In 2005, Bugatti unleashed a machine so audacious that even today it commands respect. The Veyron arrived with 1,000 horsepower, four turbochargers, and a top speed that left competitors speechless. Two decades later, one collector decided that anniversary celebrations and museum pieces weren’t enough tribute for such a revolutionary achievement.

The result is the F.K.P. Hommage, a one-off hypercar that channels the Veyron’s iconic silhouette while hiding Chiron Super Sport mechanicals beneath its red and black bodywork. Named for Ferdinand Karl Piëch, the Volkswagen Group patriarch who championed the original project, this creation incorporates design elements from an abandoned Veyron facelift that never reached production. It’s automotive archaeology meeting cutting-edge engineering, wrapped in a package that costs north of €10 million.

Designer: Bugatti

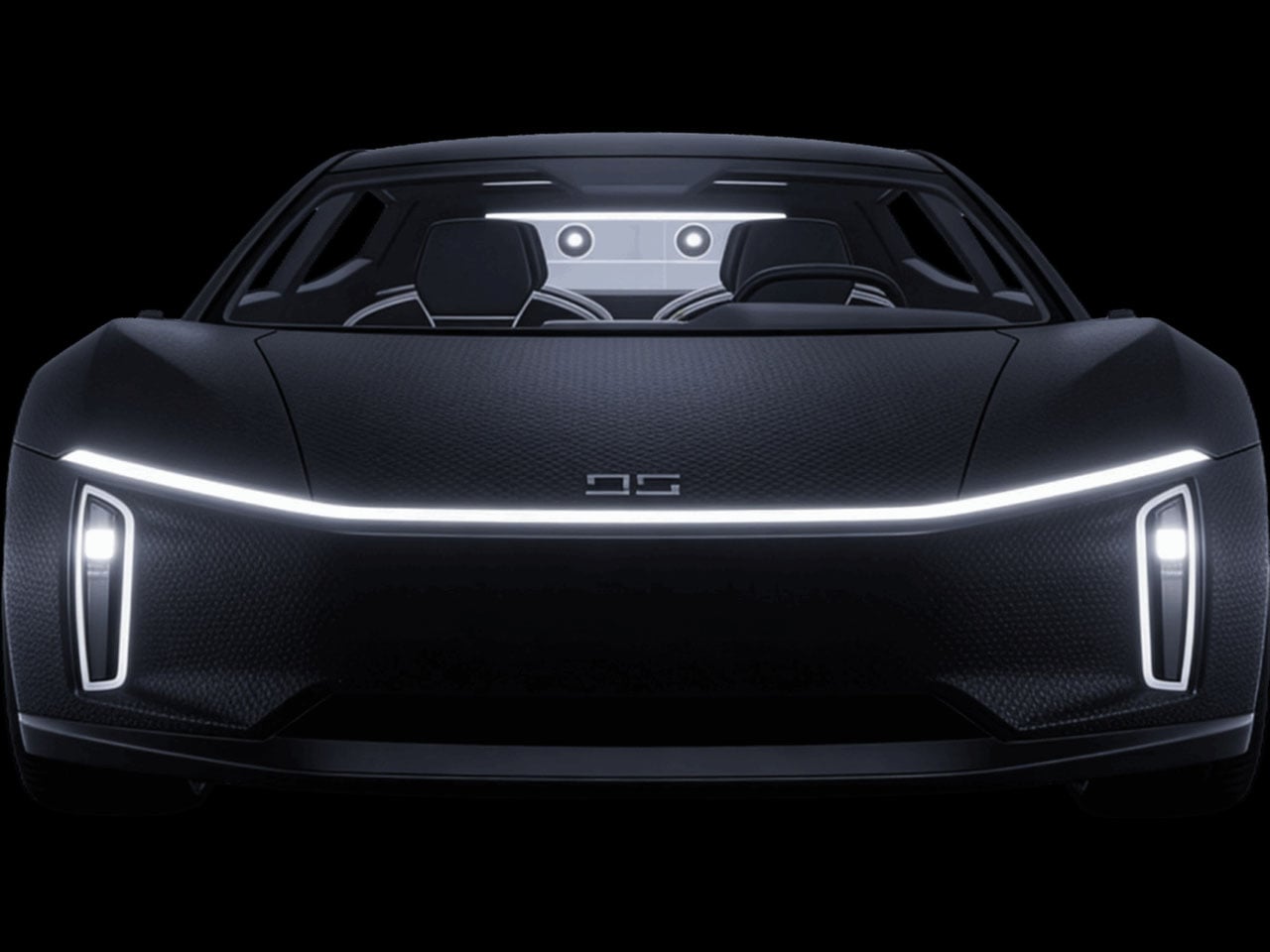

This is the second car from Bugatti’s Programme Solitaire, their bespoke division that handles exactly two ultra-custom builds per year. The first was the Brouillard, which took the Mistral roadster platform and wrapped it in equestrian-inspired design language. The F.K.P. Hommage takes a different approach entirely. It asks a simple question: what if Bugatti had kept refining the Veyron on the Chiron’s platform instead of replacing it? Chief designer Frank Heyl actually had sketches for a Veyron facelift back in 2008, concepts that never materialized because Piëch wanted something more radical. Those sketches became the foundation for this car. The headlights, those hollowed-out “light tunnel” taillights, even the adjusted proportions all stem from that unrealized project.

The exterior proportions mirror the original Veyron almost exactly, though it sits about an inch and a half wider. Every single body panel was designed specifically for this car. Nothing got copy-pasted from the parts bin. The horseshoe grille stands more upright now, three-dimensional and aggressive in ways the original never attempted. Those L-shaped LED headlights give the front end what Heyl calls a “concentrated stare,” which sounds like marketing speak until you actually look at the thing head-on. The side intakes got tightened up, the twin roof intakes lean forward more dramatically, and the rear diffuser flares outward at sharper angles. The taillights grew slightly larger on the outboard sections, creating better visual balance. Even the fuel filler got repositioned for better aerodynamic flow.

The red and black scheme matches the first production Veyron from 2005, but Bugatti couldn’t just spray it red and call it done. The base is actually silver, with red pigment incorporated into the clearcoat to create depth and luminosity that straight red paint never achieves. It’s the kind of obsessive detail that adds weeks to the build process and thousands to the cost, which matters zero percent when your budget already exceeds €10 million.

