Martina Mancini’s Ocean washing system is as sustainable as it is ergonomic, with special filters that recycle out microplastics and hidden adaptive features for intuitive and accessible operation.

Each time we wash a load of laundry, microfibers detach from our favorite polyester and acrylic clothes and end up in wastewater. Contributing close to 35% of the microplastics found in our oceans, washing machines are due for a sustainability cleanup. Designer Martina Mancini was recently recognized by The James Dyson Award for her work in developing an ergonomic washing machine called Ocean that filters out microplastics and recirculates the water used between cycles.

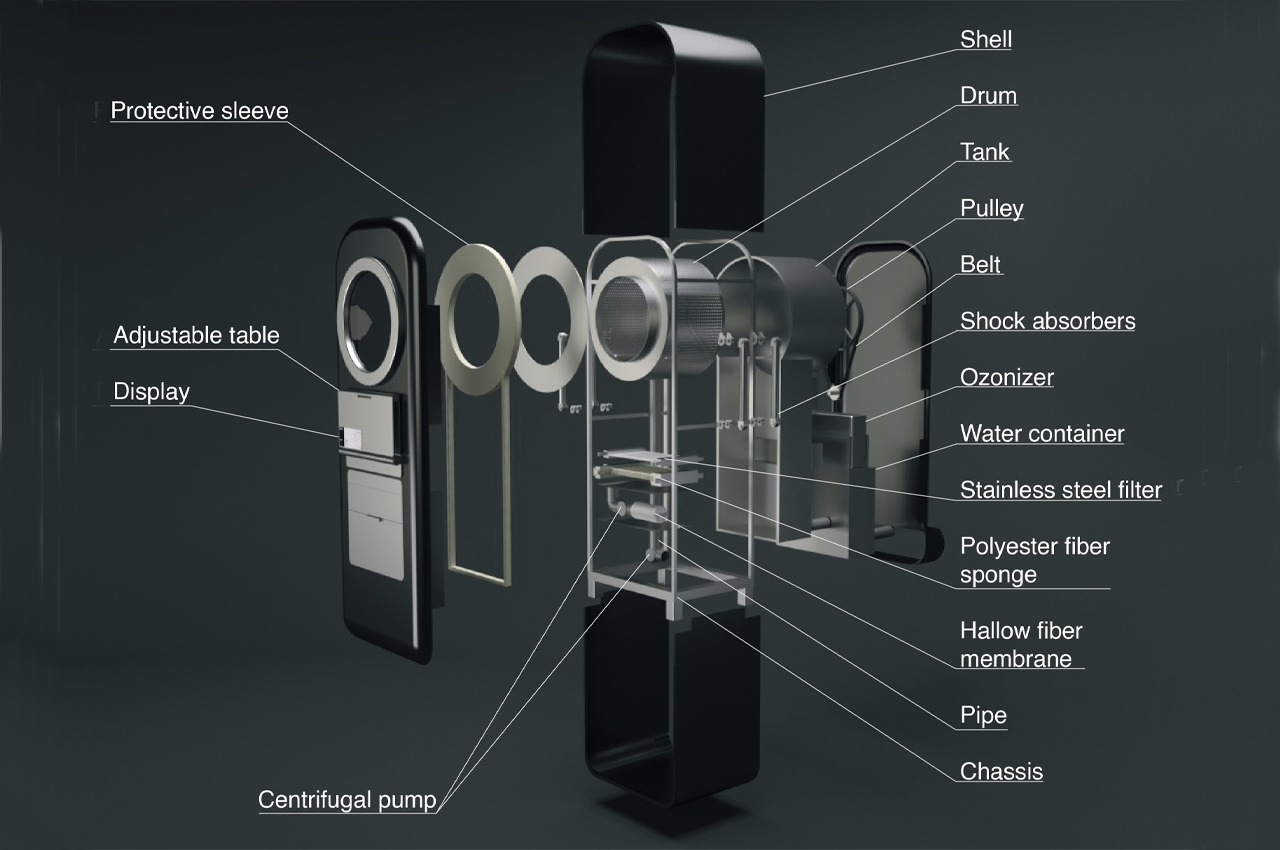

With Ocean, Mancini set out to develop a washing machine that’s friendly to the environment and ergonomic for most users. The Ocean is designed like preexisting washing machines, equipped with a basket, drum, and display control panel, to ensure familiarity during use. Once the clothes are placed inside Ocean’s drum and basket, users can start their wash cycle by selecting one on the machine’s front display panel. From there, water flows into the drum from a centrifugal pump that’s connected to a purification filter to prepare the water for recirculation once the cycle is complete.

