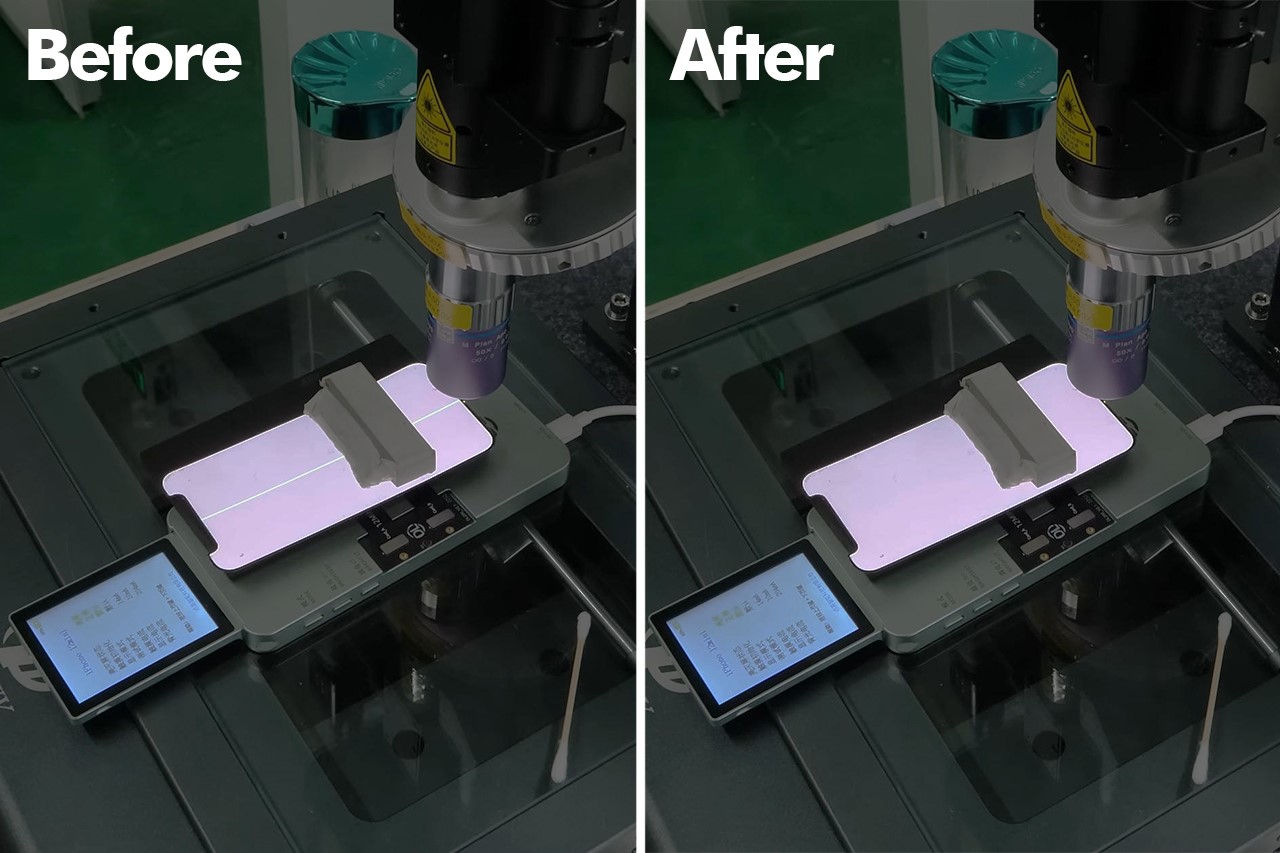

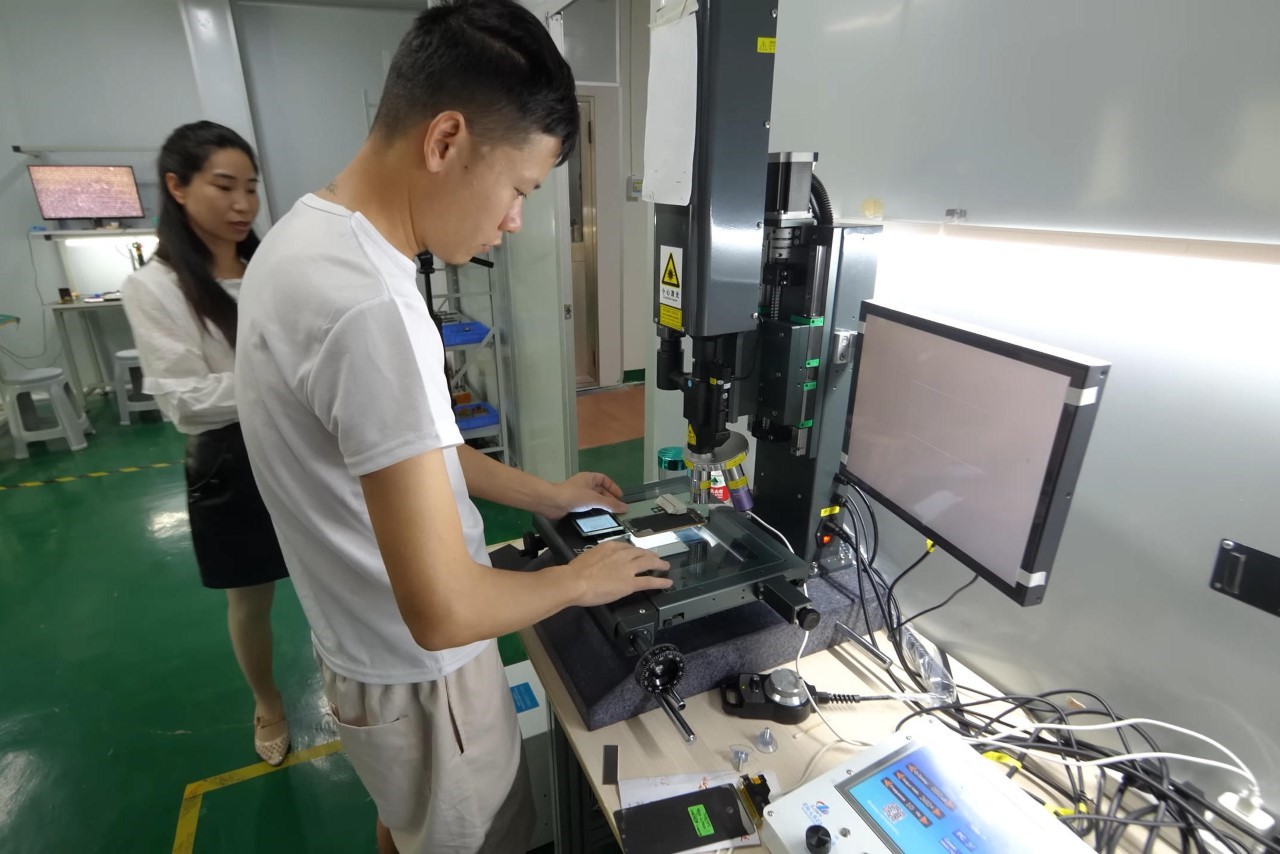

Uncovered by YouTuber Spare Parts, this novel machine can fix OLED displays that have weird lines running across them. The machine (shown in China where Spare Parts spends the bulk of his time making videos) uses a laser to fix the damaged or dead pixels, reviving phone displays… and it’s so advanced it can fix the displays while they’re still on! In theory, this solves pretty much the only problem there is to solve with damaged displays. Barring probably torn or shattered OLED screens, the machine fixes any problems with the flex cable or with dead pixels creating those annoying vertical lines across your screen.

