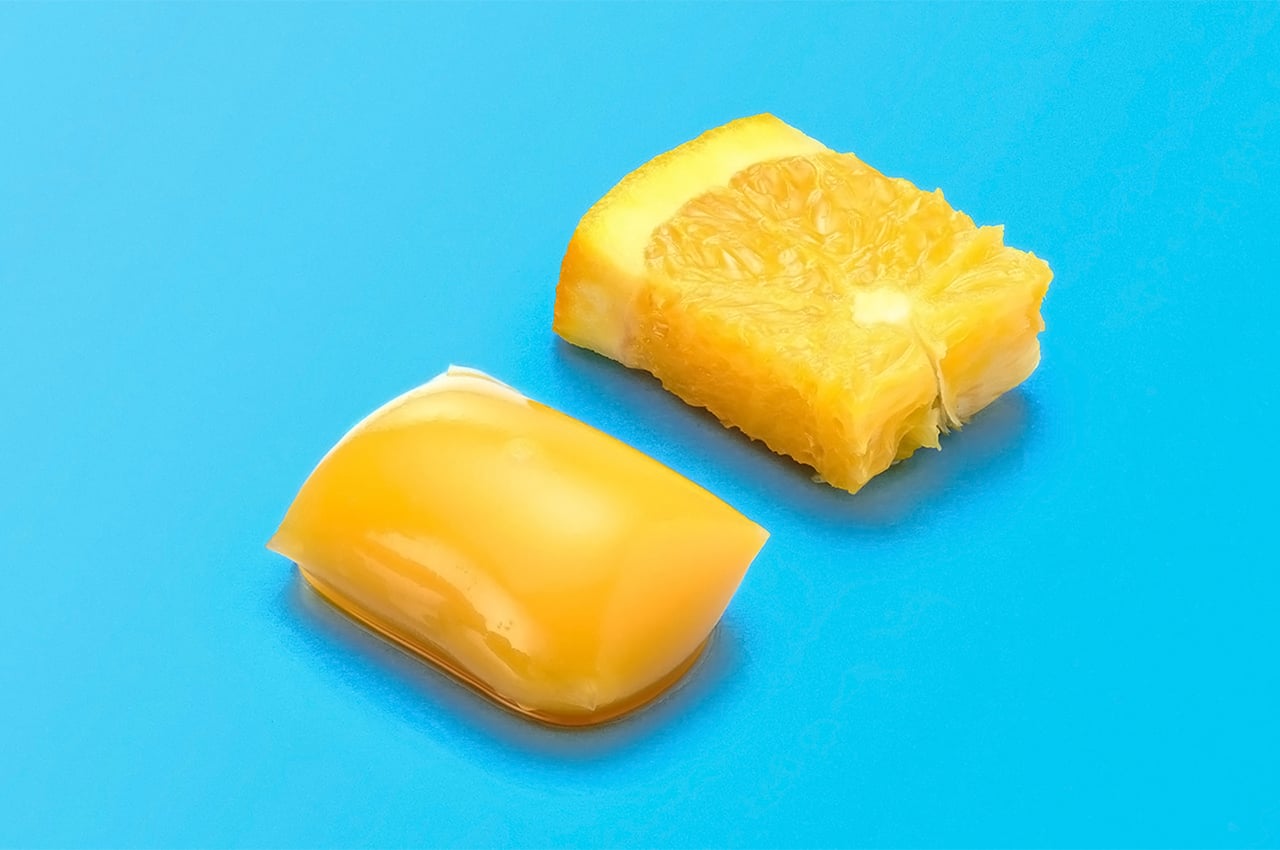

Over the past few years, we’ve grown more aware that plastic water bottles are among the biggest pollutants in the world. A lot of the more eco-conscious people have resorted to bringing their reusable water bottles and stopped consuming these plastic bottles. Still, plastics remain a big problem and these bottles in particular take 450 years to break down. There are a lot of studies and moves to combat this issue and now we are getting the “first biodegradable water bottle”.

