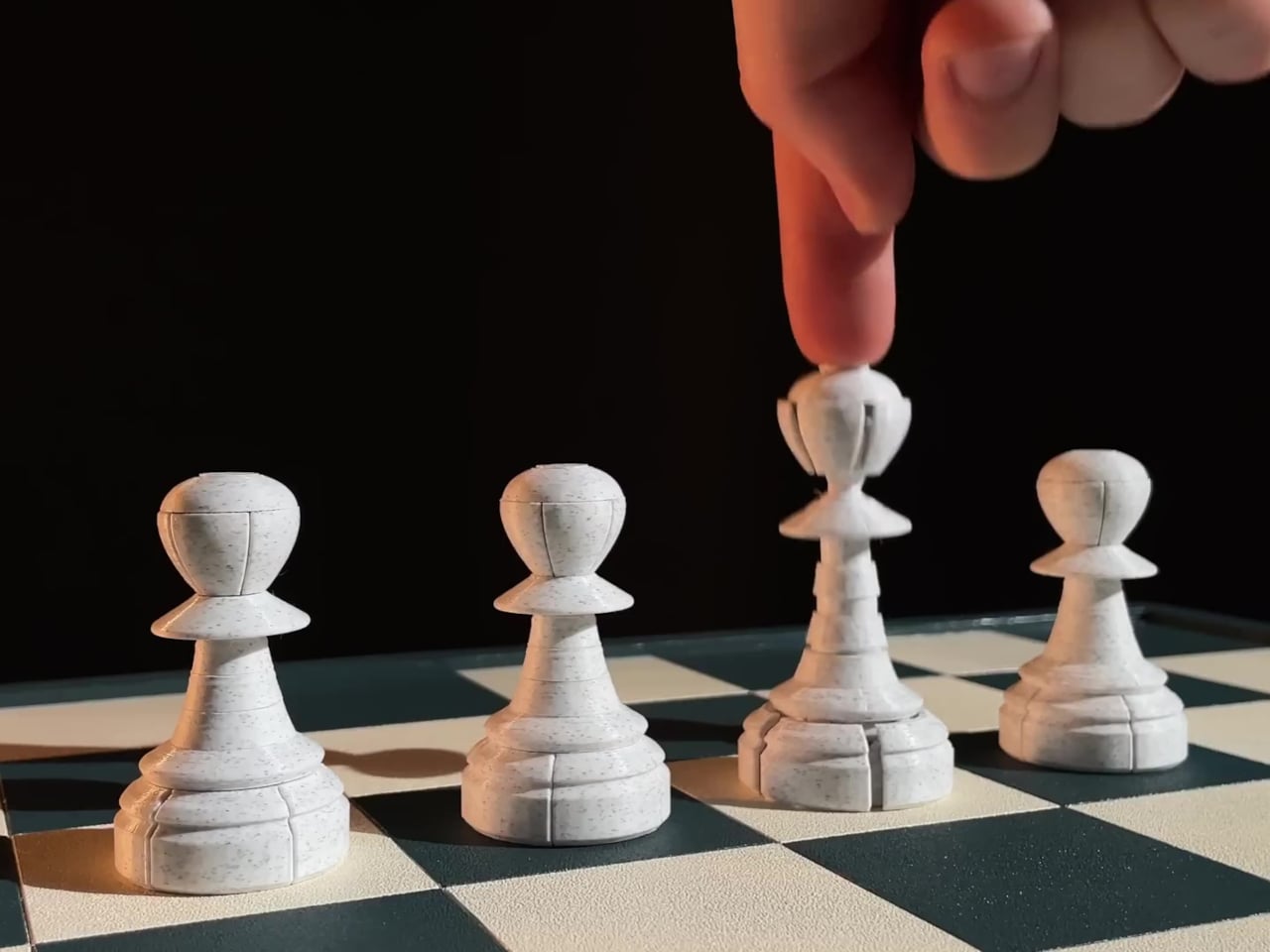

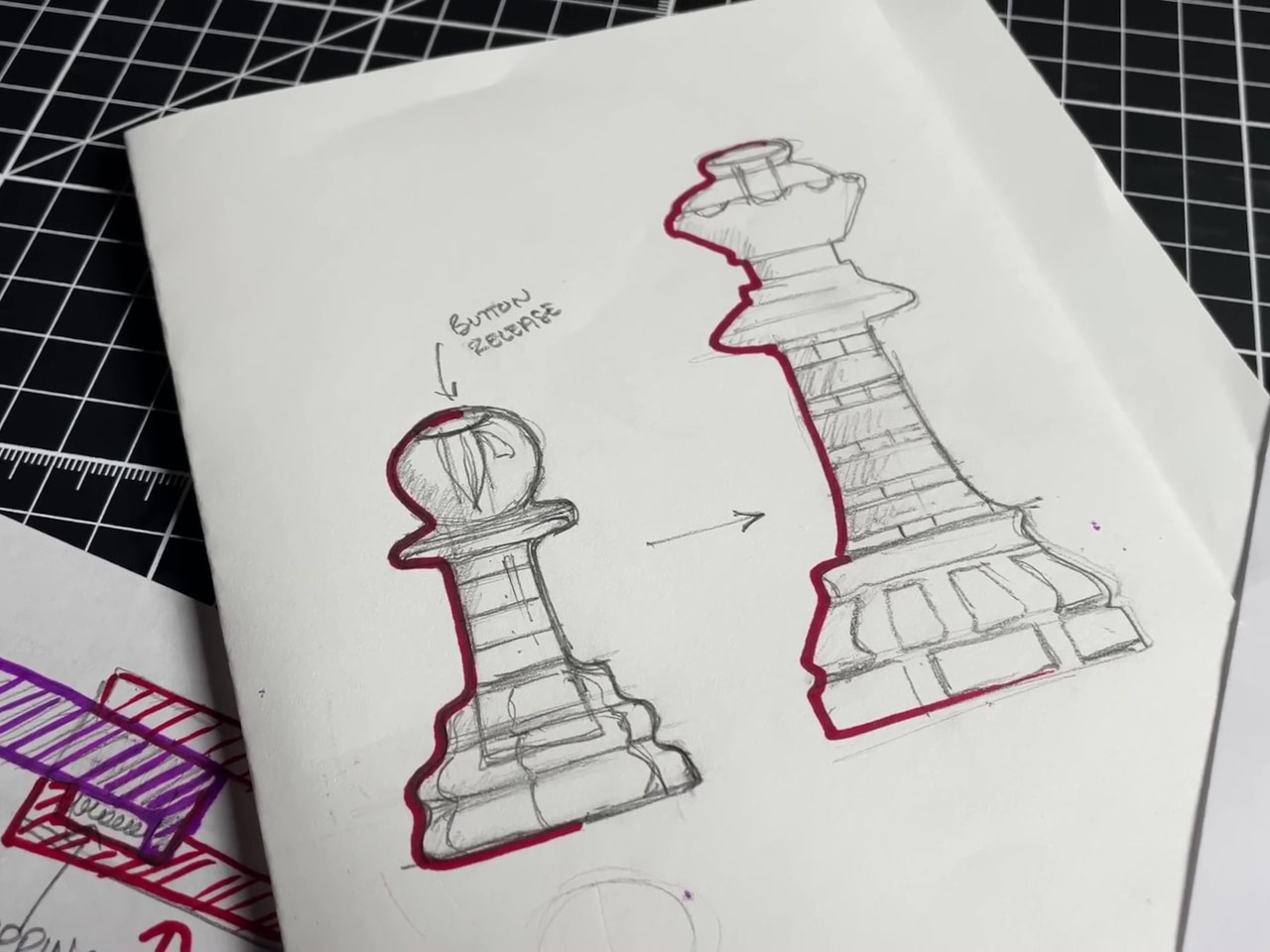

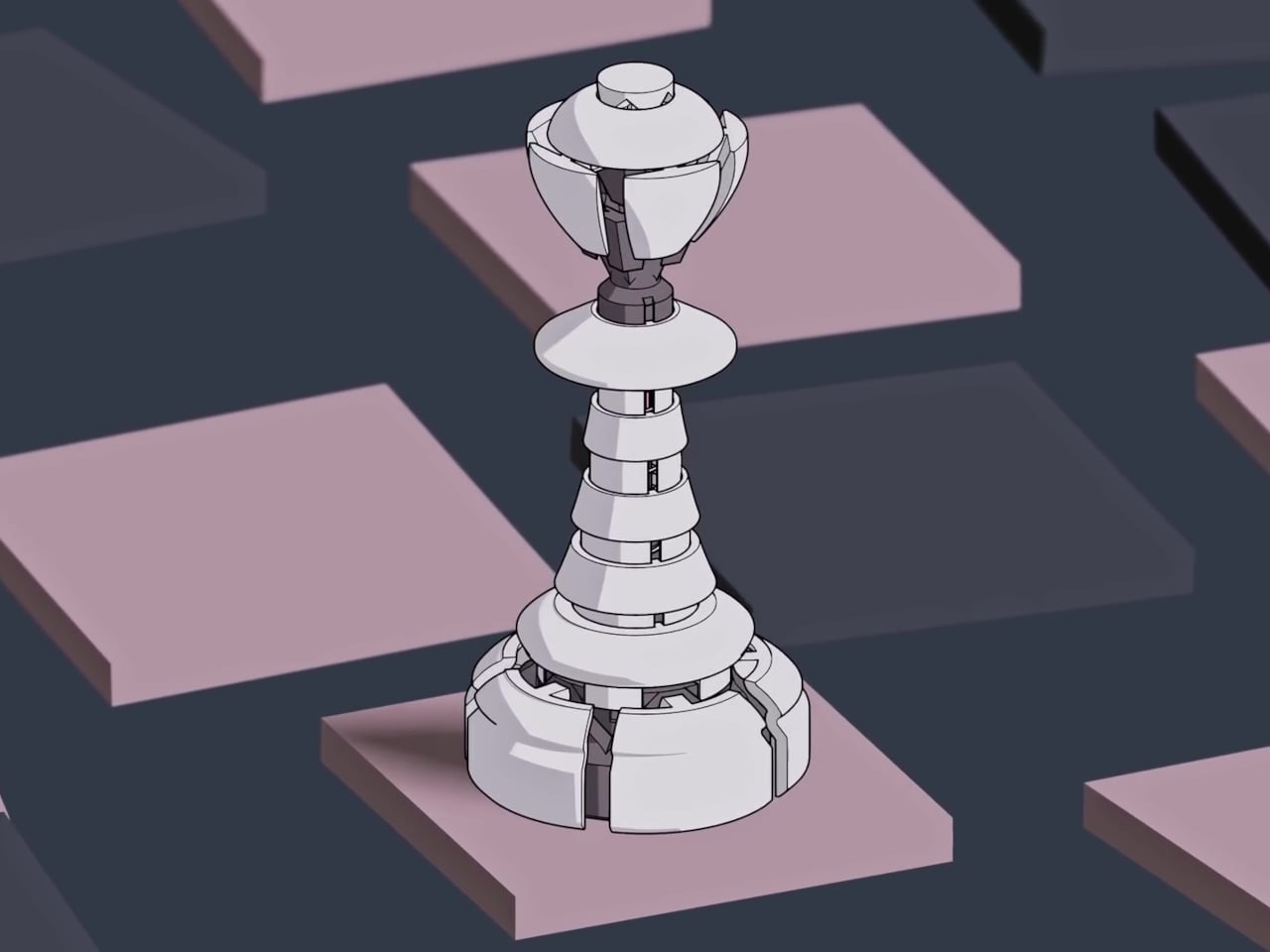

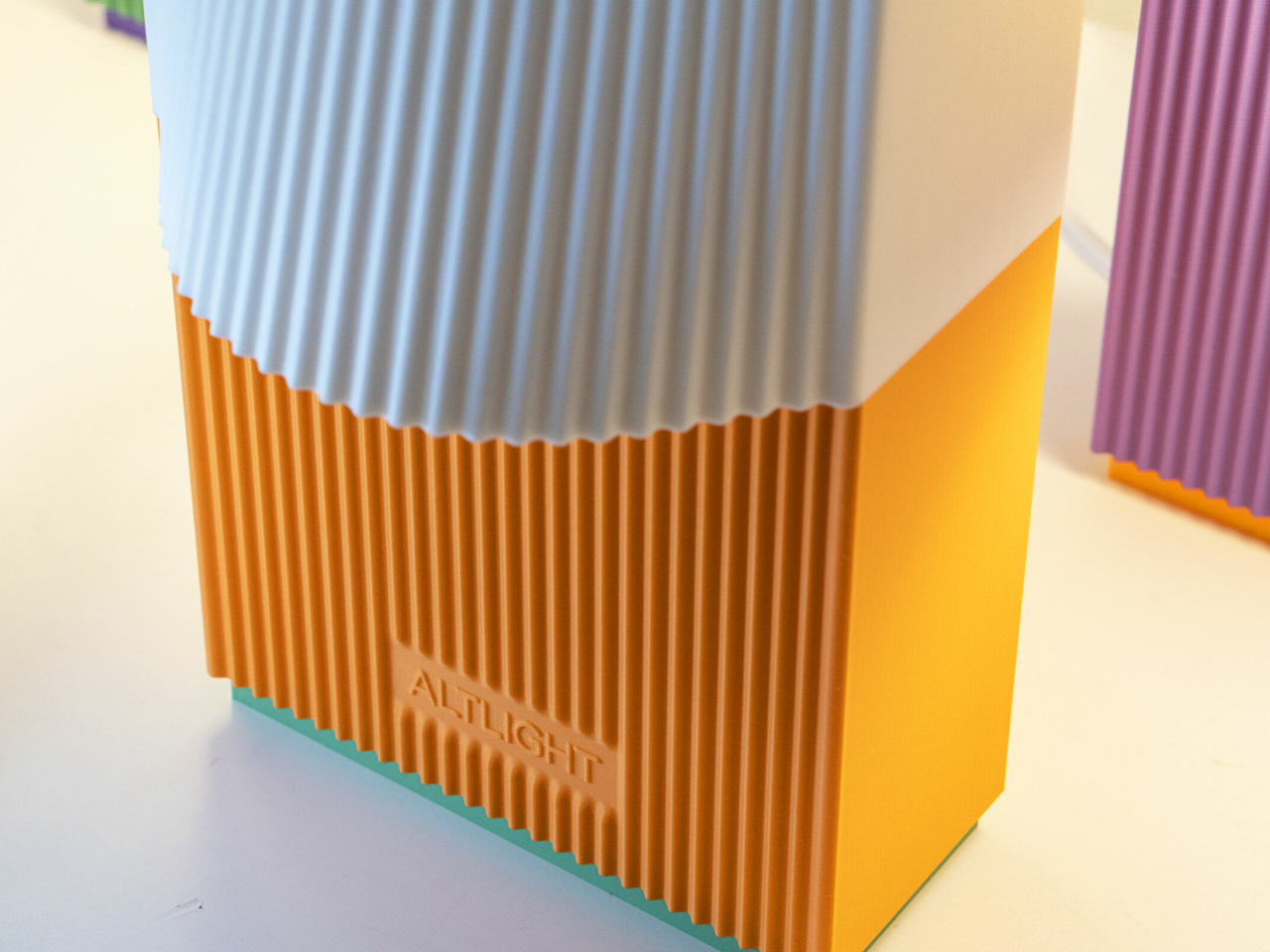