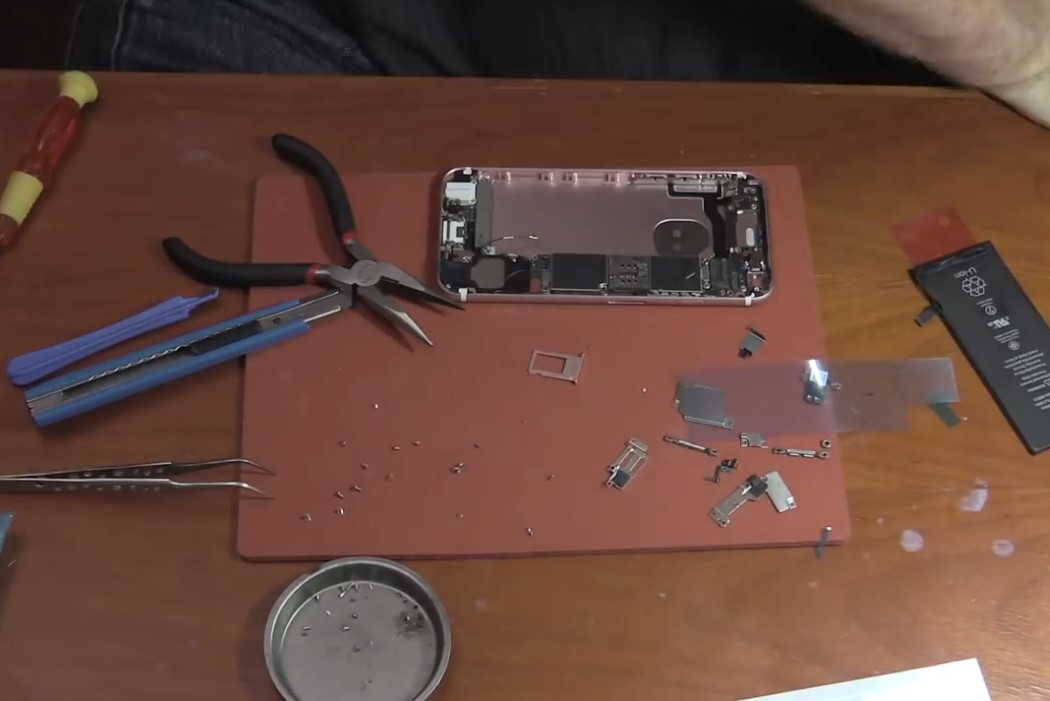

The technology is incredibly fascinating, but even more so when described by Scotty Allen (who goes by his YouTube moniker Spare Parts). Allen’s worked on crazy projects in the past including building his own iPhone from scratch, and actually even attempting to design a flexible iPhone, so this unique machine is right