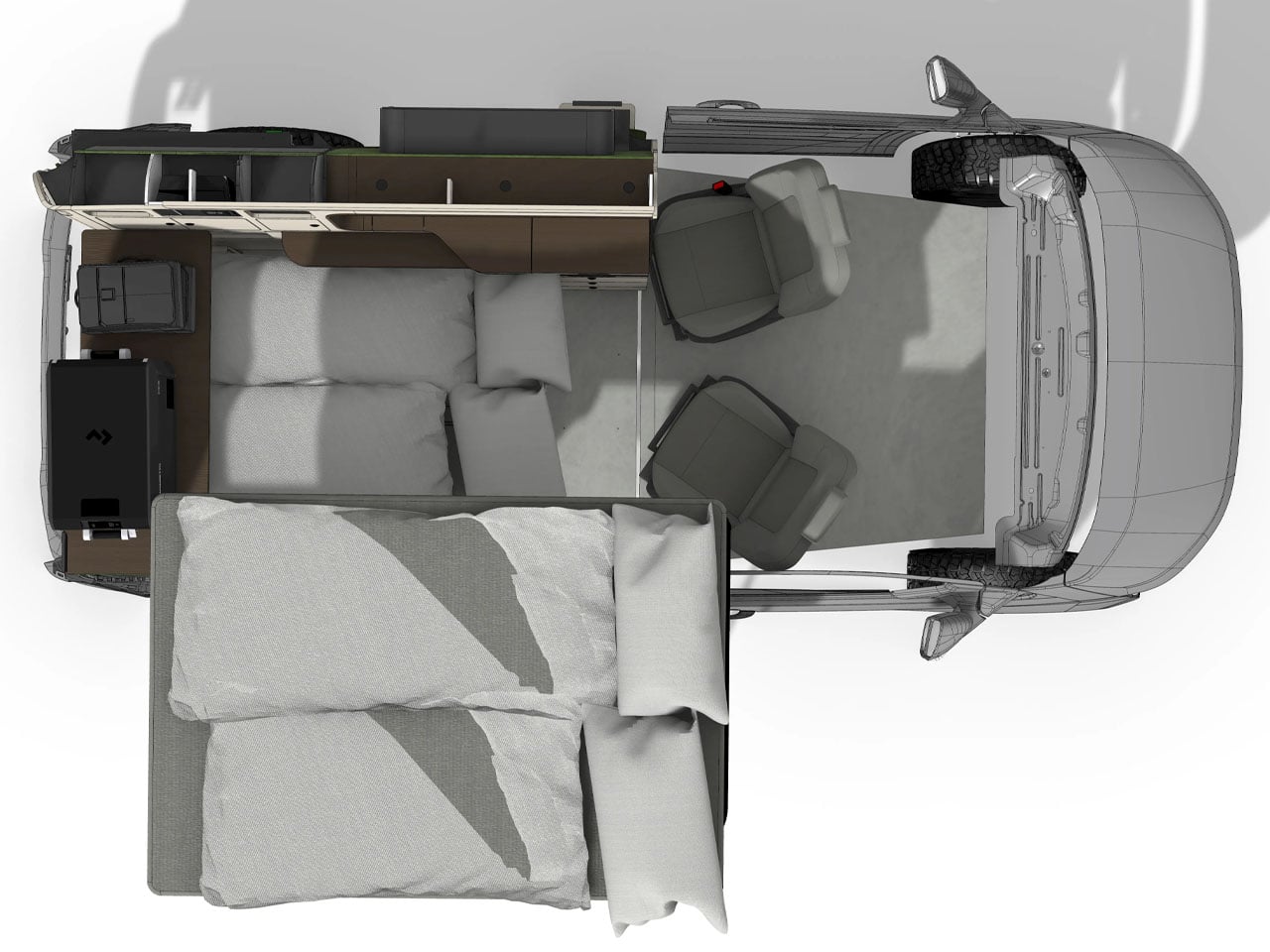

Then you open the door and realize the exterior was just foreplay. The cabin blends Chiron architecture with Veyron soul, keeping the newer car’s instrument cluster while introducing a completely redesigned steering wheel and a wider center console. That console gets machined from a single block of aluminum, which sounds impressive until you remember they’re putting a $200,000 Audemars Piguet Royal Oak Tourbillon inside it. The 43mm watch sits in a rotating mount that serves double duty. It hides the timepiece when the car’s off, protecting it from opportunistic smash-and-grab artists, and it spins the watch several times per hour to keep the automatic movement wound. No mechanical connection to the car, just a motorized gondola doing its thing on a timer.

The seats wear custom couture fabrics woven by a Parisian textile house, because apparently Italian leather alone doesn’t sufficiently communicate exclusivity. Piëch’s signature gets stitched into each headrest, with his initials and birthday embossed into the leather by your right knee. These details matter in the rarefied world of eight-figure automotive commissions, where differentiation comes down to whose signature adorns your headrest.

