It’s no secret that I’m still afraid that in the far future, robots will rise up against humans when they gain their own intelligence and realize that we’ve been treating them unfairly all these years. That probably comes from watching too much science fiction movies and series where robot overlords rule over the earth. But for now, we’re seeing amazing (sometimes scary) advancements when it comes to robotics and how they will eventually be able to work alongside humans.

Designer: Brett Adcock

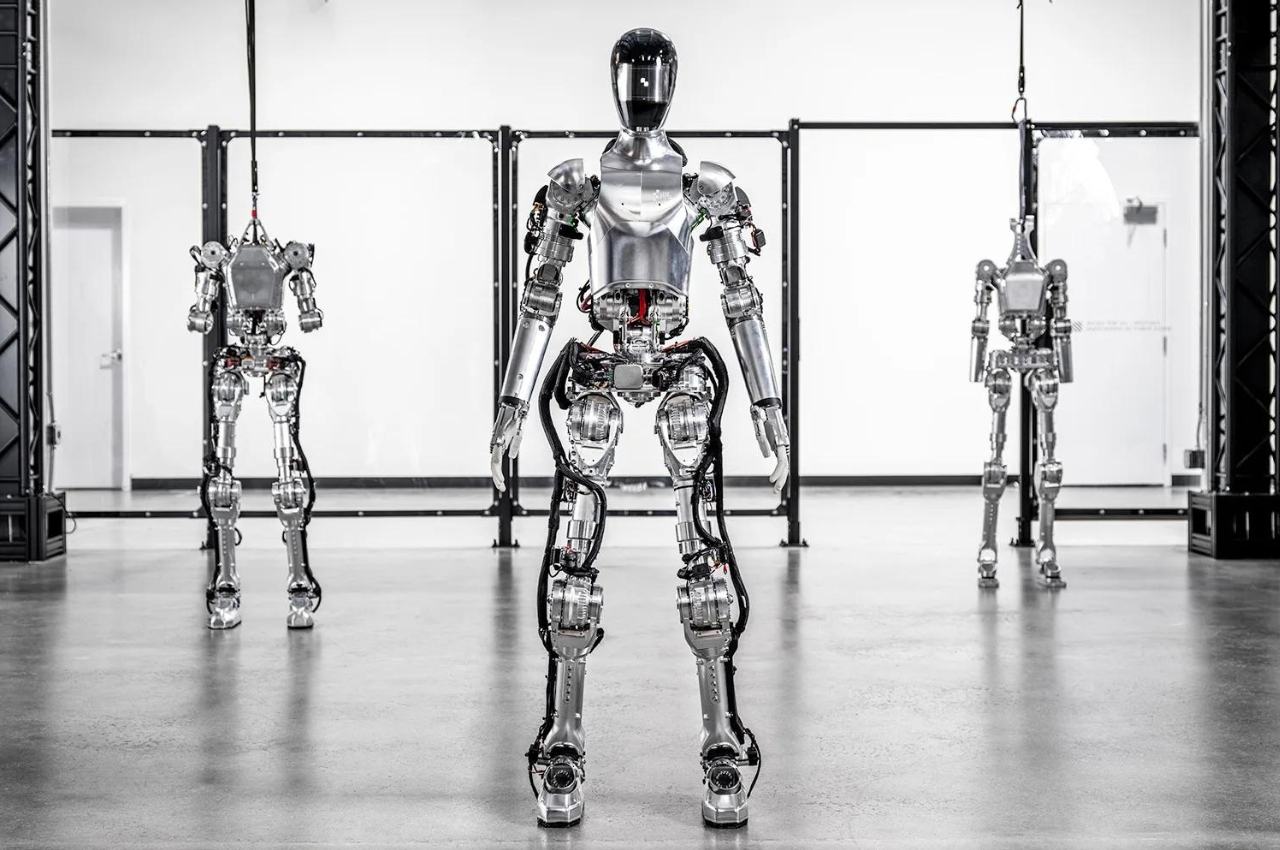

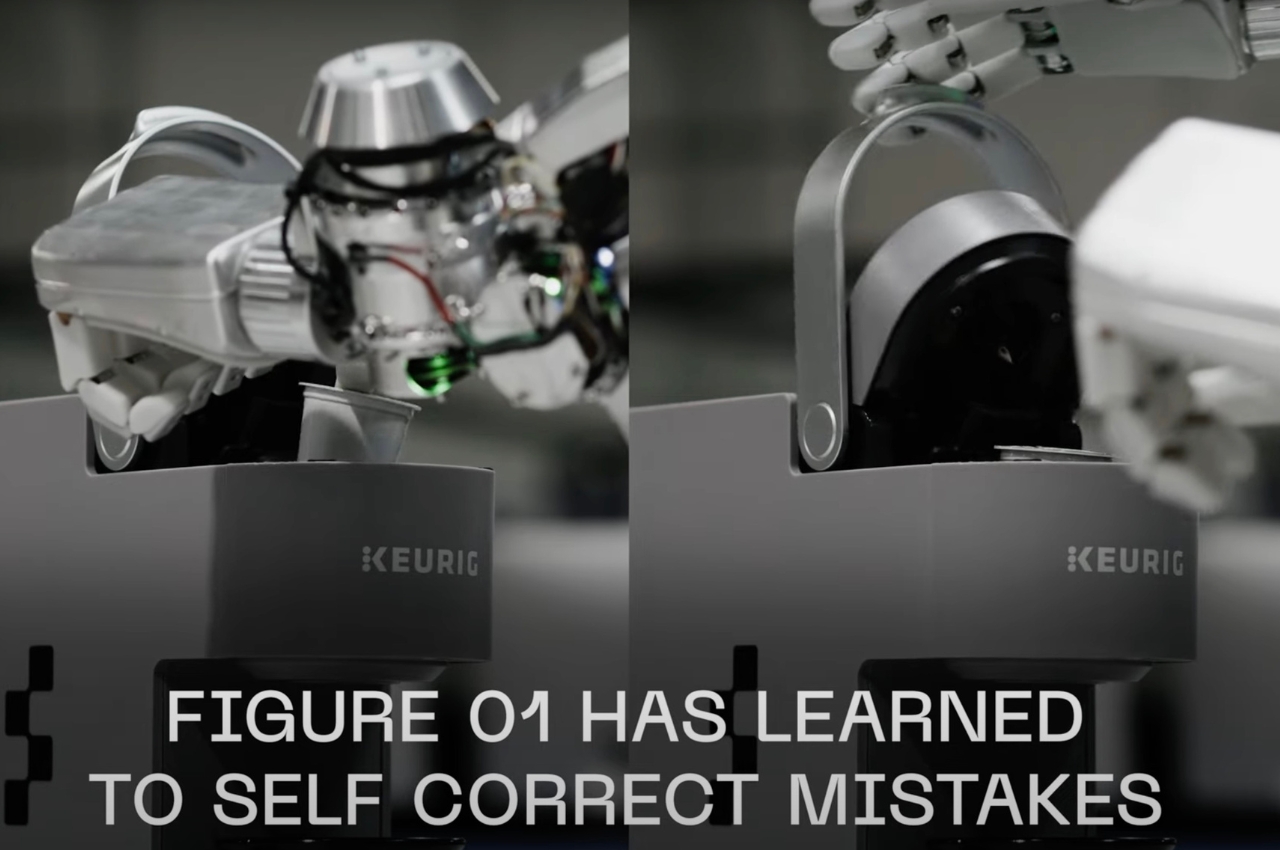

The Figure-01 Humanoid Robot has been designed to help you handle some of the simple daily chores, powered by artificial intelligence. Aside from being able to do automated tasks, it is trained to be able to think, learn, and interact within human environments. It is also able to improve on its capabilities by learning from the previous tasks it is able to perform.

The humanoid robot uses some pretty powerful graphic processing units (GPU) to drive the AI learning and system, letting it process some of the complex algorithms needed to train them. The idea is for these robots to eventually fill in the gap in the labor market when it comes to things like warehouses, transportation, and retail. Of course the aim is not to replace humans but to be able to work alongside people and work within an environment with both other robots and humans.

