People have seemingly taken a greater liking for personal mobility these days, ranging from hulking motorcycles to sophisticated e-bikes to traditional yet versatile bicycles. Regardless of the type of two-wheeled transportation, they’re all bound by one common trait and the same weakness. They naturally rely on their wheels to get you places, and the ride is immediately over once you get a flat. You are unlikely to have a spare with you, and the nearest gas station might still be blocks away. You could bring an air pump with you all the time, but their convenience comes at the cost of portability and performance. Not unless you get this unbelievably small air pump that easily slips into your pocket while still delivering the air pressure your tires need, multiple times over.

Designer: MINI PUMP

Long gone are the days when bicycle tire pumps were tantamount to getting some exercise, coming in long metal cylinders that are just begging to be left behind at home. There are smaller versions these days, of course, that utilized motors to give your arms a break, but they’re still not that convenient to stow in small bags. Tiny electric pumps have started popping up left and right, but they sacrifice actual usefulness just to boast about their size.

The MINI PUMP seeks to address all those problems with a small package that belies its functionality. For an accurate size comparison, the MINI PUMP is just as small as the AirPods Pro case, the gold standard for pocketable accessories. At only 115g in weight, there’s no longer any reason for you to leave the house unprepared for any eventuality, especially when you can just slip this deceptively simple product into your pocket or your EDC kit. You might even want to leave one near your bike all the time, ensuring you’ll never panic ever again when you notice your flat tire.