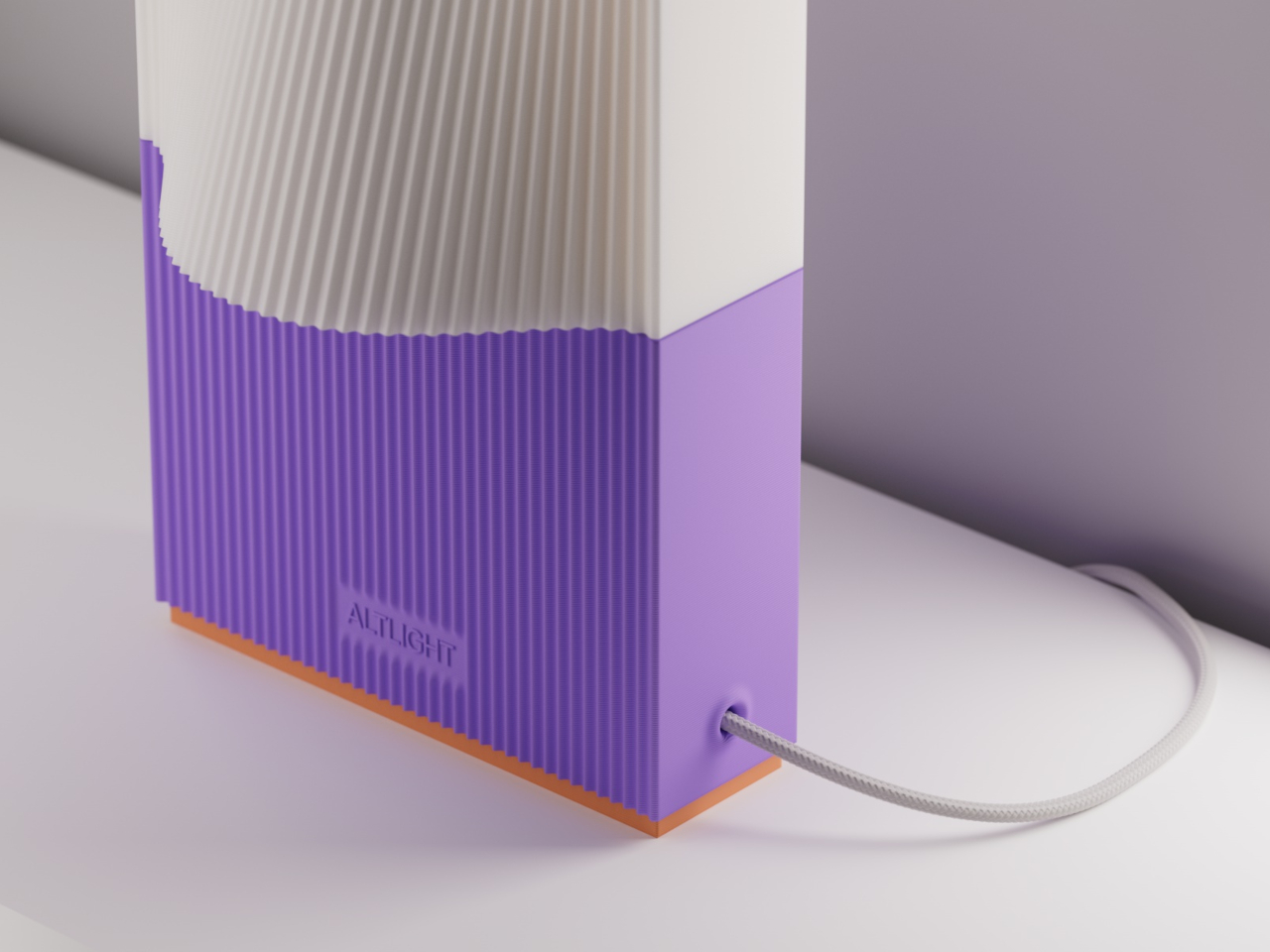

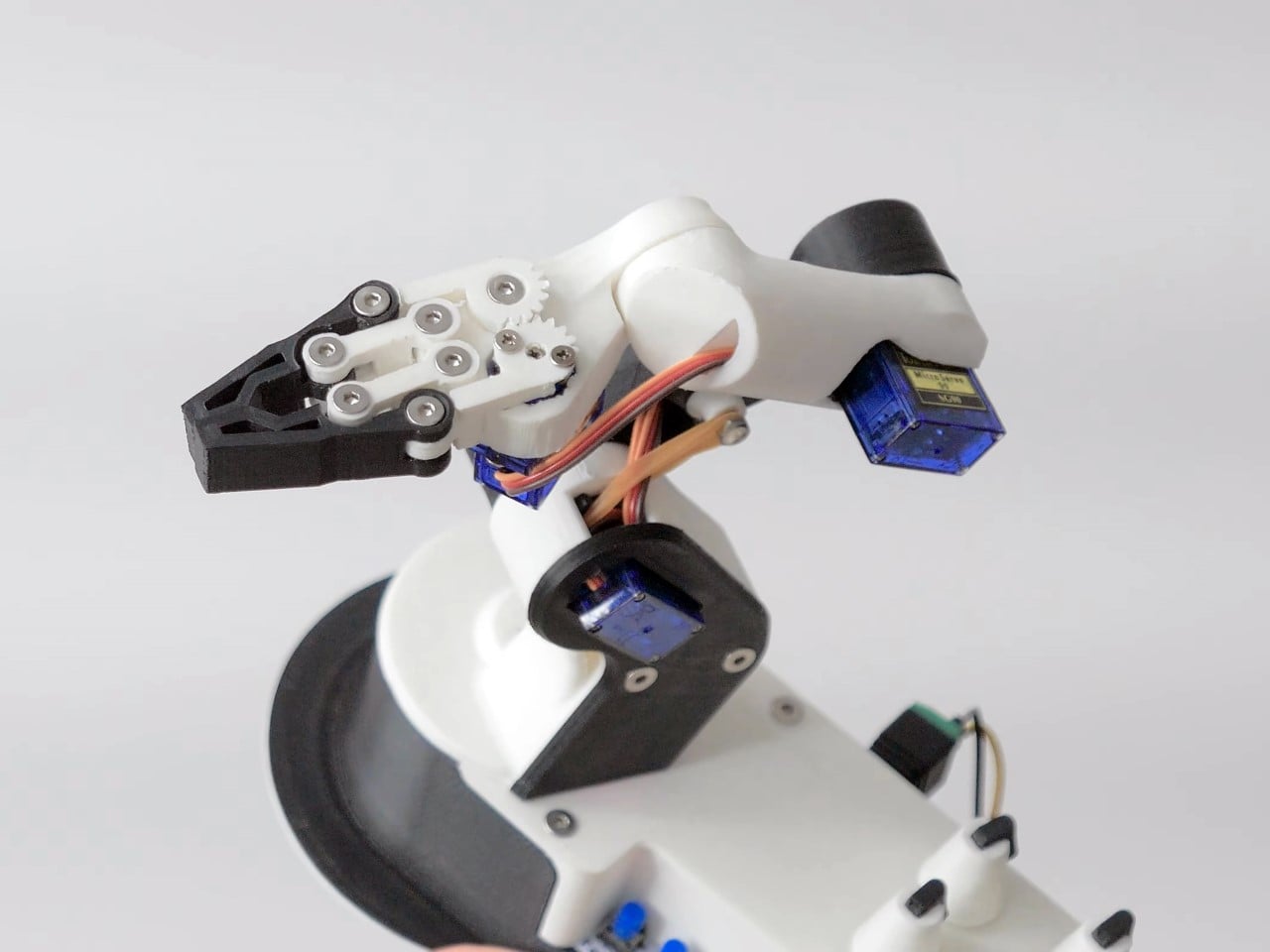

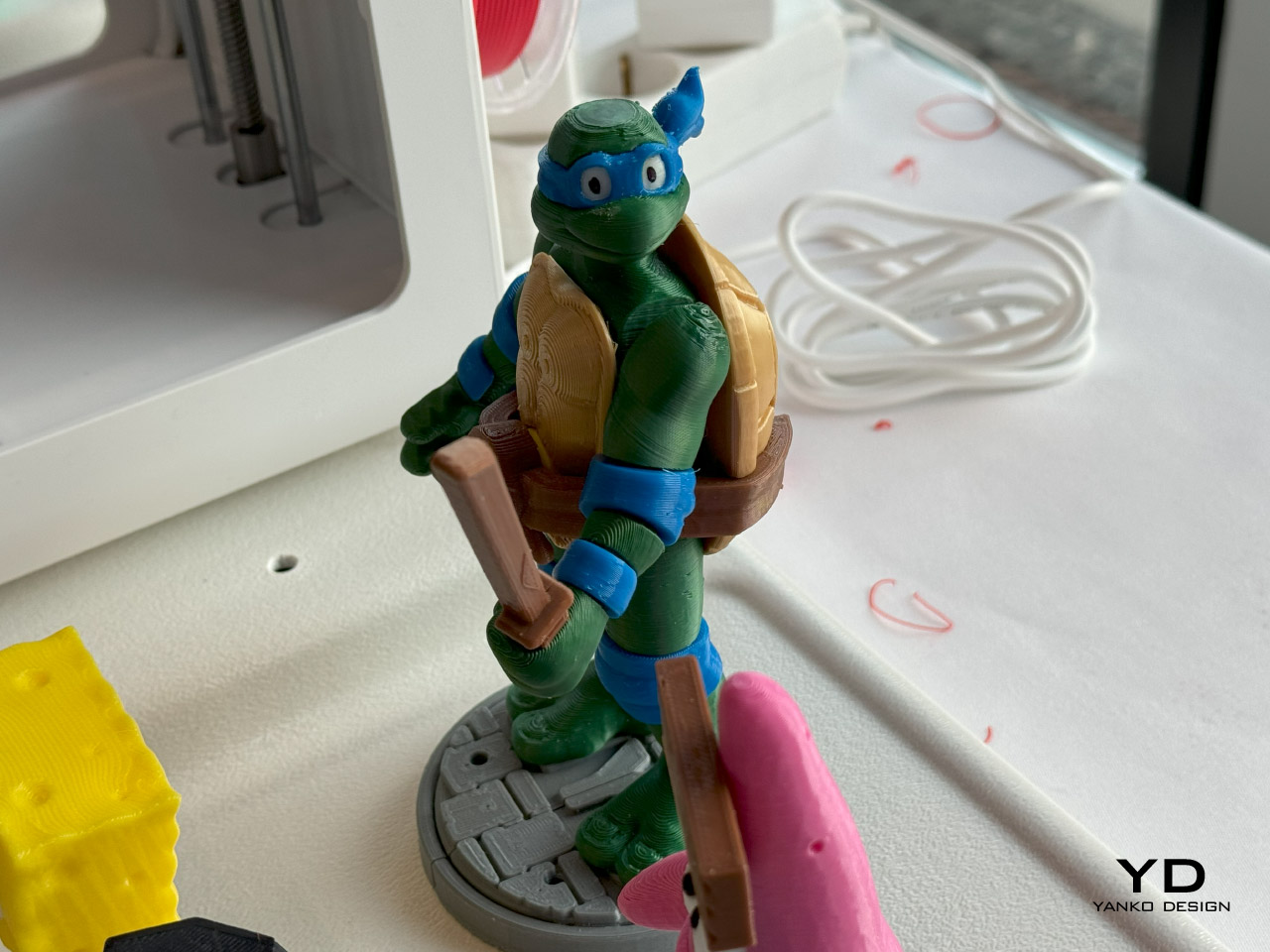

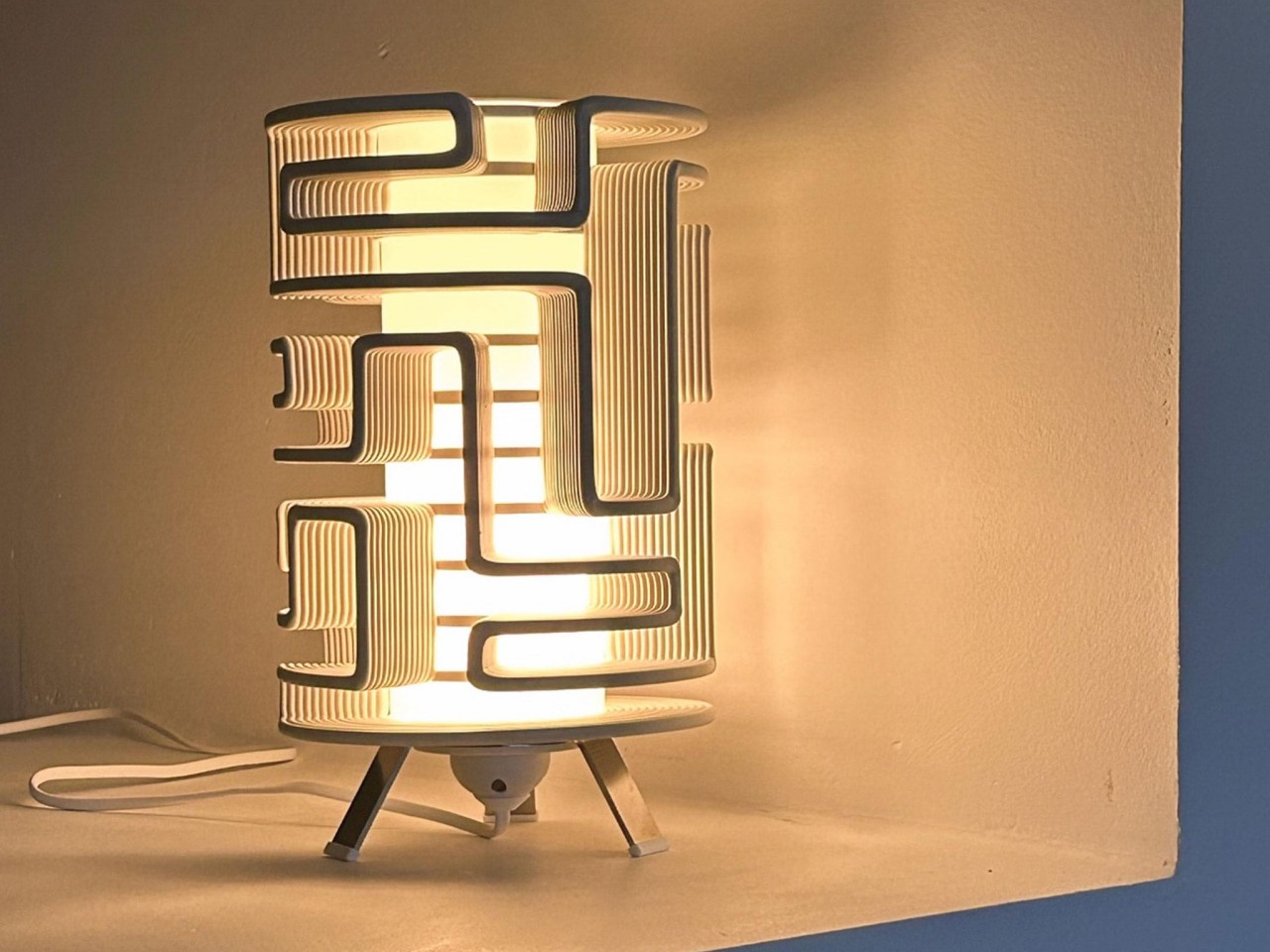