Designer: Cove

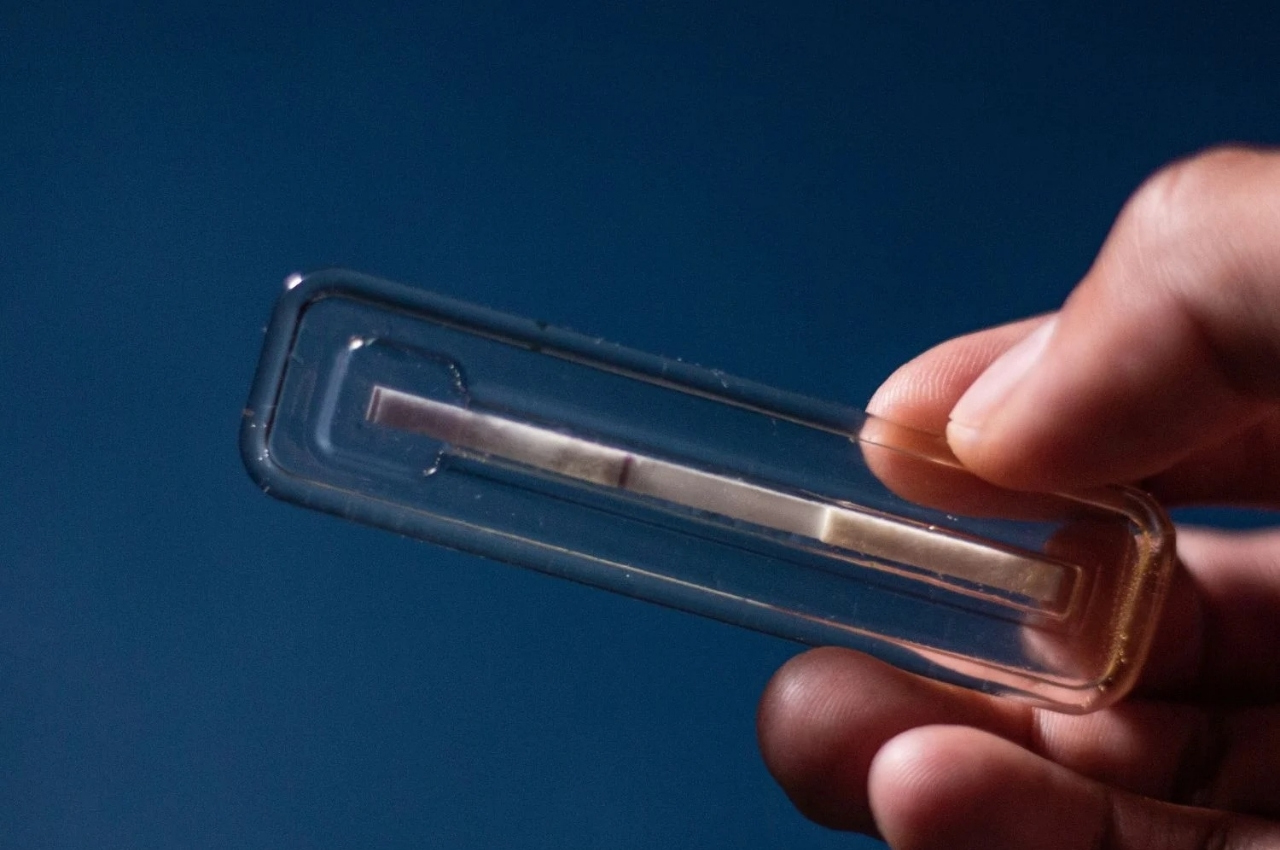

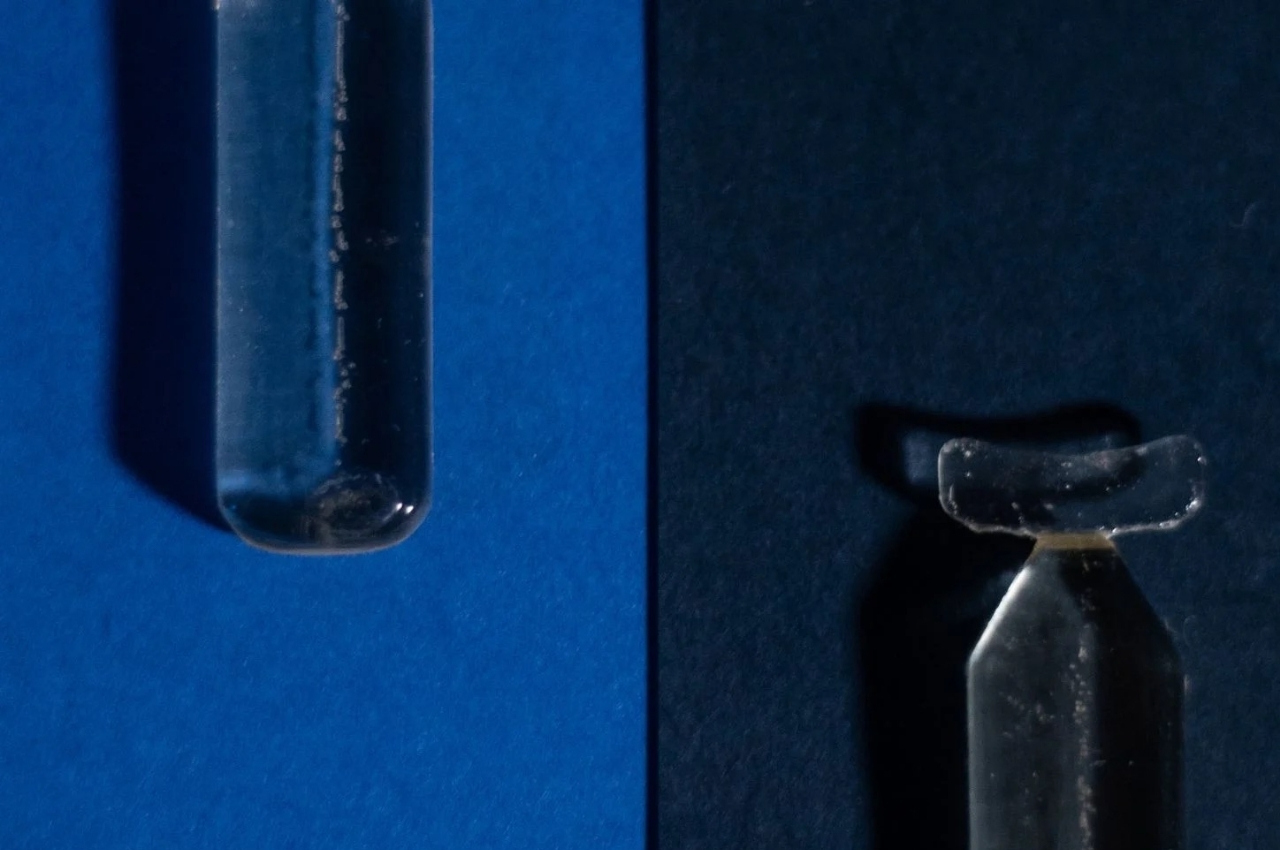

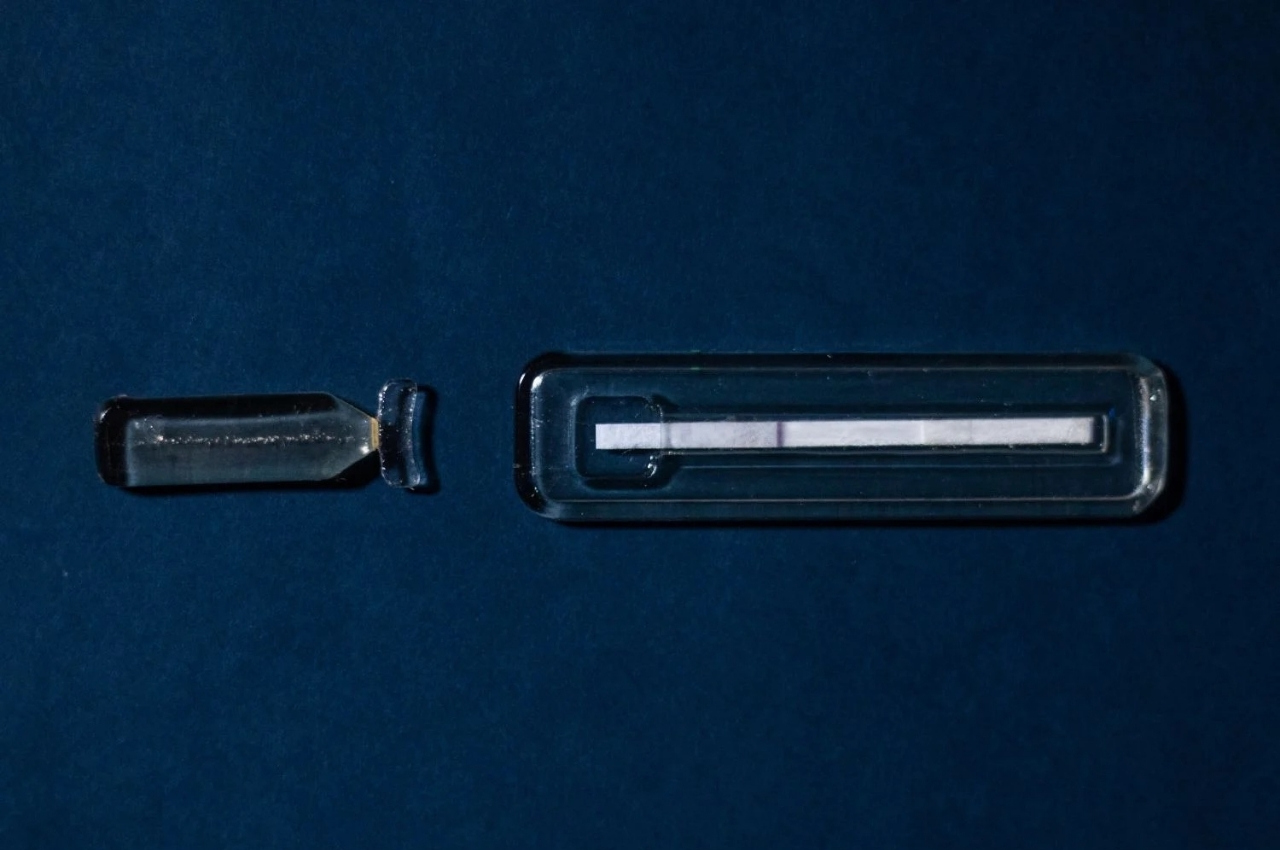

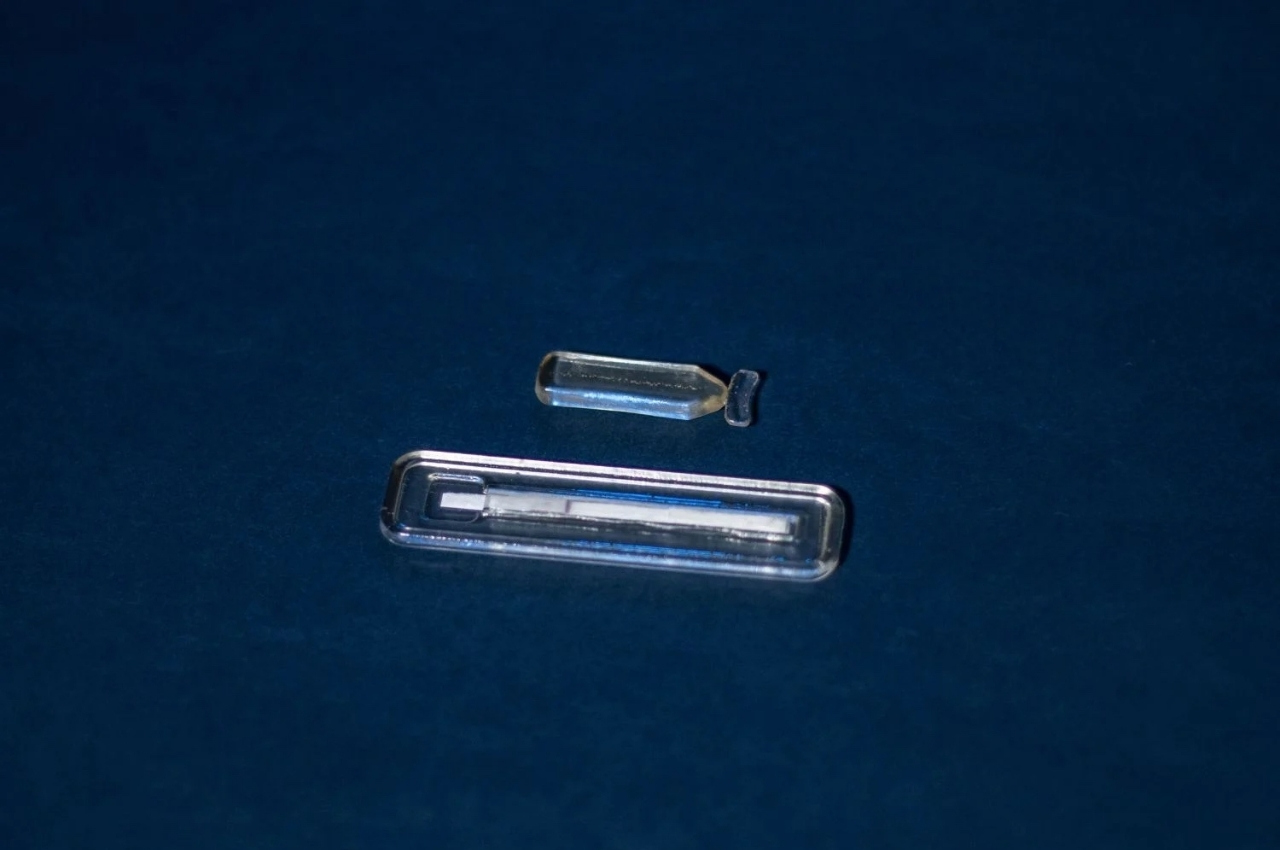

These water bottles created by the California start-up is made up of PHA, a material made through fermentation but still looks a lot like plastic. The design itself looks like a typical water bottle except it’s not transparent and looks more like a milk container. The feel is also that of plastic so it may not be reusable since it’s meant for single use or at least up to a few uses at the very least. It’s described as plastic-free, biodegradable, non-toxic, renewable, compostable, and recyclable.

PHA is a biopolymer that comes from feeding things like vegetable oil, sugar, and food to microbes. They will then turn these materials into a polymer in their cells and these can be extracted and turned into PHA. When this material is exposed to other microbes during the composting phase, it can be broken down easily. How long it decomposes though depends on the environment but they estimate it to be around 1.5 to 4.5 years. It’s still not ideal but at least it’s way shorter than 450 years.

The Cove still water bottles officially became available publicly at Erewhon, an organic grocery in the California area. This is a great alternative to the truly wasteful single-use plastic water bottles that have been causing problems to the earth, especially the oceans, for decades now. While it’s still better to use the reusable water bottles that you can carry with you anywhere, at least there’s a viable option now for plastic water bottle manufacturers.

The post World’s first biodegradable water bottles made with PHA degrade 200 times faster than plastic first appeared on Yanko Design.