Nobody ever designed anything iconic by following the rules. The BMW i Vision Circular Concept works on the same principle – it has an appearance that’s car-like enough to not be mistaken for anything else, yet the design team takes deliberate decisions to deviate from certain norms, creating a car that looks and feels really refreshing. Here are a couple of my takeaways that could become design lessons in the future… and yes, I’ll be bringing up the Tesla Cybertruck.

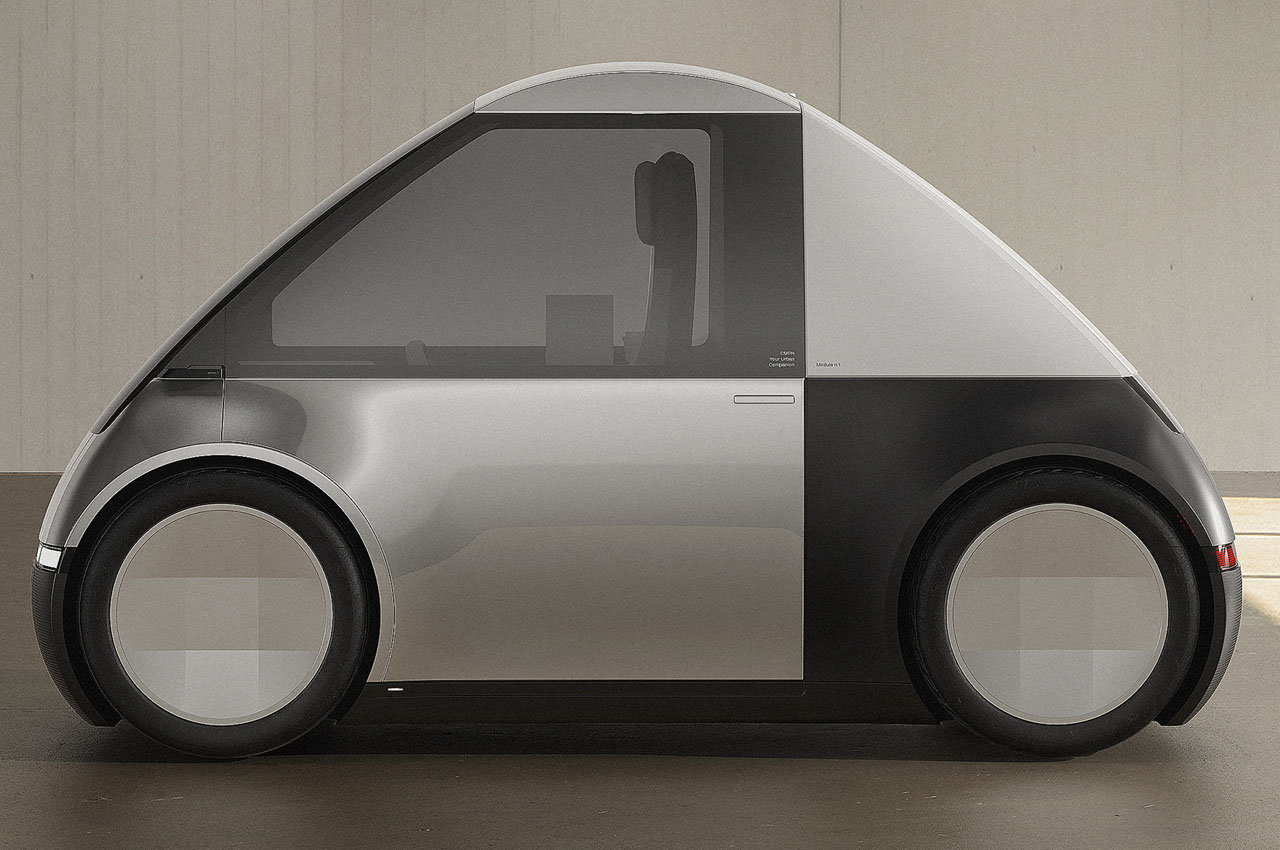

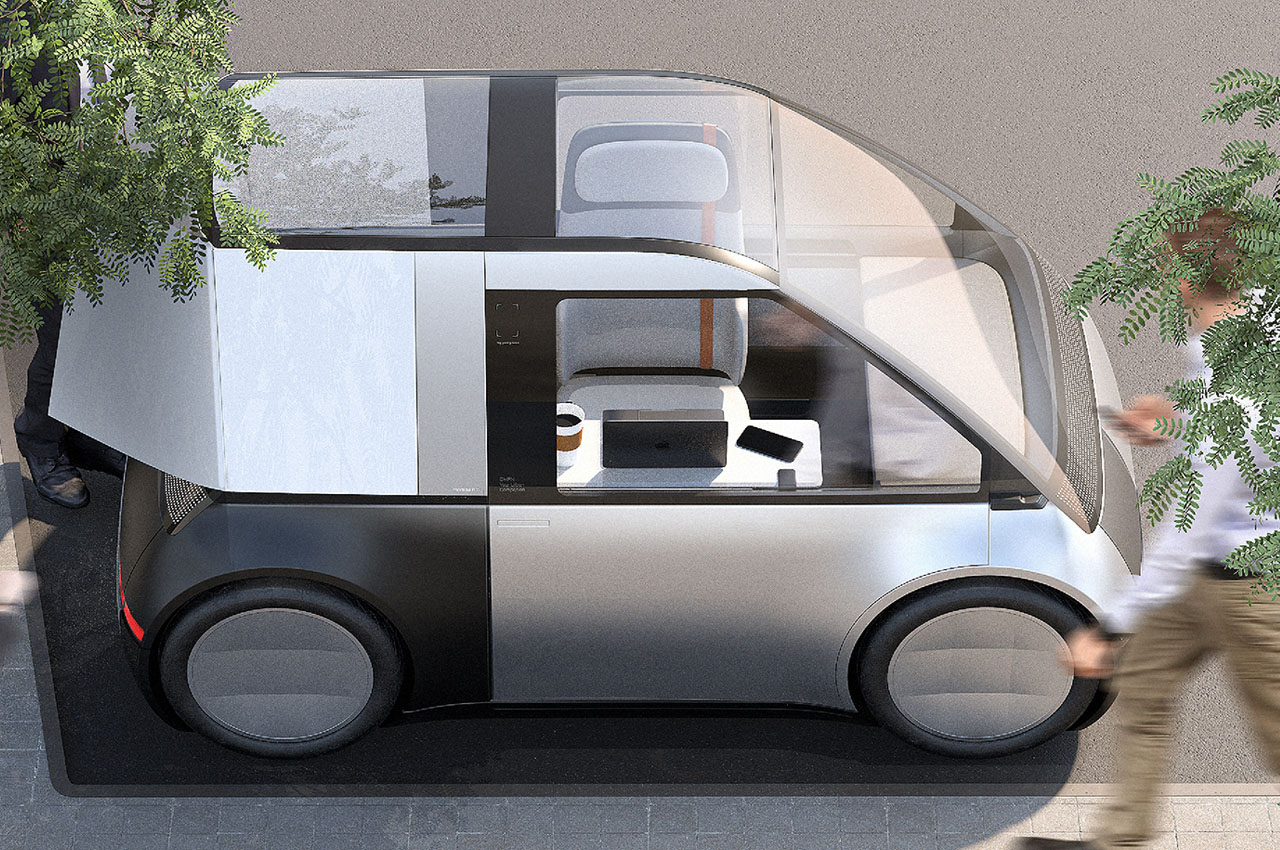

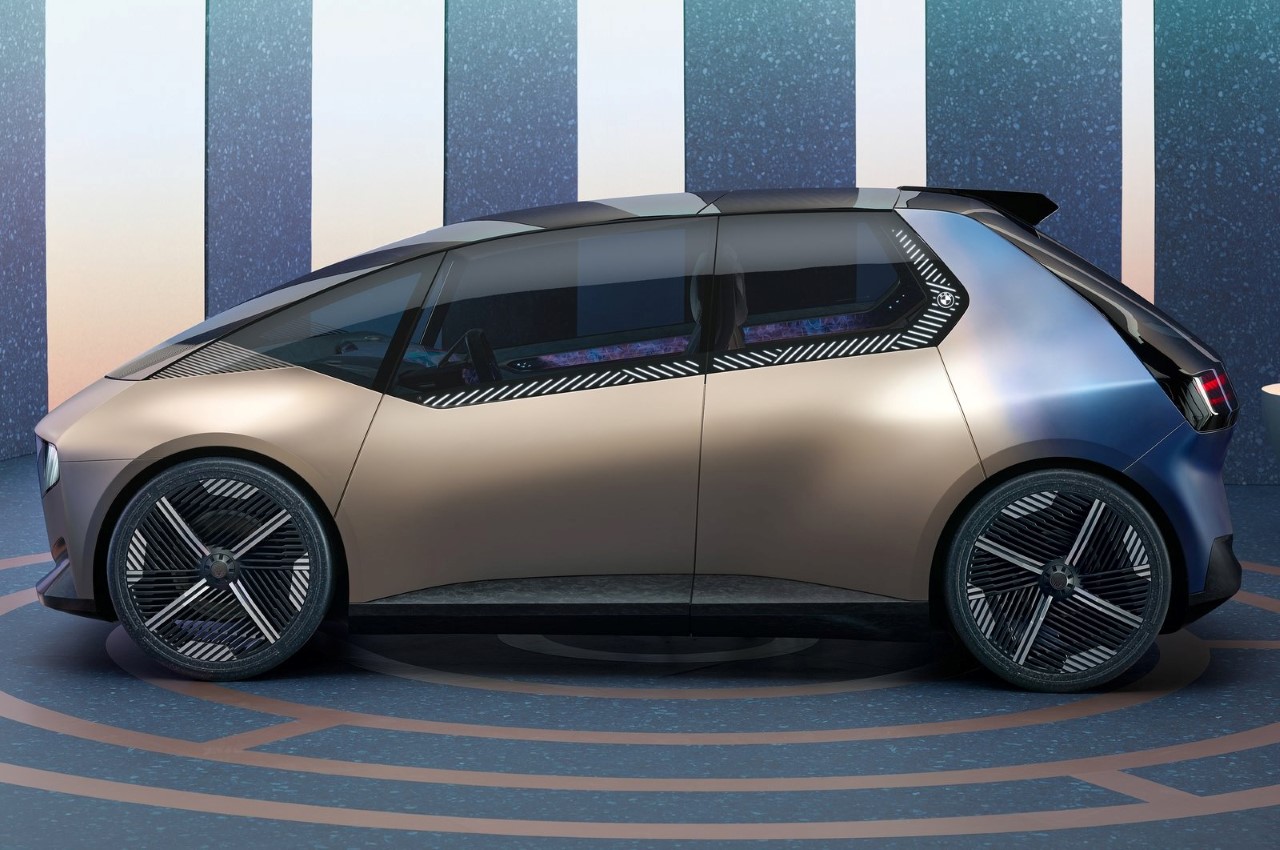

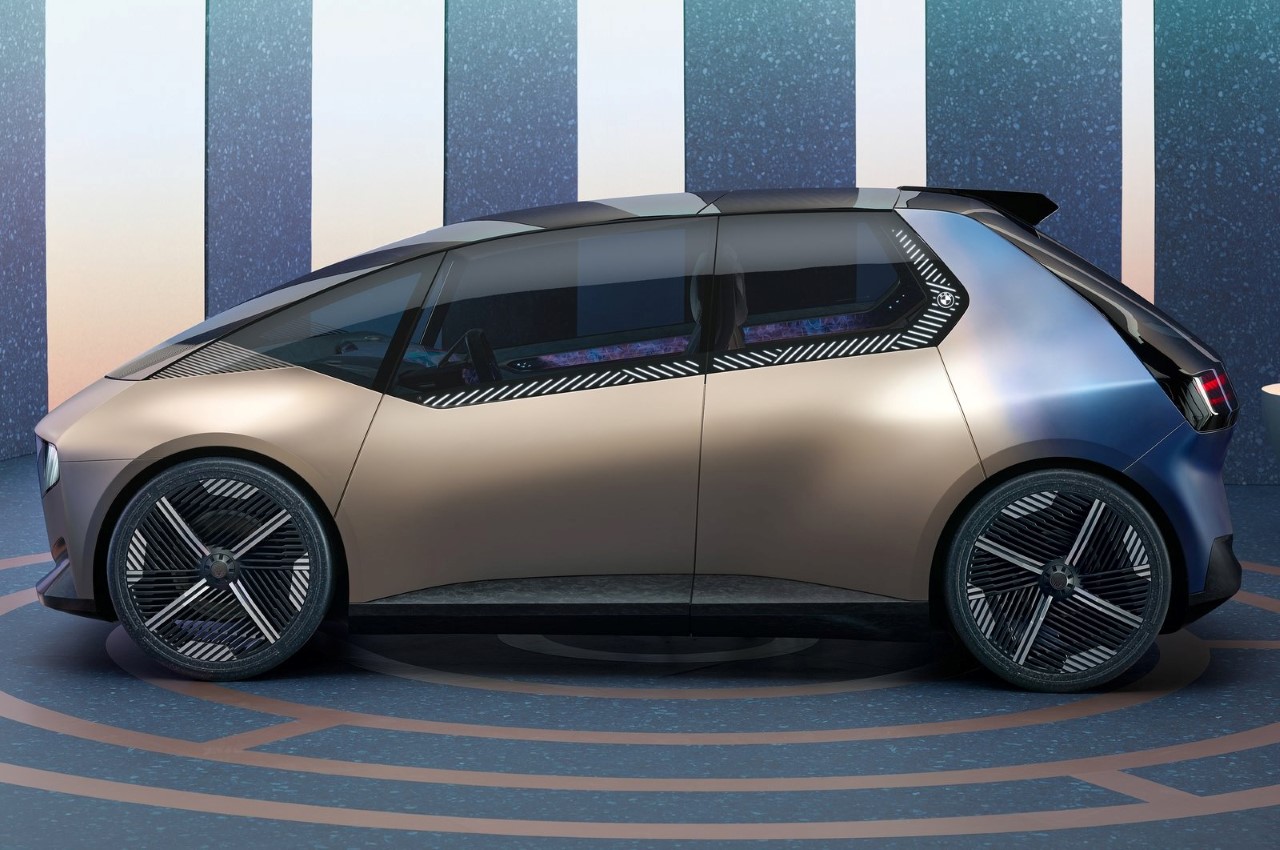

Just to cover the basics, the i Vision Circular Concept debuted at the Munich Auto Show as BMW’s first-ever ‘100% recyclable’ car. Designed for the year 2040, the i Vision Circular Concept comes with a design featuring parts that are completely detachable (thanks to the use of intelligent fasteners like cords and press-fit joints instead of glue and welding) and easy to fix/repair. The car’s body is made from recycled aluminum, its interiors use fabric made from recycled plastic, and even the tires are made from a “sustainably cultivated” natural rubber. As one would expect with any eco-conscious automobile, the i Vision Circular Concept runs on an electric powertrain too… and while managing to balance all those bits of innovation, the i Vision Circular Concept looks like an absolute stunner. It’s unconventionally shaped, looks decidedly modern, makes incredible use of volumes, surfaces, edges, continuity, and lighting, while still ensuring that the car follows BMW’s brand DNA and retains its iconic design language… and if that wasn’t impressive enough, the car also doesn’t use a single drop of paint.

