The global climate crisis is an ongoing, and worsening, part of everyday life. As a global phenomenon, it is now undeniably pushing the needle on everything from agricultural collapse to global civil unrest, due largely to society’s dependence on CO2-emitting fossil fuels for transportation, heating, and electricity. But there’s always hope. Sustainable design is growing more and more prevalent in efforts to combat global climate change and lessen the resulting destruction of our one and only livable planet. Take this solar-powered aircraft or this sustainable coffee cup-turned-planter as recent examples of sustainable design pervading product design on a macro and micro level.

Green energy is a huge (and rapidly growing) part of sustainable design, but one of the key issues with large-scale green energy production – drawing mostly or entirely from natural energy sources like solar and wind, which produce zero carbon emissions, therefore slowing the roll of climate change – is solar panels and wind turbines provide far less energy than coal or oil power plants for the amount of land they take up. Many countries’ power grids are still mostly dependent on fossil fuel sources as a result, and since climate change ripples across the entire globe, the complex process of reaching a single unified solution is inevitably going to require the collaboration of the entire global workforce.

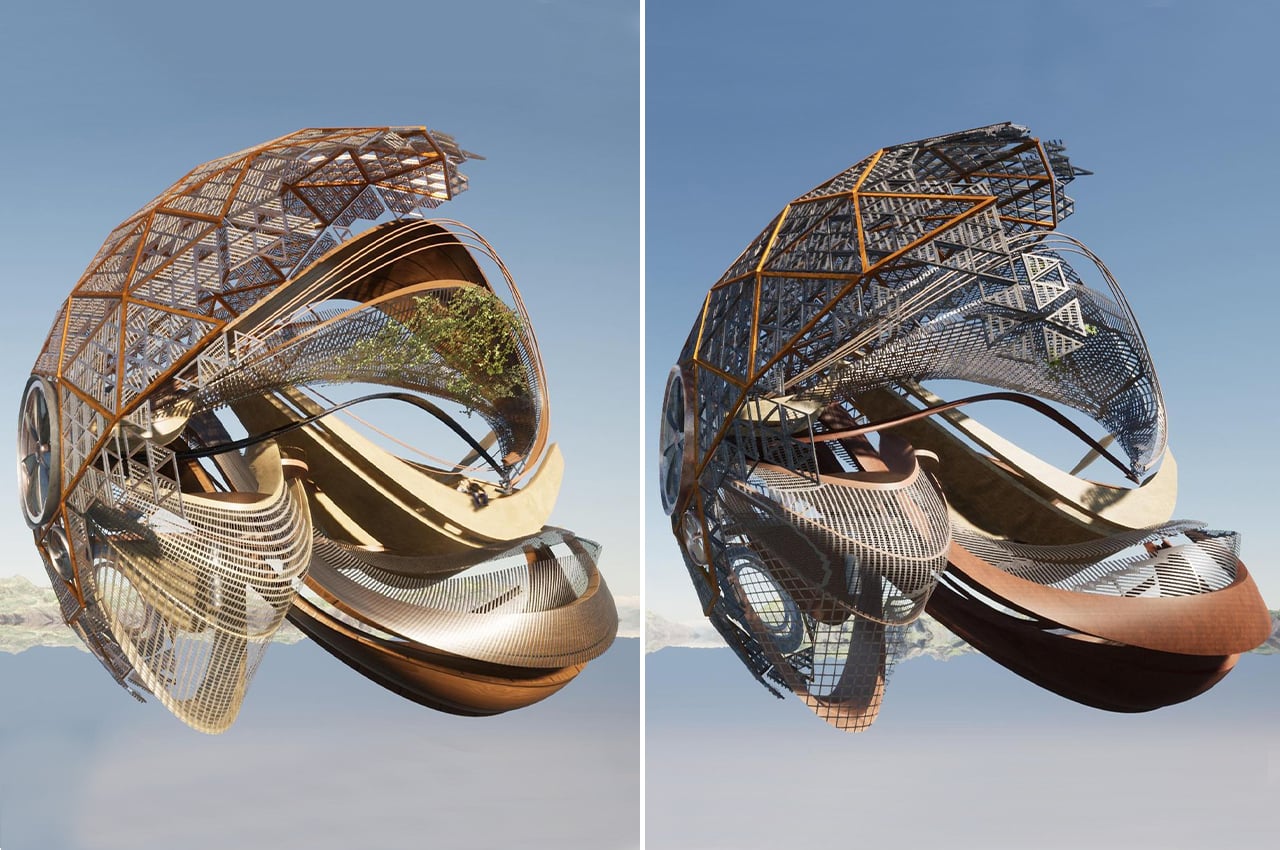

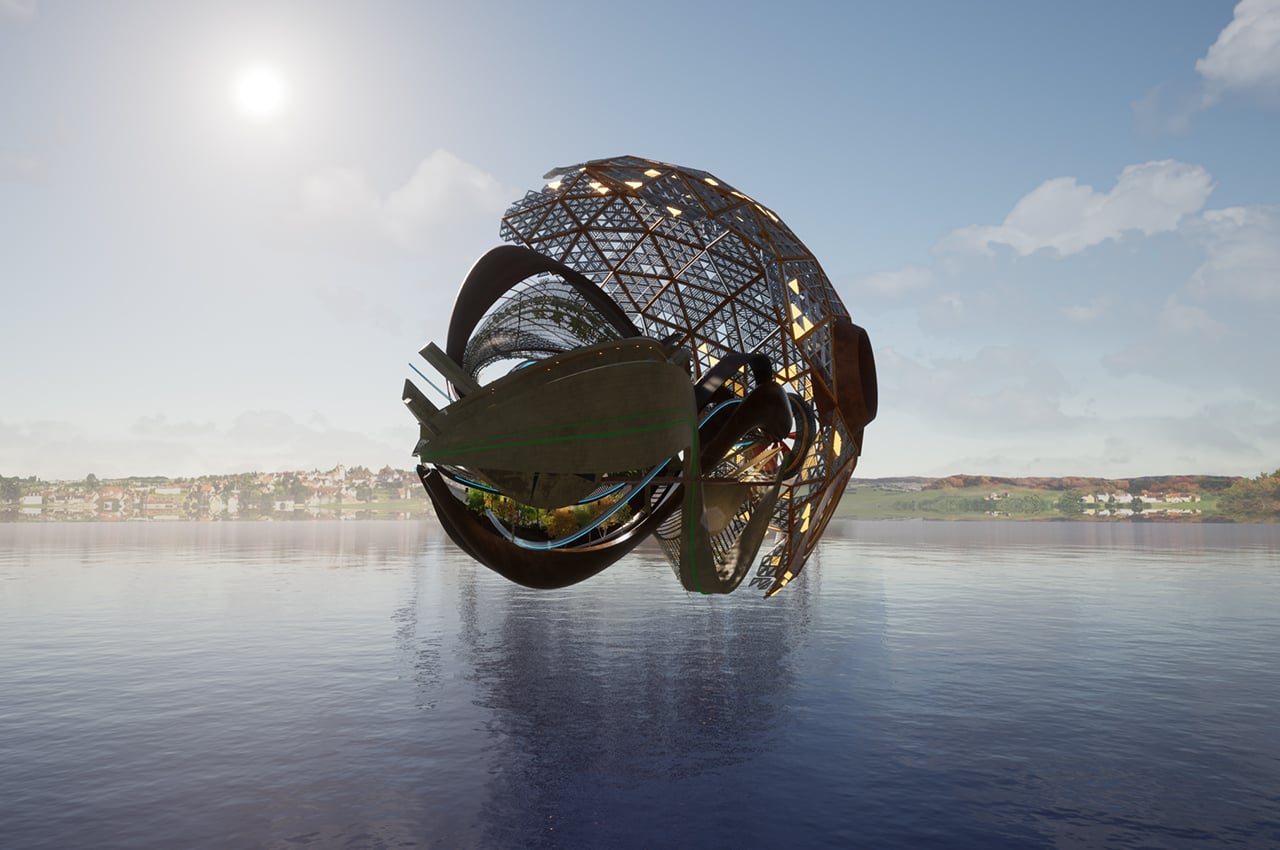

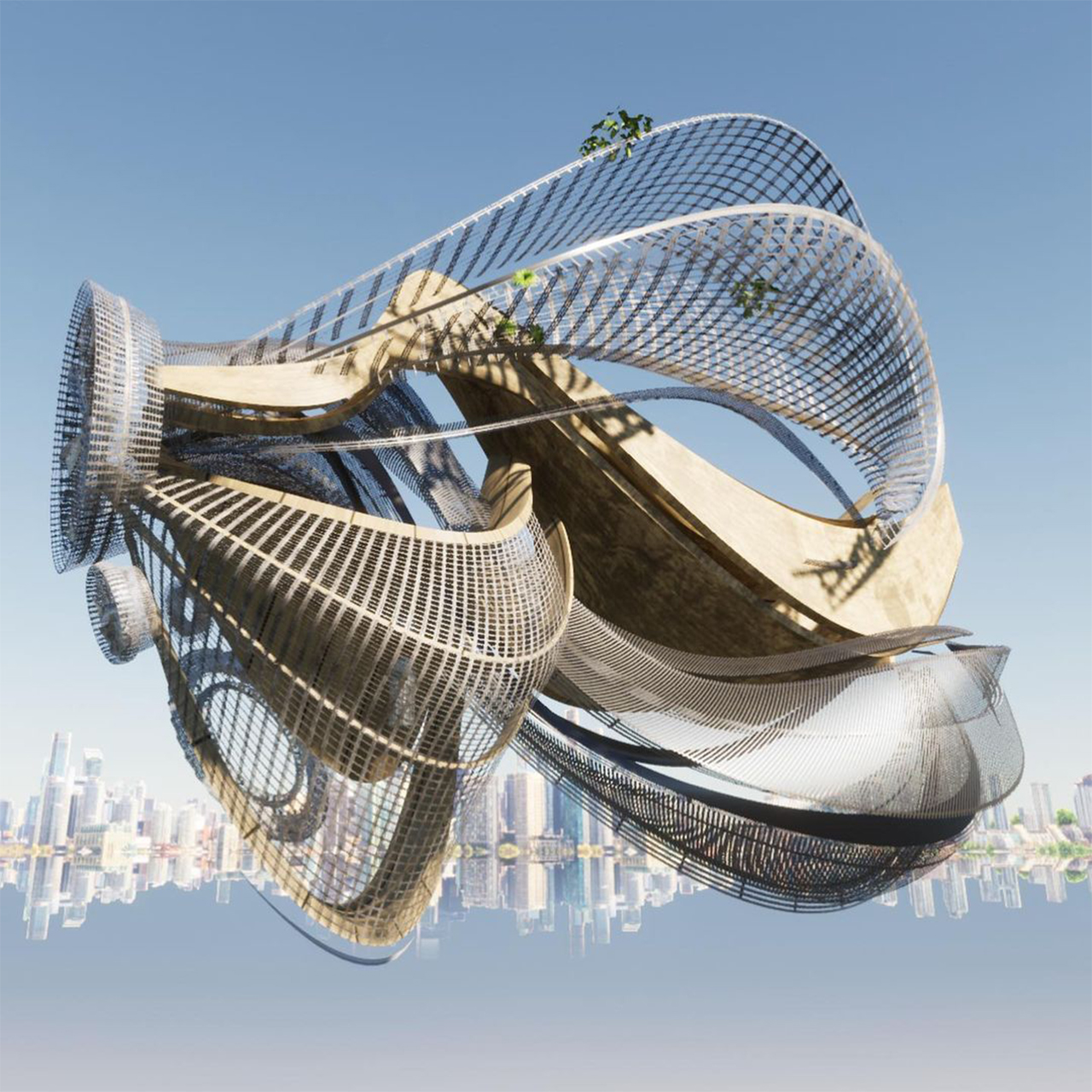

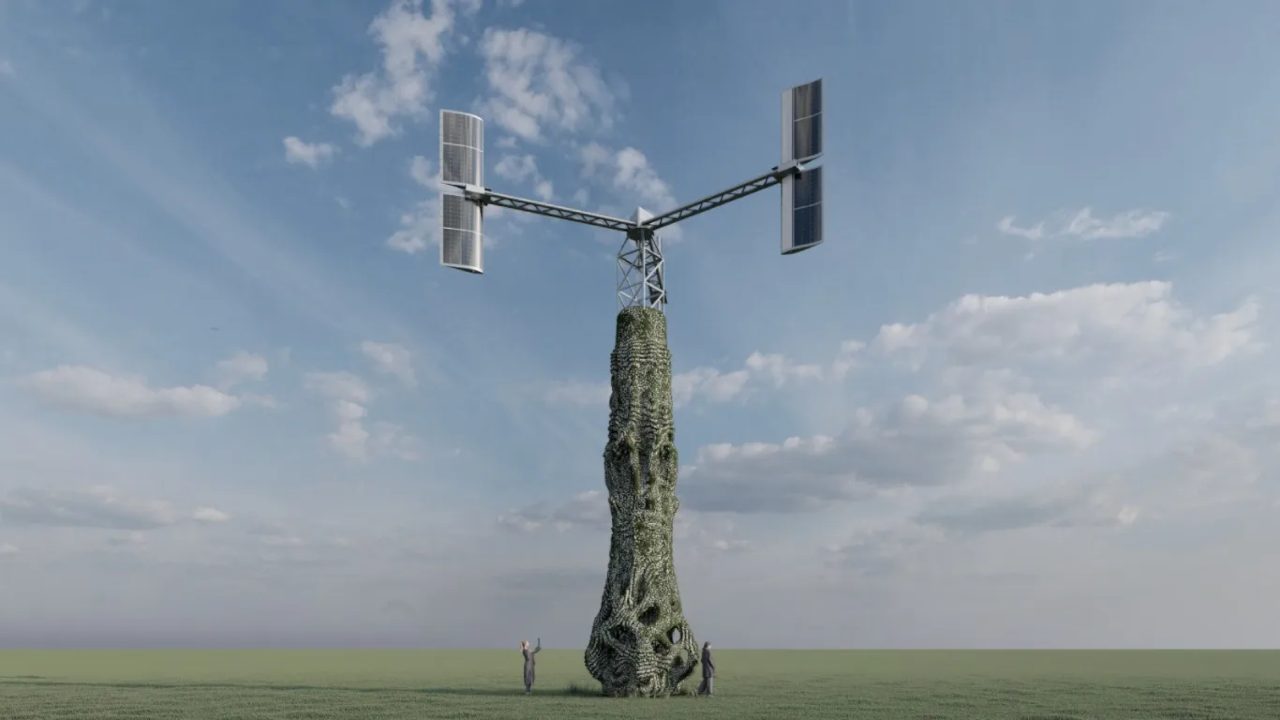

Soleolico is doing its part by putting several green energy sources together in the same space with its newly revealed photovoltaic “sails”, which are basically vertical-axis wind turbines (they have tall blades facing forward attached to a hub that’s facing upward, allowing the turbine to spin in a horizontal circumference) with solar panels mounted on the front part of the blades. As of October 6, one fully operational Soleolico unit is placed outside of the Palacio de la Magdalena in Santander, Spain, with hopefully many more installations to come.

Designer: Soleolico

Soleolico’s core idea is providing a 24/7 green energy source. Its individual blades are designed to automatically orient to the direction and strength of wind through the company’s “patented magnetic system”. Moreover, if either wind or solar become unavailable, the same system can lean on whichever resource is available, even storing excess power in built-in energy storage systems.

