Ken Pillonel takes consumer satisfaction a little too seriously. Famous for hacking previous versions of the AirPods to give them USB-C ports and make them more repairable, Pillonel has now turned his sights to the AirPods Max (which hasn’t received an update in over 3 years, as he points out). The regular AirPods and even the iPhone have both made a concerted shift to USB-C, but Apple surprisingly forgot to upgrade their flagship headphones, leaving it in the lightning era.

No stranger to hacking (ahem, upgrading) Apple’s accessories, Pillonel decided to build a USB-C AirPod Max before Apple did. The video above takes us through the journey, showing how Pillonel disassembled the existing AirPods Max, designed a new PCB with a USB-C port, and mounted it (with relative ease) in the headphones, giving them the upgrade they severely needed. The best part, Pillonel even sells his PCBs on his own website, encouraging other people to hack their AirPods Max too and upgrade them to USB-C.

Designer: Ken Pillonel

The AirPods Max debuted in December 2020, which means they’re one of the only mainstream Apple products to not have received a major upgrade in years (they were announced even before the AirTag). Realizing that now was a better time than ever, Pillonel decided to take his AirPods Max for a spin, cracking them open to see the assembly inside and whether it would be easy to upgrade it. Luckily, the lightning port was relatively easy to upgrade without any invasive procedures to the headphone’s body itself. Apple designed the port with a removable metal lip that allowed it to magically become wider (it’s almost as if Apple was preparing for this transition in advance), and knocking the lip out made the hole perfectly sized for a USB-C port.