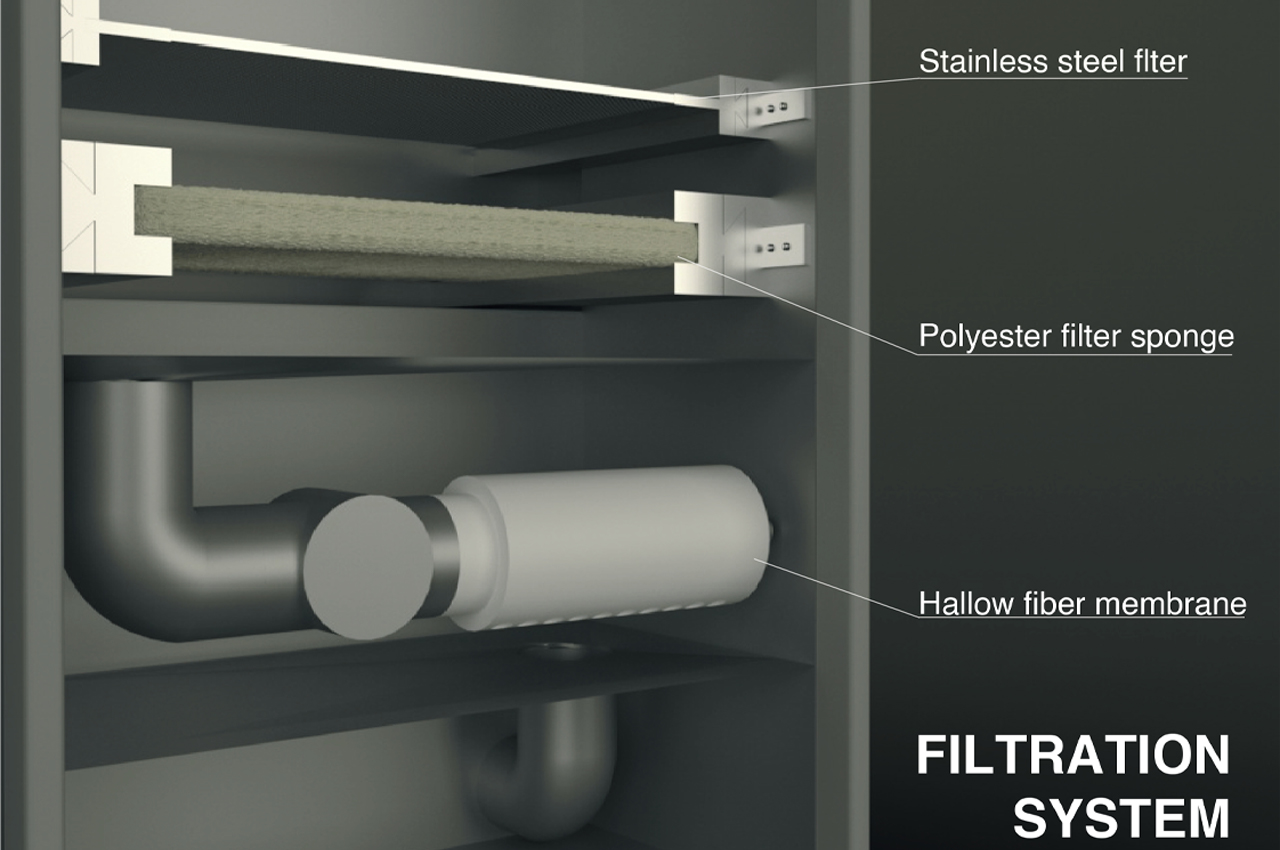

The post-cycle water purification process first passes through a stainless steel sieve grid and then a polyester filter sponge to remove larger microplastics. Following that, the water surges into a pipe that’s connected to the machine’s centrifugal pump, which propels the water against a hollow fiber membrane through a tangential filtration process. Once the filtration process makes its rounds, the water is purified by an Ozonator before recirculating for future use. Ensuring that Ocean is as ergonomic as it is sustainable, Mancini designed the washing machine so that users can remove the machine’s filters on their own before obtaining a new one from an offsite factory. There, company workers will remove and recycle the microplastics to give them a new life.

Given that the hardware required to construct Ocean would be bulky, Mancini knew the washing machine would reach a higher height than those already on the market. Working with a bigger machine allowed Mancini to incorporate more ergonomic features, including an adjustable table located beneath the drum, where users can prepare their laundry before and following washing cycles.

Designer: Martina Mancini