The majority of sustainable designs today focus on using responsibly sourced or biodegradable materials as well as the ability to recycle components at the end of the product’s life. While these are indeed a big leap compared to common production practices, it’s still from the ideal. Even sustainable materials like wood, metal, or bioplastics produce material waste that still gets discarded at the end of the production process. And depending on the materials involved, recycling can actually consume more energy and even result in more pollution, offsetting whatever benefits it should have brought. Another approach to sustainability is to actually reduce the materials used and, therefore, the materials that need to be recycled, as what this rather unconventional “two-piece” stool design tries to propose.

Designer: Kitae Pak

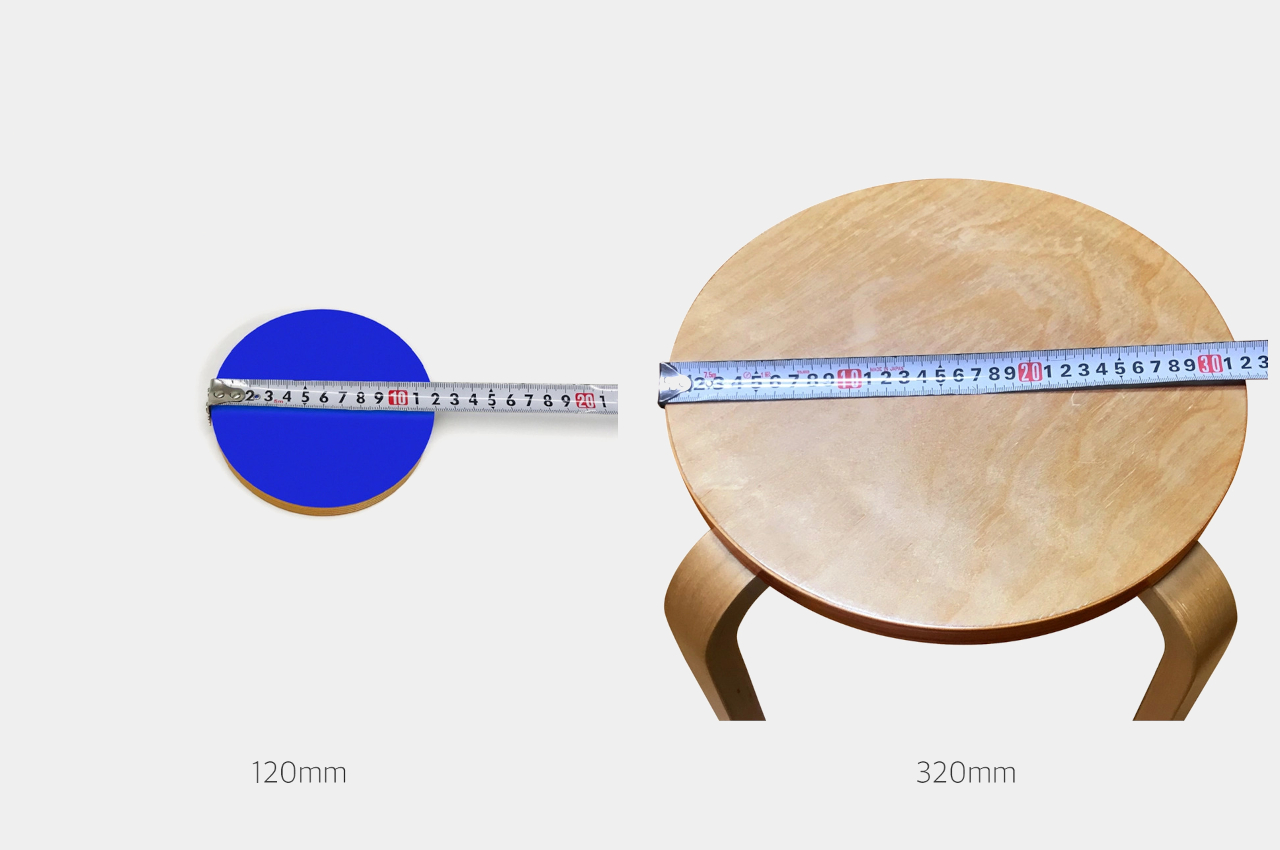

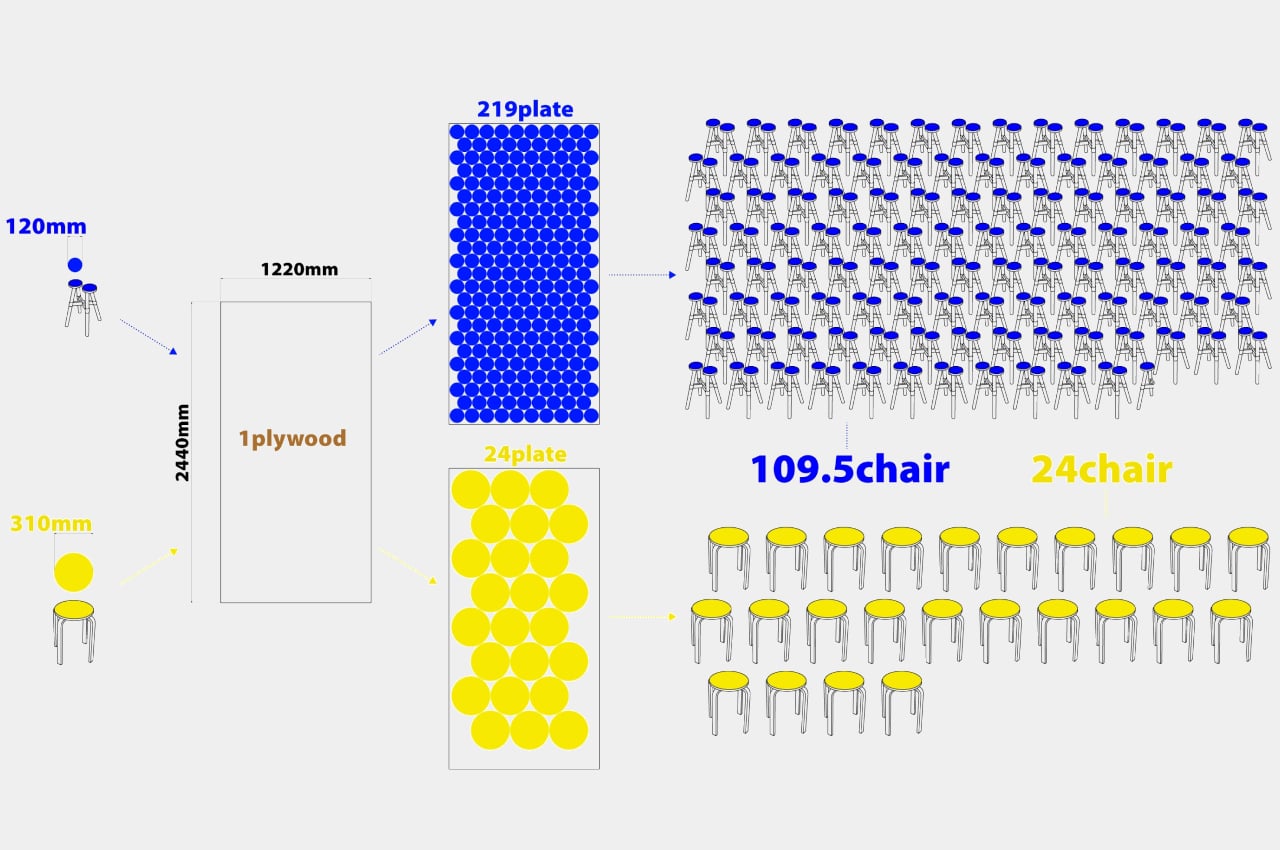

The less materials you use for a product, the more products you can make out of that material. If a single 1,220mm x 2,440mm sheet of plywood would normally yield 24 circular plates with a diameter of 310mm, you could potentially squeeze 219 plates with a diameter of 120mm. That’s the kind of increase in yield that the Dots stool concept is claiming, making more efficient use of a material without compromising on quality, at least in theory.