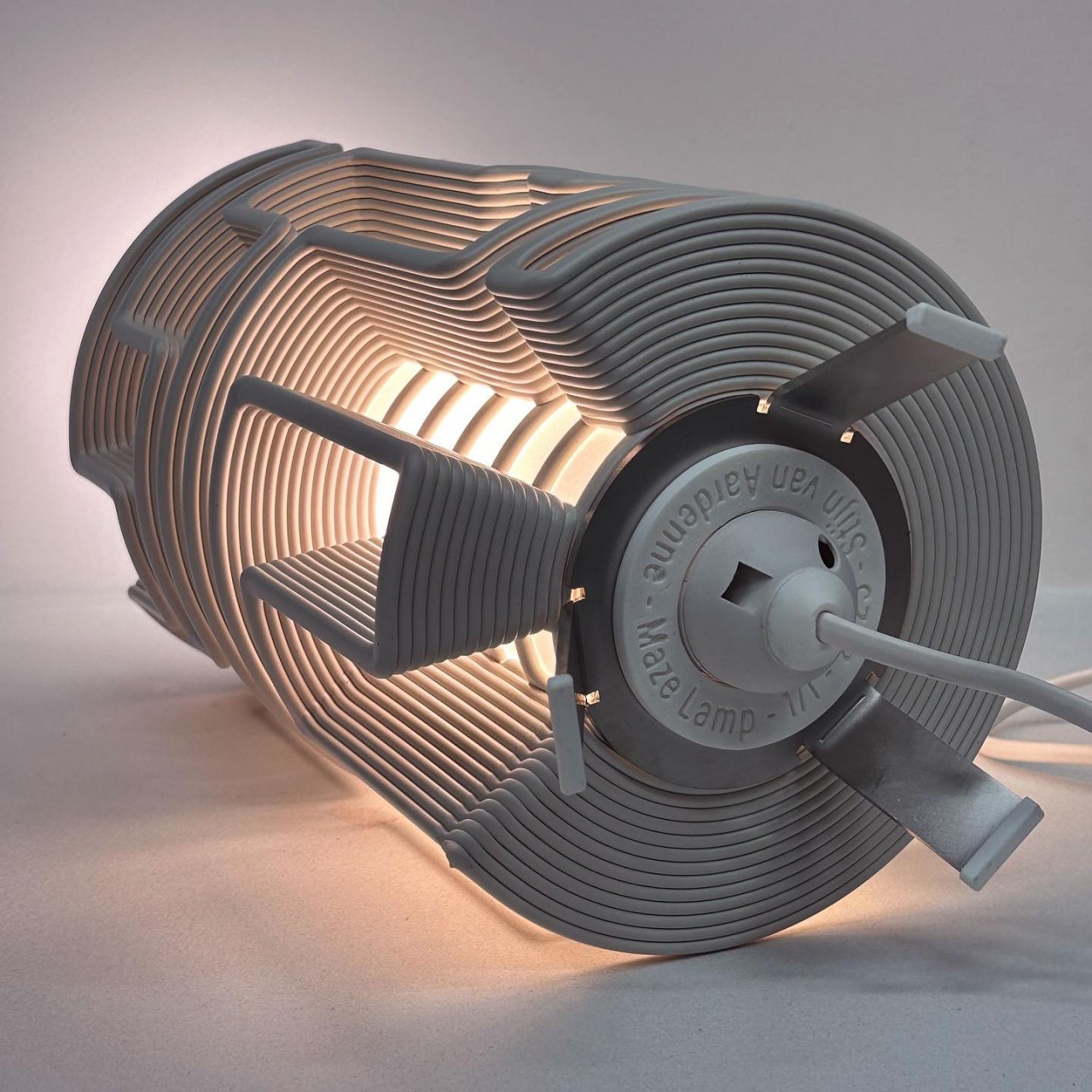

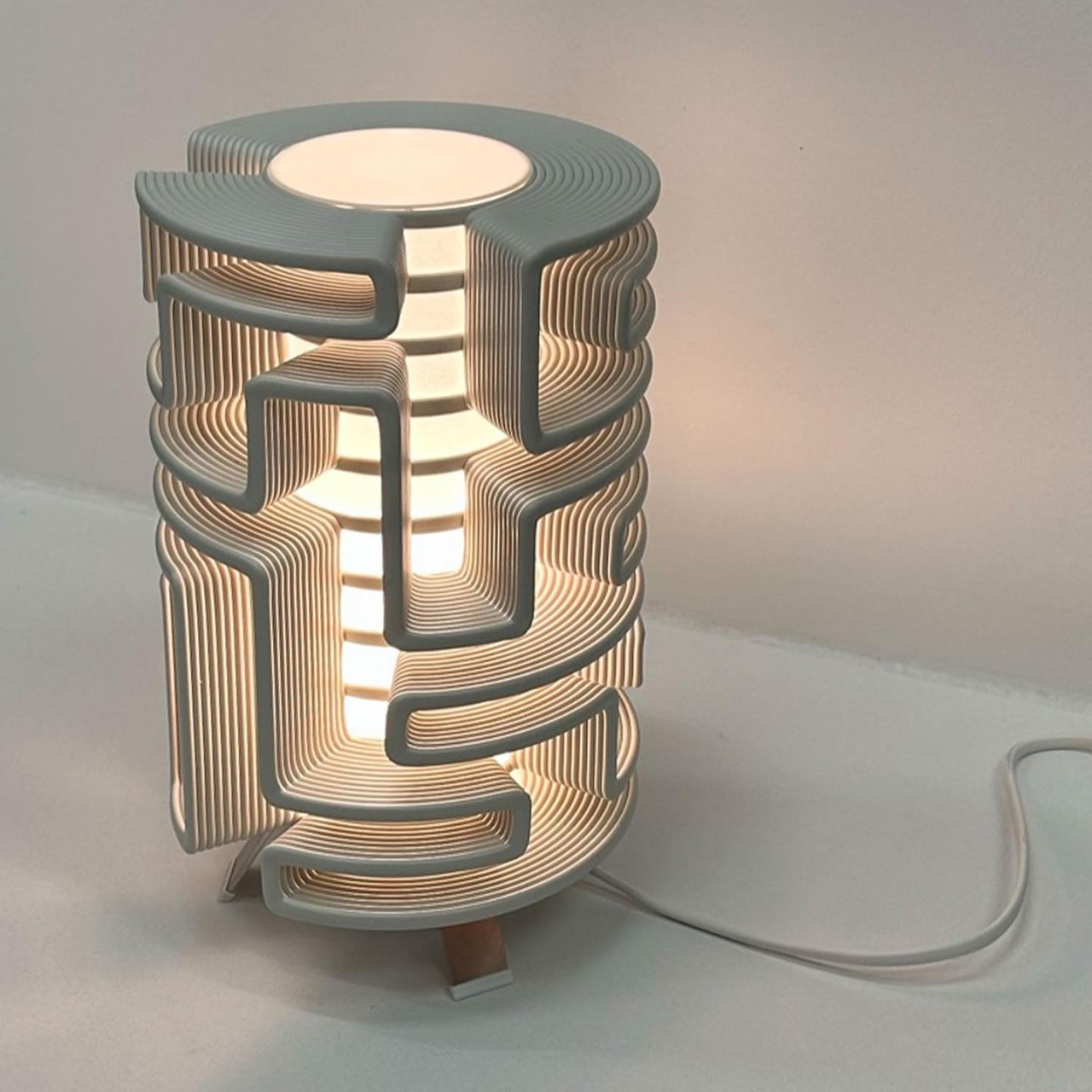

Cleaning up 3D prints, model kits, or small woodworking projects usually means fighting tools that are not really built for it. Rotary tools dig in and melt plastic, big sanders cannot reach corners, and endless hand-sanding sessions leave your fingers numb. The last 10% of a project, the fine details, often takes 90% of the time because the tools are fighting you instead of helping, turning what should be a satisfying finish work into a slow grind.

