Why do cars have air-filled tires? And why do spring suspensions exist as separate entities? What if someone just made tires out of springs, wouldn’t that kill two birds with the same stone? Moreover, spring tires would be more durable, wouldn’t require air, and could therefore never get punctured. All of these questions make a lot of sense, and to be honest, Germans even experimented with spring tires in the 1900s during rubber shortages, but soon reverted back to good-old air-filled rubber tires soon thereafter, sticking to it when they developed the autobahn too.

A YouTuber by the name of Garage54 decided to put this experiment to the test, just to see how things would play out. Instead of rubber treads, G54’s car was outfitted with wheels made of springs in the hopes of being able to travel well on snowy roads and off-road trails. Hate to give you spoilers, but the experiment almost instantly failed, in part because metal doesn’t make a good rubber substitute, and also because G54 quite literally welded springs to his tire. However, it was a great starting point for what I personally think is a pretty unique theory. The design could be optimized, material considerations could be made, and if there’s anyone I trust with getting things right, it’s The Q, who designed the Wheelless Bicycle we saw last year!

Designer: Garage 54

The project started, as most do, with seeing an image on the internet of a spring tire from the early 20th century – designed to boost off-roadability. Of course, good ideas have a certain sticky nature to them, so the fact that nobody uses spring tires anymore was a warning sign to begin with… but then again, I bet you’re just as curious as I am. What if you replaced bouncy rubber tires with bouncy spring tires? How much of a difference could it really make?!

The process of attaching springs to the wheel was quite literally as simple as sanding down the wheel, bending a few massive springs, and welding them in place. To make sure the springs don’t make direct contact with the ground (and potentially destroy the roads), an extra metal strip was then welded around the rim.

A look at the springs that were going to be attached to the wheel

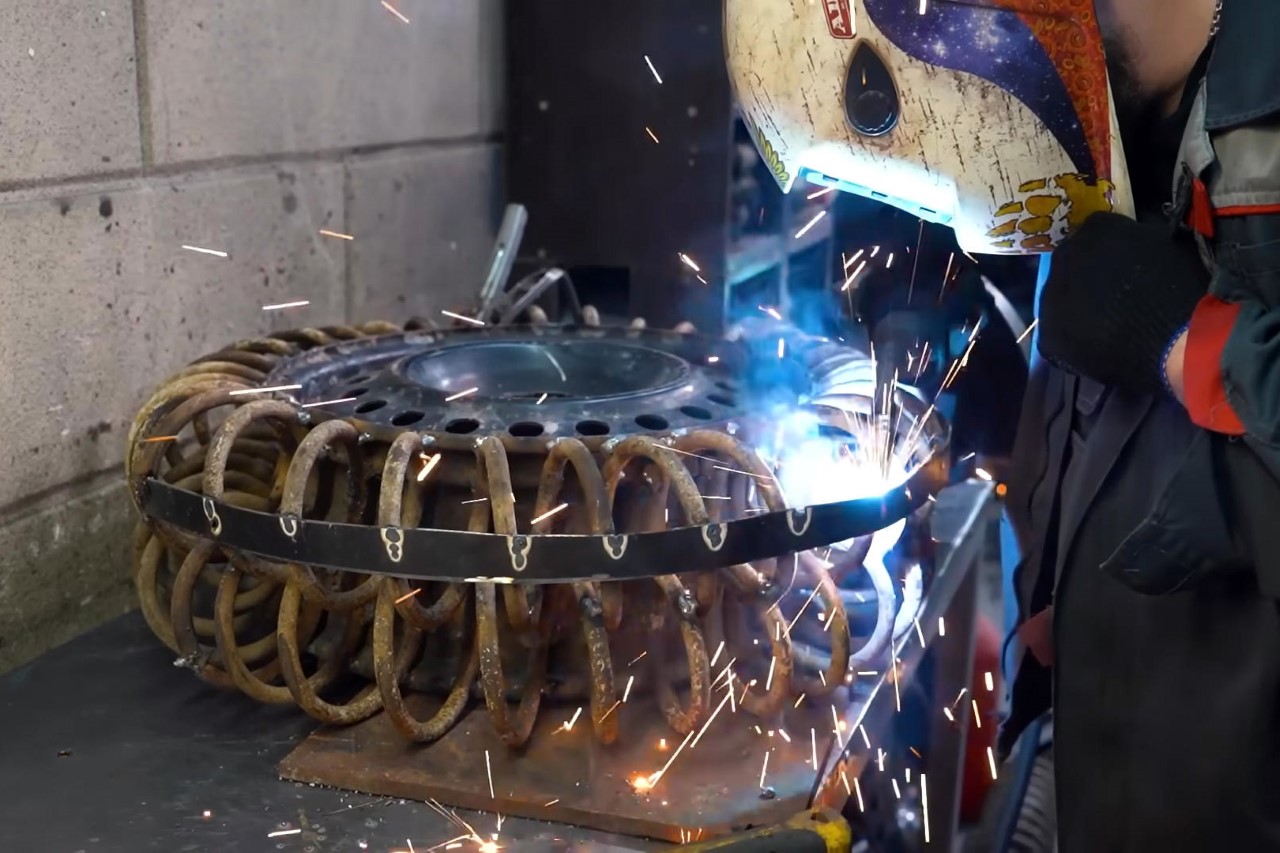

Bending and spot-welding the springs in place

Attaching the rim

Finally, the new tires got a spray of red paint to increase their visibility. Even in their new avatar, they were just about as thick as the original wheels, making the modification incredibly easy.

G54 then attached the tires to his Mercedes-Benz G-Class

The tires, however, ran into a few snags as G54 drove the car on sludgy snowy roads. For starters, metal doesn’t provide much friction, so even though the spring shape promised to easily conquer off-road paths, the tires tended to either rotate in place or slip in all four directions. Secondly, rubber and air are infinitely lighter than steel springs, so the new wheels added immense weight to the car, causing it to literally sink in the snow – this happened especially when the car was stationary. What also didn’t help the weight problem was the fact that snow managed to fill right up inside the hollow spring tires, adding to the vehicle’s bulk. The springs also managed to catch stray twigs and branches, creating more problems than they solved. And as far as suspension was concerned, the new wheels hardly offered any improvements.

Although an instant flop, the experiment had a few areas of improvement. For starters, manually welding together a metal wheel will result in imperfections that then affect the car’s performance. However, before we dismiss metal tires entirely, it’s worth noting that NASA has been extensively testing airless metal mesh wheels for its Mars rover, allowing the vehicle to quite literally drive on the most off-road terrain mankind has ever witnessed! If NASA can do it, I’m sure us normies could figure something out too!

The post With Springs for Tires, this SUV is Breaking All the Rules to Test a Simple Theory first appeared on Yanko Design.