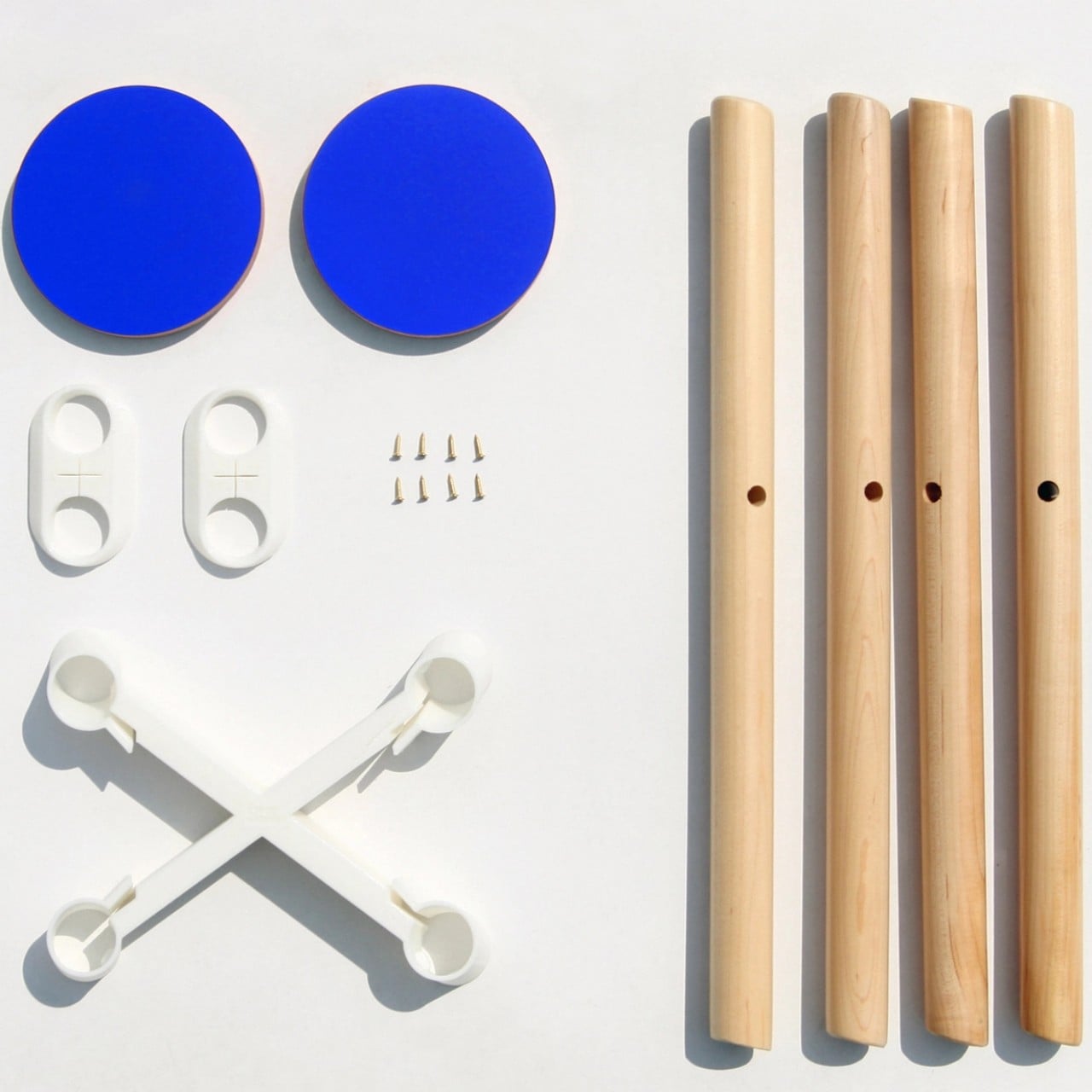

The concept accomplishes this by completely redesigning what a stool is expected to be. Yes, it’s still a piece of furniture for seating, but there’s no hard rule that the seat has to be one large and whole piece. Instead of a single big circle, the Dots stool utilizes two smaller discs to support the body at rest, hence the name. It delivers the same function but at a significantly lower material consumption right from the start.

With this minimalist design, which consists of two wooden rods for legs and recycled plastics to connect the pieces into a stable whole, you can make 4 times more Dots stools than a regular stool using the same materials. This kind of conservation means that the production process itself would use less materials and energy to produce the same number of stools, while recycling would also use less energy and water as well. And since it’s mostly made of wood, the stool can also be repurposed for other designs or returned to the Earth one way or another.