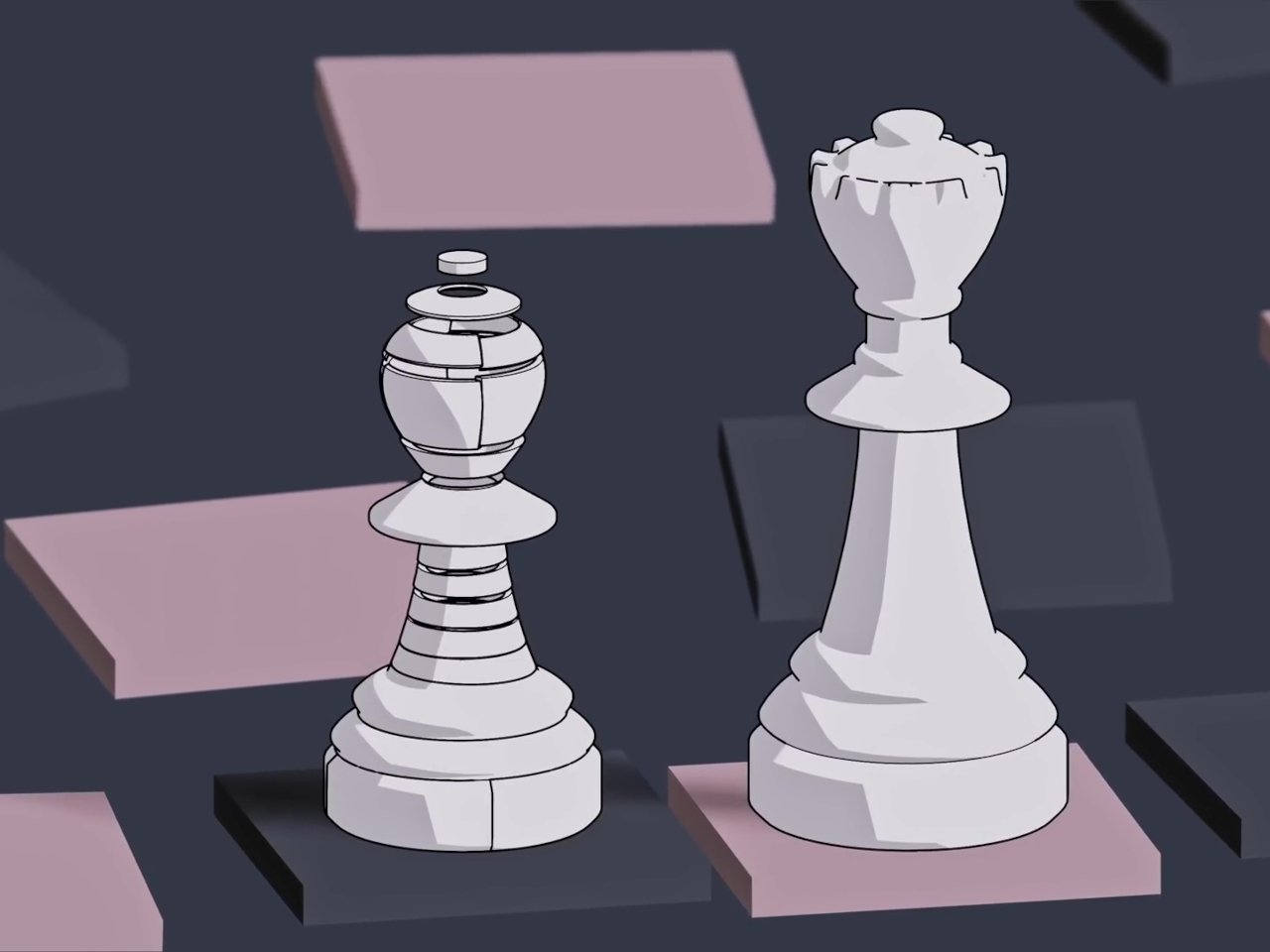

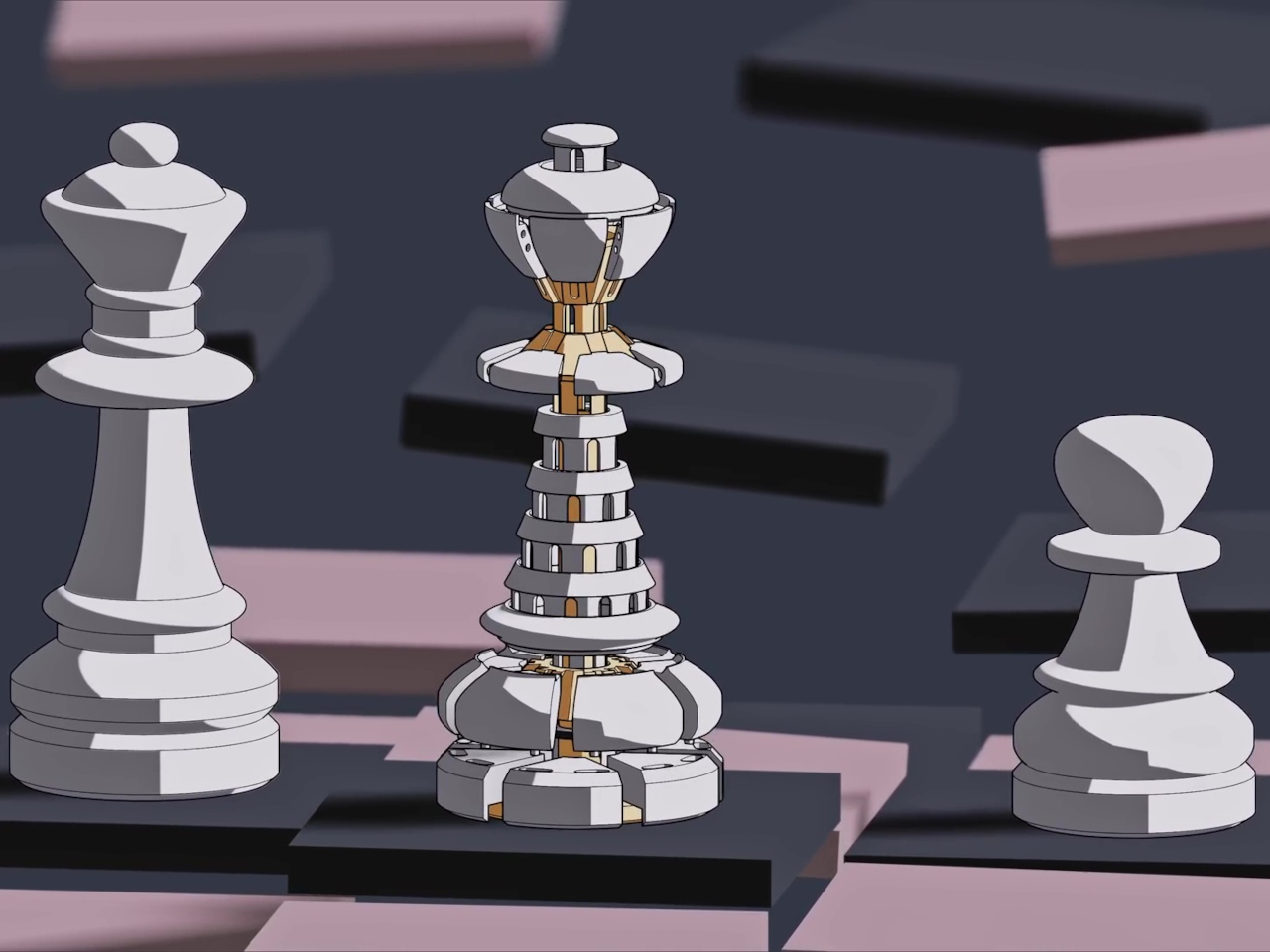

NeoSander is a mini electric reciprocating detail sander built specifically for that last 10%. It is palm-sized, cordless, and powered by a high-speed reciprocating linear motor that drives the sanding head directly at up to 13,000 strokes per minute. Instead of being a shrunken version of a big sander or a repurposed rotary tool, it starts from the question of what fine sanding actually needs: tight, controlled, straight-line motion with minimal vibration and maximum access to awkward spots.

Designer: HOZO

Click Here to Buy Now: $69 $99 ($30 off). Hurry, only a few left!

