Located in Orani, Sardinia, Exosteel comprises the world’s first housing development to use a steel 3D-printed “exoskeleton” construction system that supports and distributes all the functional elements of the building, inspired by the sculpture work of Costantino Nivola.

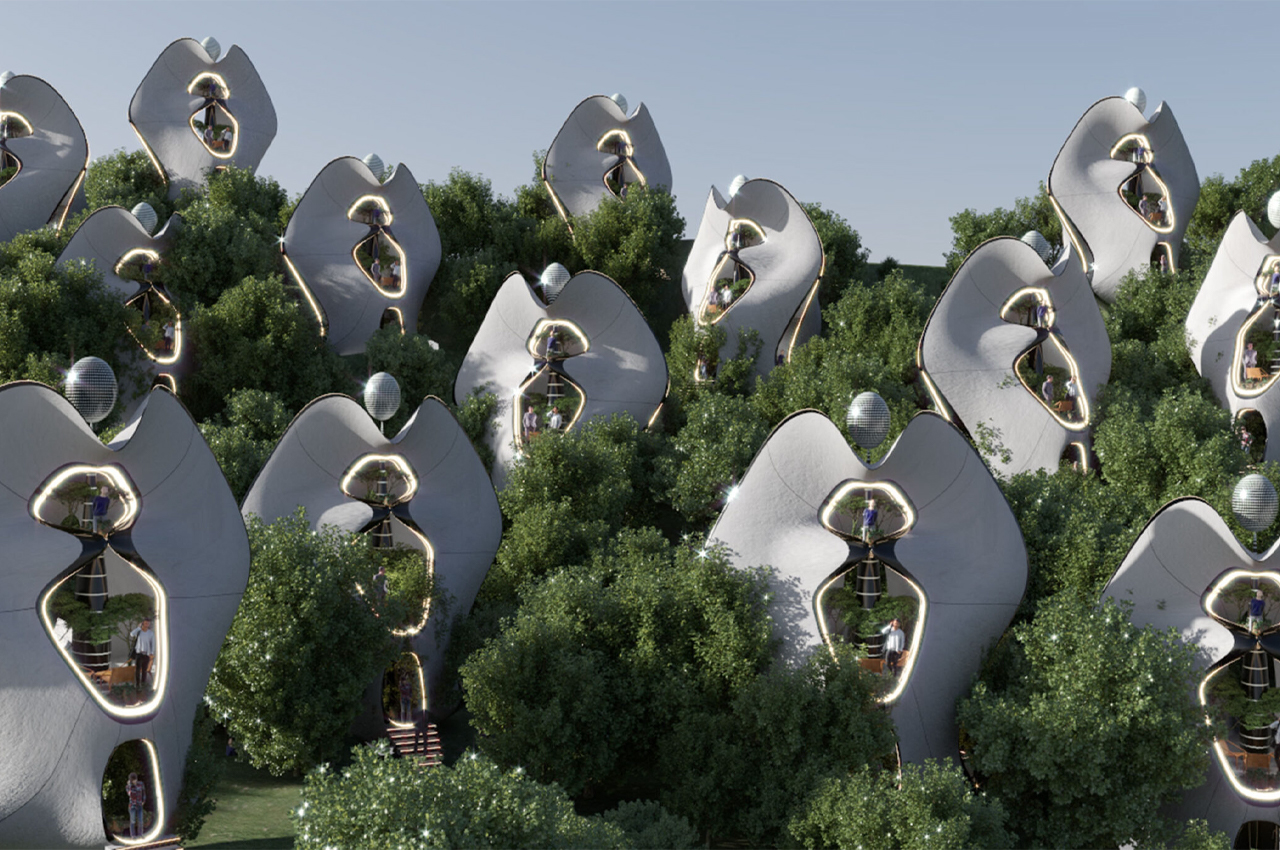

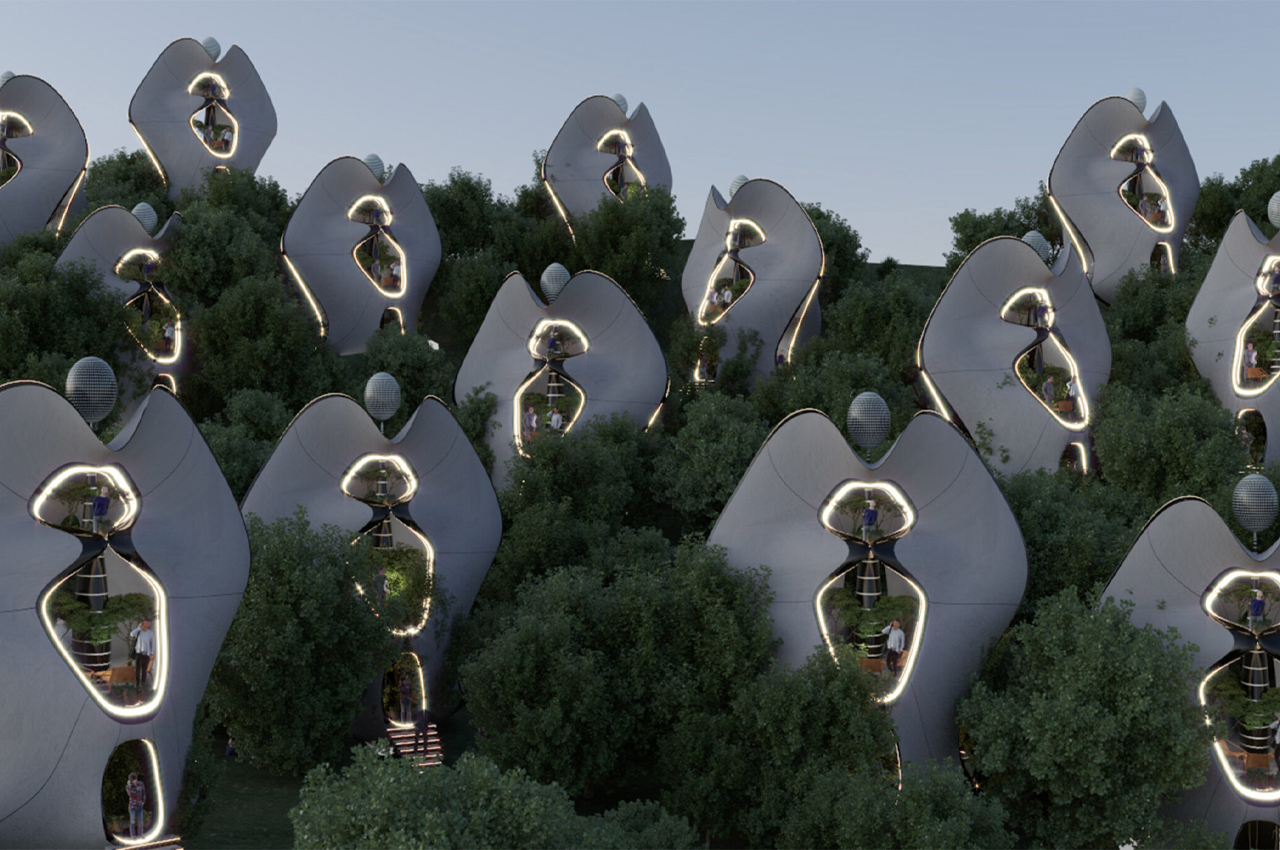