up his alley. The video does a pretty rudimentary (yet sufficiently detailed) job of explaining how the technology works.

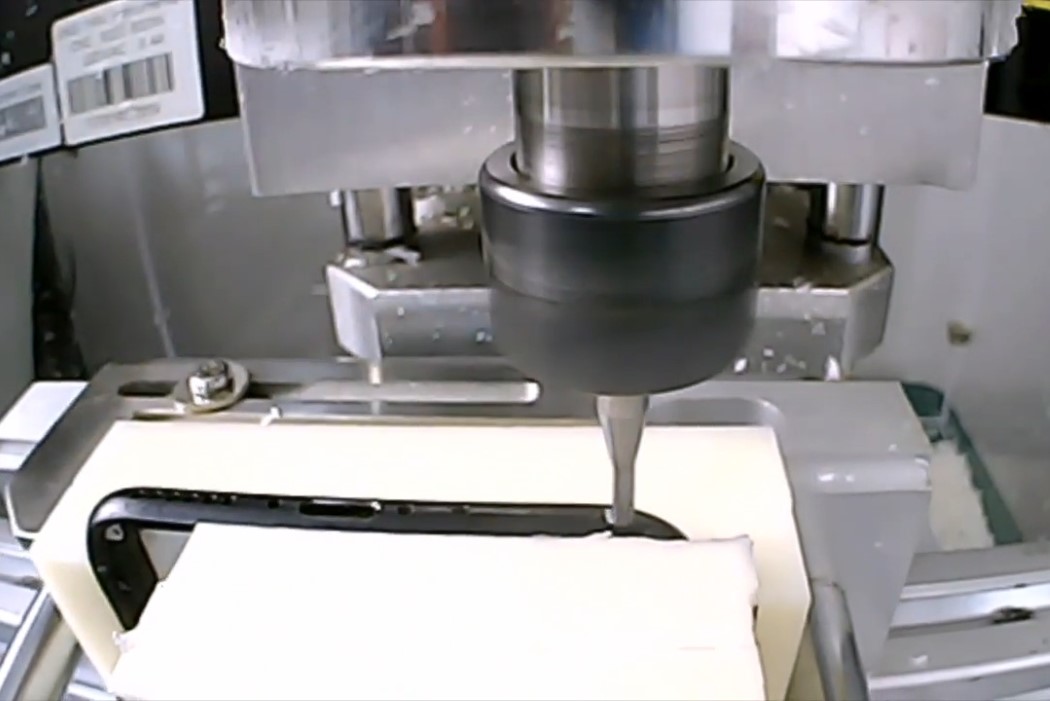

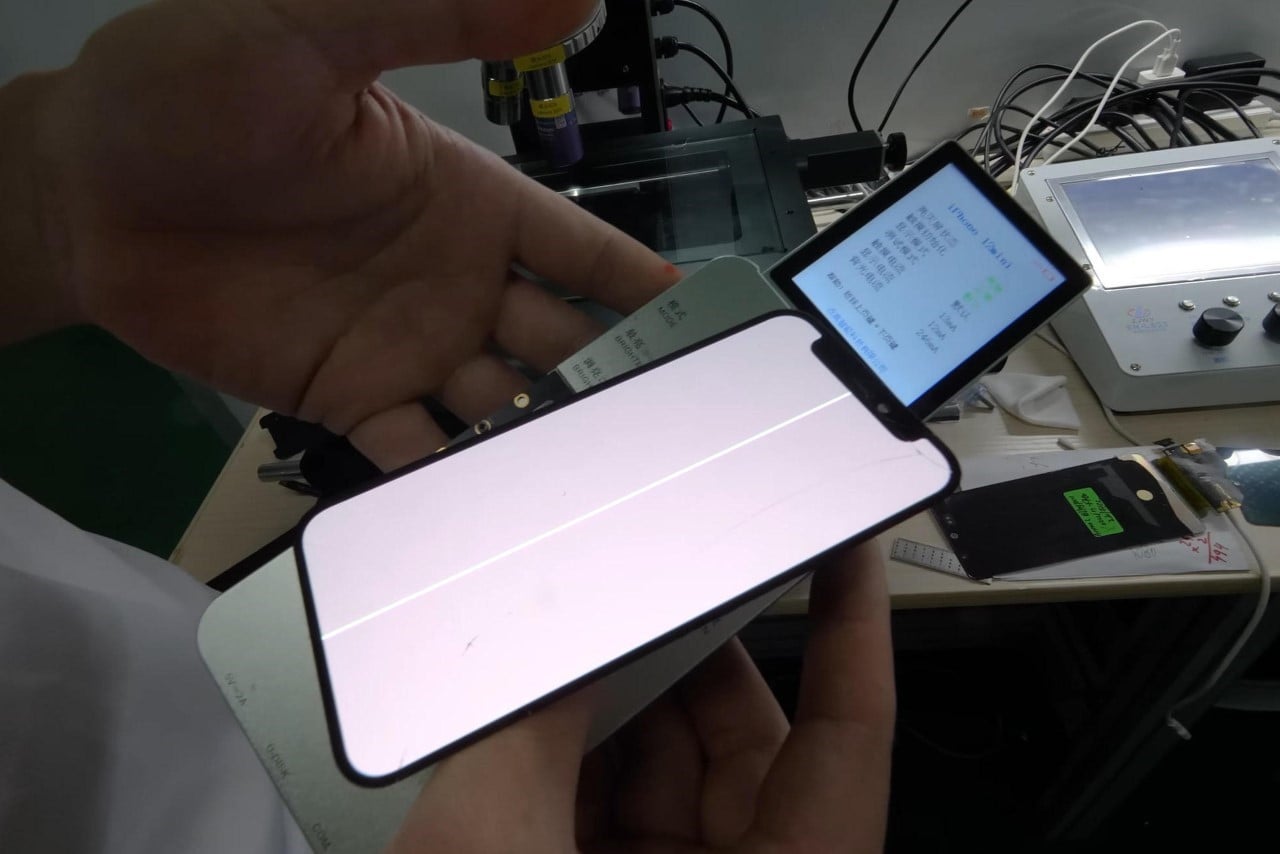

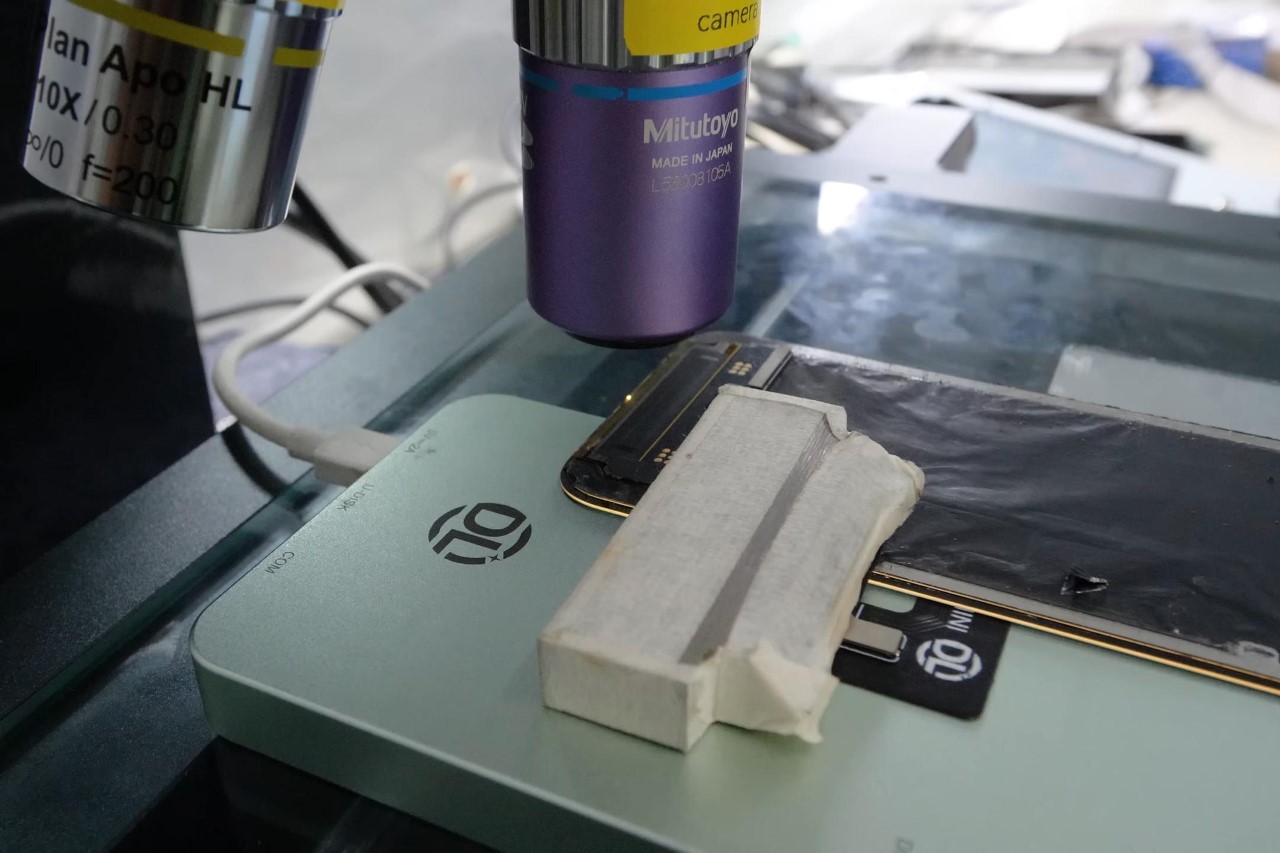

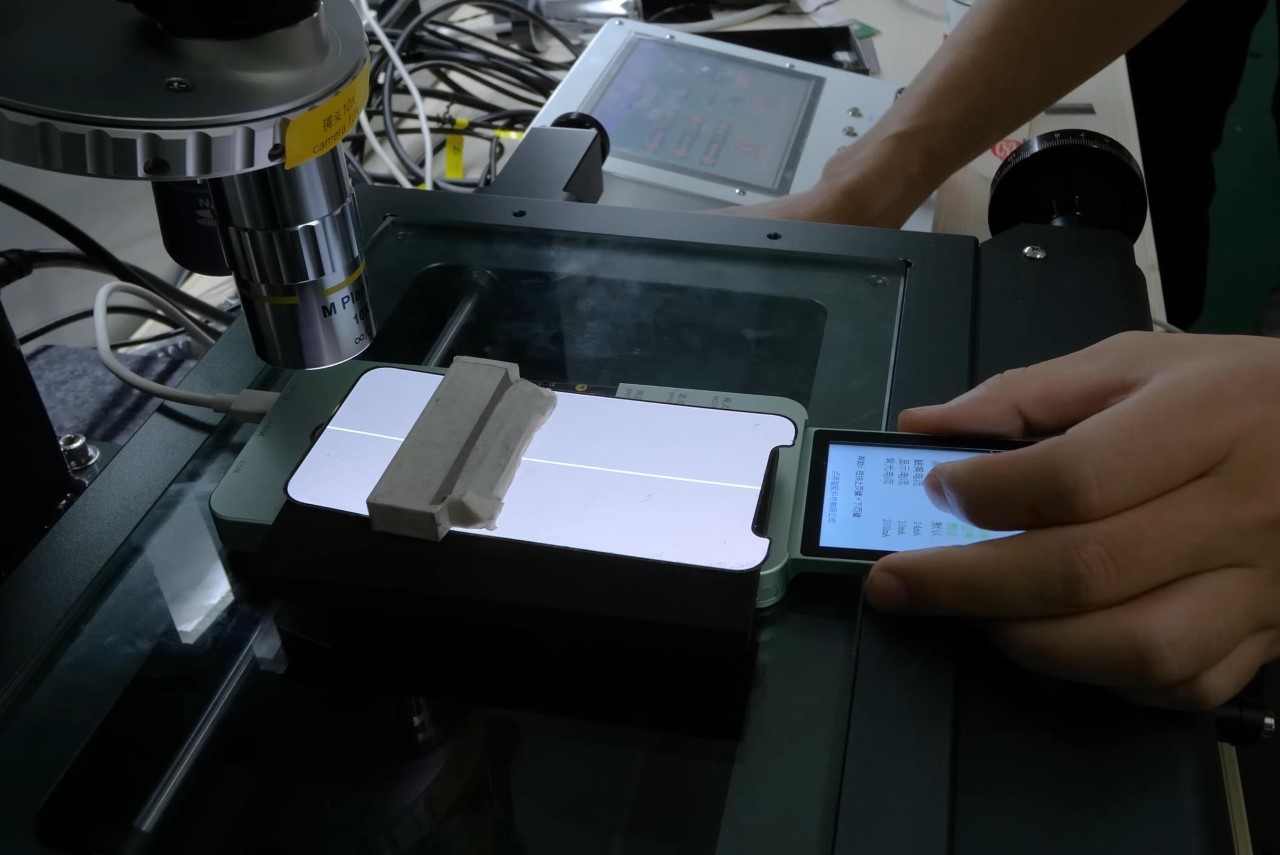

OLEDs (or even LCD displays) are manufactured in large sheets and subsequently cut out into the shapes needed for companies building televisions, smartphones, tablets, smartwatches, etc. Lasers are used in the process to help manufacture these OLEDs, and this machine uses the exact same type of laser to fix the OLED when it’s damaged. The process is laborious because it involves manually looking for the dead pixel that’s causing the problem and zapping it back to life. With millions of pixels in even a smartphone display, that’s quite a tough task… and for now, it has to be done by a human who painstakingly looks through the pixels row by row to identify any dead pixels. Once done, the laser helps rebuild that pixel, fixing the screen without really needing to change any parts!