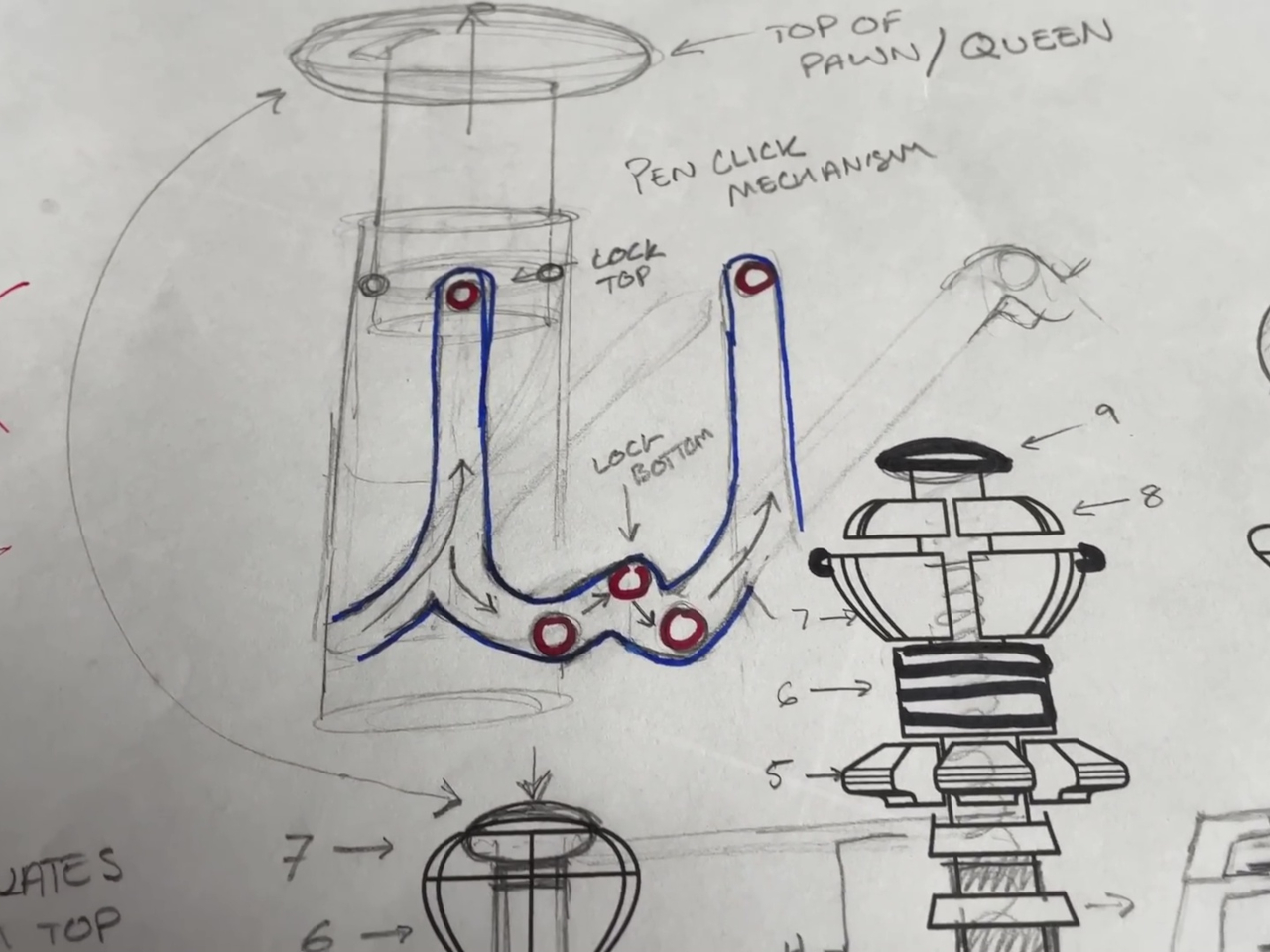

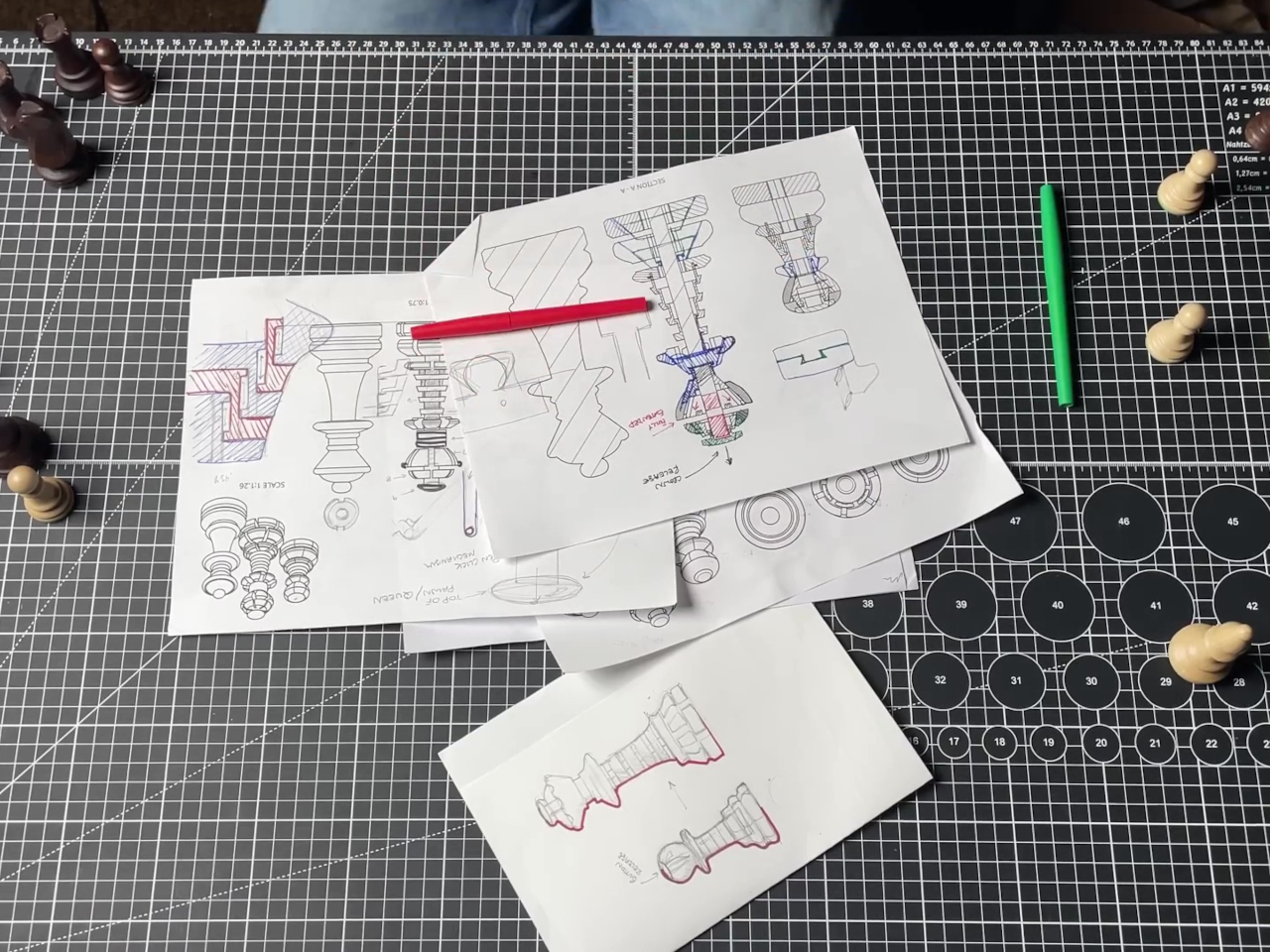

The usual reciprocating design relies on a spinning motor, gears, rods, and linkages that convert rotation into back-and-forth motion. NeoSander’s vertical linear motor pushes the head directly, which means fewer moving parts, less energy lost in the drivetrain, and faster response when you change speed. The stroke length is adjustable from 0.6 to 1.8 mm, so you can dial in tiny, precise taps for delicate edges or longer, faster strokes for leveling and shaping thicker material. As the one and only palm-sized detail sander to achieve a true 13,000 SPM linear motor, NeoSander introduces life-changing technology and delivers a game-changing breakthrough for creators who demand precision in tight, intricate spaces, permanently solving a pain point that rotary tools and other reciprocating sanders have struggled with for decades.

NeoSander’s straight-line motion covers more area efficiently while keeping the workpiece safe from gouges. At 13,000 strokes per minute, it is fast, but the motion is tight and controlled, so it does not kick back like a rotary bit or eat into fragile prints and resin parts. Stepless speed control lets you push forward for low speed and pull back for full speed, giving pinpoint accuracy on fragile edges and more aggressive removal when you are shaping parts that need heavy correction.