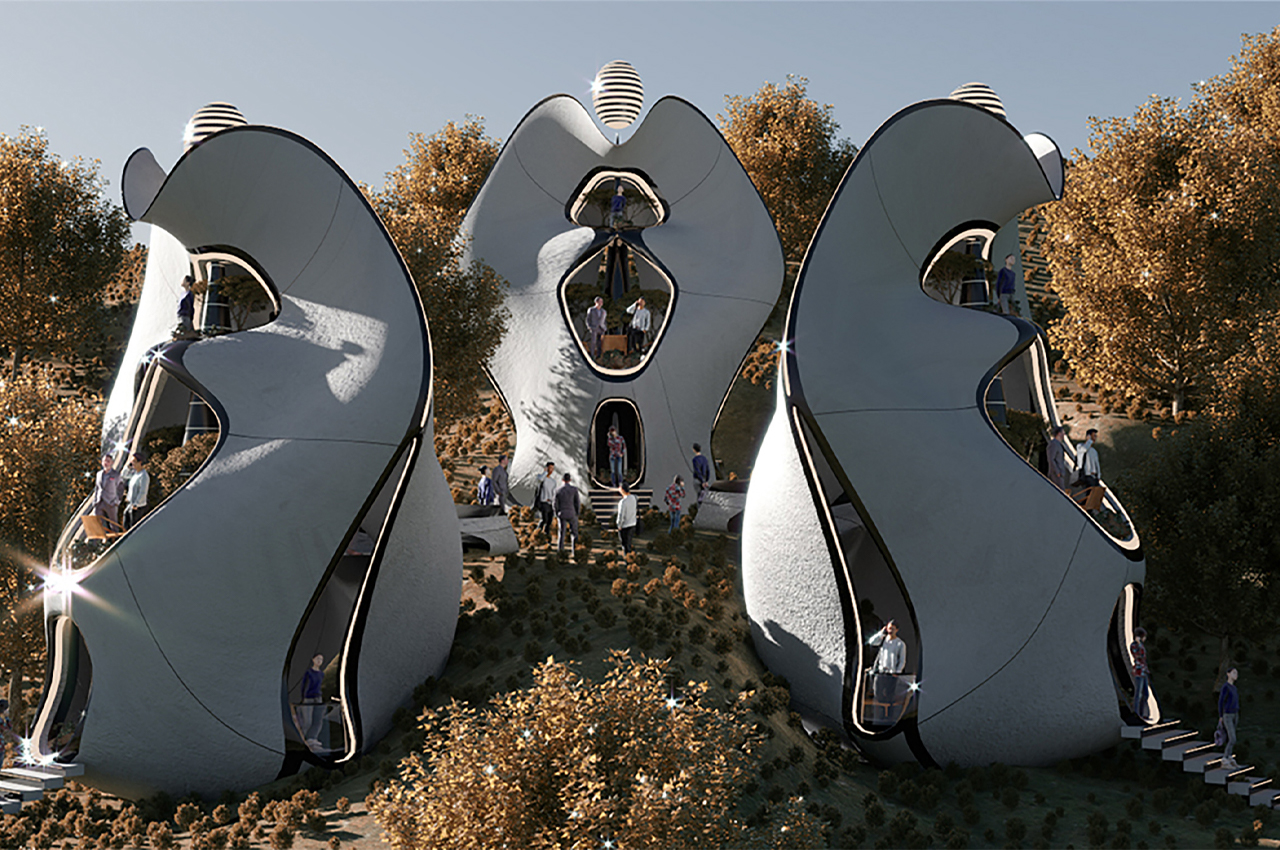

Museums are social hubs for travelers. They’re cultural and artistic landmarks first, yes. But they’re also guaranteed spots where tourists can take some respite from long hours spent wandering the city. Near the Nivola Museum in Sardinia, Italy, international design studio Mask Architects visualized a cluster of homes to function as a housing development for the surrounding community. Conceptualized as a small village of modular prefabricated steel houses, Mask Architects is the world’s first architecture and design firm to use a steel 3D-printed “exoskeleton” construction system to build the small village, calling it Exosteel.

