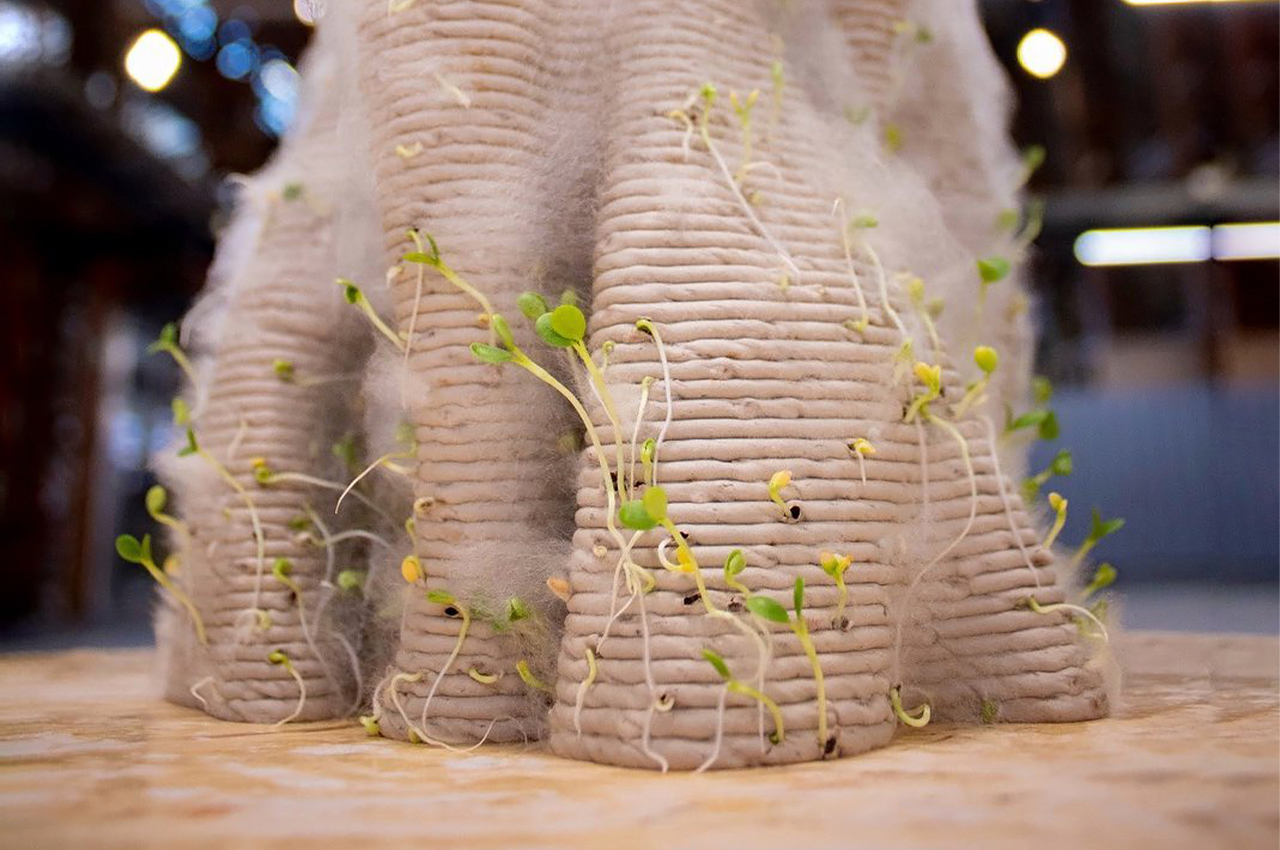

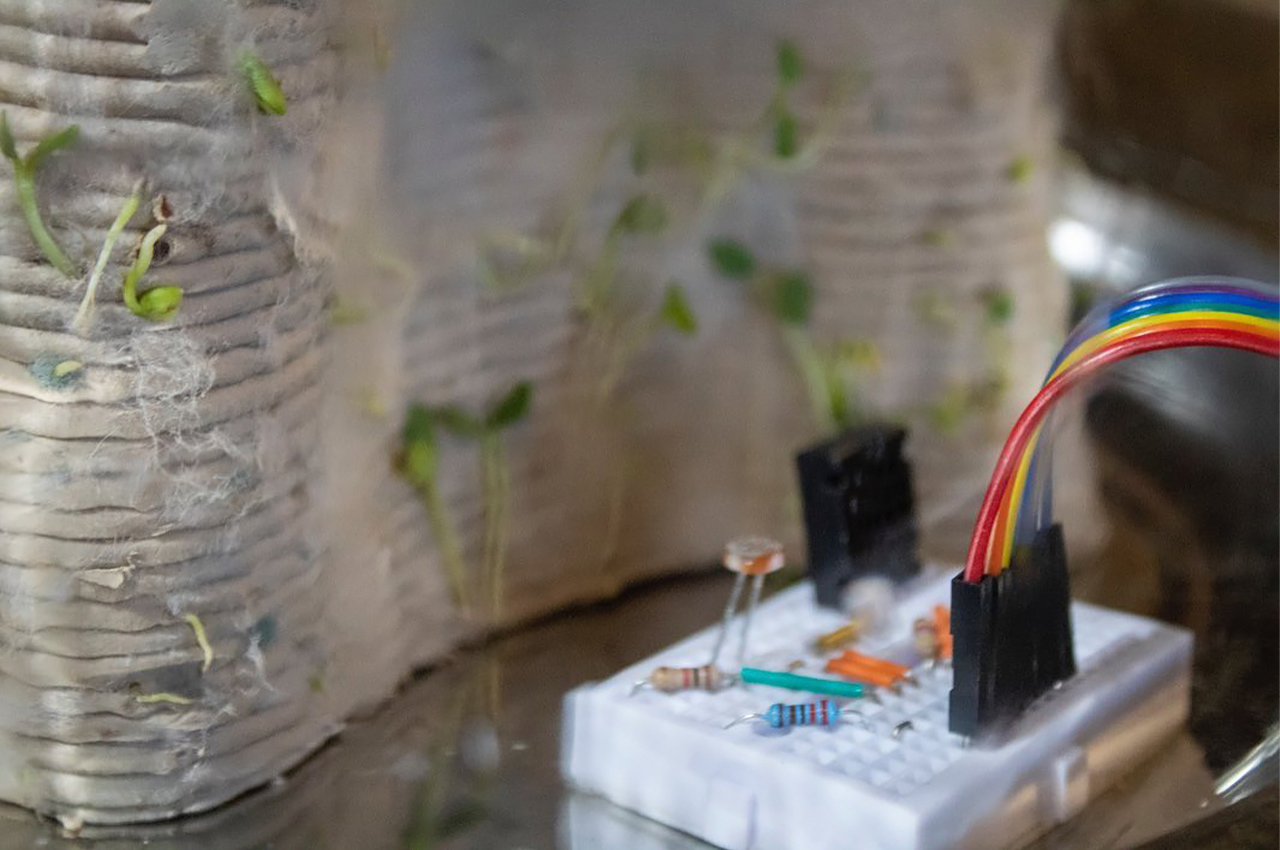

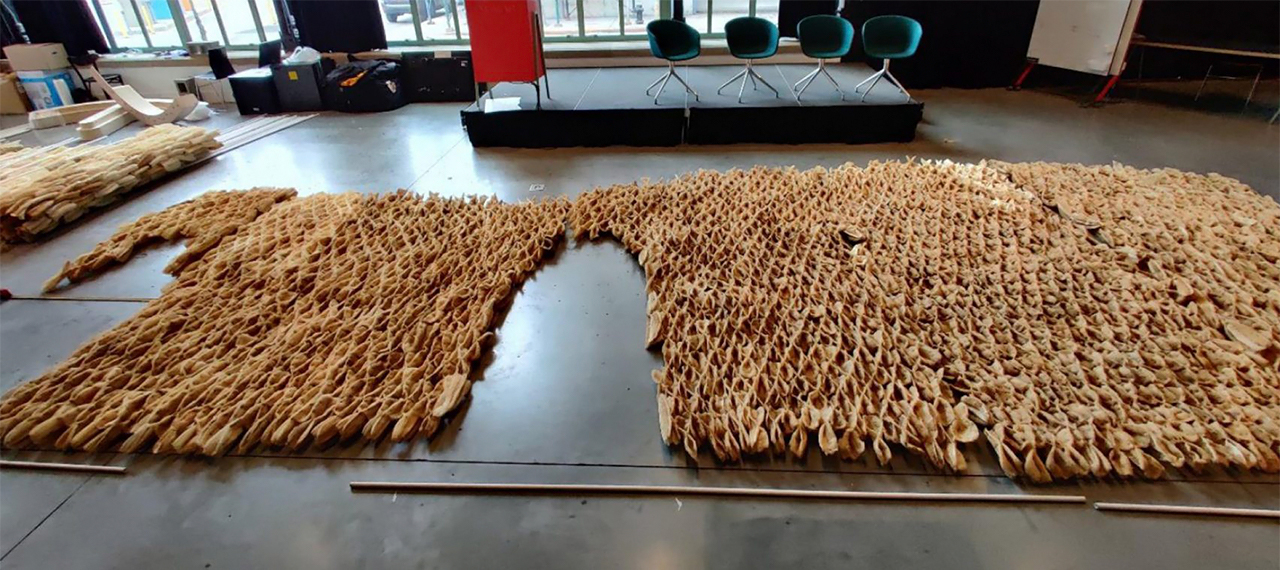

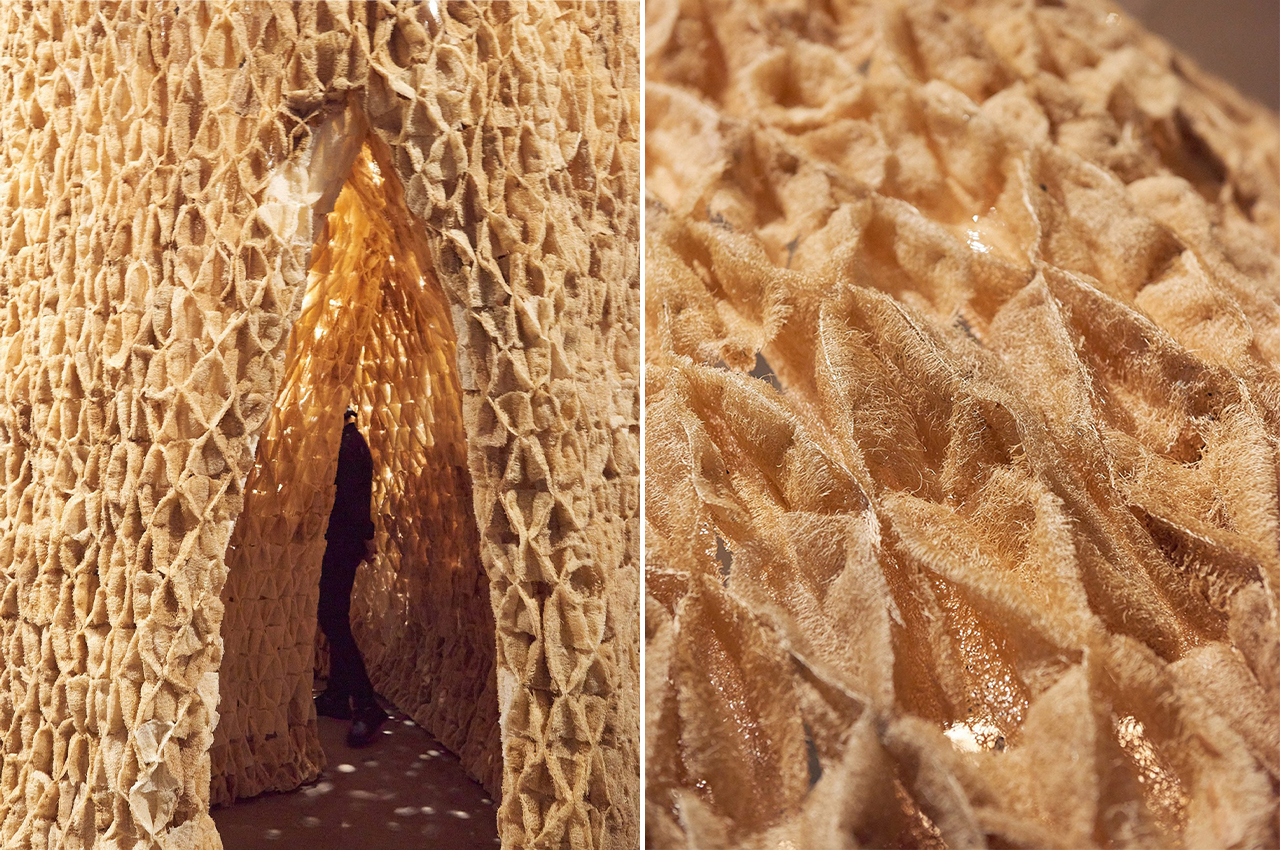

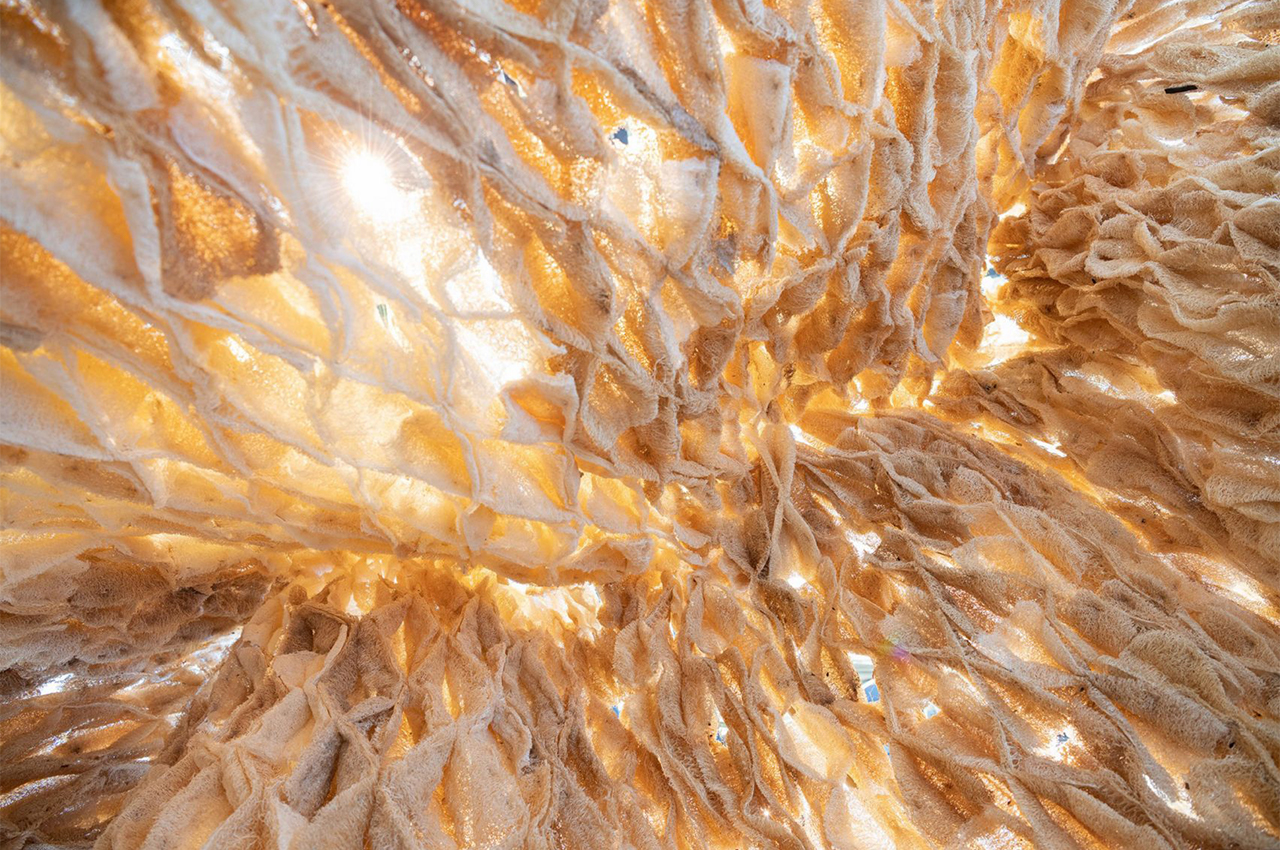

The construction industry emits 4 times more CO2 than the aviation industry and that is enough proof they must focus on ecodesign to reduce their colossal impact especially when sustainable materials, like mycelium composites, already exist! This material is created by growing mycelium–the thread-like main body of a fungus–of certain mushroom-producing fungi on agricultural wastes. The mycelia are composed of a network of filaments called “hyphae,” which are natural binders and they also are self-adhesive to the surface they grow on. The entire process is based on biological elements that also help in upcycling waste and reducing dependency on toxic fossil fuels. Mycelium composite manufacturing can also be a catalyst in developing new bioindustries in rural areas, generating sustainable economic growth while creating new jobs. Even NASA is currently researching using mycelium to build sustainable habitable dwellings on Mars – if we have to move into a mushroom house, might as well test it on Earth first, right? The construction industry has to act now if they want to build in/a future.