A futuristic form that’s edgy, but friendly.

Angular straight lines play a dominant role in visual futurism – a theory that the Cybertruck has pushed to its very limits. Straight lines can never be found in nature, so the use of them automatically makes something look artificial or man-made. Play with those parameters enough and you’ll arrive at something that looks so artificial it feels like it’s from the future. While that may have played to the Cybertruck’s strength (because the ultimate consensus, whether you liked the pickup truck’s design or not, was that it looked hyper-futuristic), it isn’t necessarily what the i Vision Circular Concept is going for. Sure, the use of sharp edges and angular lines play a major part in allowing the car to look futuristic, but the gentle use of curves give it a more friendly, relatable appeal, making it look appealing and warm instead of robotic and cold.

As far as form and surface treatment goes, the i Vision Circular Concept doesn’t really go by the book. For starters, it has a panoramic windshield that extends all the way from the front to the top and the back, and even to the sides. The front is a continuous curve too, highly reminiscent of Lamborghinis, and gives the car a wedge-shaped silhouette that’s wider than the kind seen in Lambos, but is still unmistakably different from almost every other car. It even comes with a chasm or a valley running down the bonnet, creating that bit of drama by breaking the surface, while providing a neat area to house the BMW logo. There’s also an incredibly low overhang over the front and rear wheels, resulting in a car that looks incredibly tight, yet with curves in the right places.

Eyes so pretty, you can’t stop staring at them.

Chances are that the first thing you noticed about the BMW i Vision Circular Concept was its headlights. Over time, cars have anthropomorphized to form faces, where the headlights look like eyes – a feature that’s allowed car brands to give their automobiles character and emotions, which is why the slim headlights of an Audi make it look aggressive, and the round headlights of a VW Beetle make it look fun and friendly. The i Vision Circular Concept’s eyes rely on an incredible contrast created by angular white lines on a black background. The angular lines give the car a discerning appearance without necessarily looking mean or angry, and the headlights aren’t simply relegated to a bulb and reflector located on either side of the car’s front… instead, the angular lines travel all the way across the front from left to right. BMW’s designers even used this genius move to turn the headlights into a makeshift kidney grille, fulfilling a design detail that can be found on every single BMW car from the very beginning. Since the i Vision Circular Concept doesn’t have a gas-powered engine (and therefore doesn’t need a grille on the front), the angular lines take its place, making the car concept equal parts path-breaking yet true to BMW’s legacy.