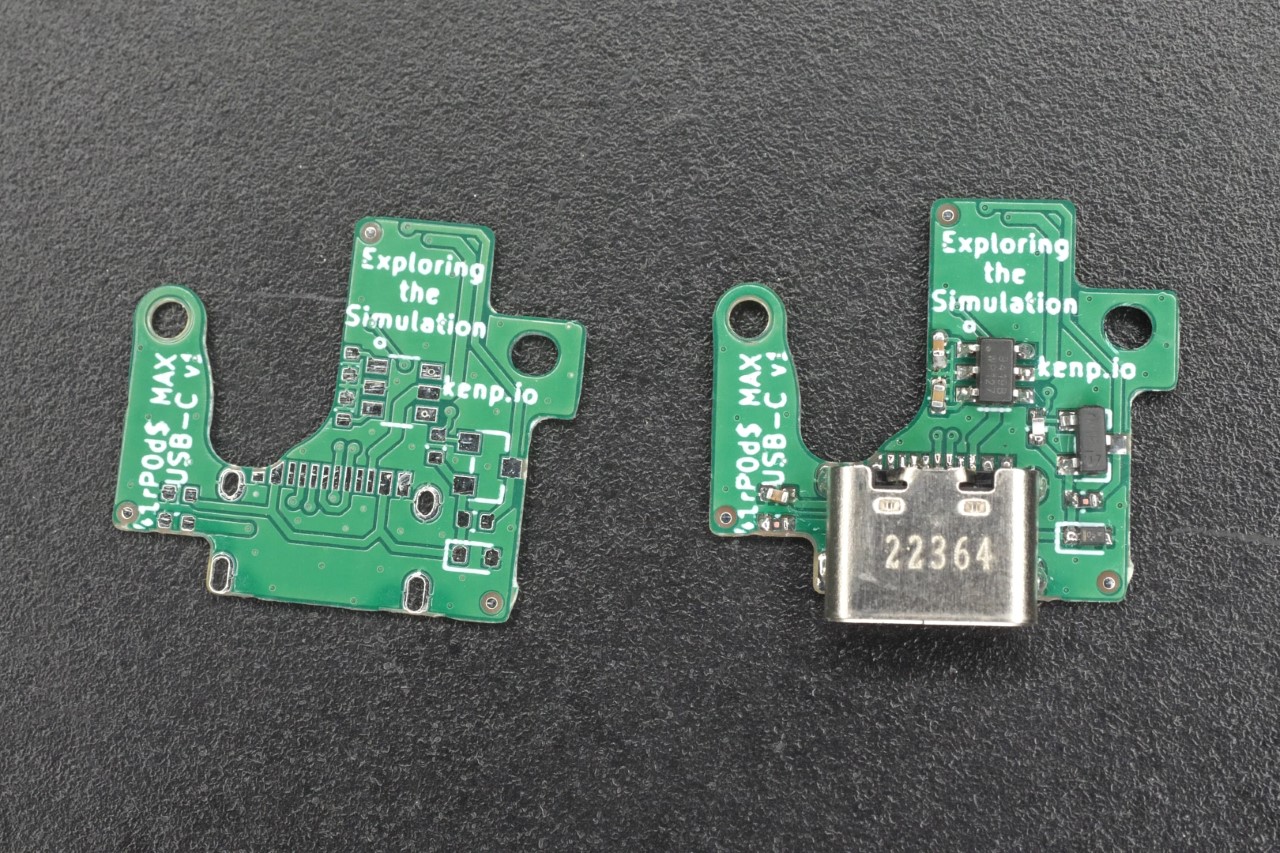

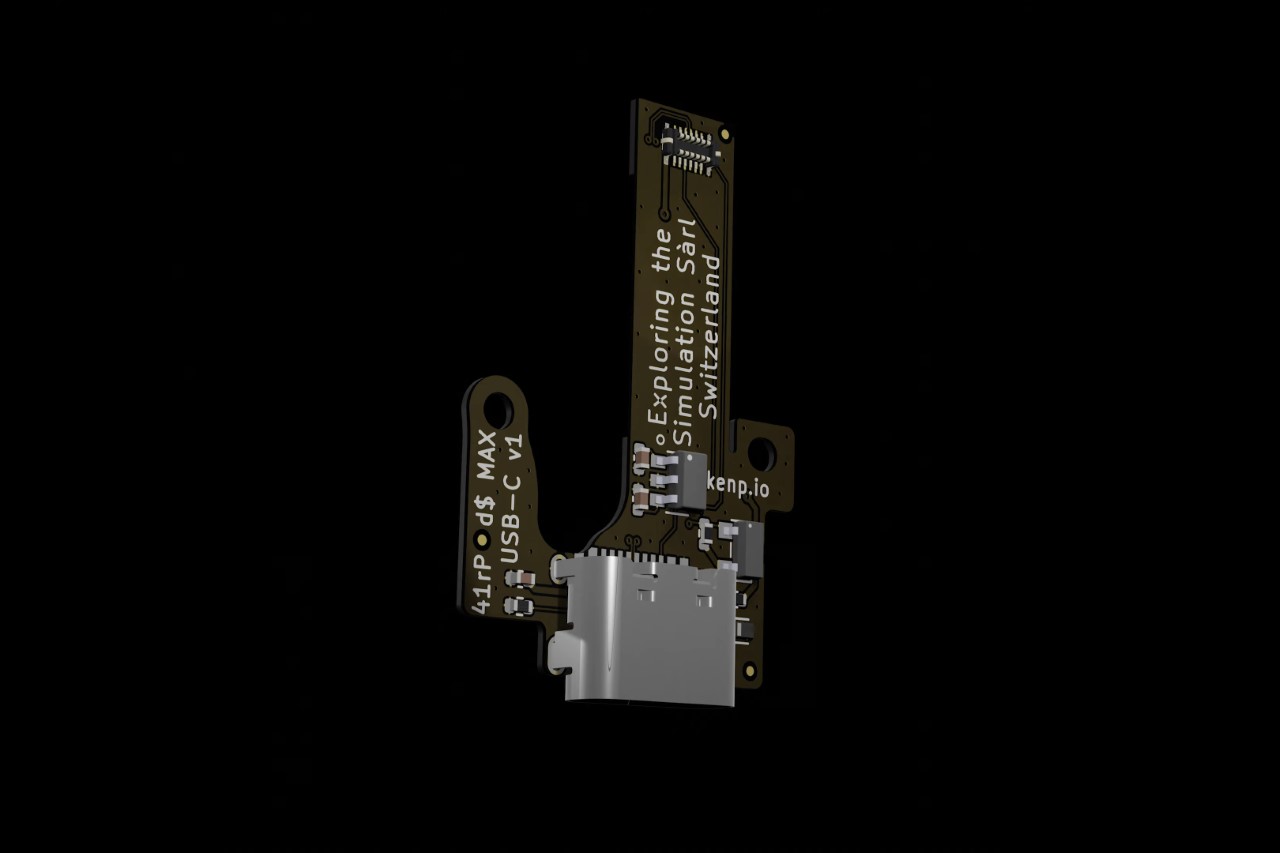

Pillonel simply unplugged the lightning connector from the existing motherboard and designed a new one that housed the USB-C port. He shared the new PCB design on PCBWay, and had the circuit boards sent to him. An older iteration featured a single-piece PCB that worked, but was susceptible to wear and tear, so Ken redesigned the PCB with a flexible ribbon cable, allowing it to bend without applying pressure on certain parts. The new PCB is available in Pillonel’s shop for 39.9 CHF ($45.3 USD).

The older PCB was prone to wear and tear if used roughly

A flexible ribbon cable on the new PCB made it much more resistant to regular daily usage

The upgraded AirPods Max (Pillonel calls it the AirPods Max 2.0) only has the one design upgrade, although knowing Pillonel, he’ll soon make the entire thing repairable and probably even figure out how to replace batteries on them. You can visit his YouTube channel here, or read our coverage on his other interesting projects here.

The post Apple AirPods Max get a USB-C port thanks to this clever engineering hack first appeared on Yanko Design.