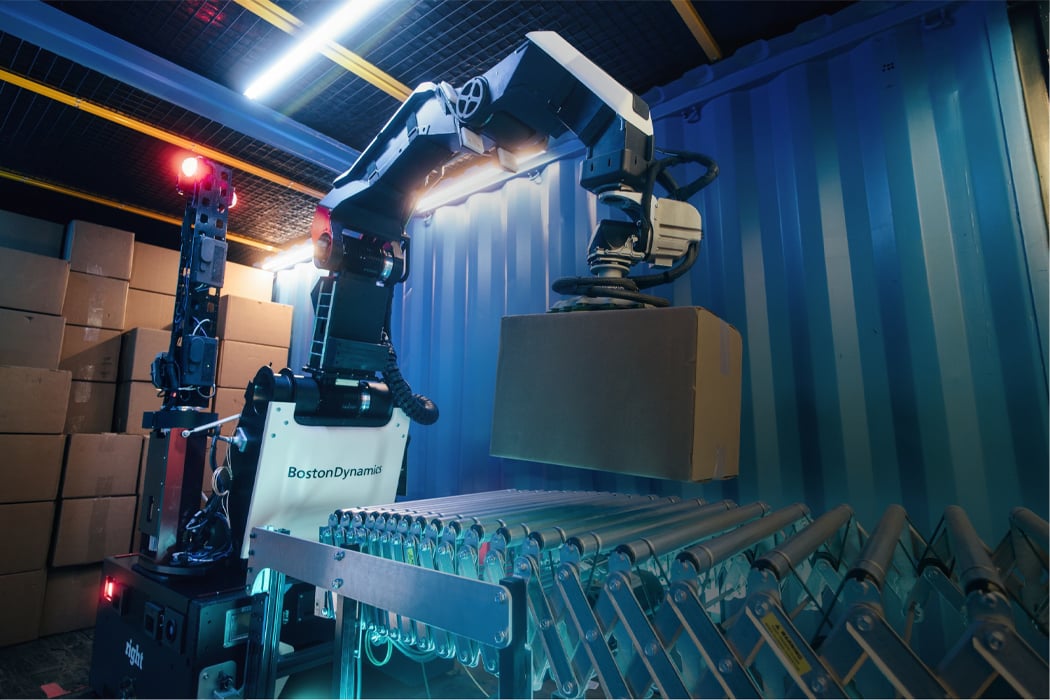

Thirty years ago, starting out as a tightknit research company, Boston Dynamics began its quest to create robots that could go where people go, do what people do, and move as people move. Today, a leading engineering and robotics design company, the team behind Boston Dynamics continues to produce and deliver commercial robotics equipped with dynamic control, cutting-edge electronics, and next-generation software. Designed for easy rollout servicing in existing warehouses, Stretch is Boston Dynamics’ latest mobile, automated case-handling robot.

