Climate change is not leaving any sphere of life untouched and a lot of that damage is irreversible. Coral reefs are one such natural treasure that is facing the harsh effects of global warming and they are dying at an alarming rate. If things continue at this speed, 90% of coral reefs will vanish by 2050. While they only occupy 0.1% of the total area of the ocean, they actually support 25% of all marine species on earth! Nemo is an award-winning device designed to assist with coral restoration in an efficient, sustainable way, with large-scale capacity. It can plant 100 corals a day and only requires 2-3 people to complete the operation.

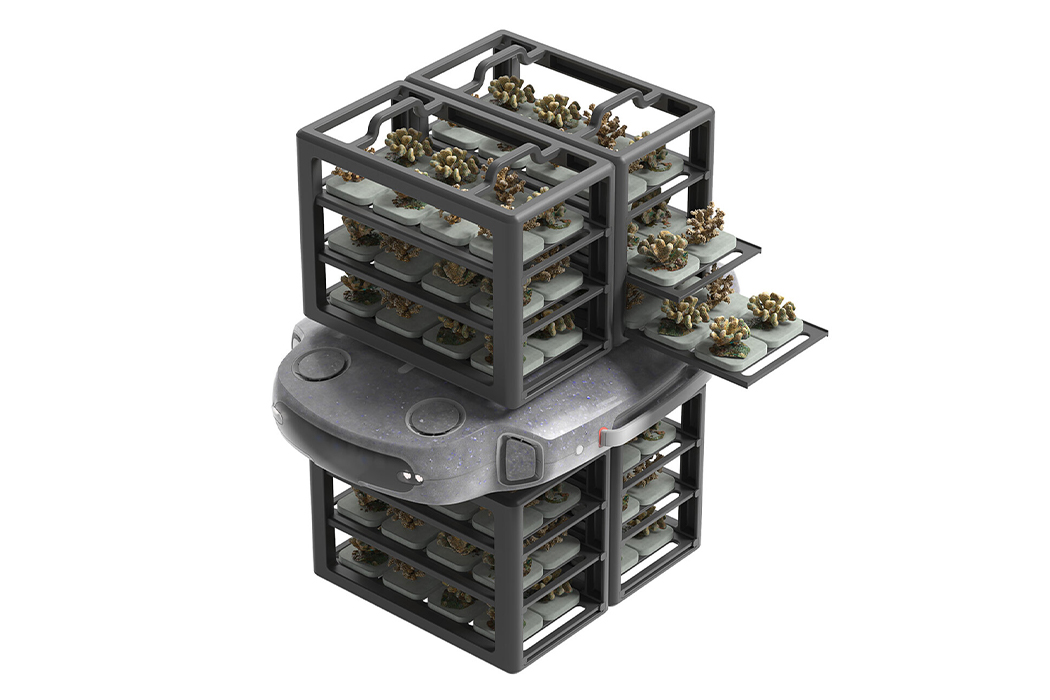

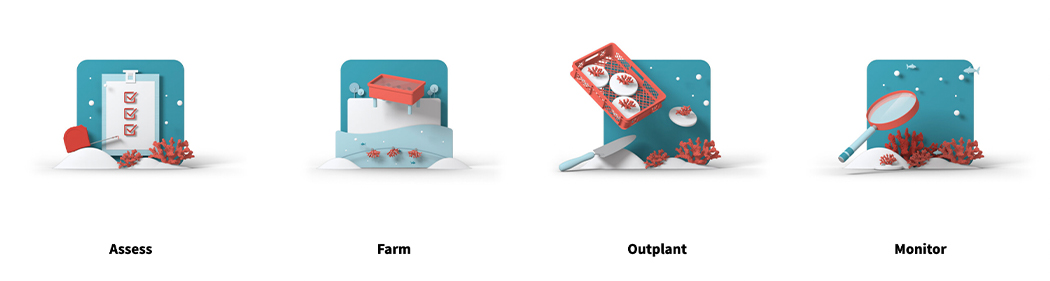

Coral reefs help us breathe, protect us from storms, provide us with food and support the economy of coastal communities – and that is why we need to save them at all costs. Nemo consists of a digital platform, a specialized transport box, and a collaborative drone that works within its four-stage service program to help municipalities. The digital platform helps scientists to research and monitor coral reefs more accurately and at the same time, it spreads global awareness about coral reefs to citizens. The platform keeps a record of all the data gathered from monitoring the reefs. The specialized transport box protects corals during their relocation from the nursery site to the outplant site by regulating the temperature of the saltwater and pH value to give the young corals the best chance for survival during their journey. Meanwhile, the collaborative drone helps scientists monitor by 3D scanning and mapping the coral reefs. This information is uploaded to a digital platform for the benefit of coral restoration agencies. The main parts of Nemo are made from recycled plastic to reduce its environmental impact.

“We used a human-centered design approach to help solve an environment-centered design problem. We combined the best of both processes and implemented our findings from both approaches. The process behind Nemo was also highly iterative and involved multiple experts from different sectors. During our research, we got feedback from experts on our concepts and ideas to verify them and to make sure we were heading in the right direction. We also hosted creative workshops to get input from more designers across disciplines to make our product better which included digital prototyping and iterative sketching exercises,” said the team while describing their process of creating Nemo. The system uses a combination of growing corals on pre-manufactured locally recycled structures using bioadhesives and drilling holes into the ocean floor to optimize the process for 2-3 people instead of the traditional 10-15 team which saves the restoration agencies’ resources.

Nemo was created to rebuild and support healthy ecosystems which is crucial for a sustainable future, it was the answer to the question “How can the journey towards a more sustainable, efficient, and simple coral restoration process be designed?” While there are many coral restoration efforts and technology, none are as comprehensive as Nemo because it goes beyond just planting new corals and takes the entire lifecycle as well as education about the crisis into account. It allows coral restoration organizations to scale up their efforts and accelerate the positive impact. Nemo has been shortlisted for the James Dyson 2021 National Winner and has also been recognized at the Red Dot Concept Awards 2020, the Core77 Design for Social Impact Notable, and Core77 Transportation Notable.

Designer: Elias Thaddäus Pfuner and Mario Kapsalis