3D Printing is gaining more momentum and popularity than ever! Designers and architects all over the world are now adopting 3D Printing for the creation of almost all types of products and structures. It’s a technique that is being widely utilized in product design, owing to its simple and innovative nature. But designers aren’t employing 3D printing only to create basic models, they’re utilizing this technique in mind-blowing ways as well! From 3D printed artificial coral reefs to a menacing two-wheeler design with 3D printed bodywork, the scope of this dependable technique is unlimited! Dive into this collection of humble yet groundbreaking 3D printed designs!

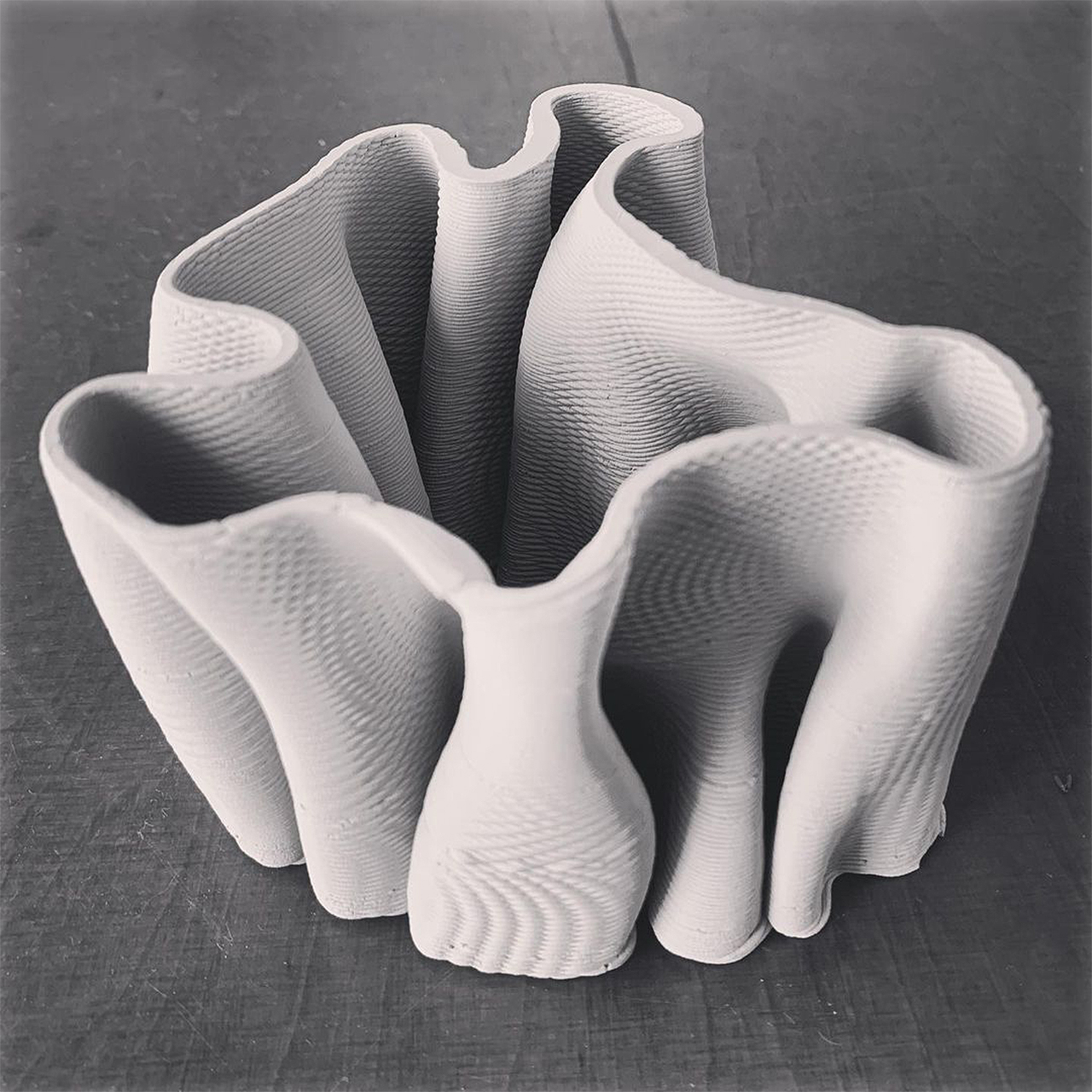

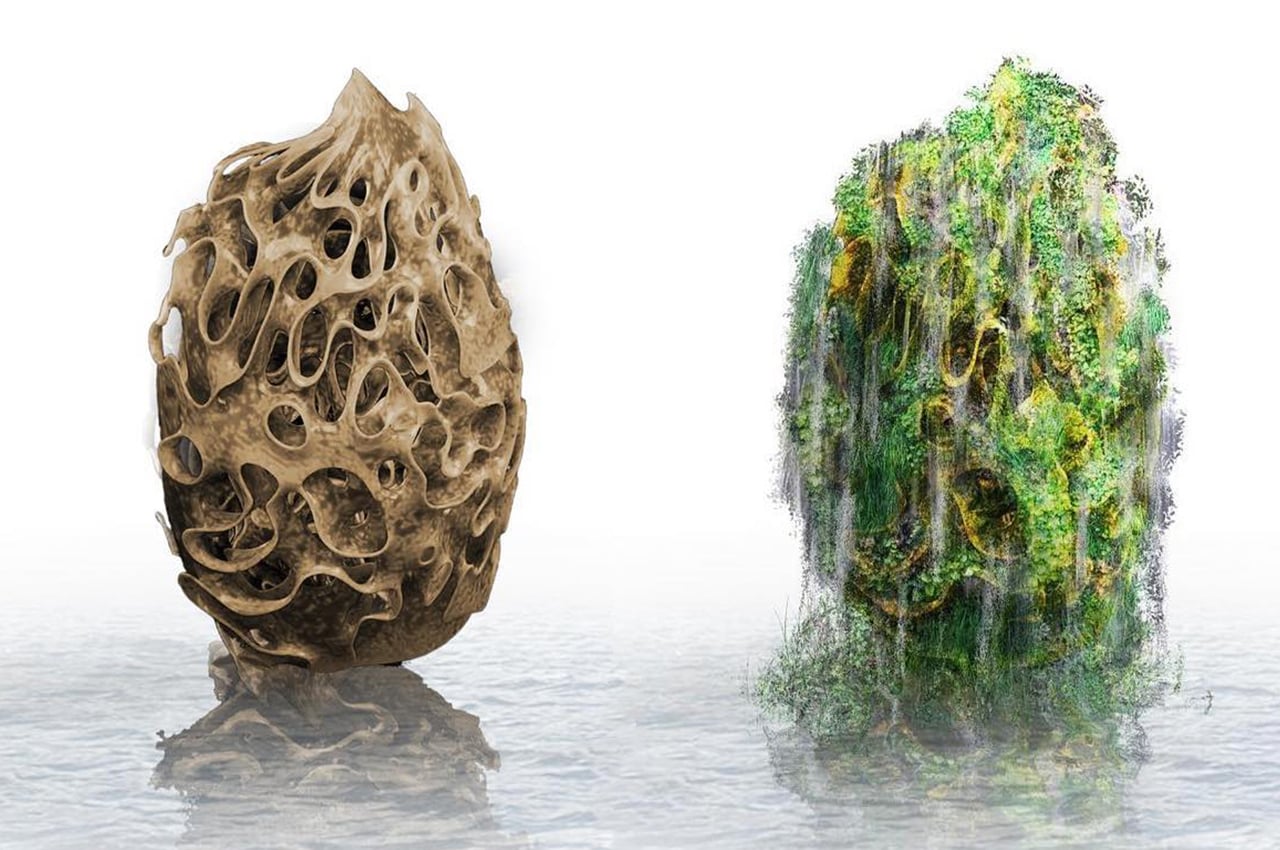

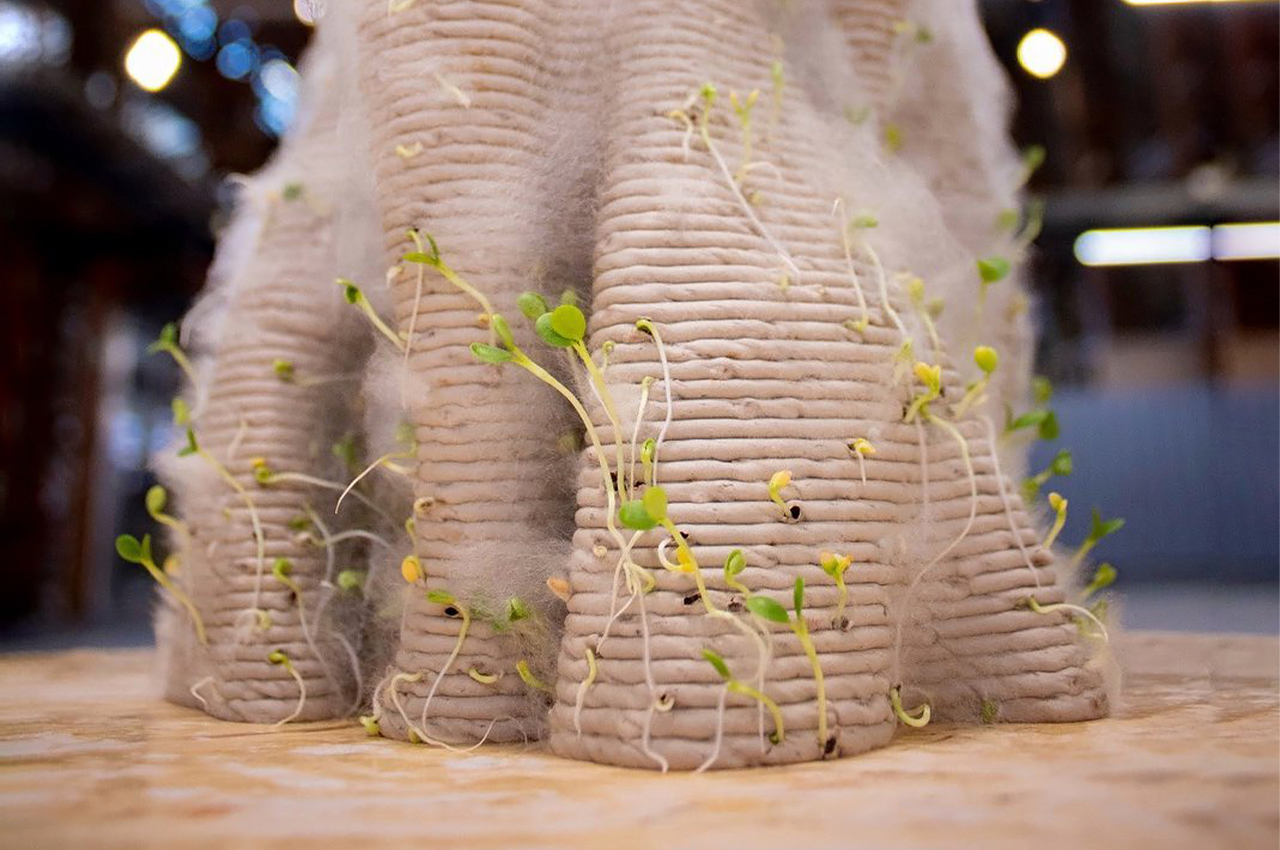

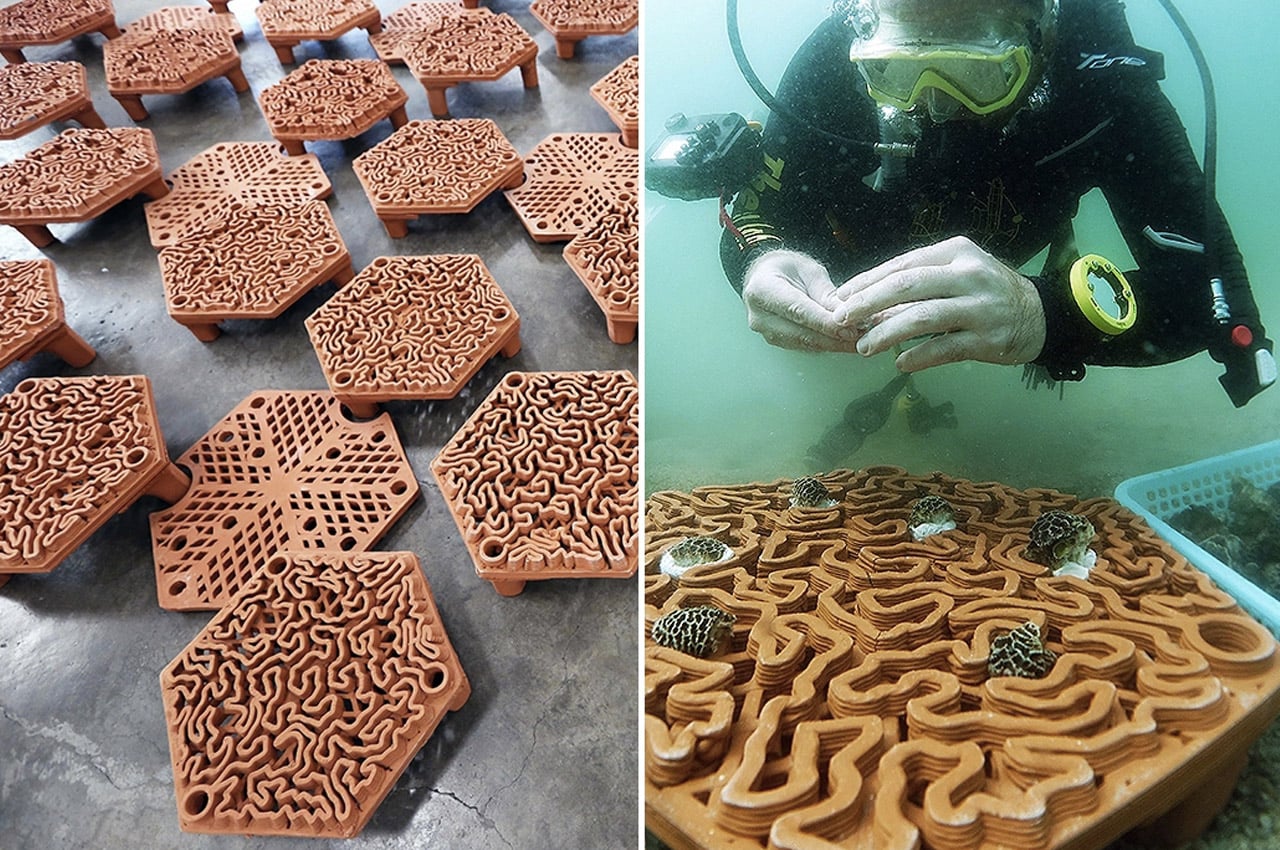

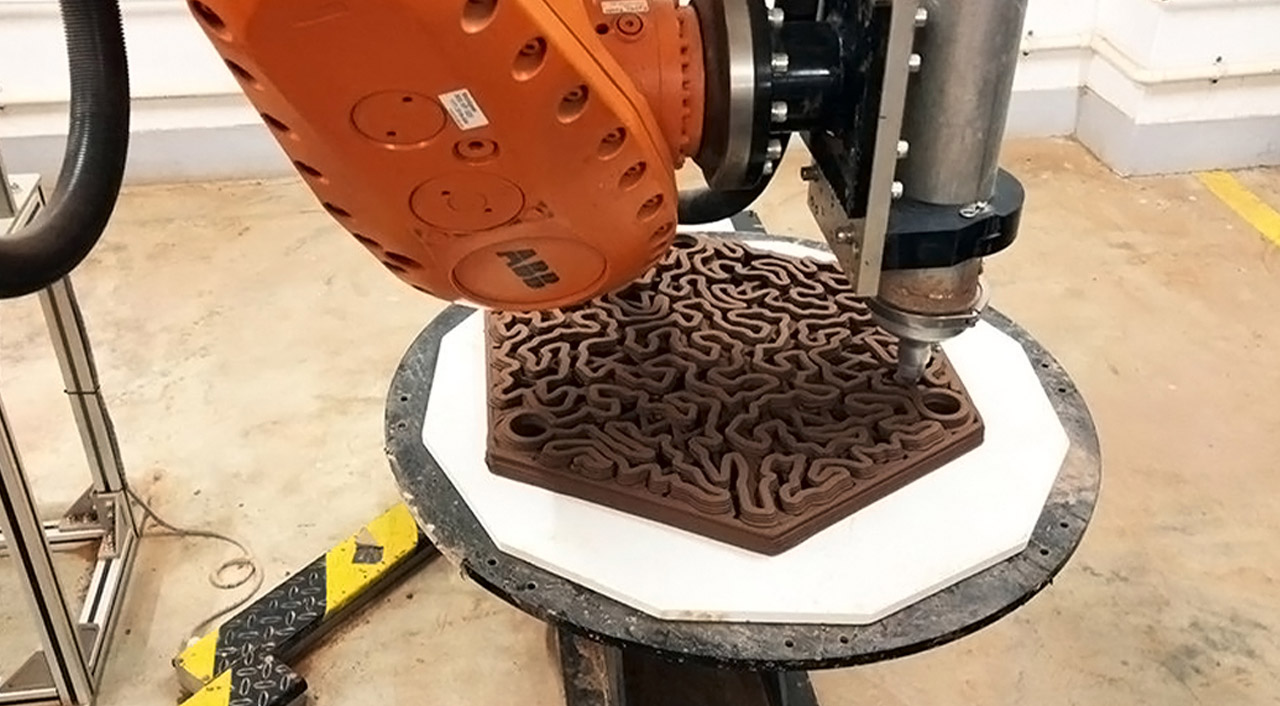

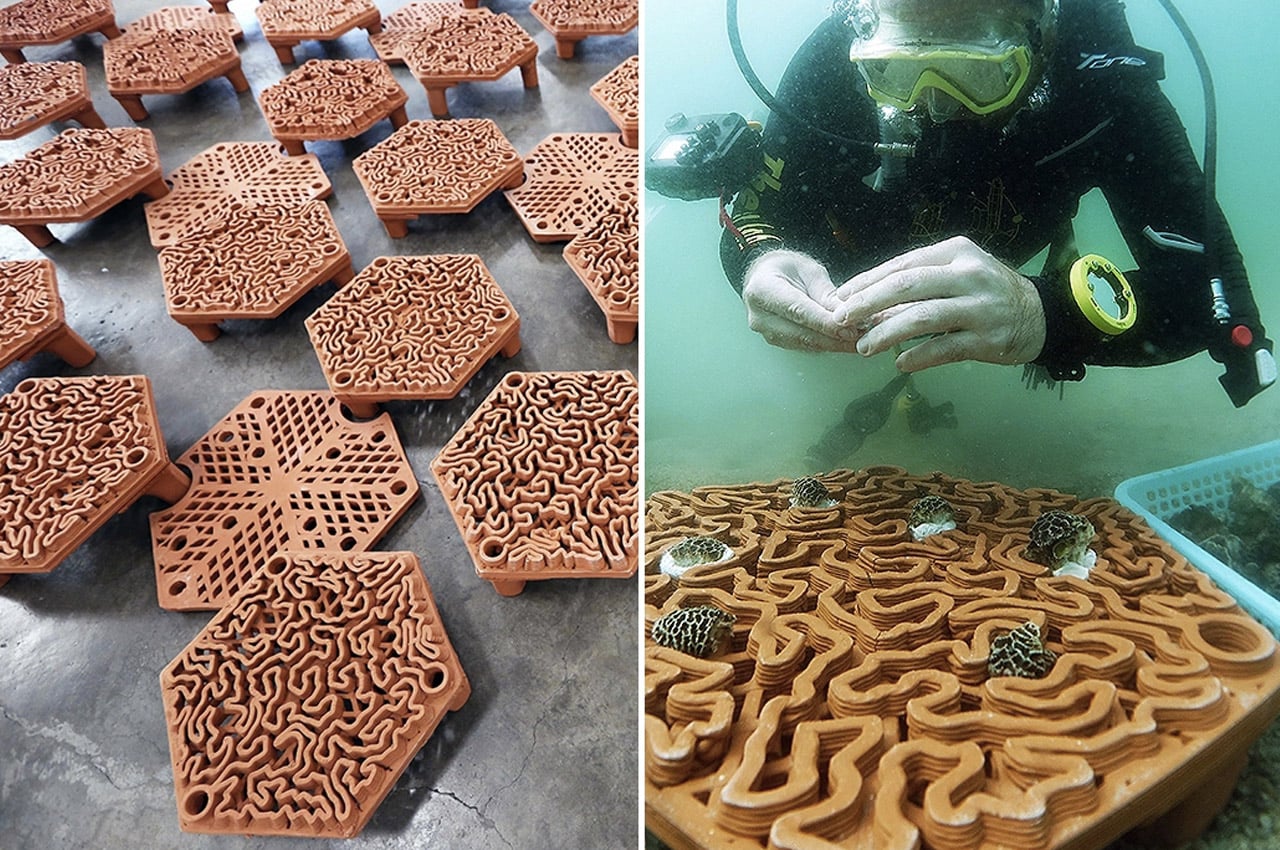

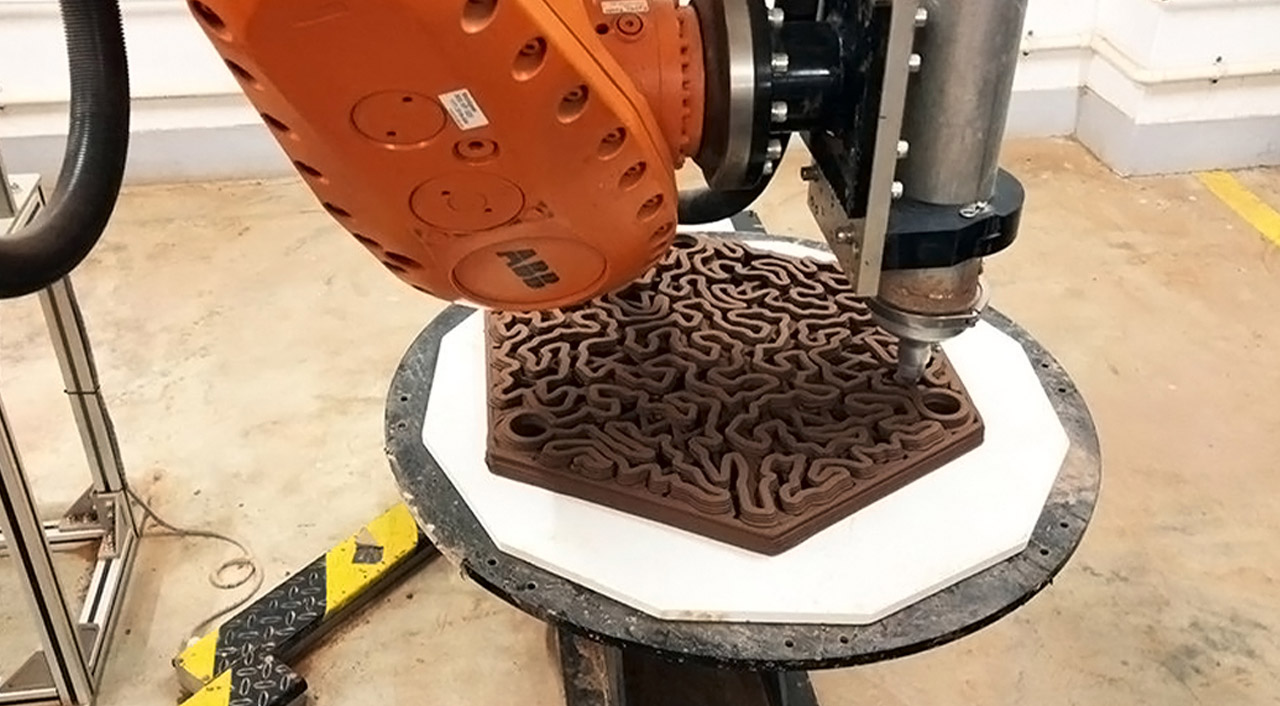

Hong Kong saw an 80% decline in the coral population in Double Island, Sai Kung, over the past decade and that drove the team to come up with a solution that would not only help