3D printing has truly revolutionized the design and production industry, giving anyone the power to create almost any form they can think of. That revolution, however, came at a price to the environment, increasing the use of plastic material even further. Thankfully, there has been some significant pushback and changes in this young industry, as different kinds of material become printer-compatible, including food, metal, or even wood. There are even attempts at using alternative source materials for plastic, like this playful 3D-printed lamp that uses a base that you might have never thought of: corn starch.

Designers: Alexandre Touguet, Lise Rissel

Of the many types of materials used for 3D printing, PLY or polylactic acid plastic is one of the most popular. Unlike most plastics that are made from petroleum, this thermoplastic uses organic material, in this case, corn starch. This gives PLA a more sustainable character, although sometimes minimally so. It is biodegradable, but only under specific conditions that aren’t always easy to meet naturally.

It’s still a step in the right direction, nonetheless, especially since it opens the doors to more interesting designs when used in 3D printing. ALT Light is one such example, using 3D printing to bring not only light but also a joyful atmosphere to any space. Although its design might be possible to execute using traditional manufacturing processes and harmful plastic, the product demonstrates the economic and environmental benefits of a more sustainable approach to design and production centered around 3D printing.

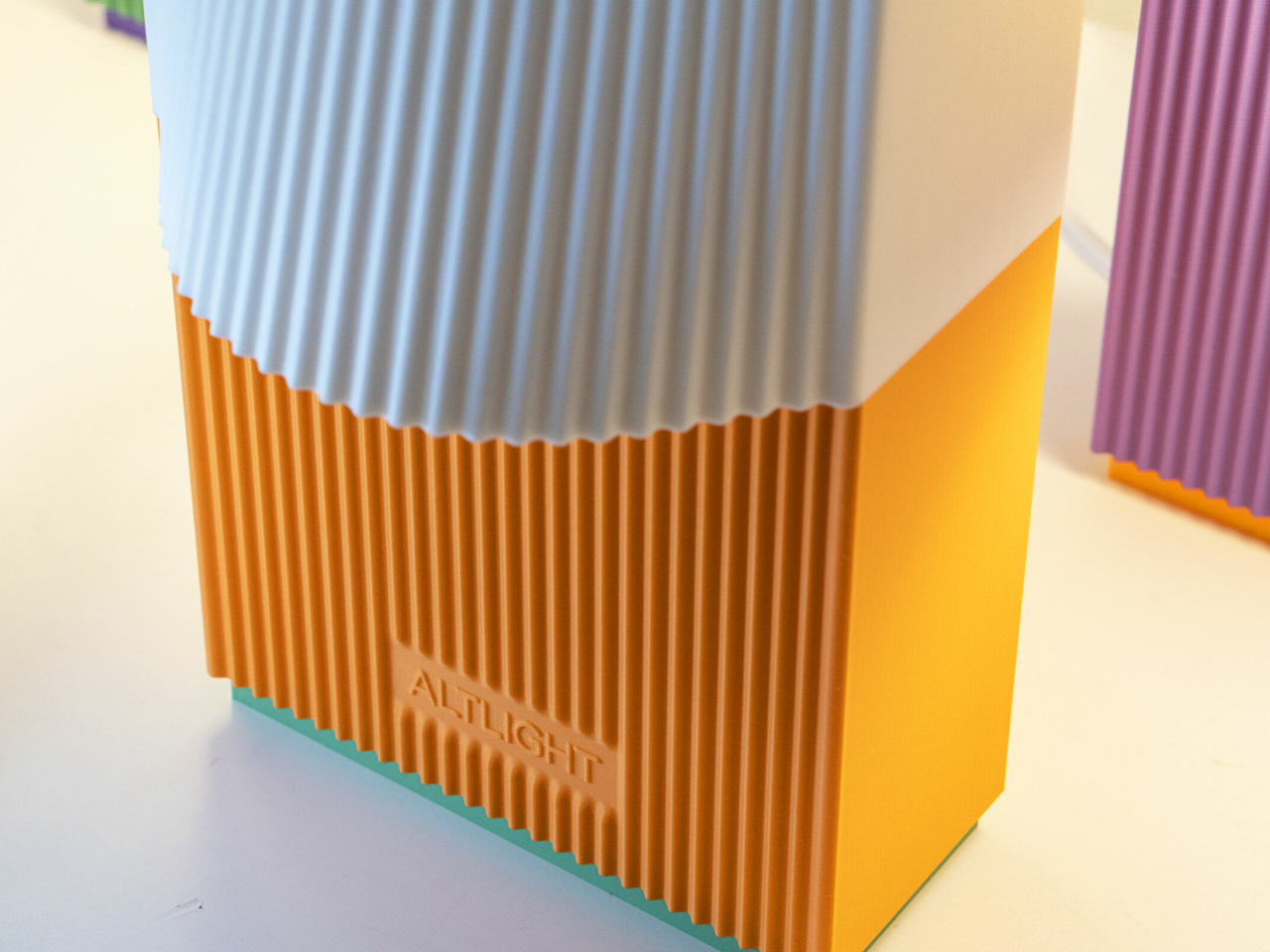

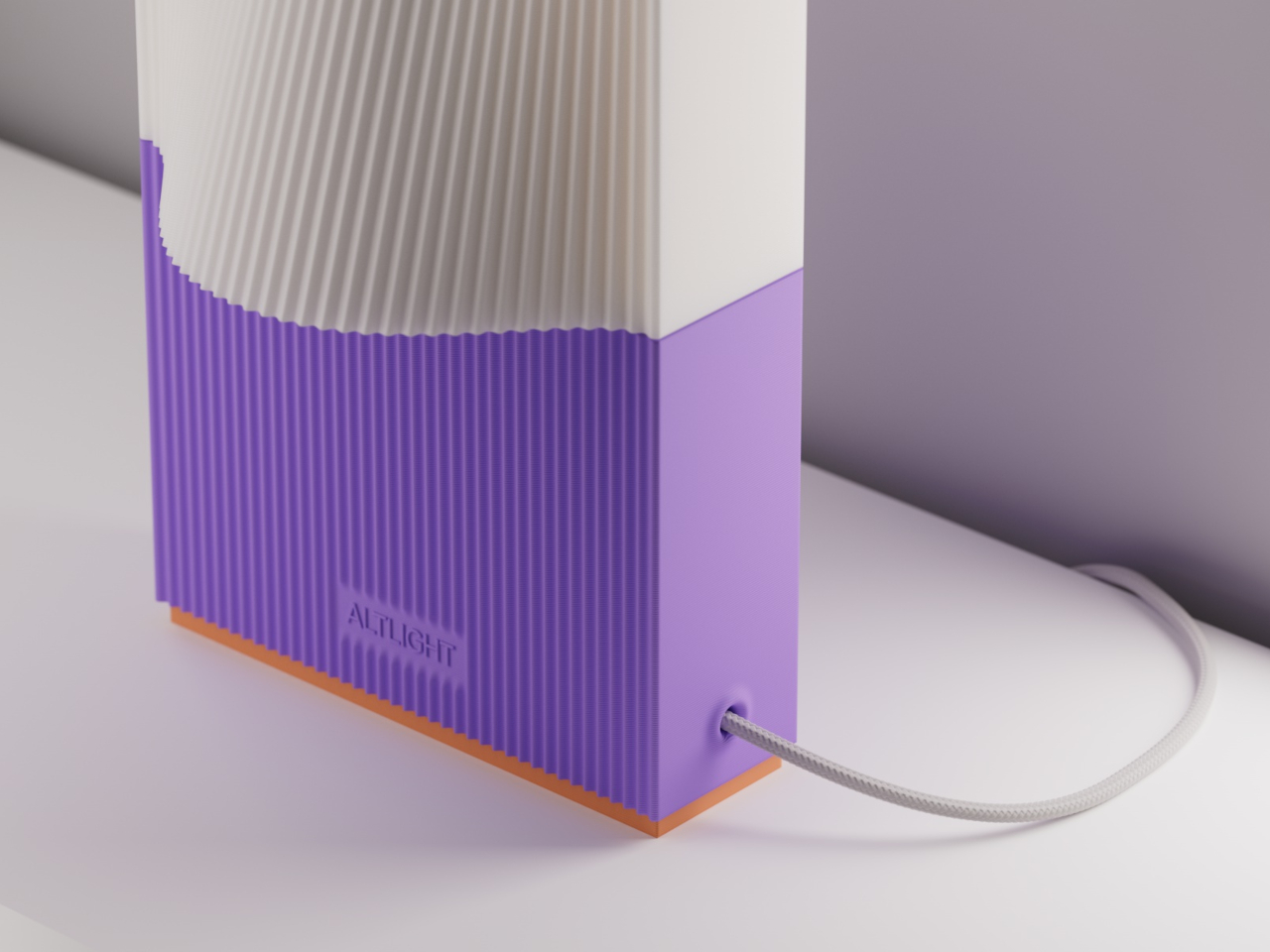

ALT Light starts from the bottom with a normal rectangular block, if you could call a block with vertical ridges “normal” in the first place. As you lift your eyes, higher, you are the block seems to flare open, creating the semblance of a traditional conical lampshade. It stops halfway through this transformation, though, creating a sense of instability and dynamism simply through forms, as if the lampshade is trying to break free from its confines.

The lamp can come in different combinations of colors for the base and the lampshade. The transparent top gives it a jelly-like appearance, while the translucent version is like hard candy. The ribbed surface does more than just make the forms look interesting, they also create an interplay of light and shadow that mesmerizes the viewers. In addition to their unique designs, these lamps are all made in order to cut down on material waste, and each creation has minute imperfections that give each ALT Light lamp its own unique character.

The post 3D Printed lamps made from cornstarch plastic exude cute candy-like vibes first appeared on Yanko Design.