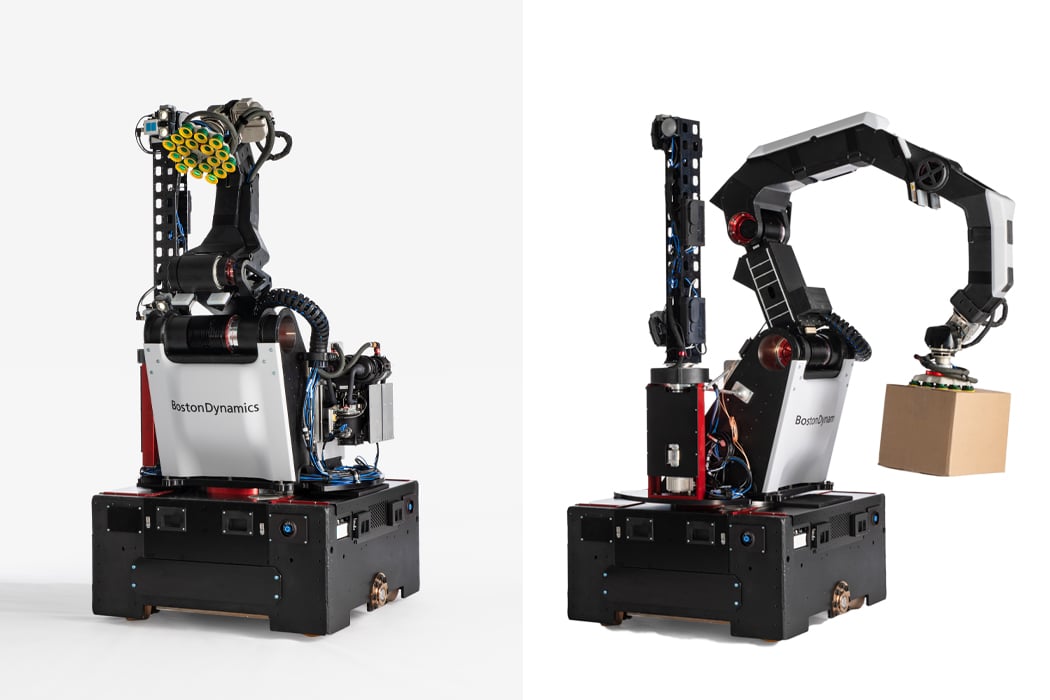

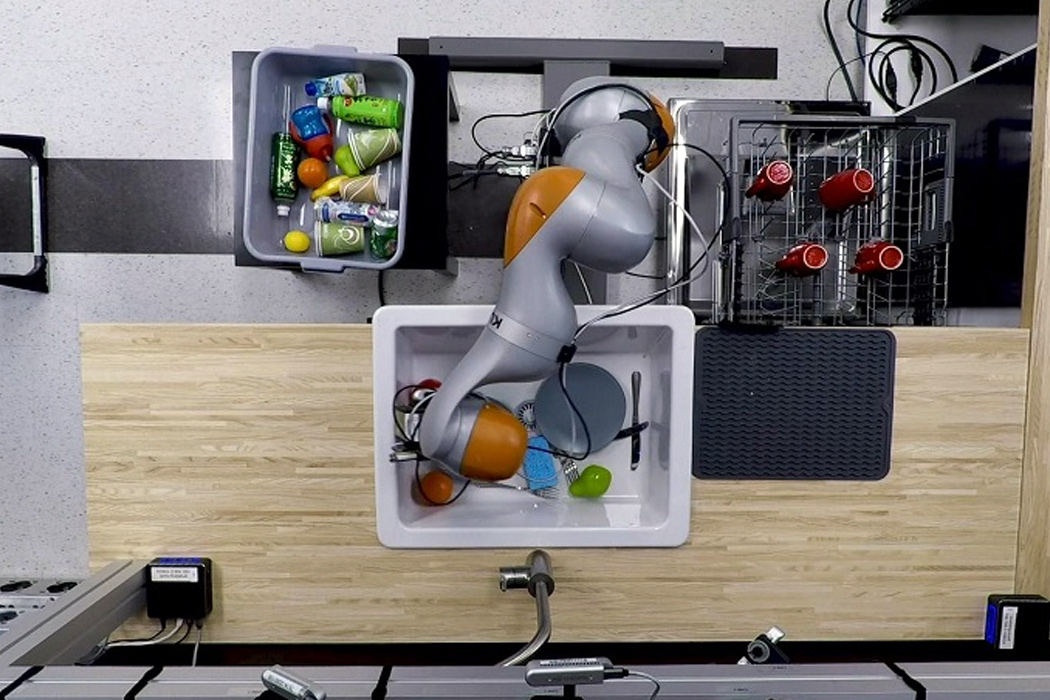

In appearance, Stretch resembles an excavator or backhoe construction truck, with a solid, bottom-heavy base and tensile robotic arm. Filled out with four small wheels for tight turning and lots of movement, Stretch’s mobile base is capable of sliding in every direction and designed to allow the fuller robot to fit anywhere a pallet fits. The long robotic arm provides plenty of reach and height with seven degrees-of-freedom, granting Stretch access to cases and shipping goods throughout any freight space or pallet.