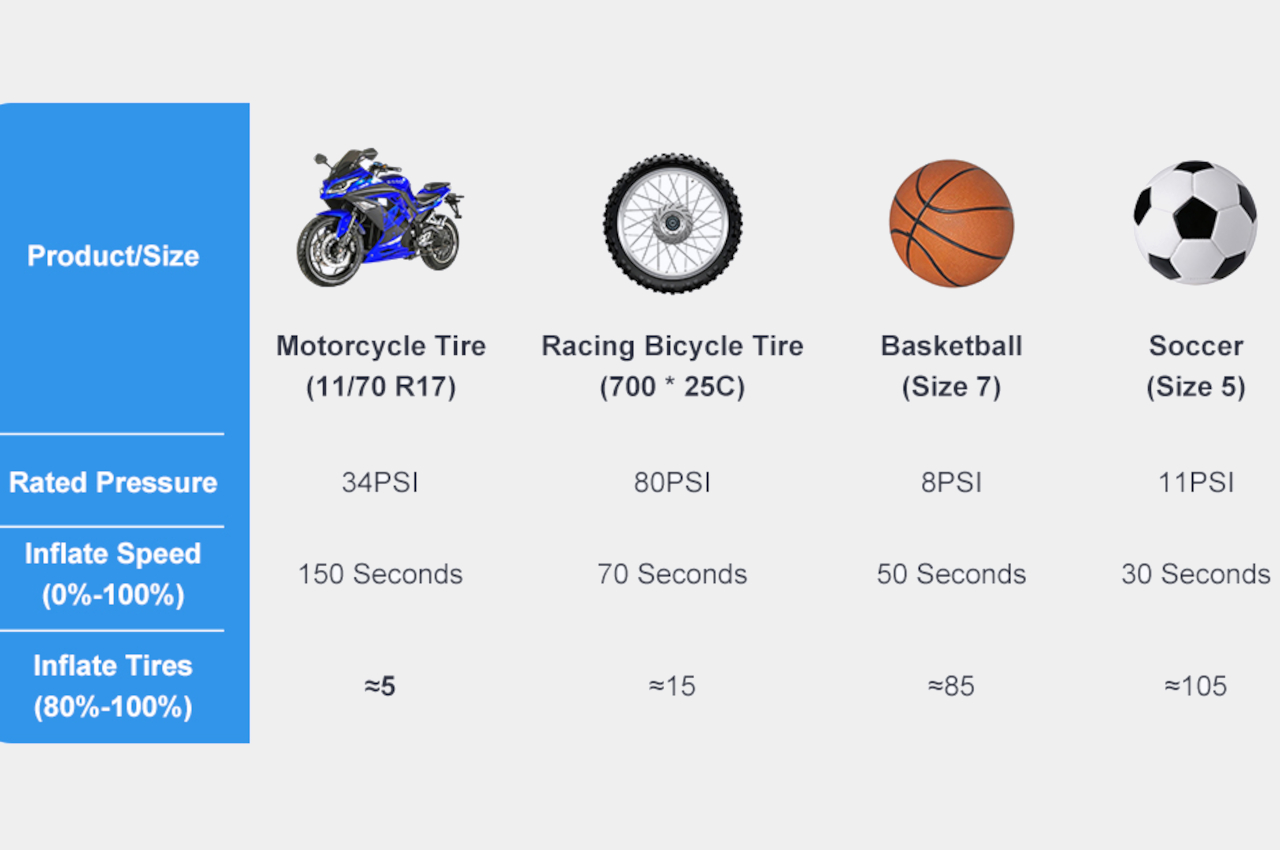

Despite its unassuming size, the MINI PUMP is well equipped to inflate a wide variety of objects, not just tires. It can generate as much as 100 PSI of pressure, which means it can even pump motorcycle tires in a pinch. For an average 700x25C road bike tire, the MINI PUMP can put out 0 to 80 PSI in just 70 seconds so you’ll be back on the road in no time. With a 350mAh battery, you can inflate three road bike tires on a single charge. A unique design lets you swap out nozzles to be compatible with a variety of tire valves, including Schrader, Presta, and Dunlop.

The MINI PUMP can do more than just inflate tires though. It can also pump flattened balls or even blow away dust from camera lenses or hard-to-reach cracks. Its built-in battery charges from zero to full in just 25 minutes, so you won’t be wasting time waiting for your new traveling sidekick to be ready. Save yourself from the stress of having a flat tire or ball at the most inconvenient time and place with this small and lightweight MINI PUMP that packs a large punch, only $70 on Kickstarter.

The post This incredibly lightweight tire inflator is just as small as an AirPods Pro case first appeared on Yanko Design.