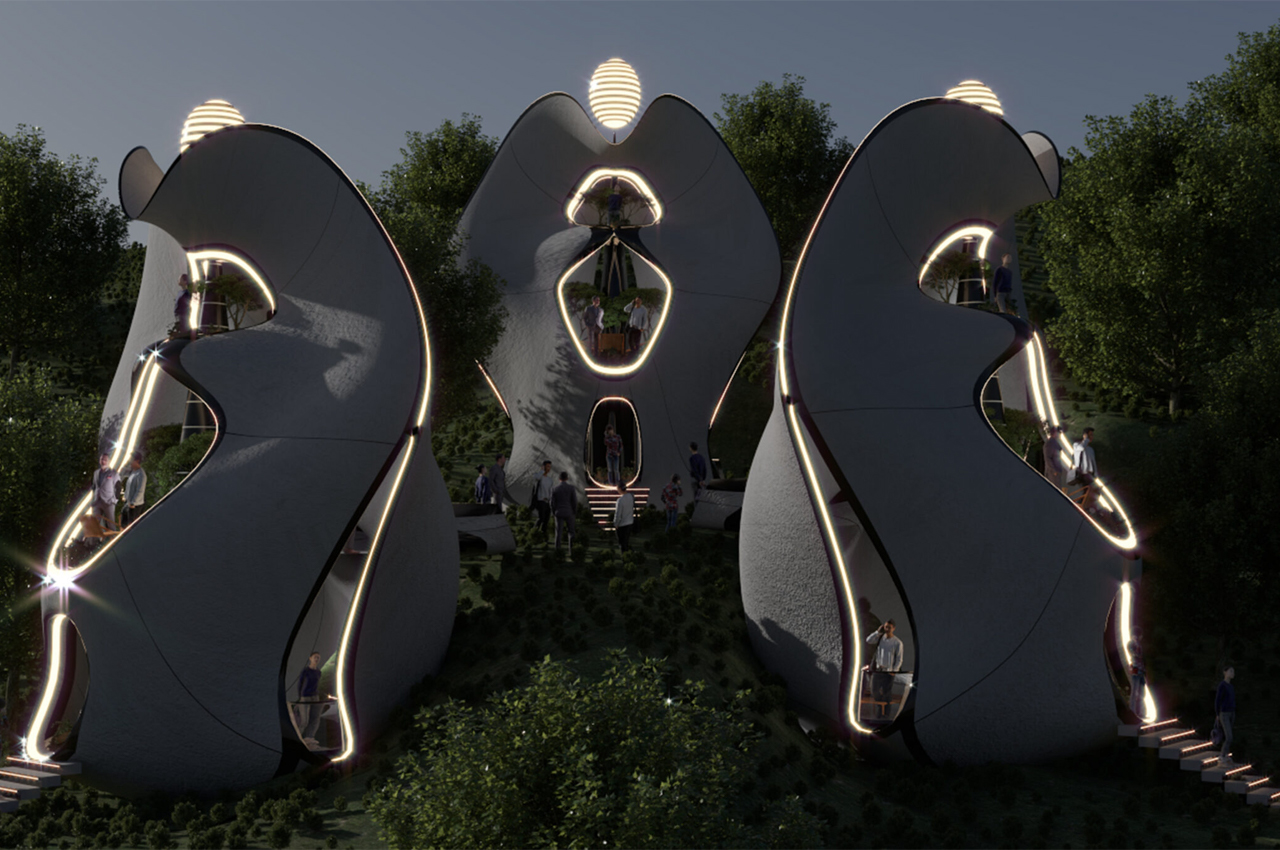

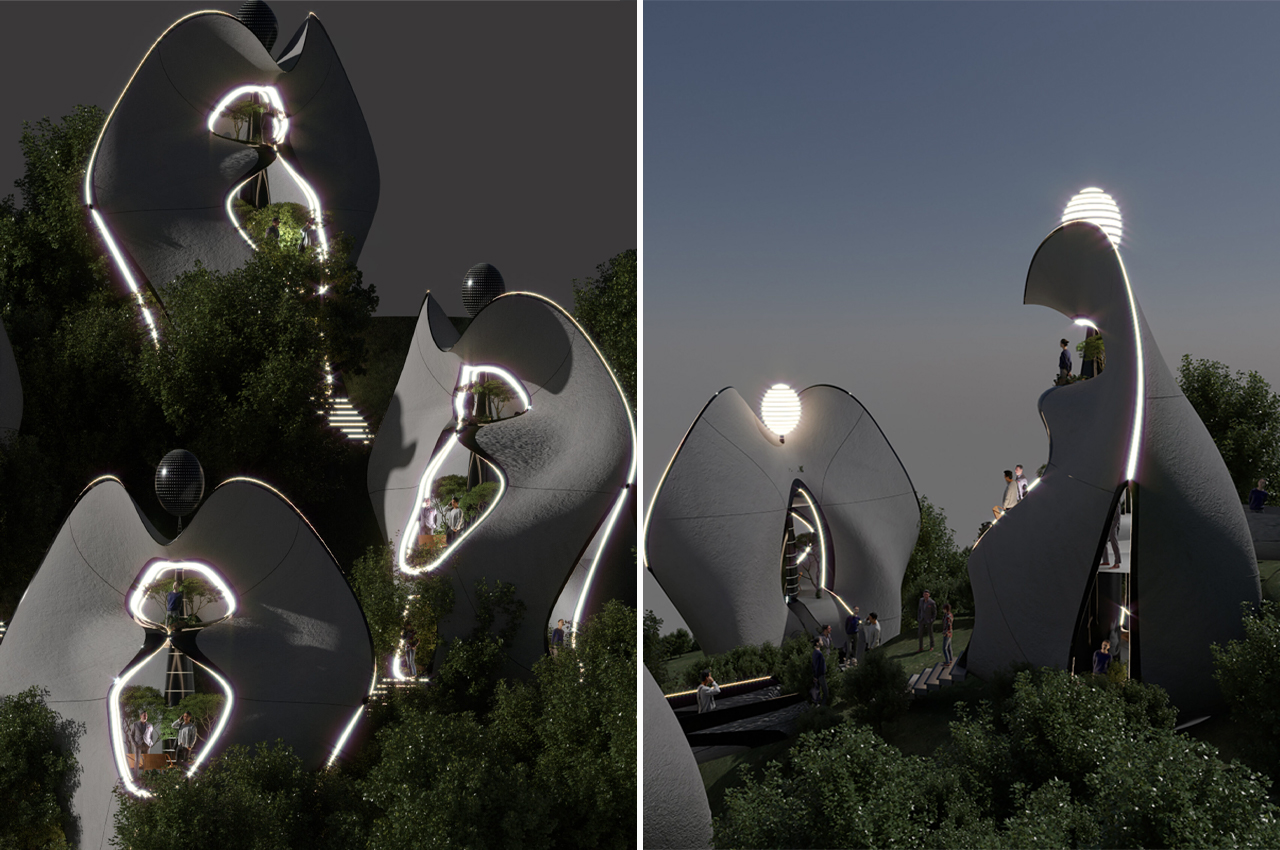

Exosteel comprises a group of modular steel homes that would be constructed using a 3D-printed construction system that supports and distributes all the functional elements of the building. Mask Architects co-founders Danilo Petta and Öznur Pınar Çer felt inspired by Costantino Nivola’s sculpture work, in particular a travertine sculpture called ‘La Madre.’ Punctuating the terrain of a sloping mountainside in Sardinia, Exosteel is comprised of heart-shaped, white homes with center ‘energy towers,’ oriented in the same way as the head on Nivola’s ‘La Madre.’