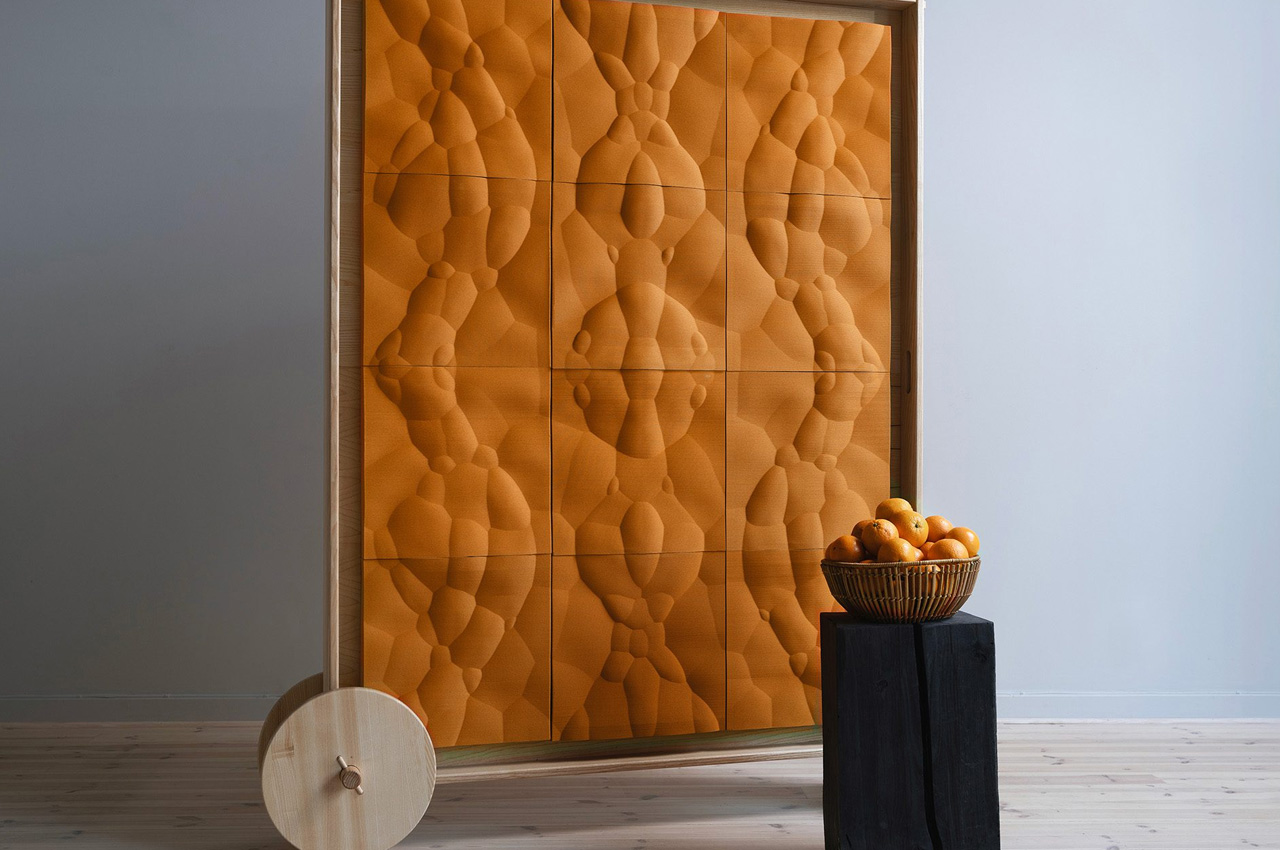

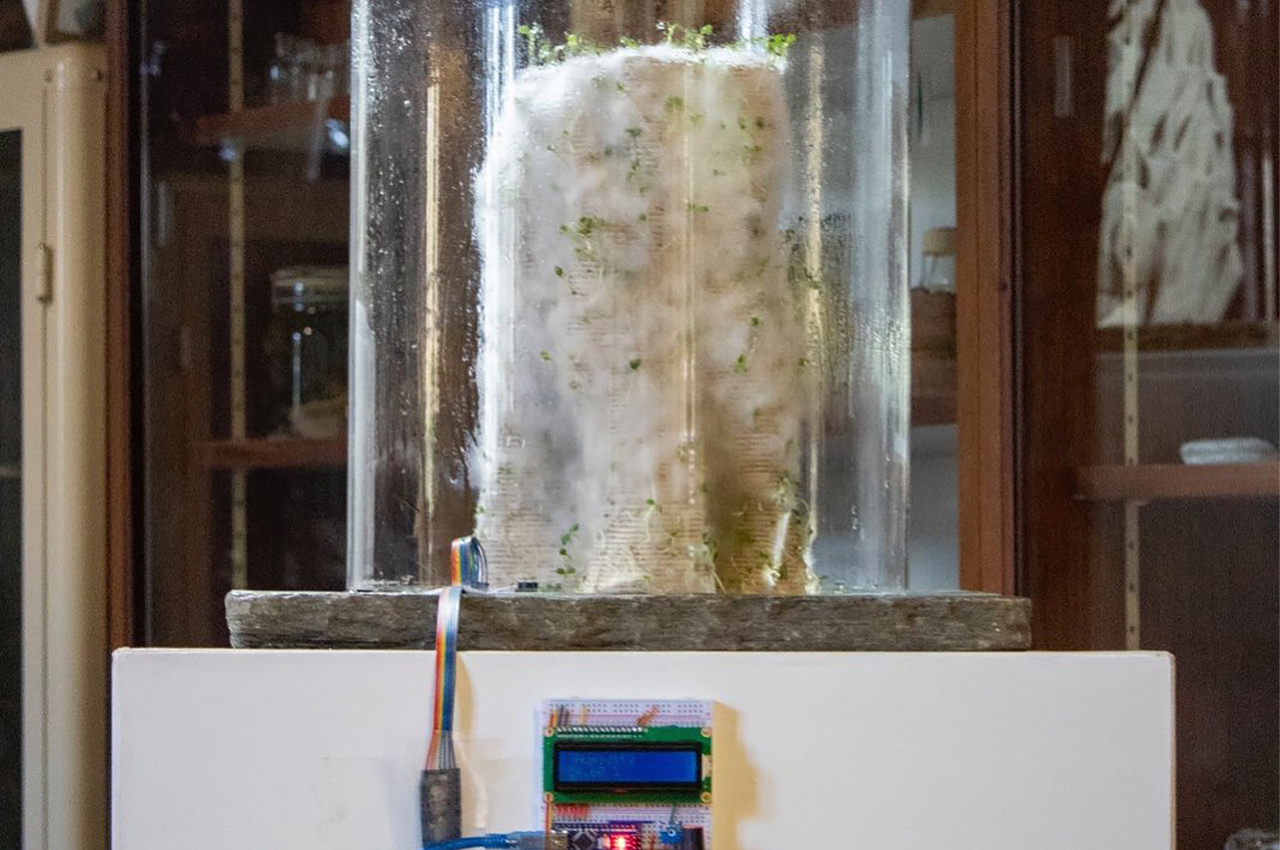

Mycelium, or the vegetative part of a mushroom, has found itself in the limelight for being a cheap, sustainable, and vegan alternative to suede and leather. If treated correctly, it looks and feels just like leather, offering a cruelty-free and biodegradable alternative that doesn’t have as much of a carbon footprint either. Teaming up with researcher Ninela Ivanova, British designer Sebastian Cox’s “Mycelium + Timber” examines the viability of mycelium as a potential material in commercial furniture design. The mycelium fibers are bound to scrap strips of willow wood, which provides the base and fodder for the fungus to grow. The result is the absolute antithesis of mass production. Designed in part by nature, each lamp is unique, has its own aesthetic, and is beautiful in its imperfections.

This mushroom helmet will grow on you as it grows. Yes, read this slowly and carefully: this mushroom helmet will grow on you as it grows. “What do you mean?!” you say and I assure you that statement is not wrong, there is an explanation for it. The Grow It Yourself Helmet is a sustainable product made from mycelium which is the vegetative part of a fungus. Mycelium is the thready hyphae that are tightly woven into mass branch-like networks making it a strong sustainable material. The network of filaments are natural binders and they also are self-adhesive to the surface they grow on. The entire process is based on biological elements that help in upcycling waste. The process of making this helmet also gets the kids involved in a meaningful activity that teaches them about sustainability and safety.

