Concrete jungle is not just something Alicia Keys sang once, cities are becoming more paved with every passing day leaving scarce patches of greenery. Having concrete structures everywhere is not appealing to the eye but at the same time makes it harder for cities to use rainwater because they don’t have surfaces to absorb it. This makes it harder for them to maintain natural public spaces and green starts turning to gray. To solve this problem, Barbara Standaert made the Waterbench – it is exactly what you think. The design combines a bench, a rainwater barrel, and a planter into one to restore some greenery into the urban landscape.

Rainwater is used in public spaces to create self-sufficient green. The permanent water supply always guarantees a dry seat, even in rainy weather, requires hardly any maintenance, and ensures a permanent green touch in the city.

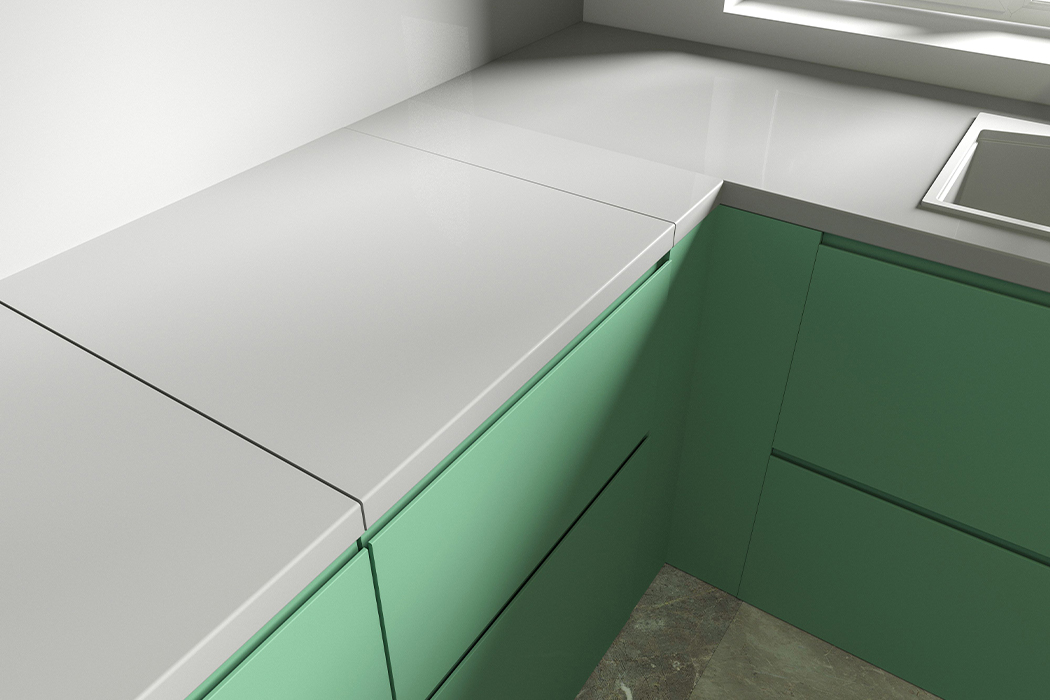

The rainwater naturally seeps through the porous concrete cover and is collected in a water-tight concrete reservoir where the plants find their water and food. The water is naturally absorbed and transported to the plants by a nylon cord. The Waterbench Rainwater buffer + water reservoir for plants Cover made of permeable concrete Collection trough in architectonic concrete water reservoir: +/- 280 liters.

Length 250 cm, Width 174 cm, Height 45 cm Weight: +/- 1,300 kg for the collection tray, +/- 1,100 kg for the cover. It is available in grey, other shades possible upon request. Overflow, allowing water to escape if the tank is full. The element rests on rubber stands, allowing excess water to run off. Another advantage of the Waterbench is the option to ‘plant’ the bench with little prior effort, in line with the particular needs of the environment.