While the design does check all the right sustainability boxes, it does raise questions on conform and stability. It’s arguable that it does serve its function well, but neither its appearance nor its ergonomics inspire complete confidence. It’s not a complete loss, however, as the experiment proved that there’s still a lot of room for improvement even for already sustainable designs.

The post Odd sustainable stool concept prioritizes minimizing materials over recycling first appeared on Yanko Design.

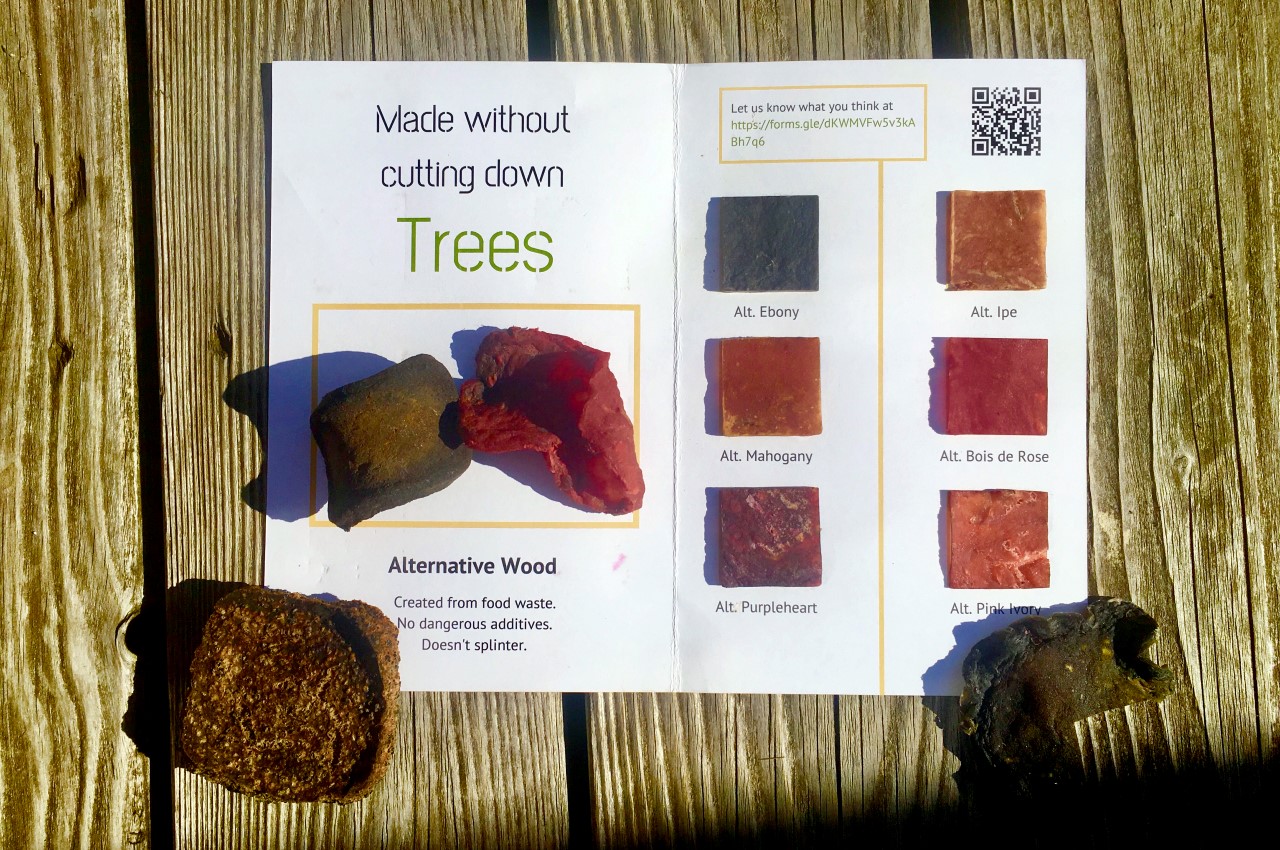

(a kombucha-based wood-alternative) now progresses to the international stage of the James Dyson Award to compete with the other participants, with the international winner being declared on the 17th of November.

(a kombucha-based wood-alternative) now progresses to the international stage of the James Dyson Award to compete with the other participants, with the international winner being declared on the 17th of November.