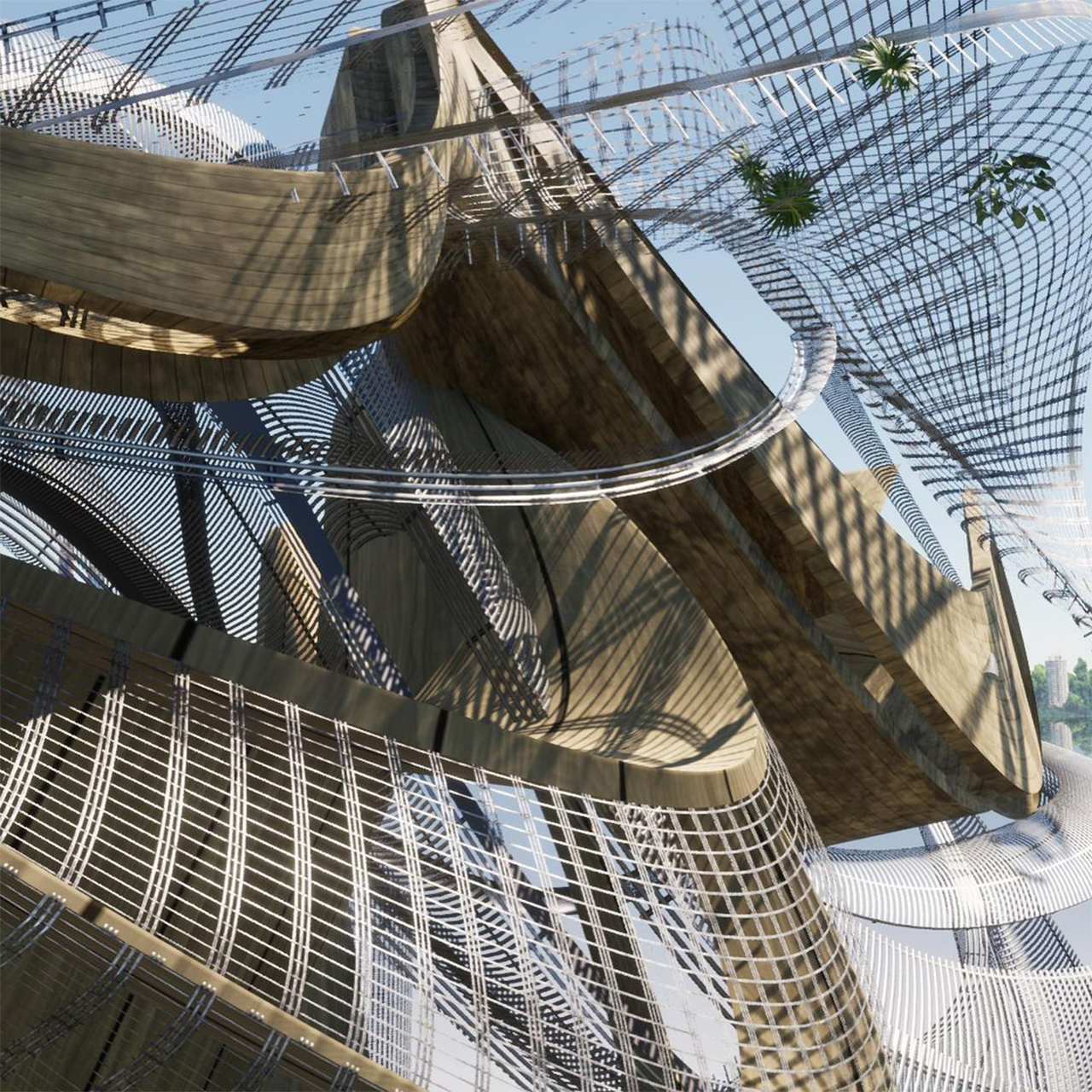

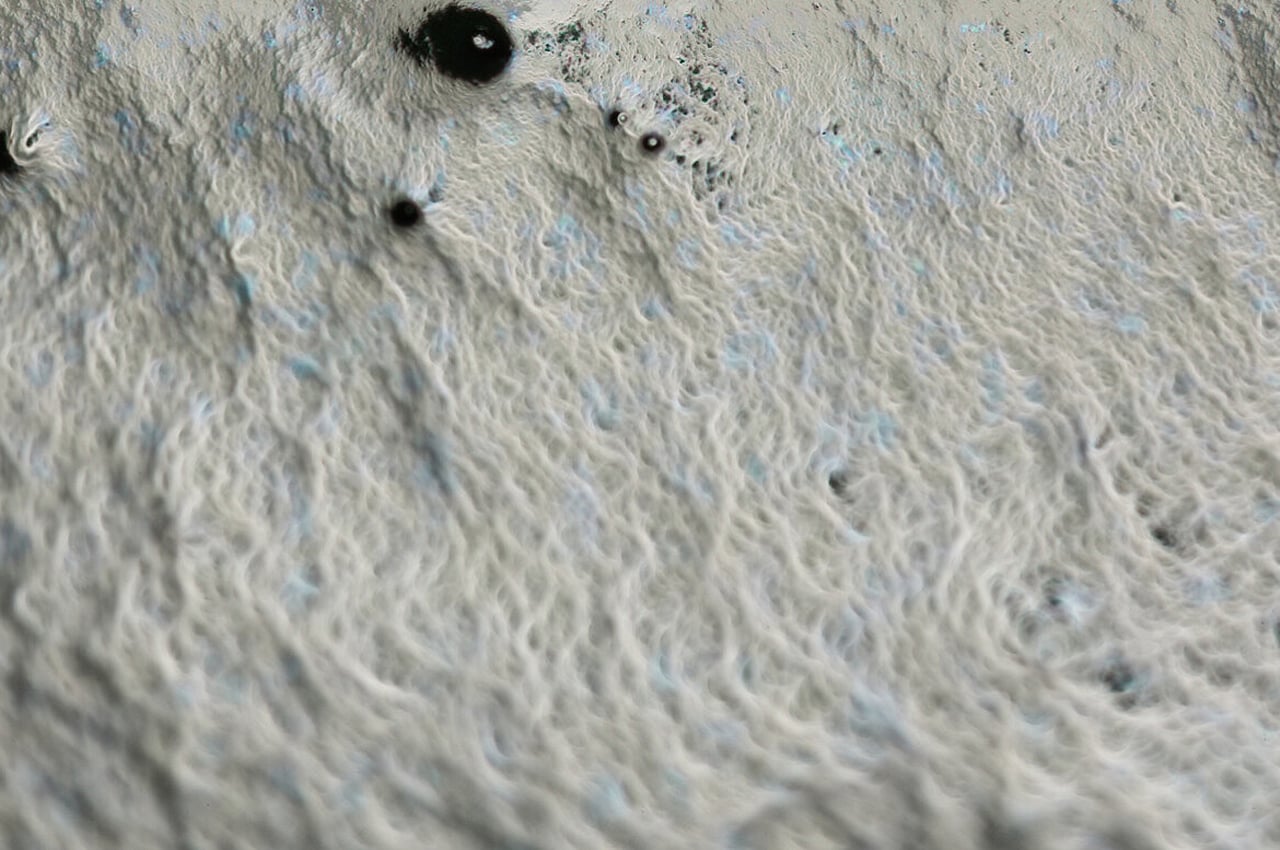

Generating green energy isn’t Soleolico’s only function. It also scrubs CO2 out of the air via a 3D-printable coating made of “natural agents” that make it similar to a tree. The company even goes as far as calling it the world’s “First Technological Tree”, given its ability to integrate naturally into forests and other important and complex ecosystems while providing a higher energy production capacity than traditional wind turbines.

The aforementioned 3D-printable coating, currently produced at the LaMáquina manufacturing center in Barcelona, Spain, uses Pure.Tech organic 3D-printing technology. According to Aldo Sollazzo, the Director of Pure.Tech, “the installation of 1,000 units of Soleolico absorbs the same amount of CO2 as 287 trees in a year, according to our calculations, based on data from the European Environmental Agency and our certified laboratories”.

That’s not all. Soleolico’s “sails” design can also display advertisements and branding imagery, making them function as self-sustaining electric billboards. It’s unclear how quickly it (and other technology like it) will catch on en masse, but the fact that such an invention exists and can be produced quickly thanks to new advancements in 3D-printing tech is ultimately hopeful.

The post This 3D printed wind turbine design uses solar arrays for 24/7 green energy first appeared on Yanko Design.