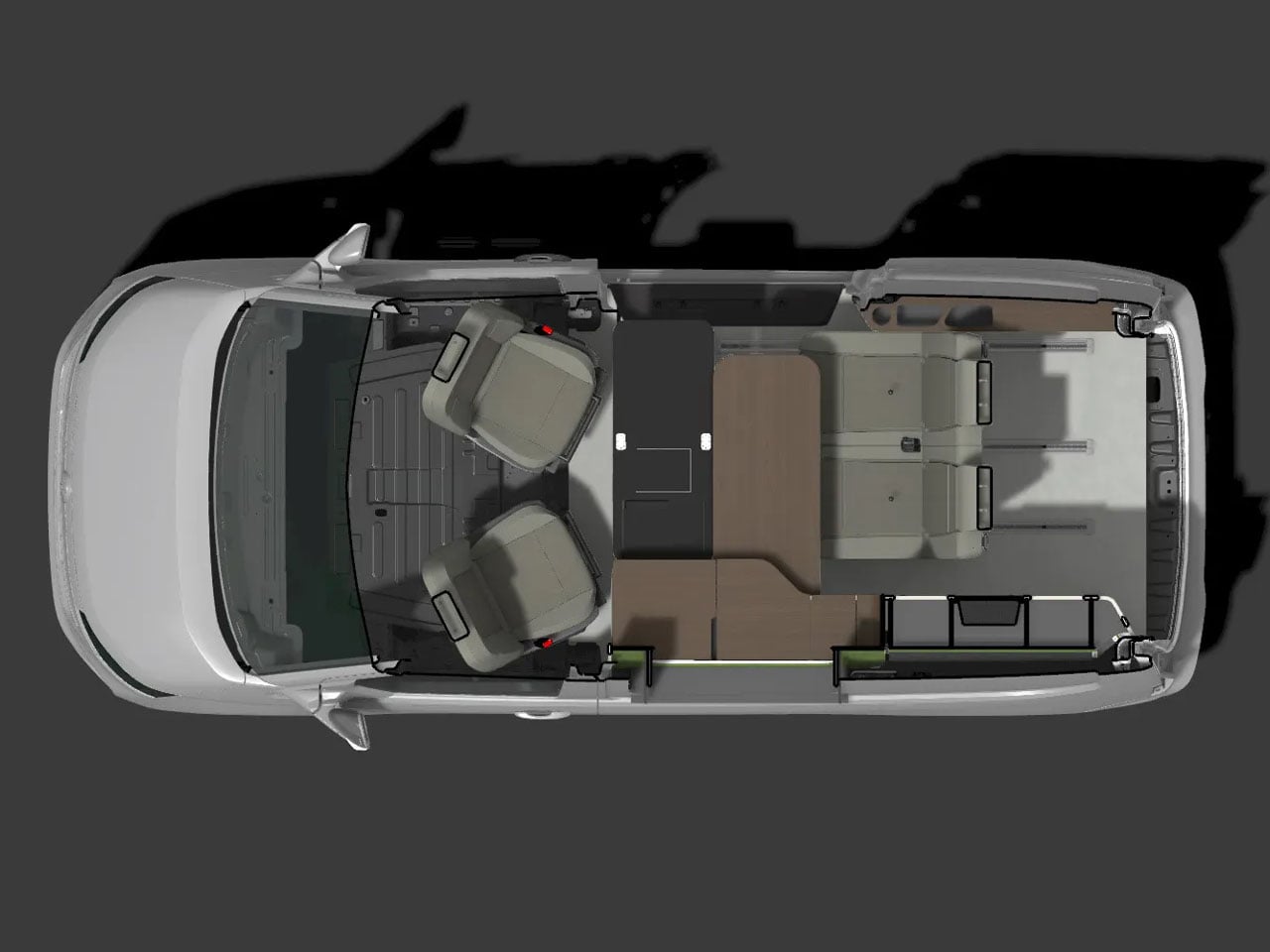

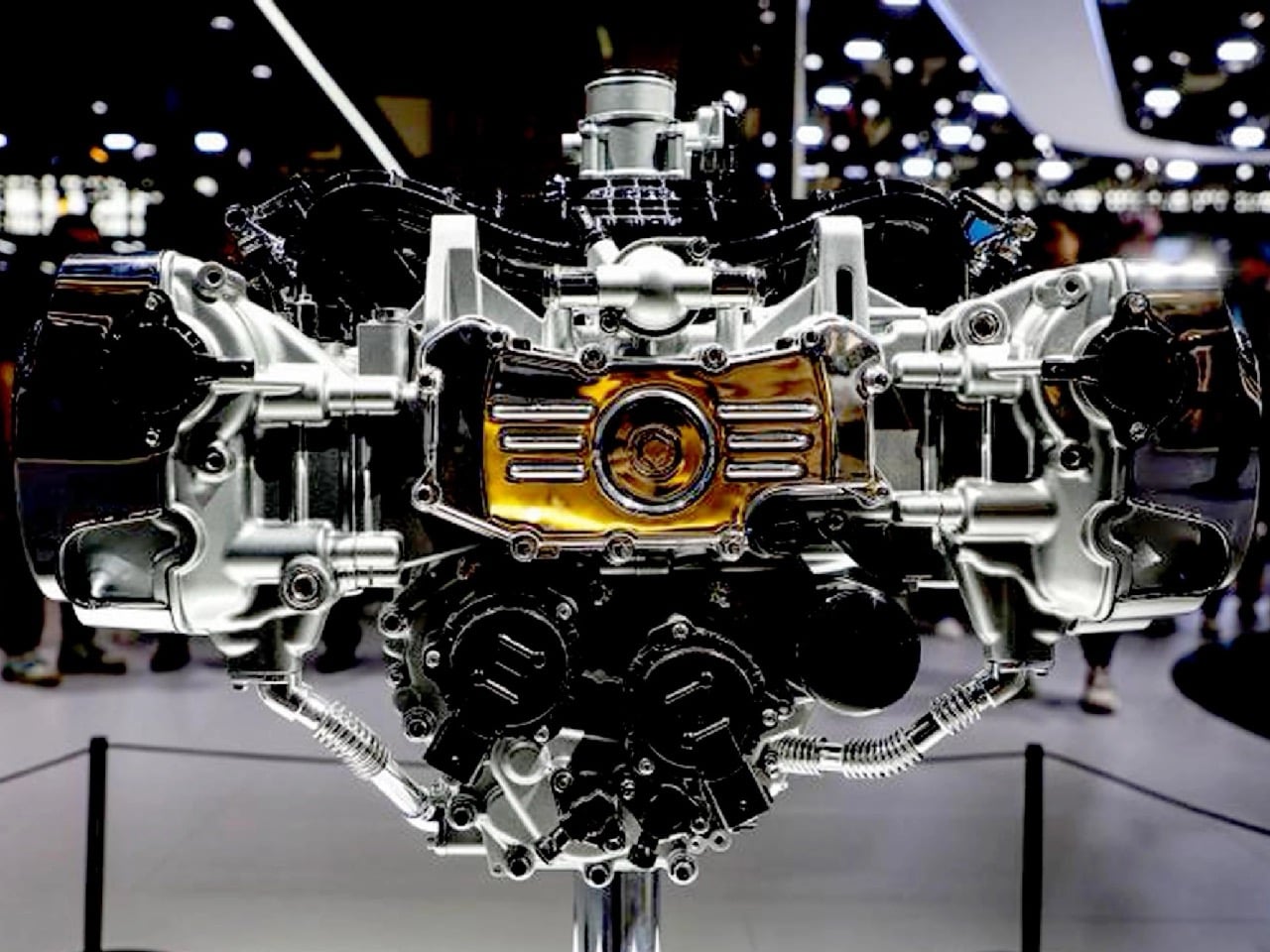

Under that engine cover sits the Chiron Super Sport’s 1,578-horsepower W16, complete with upgraded cooling, enhanced intercoolers, and a reinforced gearbox. The wheels measure 20 inches up front and 21 inches out back, significantly larger than the Veyron’s original 18/20 setup but necessary to accommodate modern Michelin rubber and the massive brake calipers hiding behind those spokes. The owner reportedly already possesses a matching Veyron, which means they’ll soon park both side by side and spend entirely too much time explaining the differences to confused onlookers.

The F.K.P. Hommage debuts at Rétromobile Paris before embarking on the typical hypercar show circuit, hitting Monaco, Pebble Beach, and whatever other gatherings attract people wealthy enough to consider €10 million reasonable for a car. Delivery happens in 2027, giving Bugatti’s craftspeople enough time to obsess over every stitch and surface. By then, the W16 engine will be completely retired from production, making this one of the final expressions of Piëch’s original vision before Bugatti transitions to the V16 hybrid powertrain in the Tourbillon.

The post The Bugatti Veyron Turns 20 and Gets a 1,578 HP Makeover Nobody Saw Coming first appeared on Yanko Design.

s

s