that region but also the rest of the world that was blessed with corals. The team from Swire Institute of Marine Science (SWIMS) of the University of Hong Kong (HKU) and its Robotic Fabrication Lab of the faculty of architecture worked together to 3D print terra-cotta tiles that will act as artificial reefs. The result is a mesmerizing, organic swirl of line and negative space that reads like a burnt orange topographic map—and mimics the natural patterns of the coral itself. Why terra-cotta? It’s highly porous with “nice surface micro-texture” for marine organisms to latch on to, says team member Dave Baker, and an eco-friendly alternative to conventional materials such as cement or metal, the HKU team says.

Austria-based Vagabund Moto is one custom motorcycle shop that keeps pushing the envelope of design, materials, and processes. Their 15th build based around the BMW R nineT justifies the fact, as founders, Paul Brauchart and Philipp Rabl spray their creative magic over the two-wheeler for a facelift that’s so desirable for a speed junkie. The amount of metalwork is owed to craftsman Bernard Naumann! The client asked the team to make this the best ever two-wheeler they’ve ever worked on and the final result is called “Tin Man.” It has an extensive shell of bodywork highlighted by the monocoque tank cover and the seating configuration. It also has an underlying monocoque part that doubles as the under-seat storage. This is the most exciting bit of the bike is the 3D printed remote control that opens up the upper layer moving on hydraulic shocks. When open, the Motogadget dash is visible through the acrylic window in the cover.

Kairi Eguchi’s 3D-printed pen has a pretty unique way of balancing minimalism along with an expressive design. It’s rather simple if you break it down by its cross-section – The pen’s basically square-shaped, but it isn’t just a simple extruded square. Somewhere down the middle, the square profile makes a gradual 180° twist, creating a form that’s wonderful to look at and has a tactile appeal!

They look like wood, feel like it too. Hell, they even have those grain patterns that you associate with wood, but don’t let your eyes or fingers be fooled. This line of homeware designed by Yves Behar’s fuseproject isn’t made from actual wood. The technology you’re looking at lies within the domain of 3D printing, but it’s much more advanced than you’d think. Developed and pioneered by Forust, a subsidiary of Desktop Metal, this 3D printed material is a unique composite of recycled sawdust and bio-epoxy resin… but here’s where it gets interesting. Forust’s printers can actually print annular rings, knots, and grains into the printed wood. These details don’t exist on a surface level either. You can sand them and run a coat of polish over them and they’d look exactly like real wood.