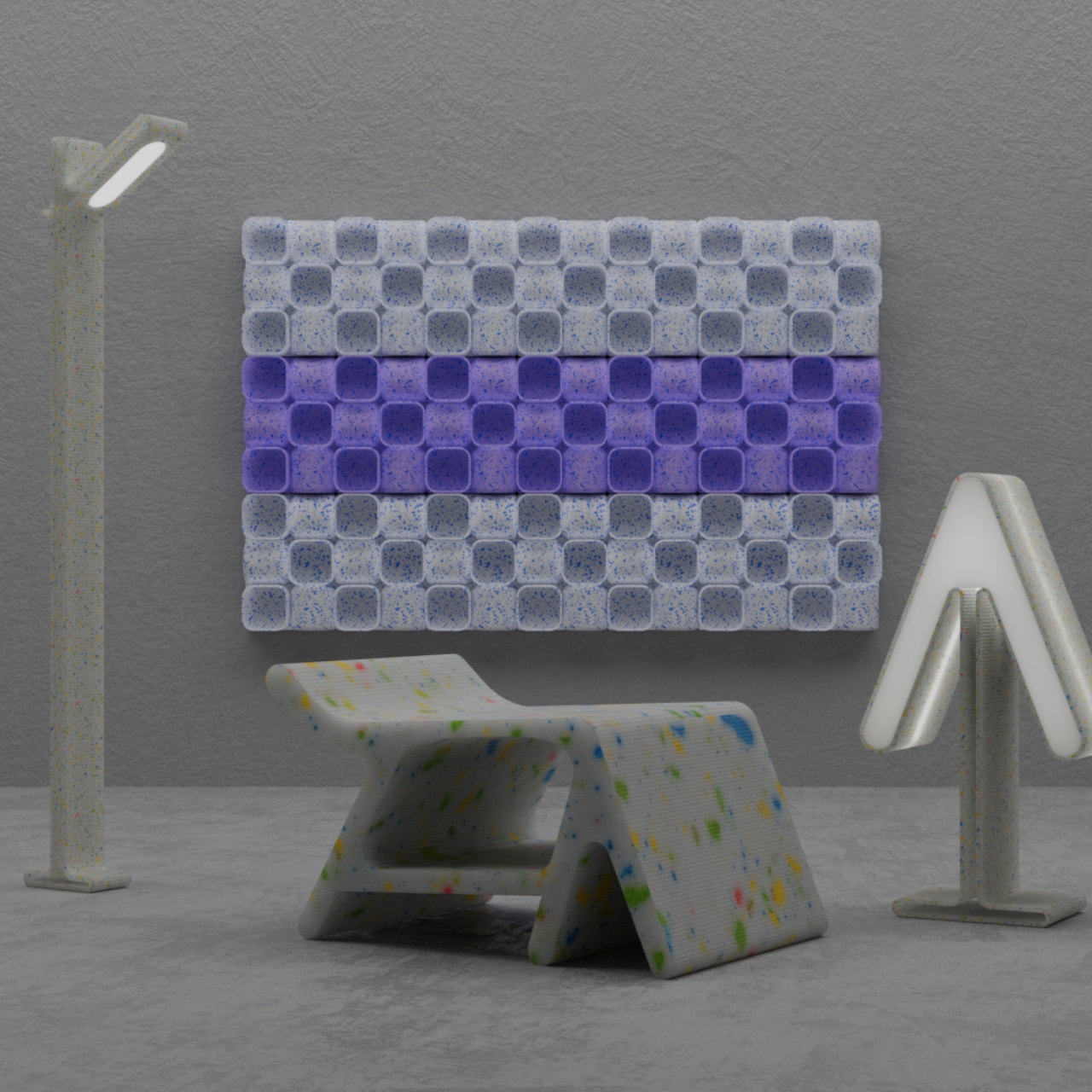

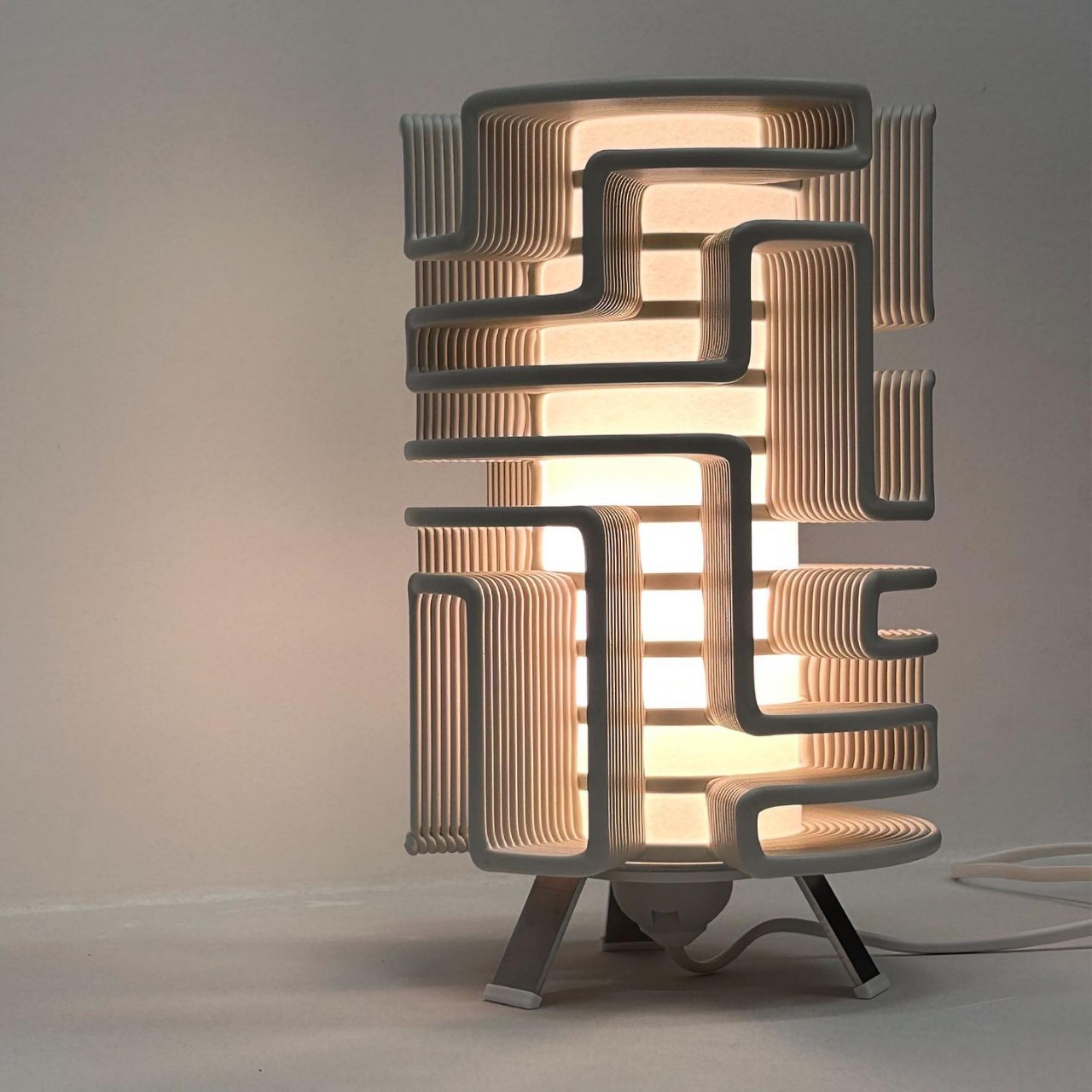

The front end is where the system gets smart. Eight interchangeable sanding heads handle different shapes, pointed tips for crevices, slim and wide flats for edges and planes, half-cylinders and arcs for curves, and acute and right angles for corners. Pair that with eight grits of sandpaper, from rough 180-grit to fine 1,500-grit, including foam-layer sheets that flex to irregular surfaces. A color-coded storage block keeps head-and-grit combos sorted, so you can grab, snap, and keep working instead of playing peel-and-stick roulette between every pass.

The same back-and-forth motion that sands also drives a tiny reciprocating saw. Swap to a curved saw blade or jigsaw-style blade, and you can cut sprues, trim parts, or slice small pieces of wood and plastic without changing tools. The 0.2 mm micro teeth use a wave-shaped, double-tooth pattern and an anti-binding design that clears dust as it cuts, making passes smoother and less likely to jam mid-stroke. It turns NeoSander into a dual-purpose tool for both cleanup and small fabrication tasks.

NeoSander feels light in the hand, a 3.13 oz aluminum-alloy shell with a dustproof silicone cover and IP54 splashproof rating, small enough to guide with fingertips. Inside, a counterweight moves opposite the sanding head to cancel most vibration, so your grip stays steady instead of buzzing. The cordless design uses a 3.7 V, 1,100 mAh battery with dock charging, giving around 45 minutes of heavy-duty use or up to 240 minutes of lighter work between 30-minute charges, which is enough for multiple sessions without tethering to a cable.

A tool like this changes the rhythm of making. Instead of dreading the cleanup phase, you have a small, precise machine that can sneak into tight spots, swap heads and grits without breaking flow, and even handle tiny cuts when you need them. For people who live in the world of miniatures, prints, and fine edges, NeoSander feels less like a gadget and more like the missing link between rough shaping and the moment a piece finally looks finished, where the details stop feeling like tedious cleanup and start feeling like the reason you made the thing in the first place. Novices and casual makers will appreciate the accessibility and beginner-friendly NeoSander Pro kit at $69, while those who really want to take their designs to the next level will want to grab the $129 NeoSander Premium Kit, which adds accessories like multi-color sanding heads, saw heads, and a charging dock on top of the basic set.

Click Here to Buy Now: $69 $99 ($30 off). Hurry, only a few left!

The post This Reciprocating Detail Sander Works on Detailed Projects like Gundam Kits, Wood, and Jewelry first appeared on Yanko Design.