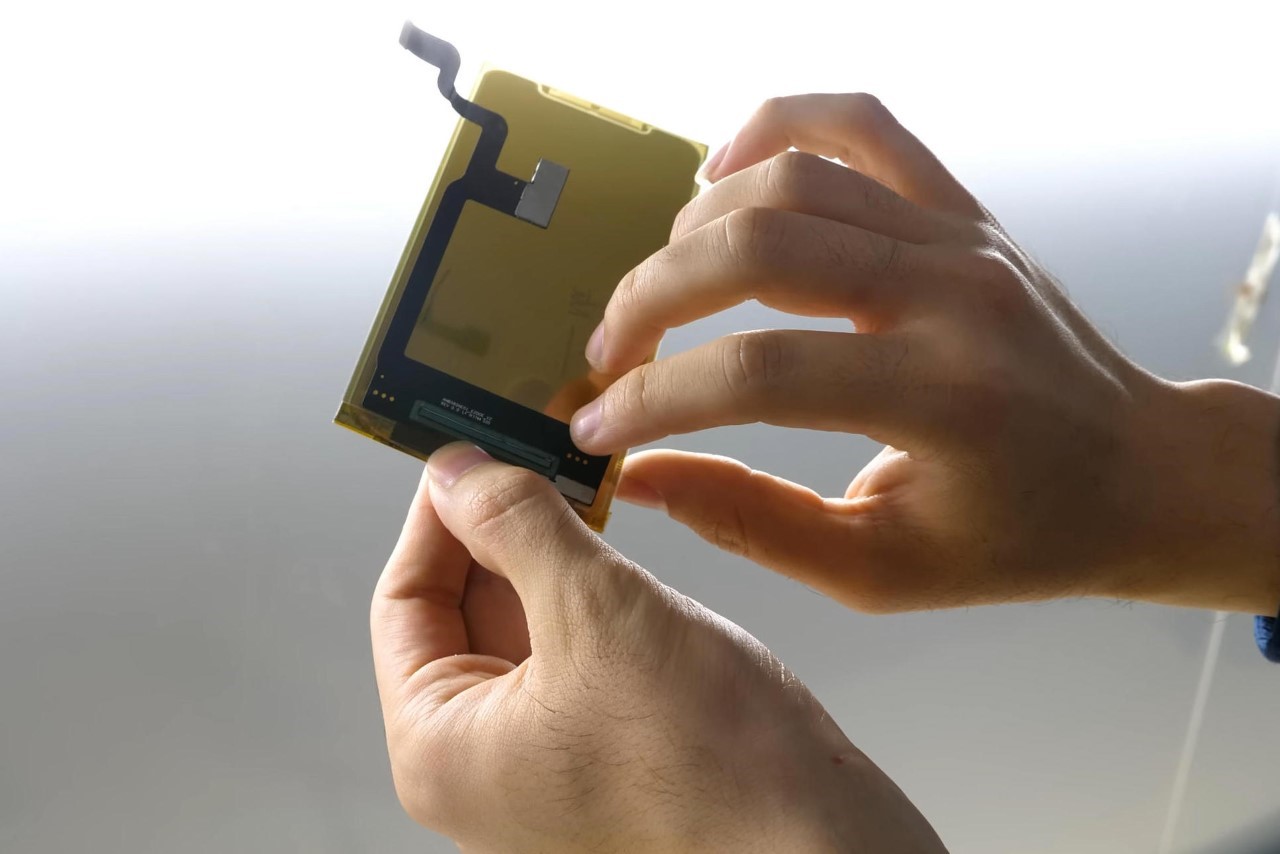

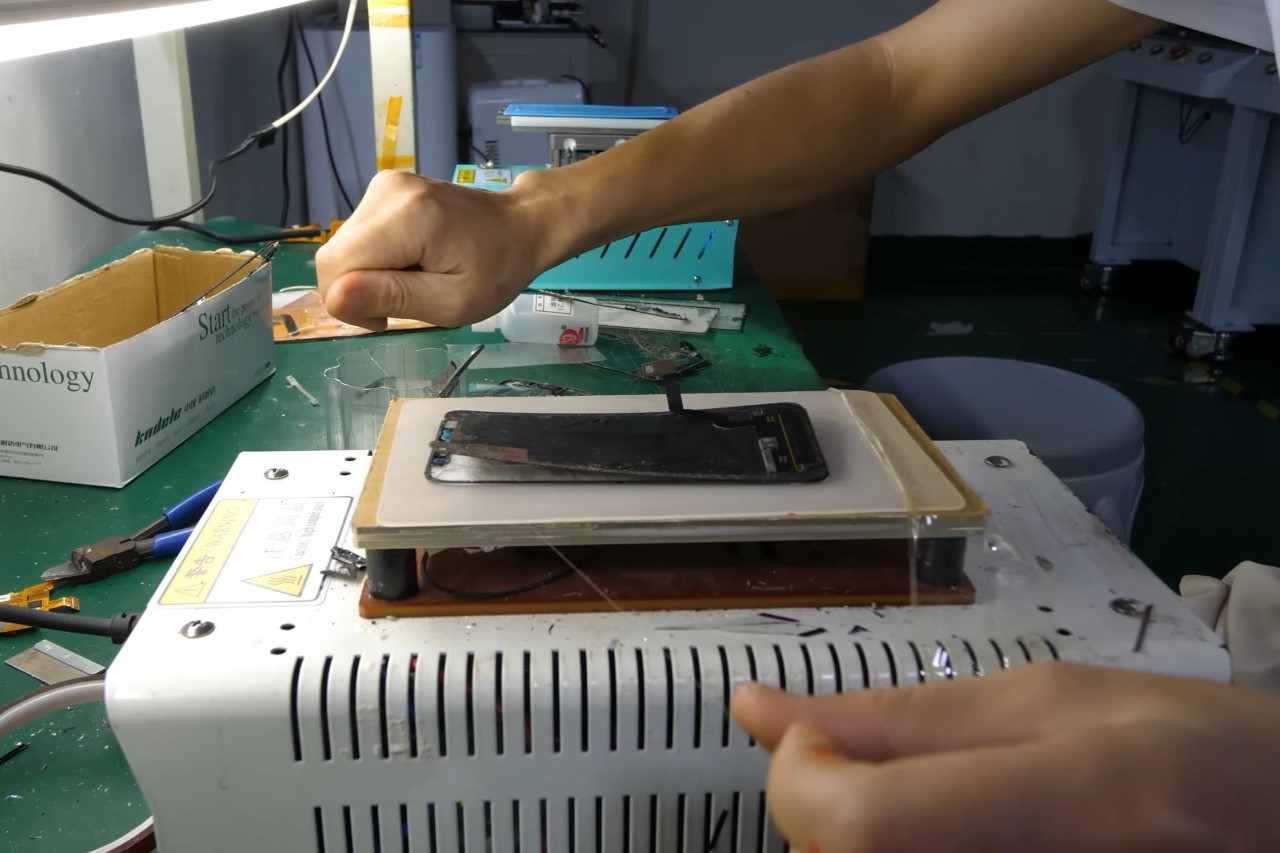

The process is somewhat invasive, and requires dislodging the screen from the smartphone itself. The machine works with both flexible as well as hard OLEDs, and it isn’t limited to just iPhones. Technically any phone with an OLED or LCD screen should do. The screen does need to be removed from the phone, along with manually separating the OLED unit from the glass on front using a metal wire to cut through the glue. If the flex cable on the display is damaged, there’s a separate machine for that. However, if there’s just a pixel or a cluster of pixels causing problems, the laser helps fix that issue. The machine can do this task even with the display running, and the video shows in real-time how the annoying line disappears as soon as that problematic pixel is fixed. You don’t need to replace any expensive parts, helping both consumers as well as companies reduce repair costs and e-waste generation in the process!

The post Insane Laser Device Fixes Broken iPhone Displays Without Even Switching Them Off first appeared on Yanko Design.