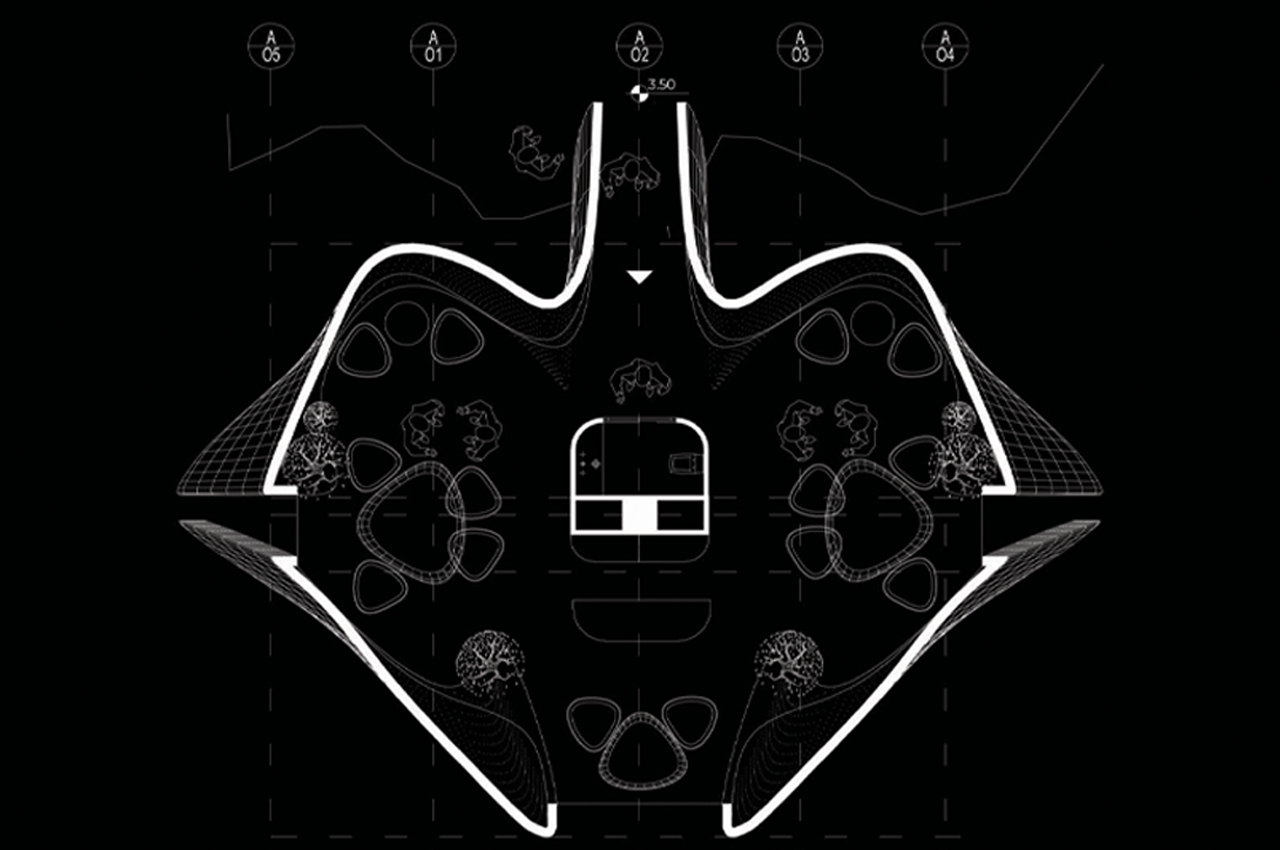

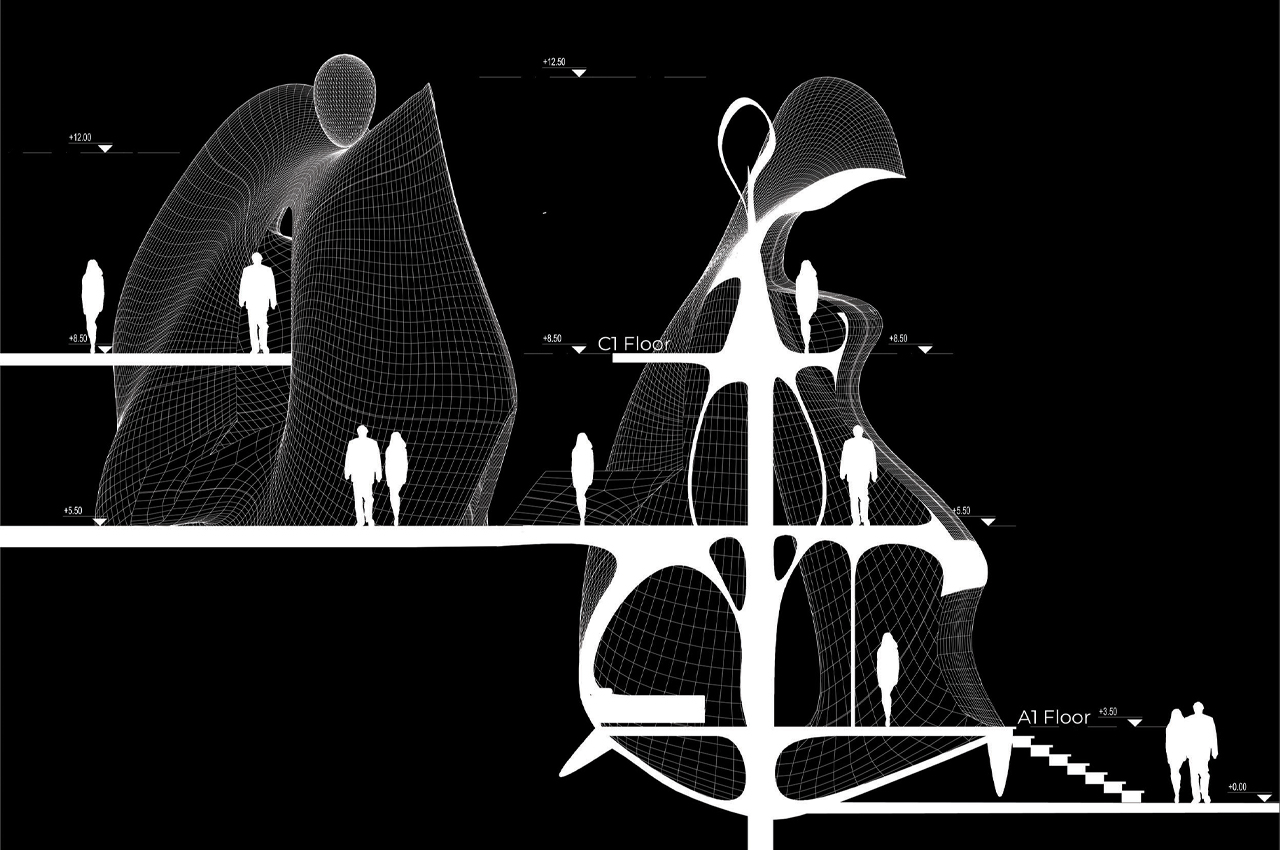

Mask Architects plan on building Exosteel by first inserting a hollow central column ⅓ of the building’s height into the ground, reinforced by wooden beams to support each home’s three floors. Then, on each floor, a perimeter frame “divides and supports the [home’s] facades made up of panels modeled to follow the organic shape of the house,” as described by Mask Architects. Following Nivola’s pursuit of binding communities together through art, Mask Architects chose Exosteel’s location due to its proximity to Orani, Sardinia’s national museum, where Nicola’s ‘La Madre’ is on permanent display.

Striving to ensure each building is entirely “self-sustainable,” Mask Architects designed each module that comprises Exosteel to be expandable and flexible to meet the conditions of Sardinia’s natural climate and weather conditions. Considering Orani’s propensity for wind, the homes of Exosteel are completed with built-in voids that guide wind through each building to the development’s communal wind turbine. As described by Mask Architects, Exosteel garners energy from individual energy conduits placed at the top of each home.

Describing the energy conduits, Mask Architects note, “Each building is centered with an ‘Energy Tower’…covered with solar panels that will harvest solar energy while the top of the central energy tower itself will rotate 360 degrees at the same time with the wind that will also generate wind turbine energy…The main centered energy tower that houses all the systems is constructed out of a steel skeleton. By connecting our bearing steel beams to this skeleton column, we actually created a completely self-supporting steel carcass metal structure.”

Designer: Mask Architects