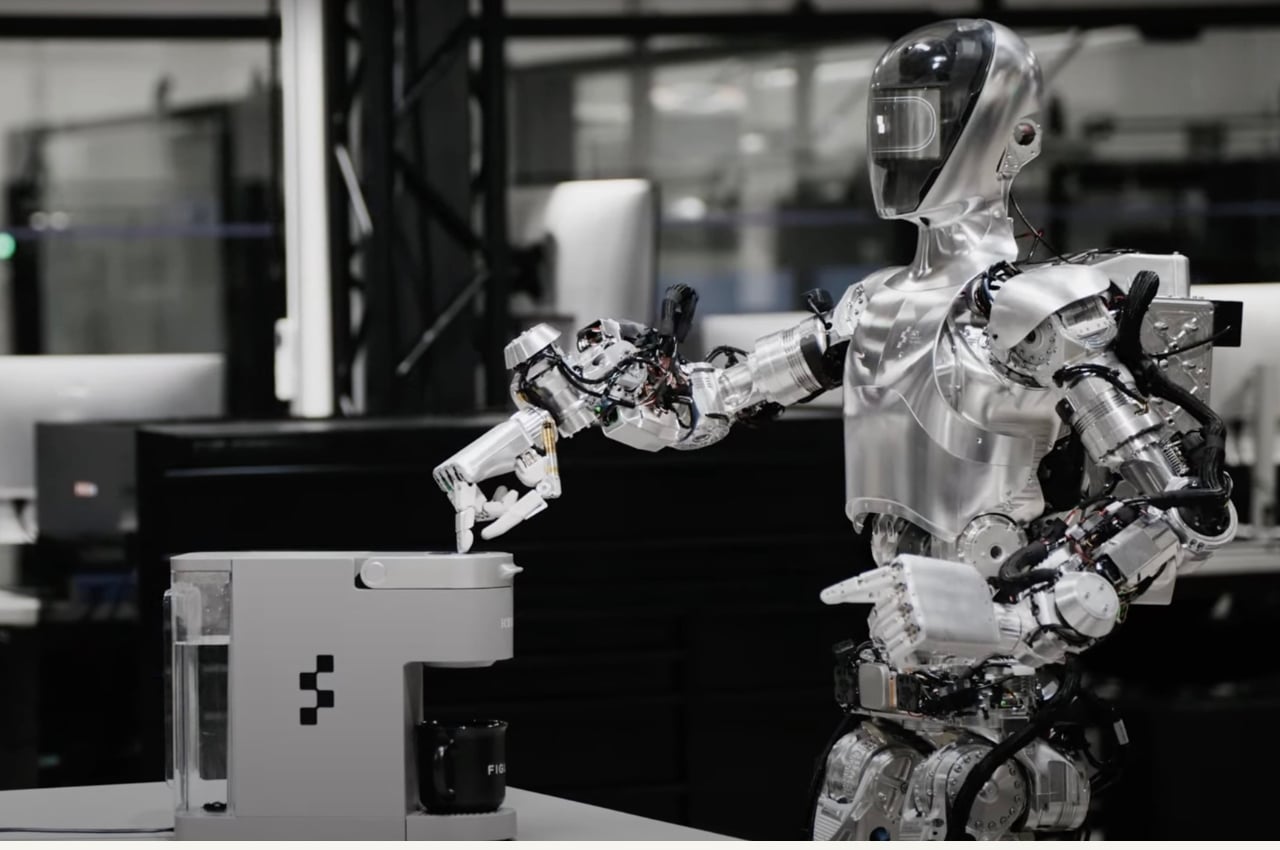

They were able to demonstrate the current capabilities of the Figure-01 Humanoid Robot by showing how it was able to make coffee after 10 hours of training using end-to-end neural networks. I wouldn’t mind having someone else get my coffee ready in the morning by the time I wake up although I’d probably have nightmares of this humanoid robot eventually taking over my life.

The post Humanoid robot can make you coffee and eventually more first appeared on Yanko Design.