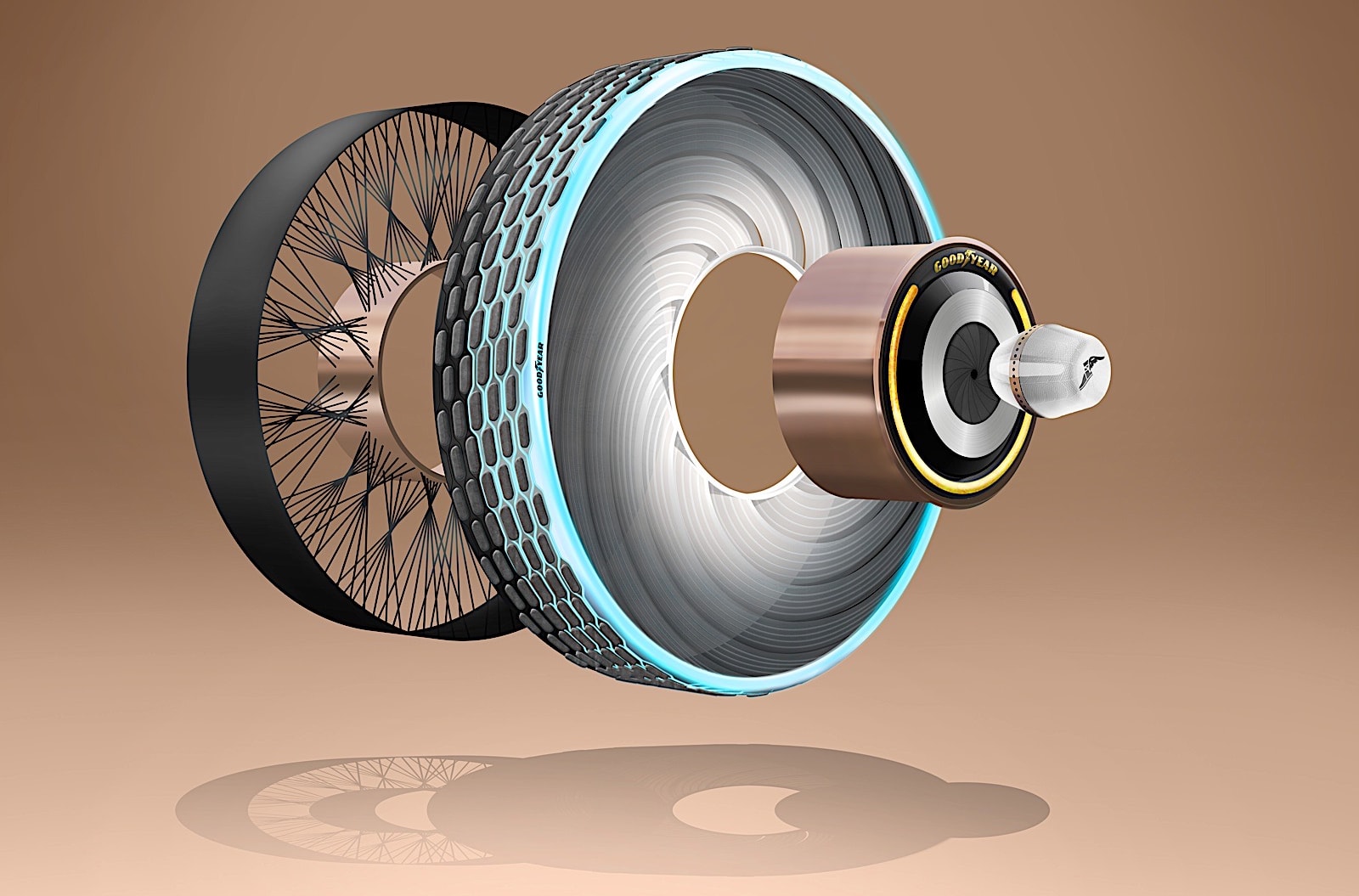

The thunk-whumma-whumpa-whuppa sound of a tire puncturing and losing pressure at freeway speeds is unmistakable. However, if Goodyear has its way humanity might not have to endure the filthy, sweaty, swear-inducing process of swapping rubber on the s...

The thunk-whumma-whumpa-whuppa sound of a tire puncturing and losing pressure at freeway speeds is unmistakable. However, if Goodyear has its way humanity might not have to endure the filthy, sweaty, swear-inducing process of swapping rubber on the s...