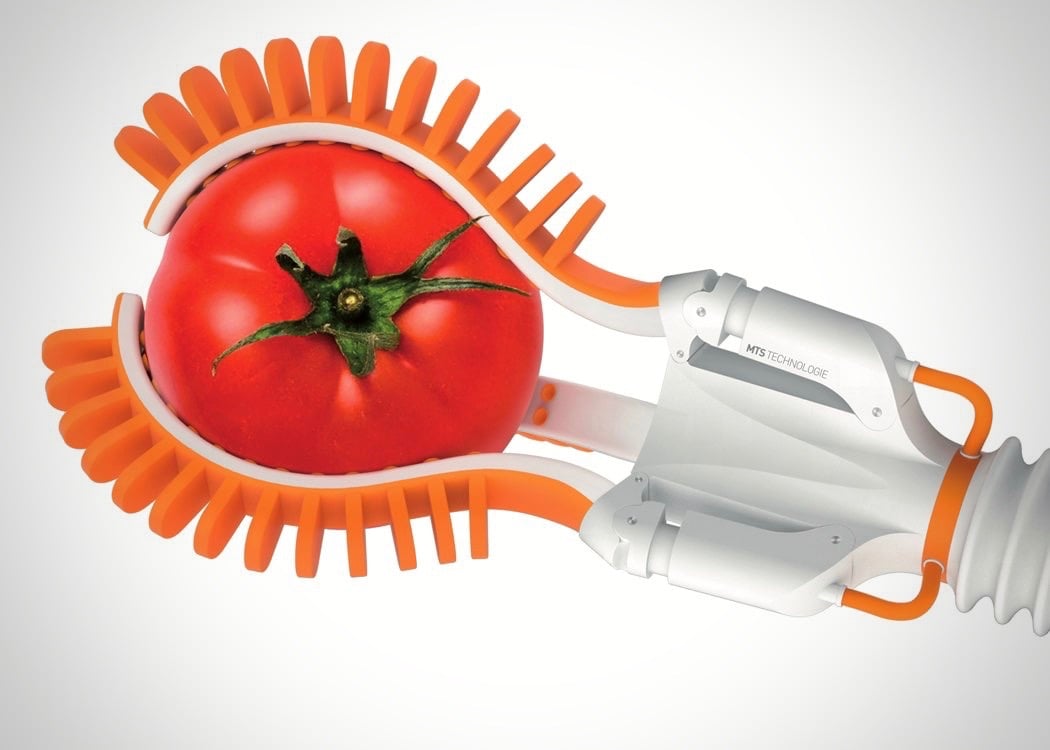

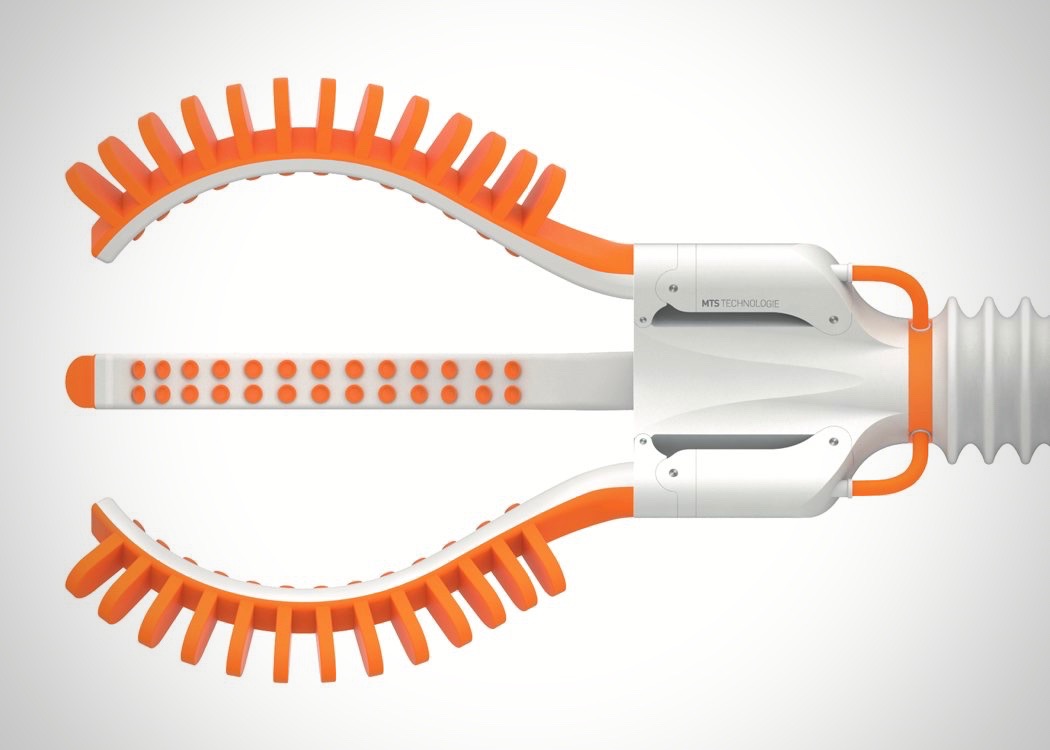

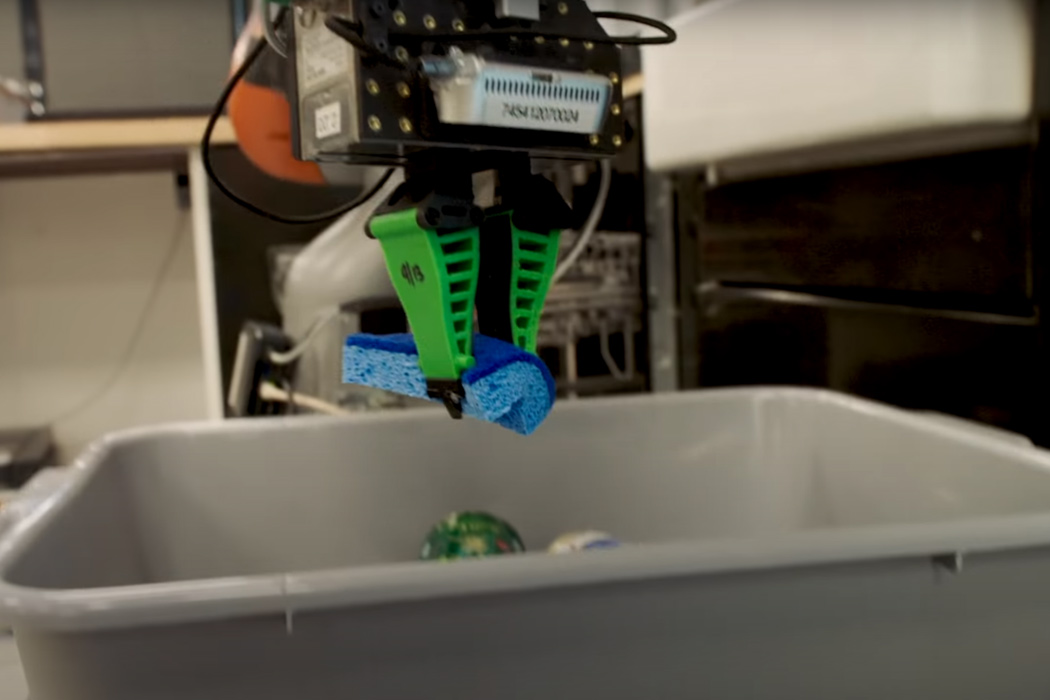

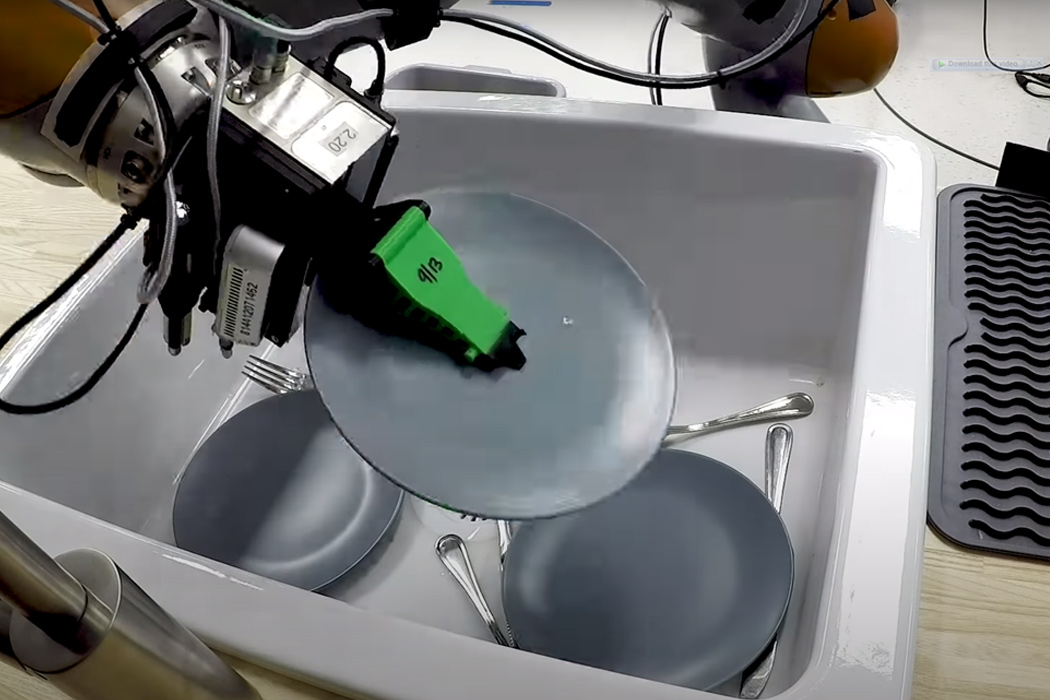

At the end of Stretch’s robotic arm, a smart gripper embedded with sensors and active controls grants Stretch with handling mechanisms to grasp a wide array of different types of packages. Keeping the whole operation going throughout the workday are high-capacity batteries and an advanced perception mast for long-lasting, precise, and stable power. Speaking of how Stretch differentiates the currently saturated truck unloading robots, palletizing and depalletizing robots, and mobile bases with arms, Kevin Blankespoor, Boston Dynamics’ VP of Product Engineering and chief engineer for both Handle and Stretch says “Stretch is built with pieces from Spot and Atlas and that gave us a big head start. For example, if you look at Stretch’s vision system, it’s 2D cameras, depth sensors, and software that allows