The Art Deco movement of the late 19th century helped create new relationships between architecture and geometry. In a time that was certainly considered flourishing, just before the world wars, Art Deco beautifully combined European sensibilities with Eastern and South-American exotic styles while expressing itself through simple-yet-complex geometric forms and shapes… quite like Picasso’s Cubist art, but with arguably more attention to symmetry and composition. The Arintzea Collection from Muka Design Lab and Gantri pays tribute to Art Deco’s influences within Basque architecture, and it’s 3D printed!

If Adidas is to be believed, they might have created the most advanced running shoe of them all. The highly advanced shoe is deemed to give runners an all-new capability they’ve not experienced so far. They call it the 4DFWD sneaker – crafted using high-tech 3D printed performance technology. Working in close quarters with Carbon, the shoe results from 17 years of athlete-driven data and the Digital Light Synthesis technology coming together to create an advanced Adidas shoe unlike anything so far. According to Alberto Uncini Manganelli, SVP, and GM Adidas Running & Credibility Sports at Adidas, “We’re always looking to combine athlete insights with new and innovative technologies to create the best performance running products.”

The sleekness of the Apple TV remote wasn’t a feature, it was a flaw, and people were constantly complaining about losing their remote and never being able to find it… so when Apple redesigned their remote, many were expecting the 2 trillion-dollar company to address this problem too. However, all Apple managed to do was redesign the remote’s controls by bringing an iPod-style jog-dial on it. For the thousands of people who don’t see themselves buying a new remote just so that they can face the same old problems, Etsy-maker PrintSpired Designs has a neat workaround – a 3D printed case that not only gives the old Apple TV remote some volume and thickness but also allows you to slip an AirTag in so you can track your remote when it inevitably gets misplaced.

The Mickey Soap Dispenser Attachment isn’t an officially licensed product from Disney but is rather a clever fan-made product that retrofits onto most foaming handwash dispenser nozzles (although the designer recommends Bath and Body Works soap bottles). The attachment basically helps distribute the foamed handwash into three large blobs instead of one, making it resemble Mickey Mouse’s iconic circular head and ears (or Deadmau5, if you’re an electronic music aficionado). The 3D printed attachment is pretty simple to install and even simpler to use. It comes in three solid colors (that gold one looks rather nice), as well as two decorated variants that resemble Mickey and Minnie.

Say hello to the Mandalorian smart speaker holder for the 4th Generation Amazon Echo Dot. Inspired by the Star Wars spin-off series, the smart-speaker holder comes 3D printed by Etsy shop Slic3DArt, quite perfectly resembling the Mandalorian helmet. Place your spherical Amazon Echo Dot within its head cavity and you’ve officially got yourself a trophy-head worth showcasing on your mantelpiece or coffee table! The purpose of the Mandalorian smart-speaker holder is purely aesthetic. It doesn’t enhance the speaker’s functions but doesn’t impair them either (it does, however, block the light ring at the base).

Designing new and unique light fixtures is no easy feat though and the designers behind HorizON, a suspension lamp with an elliptical form designed and constructed in Italy’s glass-making capital, Murano, took it upon themselves to completely reimagine the future of lighting design. On the inspiration behind HorizON, the designers say, “HorizON lamp is based on the belief that the industry of the next years won’t only evolve through a constant, technological upgrade of products, but reconsider values such as uniqueness, hand-making, and even ‘imperfection.’” Through HorizON, the creators reconsider design values by transmuting classic, craftsman artistry with 21st-century technological capabilities. HorizON’s final product is comprised of two main parts: a glass bubble crafted through a tried-and-true glassmaking tradition that enwraps its 3D-printed, LED-filled centerpiece.