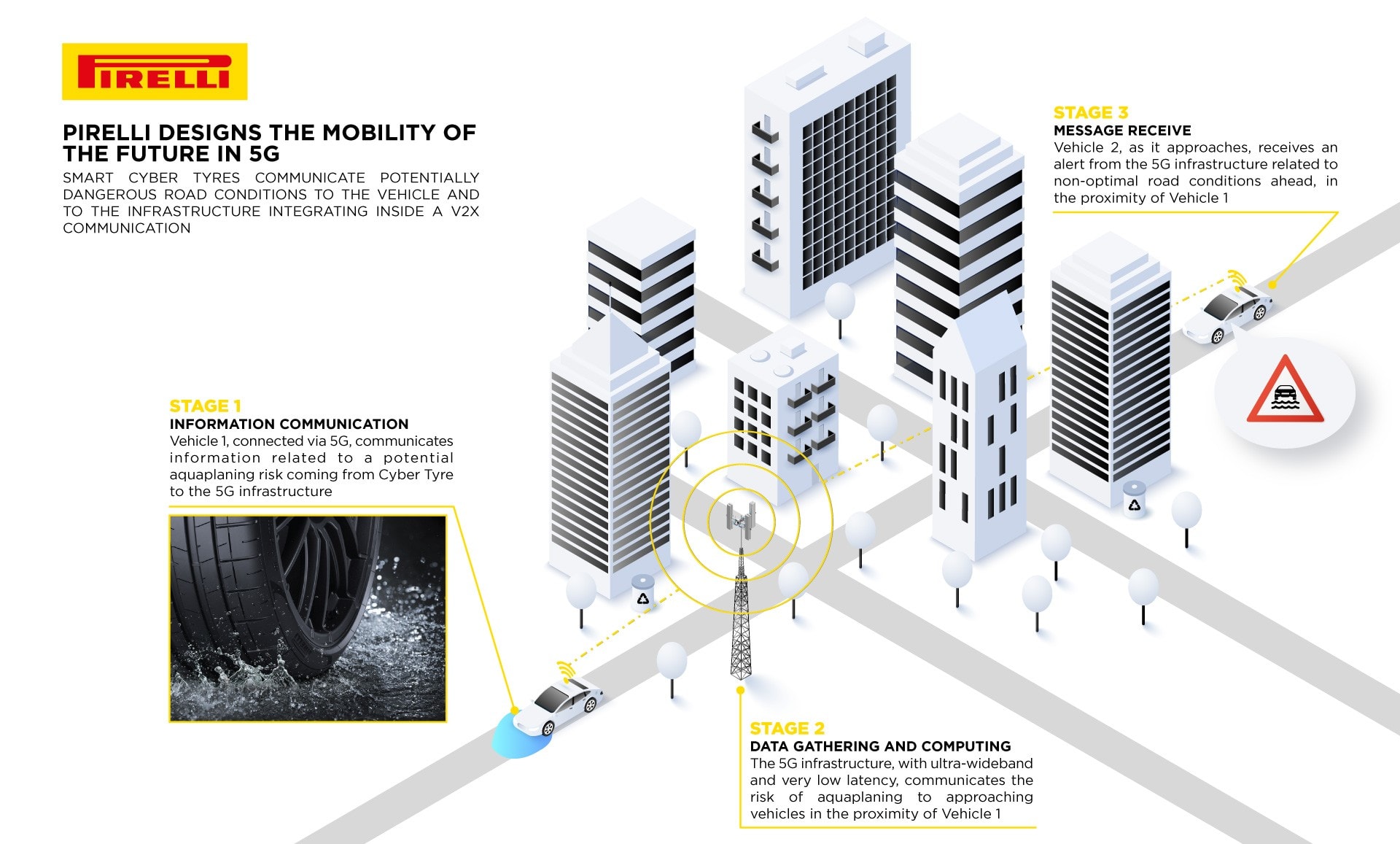

The future of cars is connectivity, with vehicles able to communicate with infrastructure like traffic lights and to share information about traffic conditions with other drivers and local authorities. Tire manufacturer Pirelli is bringing its own ap...

The future of cars is connectivity, with vehicles able to communicate with infrastructure like traffic lights and to share information about traffic conditions with other drivers and local authorities. Tire manufacturer Pirelli is bringing its own ap...

Speed kills.

That had to be on the minds of Bugatti and Michelin engineers (and driver Andy Wallace), when together they pushed a modified Chiron to 304.77 miles an hour. As you would expect, driving a production car that fast involves more than jus...

Speed kills.

That had to be on the minds of Bugatti and Michelin engineers (and driver Andy Wallace), when together they pushed a modified Chiron to 304.77 miles an hour. As you would expect, driving a production car that fast involves more than jus...