it to do obstacle detection, box detection, and localization. Those are all the same sensors and software that we’ve been using for years on our legged robots. And if you look closely at Stretch’s wrist joints, they’re actually the same as Spot’s hips. They use the same electric motors, the same gearboxes, the same sensors, and they even have the same closed-loop controller controlling the joints.”

While Stretch is still a prototype, the wheeled robot is the commercial version of a smaller, earlier model from Boston Dynamics called Handle. Stretch currently enacts unloading and building applications for trucks and warehouses, with future plans for truck loading in the works for Boston Dynamics. While the team behind Stretch has yet to name a price, Boston Dynamics is working to make the case-handling robot compatible with other warehouse systems.

Designer: Boston Dynamics

Four wheels fill out Stetch’s mobile base, allowing it to fit anywhere a shipping pallet fits.

Smart gripping technology allows Stretch to reach for and take hold of a multitude of varying package types.

Stretch’s lengthy robotic arm grants the robot access to packages throughout the warehouse and full extension for easy rollout.

The team at Boston Dynamic equipped Stretch with seven degrees-of-freedom, providing plenty of reach and height.

Stretch was designed for warehouse case-handling and truck unloading.

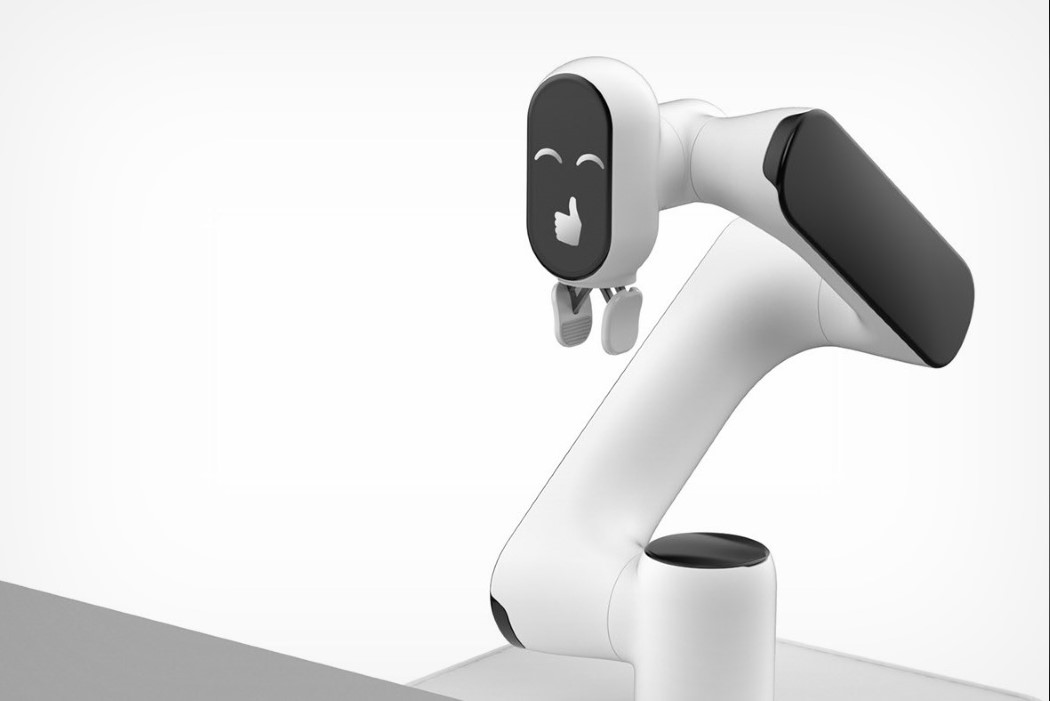

Normally when I miss breakfast, it's by choice. Today, it was because I was in a rush to get to Samsung's booth on the CES show floor and see if I could get any face time with the company's cute new rolling robot. (That, uh, didn't go so great.) The...

Normally when I miss breakfast, it's by choice. Today, it was because I was in a rush to get to Samsung's booth on the CES show floor and see if I could get any face time with the company's cute new rolling robot. (That, uh, didn't go so great.) The...