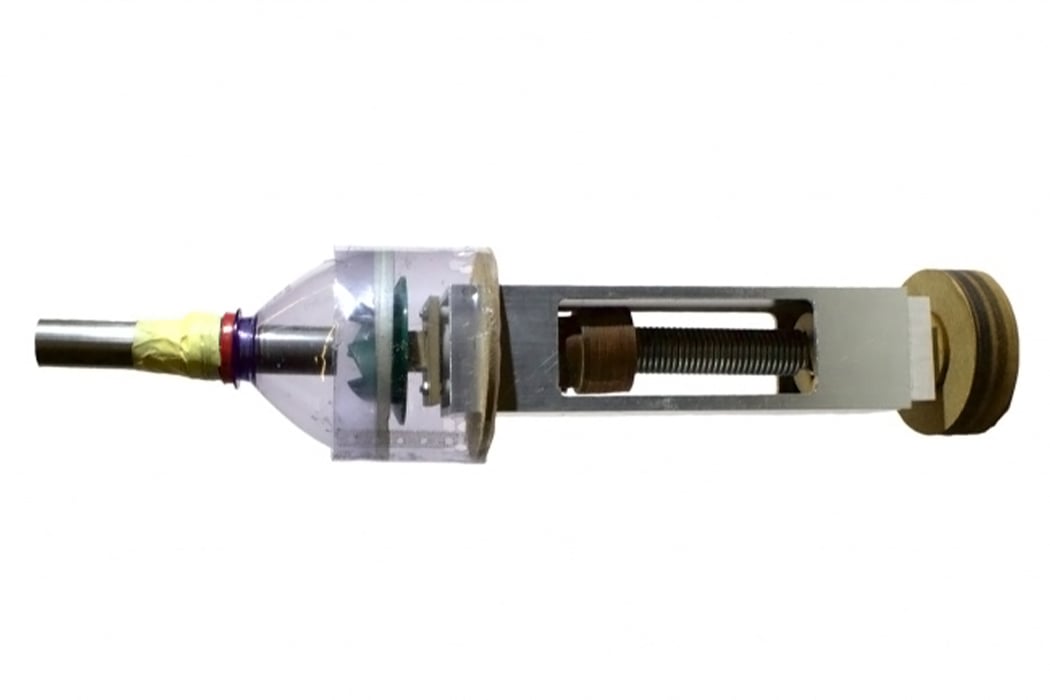

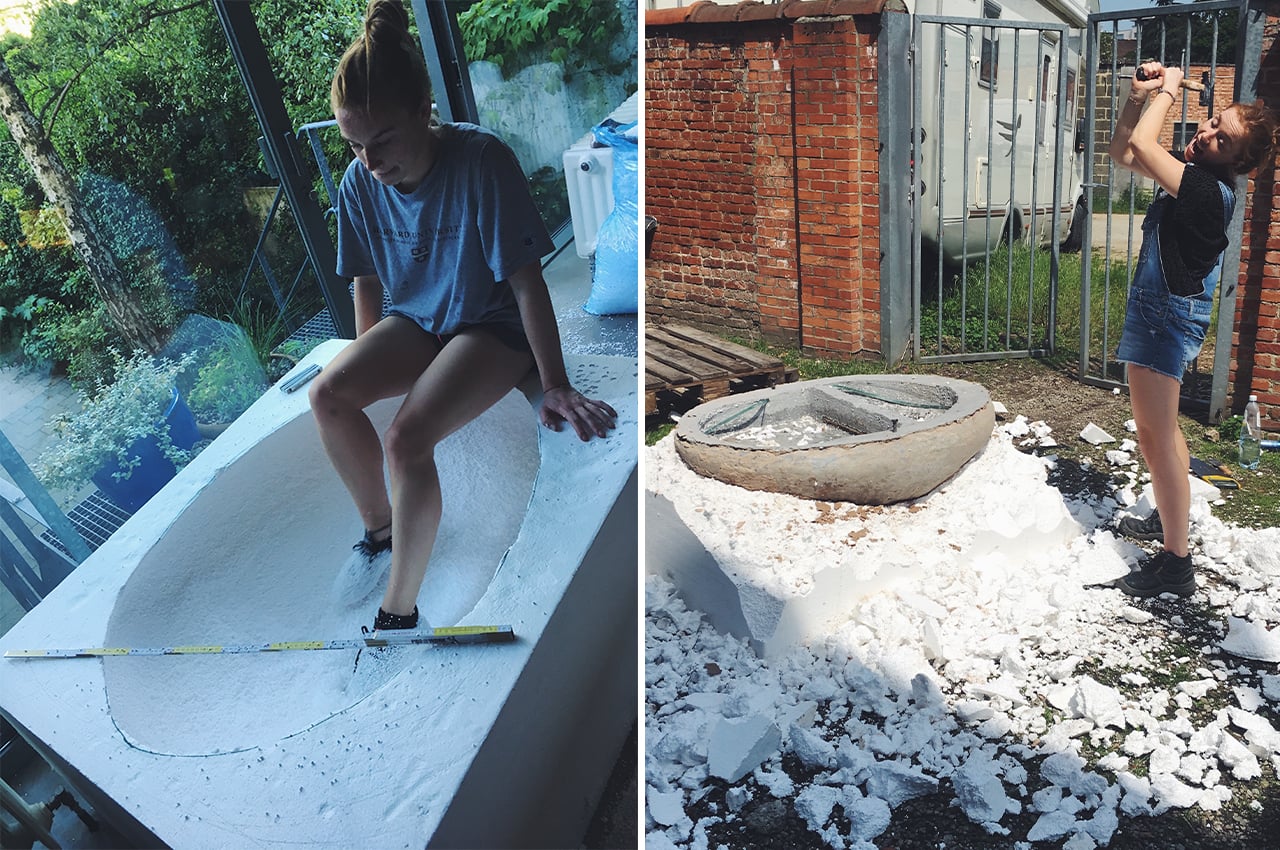

Starting with the design question “How can we restore natural processes and give back some green to our urbanized landscape?” – I started researching what is being done today to direct rainwater to nature. Porous rainwater pipes were one example. The material fascinated me. I brought it to the surface to show what it did to the audience. After this, the function to combine the material and water storage with greenery was quickly made. During my studies I made the prototype all by myself. I carved out the some mold by using my football shoes. I filled the mold in cooperation with a concrete manufacturer and transported the (way too heavy) concrete block in a rented van. One day before the jury, I still had to apply the porous top layer… After I graduated I found a manufacturer who is now producing the market suitable Waterbench.

Designer: Barbara Standaert