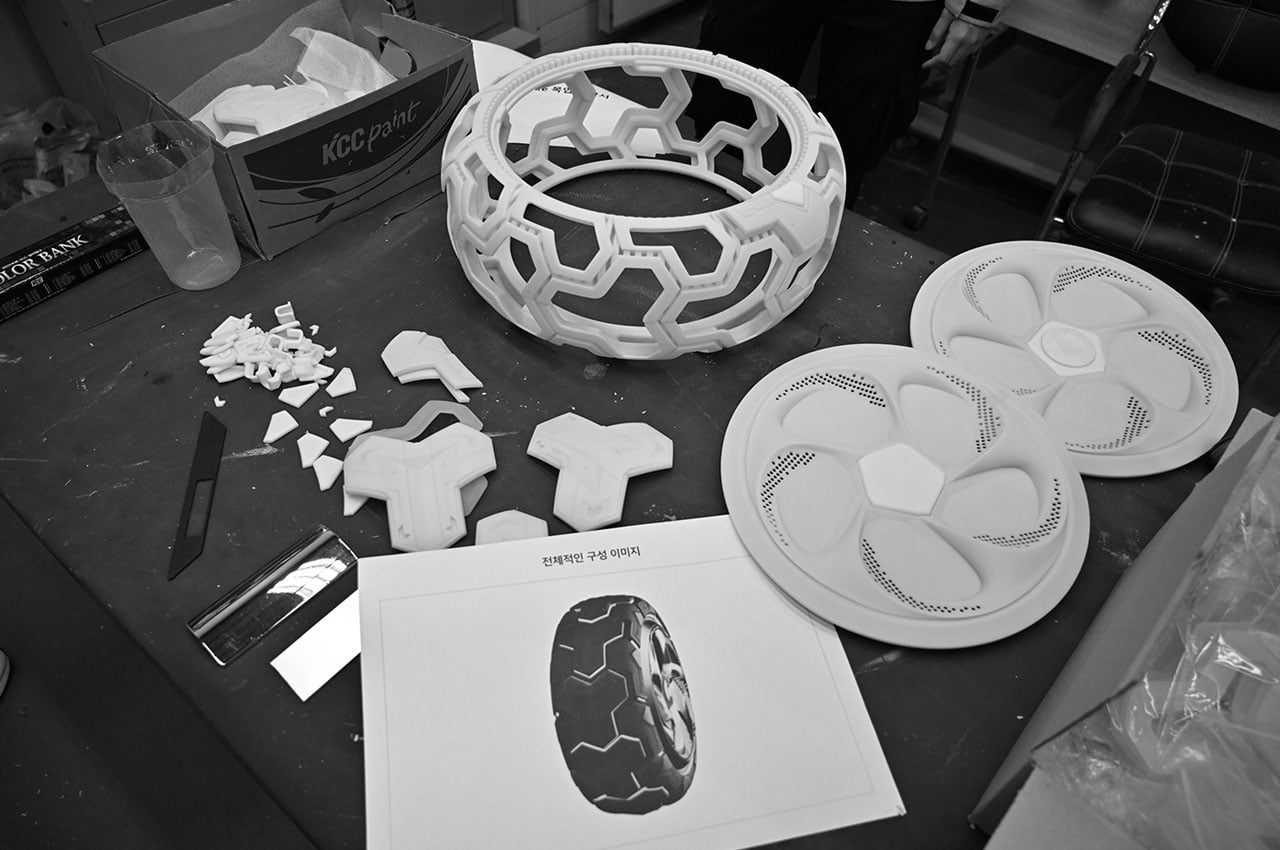

Airless tires for everyday cars might soon be far more practical. GM and Michelin have unveiled a prototype of Uptis (Unique Puncture-proof Tire System), a Michelin-made tire intended for passenger cars. It looks like Tweel and other air-free conce...

Airless tires for everyday cars might soon be far more practical. GM and Michelin have unveiled a prototype of Uptis (Unique Puncture-proof Tire System), a Michelin-made tire intended for passenger cars. It looks like Tweel and other air-free conce...