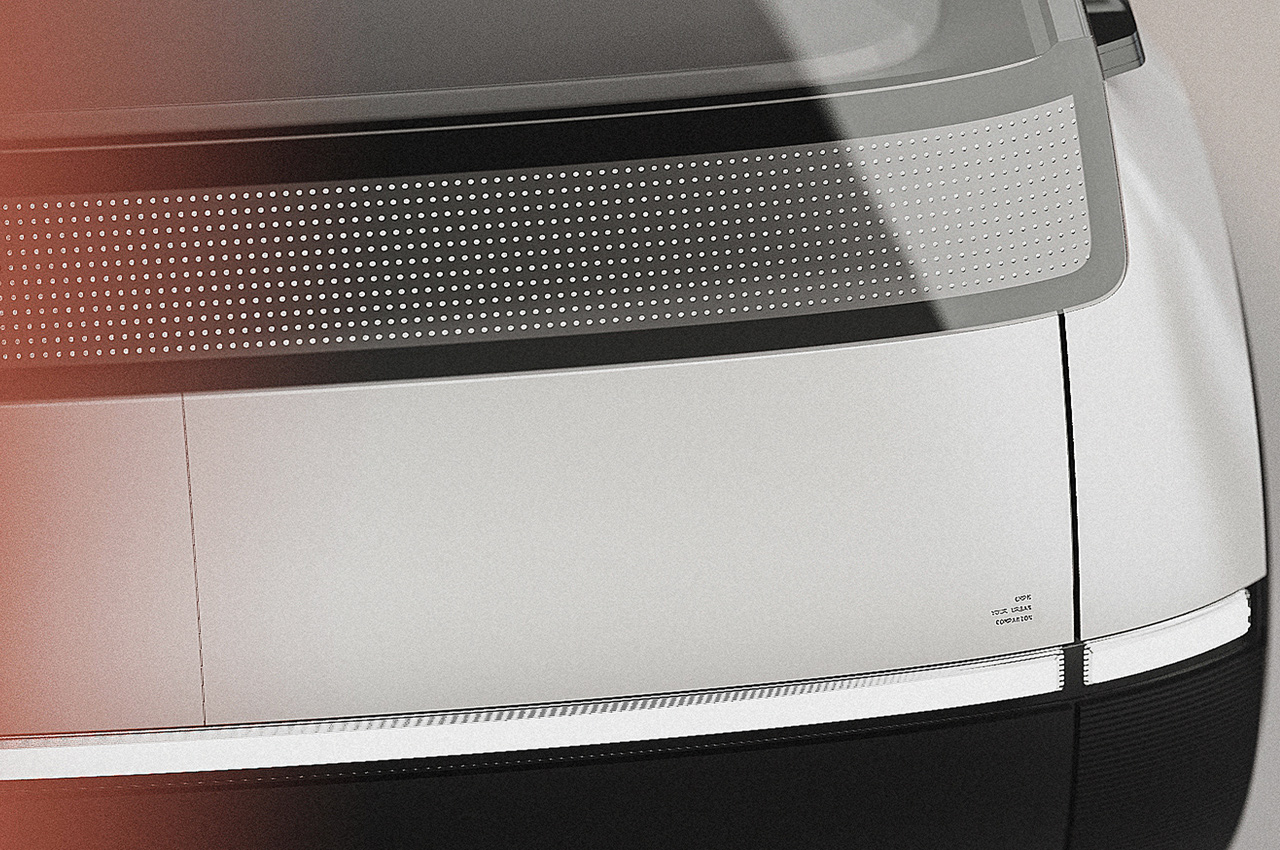

Not a drop of paint.

Easily one of the most wasteful processes in a car’s manufacturing, the paint-job needs to be conducted in a highly controlled environment by specialized robots with highly expensive equipment. The process can take days at an end, result in a massive amount of wasted resources and paint, and if gone even fractionally wrong, needs to be done all over again from scratch. Cleverly enough, the i Vision Circular Concept dodges this process entirely, saving resources and energy, but also potentially millions of dollars in the process.

The car’s eye-catching matte gold finish is the result of a process called anodizing, which involves electro-chemically layering a thin film of color on top of the car’s metal body. It’s time-saving, foolproof, and adds a thin layer of color over the metal, as opposed to multiple layers of paint. The gold color transitions to a wonderful blue-ish hue at the back that’s achieved through heat-treatment, a process often employed with steel. BMW wasn’t clear about how laborious or expensive these processes are, but just on paper, they seem quicker and more cost-effective than spraying on 7-8 layers of automotive paint onto an entire car.

The i Vision Circular Concept ultimately aims at showcasing BMW’s vision for the future, while also giving us a glimpse of what technologies they’re developing to make that future a reality. It’s pretty likely that BMW won’t ever release this car, because its purpose is more demonstrative in nature than anything else – which just makes it a perfect example of what trends automotive designers can expect to see moving forward in the industry. There’s a fair bit to learn from the i Vision Concept – from its different design decisions to how it manages to perfectly balance sustainability with style. More importantly, the fact that BMW’s designing recyclable cars is, in itself, a massive flex for the company and is definitely a direction that more automotive companies should be taking in the future.

Designer: BMW

The post Why the BMW i Vision Circular Concept looks so unique and attractive, and what automotive designers can learn from it first appeared on Yanko Design.

.

.