In researching fireproof materials to build a grill, Singer found mycelium, a fireproof, vegetative part of a fungus that’s safe and edible for humans. Mycelium hosts an array of properties that make it the ideal choice with which to build a disposable grill. Inexpensive and very easy to grow, mycelium is an accessible, sustainable alternative building material that’s water repellent, naturally insulating, and entirely biodegradable. After cultivating her own lot of mycelium, Singer constructed prototypes of MYC and envisioned the disposable grill lining the shelves of convenience stores and gas stations to bring the choice of sustainable disposable grills to the masses. Following the use of an MYC grill, instead of searching for the nearest garbage can, grillers can simply cut up and leave MYC at the campsite to biodegrade and fertilize the earth.

Developed by Bolt Threads and Designed by Chester Wallace, the Driver Bag is a debut for the one-of-a-kind mushroom leather. The bag serves two broad purposes. It’s design and styling make it ideal for owning and using in your daily life. The Mylo comes with a unique brown patina, reminiscent of distressed leather, and is just as resilient and stylish. Along with the black canvas trims, you’ve got a bag that looks as good as (if not better than) the next one, boasting two internal and three external pockets to segregate your items. The bag’s second purpose is to disrupt the leather market with an alternative that’s ecologically sustainable, cruelty-free, and can be produced in days instead of years, without the material waste and moral conundrum of using animal hides or toxic chemicals.

The Seventh Generation Beam is a customizable, subscription-based, plastic-free set that is designed to be the all-in-one sustainable oral care kit. The aim is to create 100% plastic-free packaging. The challenge is to rebrand a traditional product line and redesign the packaging system to be fully sustainable while utilizing no plastic or bioplastic. Biomaterials like tin, wood pulp, plant cellulose, food waste, grass, algae, and mushrooms are being considered. It will all be sustainably sourced, preferably materials that are at the end of their lives and can be composed into biomass to regenerate depleted farming soils.

This hive is elevated to mimic that of a natural hive. Placed 2 meters above the ground it protects the bees from critters and invaders that may want to steal honey or cause distress to the bees. It also allows for the bees to enter the hive from the bottom, which allows them to create comb with gravity as they would naturally. Second, the new hive’s material composition promotes a healthy climate while also keeping external sound disturbance to a minimum. It consists of cork, wood, and mycelium (a material made from mushrooms).

Created as a part of the Wallpaper* Re-Made project, these bio-composite containers are modeled to look like bento-boxes with a modular design that stacks up as your order increases, resulting in one larger box rather than multiple smaller boxes. This unique format provides a useful alternative to plastic containers (as it’s waterproof and leakproof too) and eventually reduces components by removing elements like lids (since the containers stack over and cover each other). Materials used to craft the packaging meet a range of criteria too, being heatproof, lightweight, recyclable, and insulating. The bio-composite polymer used to mold the containers themselves is made from cocoa-bean shells (a by-product of the cacao industry) by designer Paula Nerlich. The outer bag that carries the containers is made from all-natural materials too, including mycelium to insulate the interiors, a bioplastic known as Nuatan to provide a robust outer shell, a natural leather derived from pineapple leaves called Piñatex for the outer container’s lid, and Lexcell, a neoprene-free natural rubber used for the handles and straps on the bag and the Bento containers.

The Abacus’ most impressive feat is its commitment towards showing that tech can be sustainable too. In a world that’s literally drowning in e-waste because people want slim products, and slim products are notoriously difficult to recycle efficiently, the Abacus was made with a very clear cradle-to-grave strategy. As an all-in-one PC, the Abacus has a 63% lesser footprint than a desktop, and with a 31kWh/year power consumption rating, it’s about as energy-efficient as a lightbulb. The Abacus’ internal components are entirely reusable, and its outer body is made to be fully biodegradable. Moreover, even the product packaging is crafted from mushrooms, allowing it to easily degrade into the soil when inevitably thrown away. Who knew great tech could be cheap, energy-efficient, AND eco-friendly?! The tech giants could surely learn a lesson or two, don’t you think?

Created as an “experimental science collaboration that explores the design and functionalities of novel, bio-based, microbially grown materials”, Korvaa uses a fungal mycelium for the foam cups, fungi film as a leather substitute to cover the foam cups, and microbial bioplastics for the outer body. Designed to explore the possibility of using new, bio-based materials to create regular consumer products, the headphones were perhaps the perfect playground. They have size, weight, and ergonomic constraints… plus they require parts that are both hard as well as soft. Korvaa required multiple iterations to arrive at the materials that were finally used in its construction. Some parts needed to be cultured and grown in a mold, while others needed to be freeze-dried to be worked with.