As a self-proclaimed EDC aficionado, there’s a certain joy to writing about knives, but there’s an even bigger joy to actually see them be built. If you fancy the latter, look no further than Koss, a YouTuber who’s dedicated his life to building some of the most eclectic knives and recording the entire process for people to see and appreciate. At the end, the knife gets listed on their Etsy store, almost as a reward for the viewers, giving them the opportunity to own one of the artist’s unique works. Each knife is made just once, as Koss creates and uploads the video, creating a sense of preciousness around the knife itself.

Designer: Koss Workshop

This particular beauty is perhaps one of Koss’ most minimal designs ever. It starts off as a simple hollow rectangular copper pipe and a carbon steel billet, which Koss expertly transforms into a beautiful dagger + sheath that focuses on visual purity.

Most knives try to channel an aggressive aesthetic, given the fact that they’re weapons designed to harm and intimidate. The Copper Dagger isn’t that, it’s more of a gentleman’s letter-opener that also serves as an enemy-opener too… which explains why it looks as minimal as it does. The knife eschews any unnecessary detail, relying simply on showcasing its materials. There’s no pocket-clip, no jimping, not even as much as a textured grip. Just a beautiful dagger-point blade with a fuller groove running along the center to provide stiffness and character.

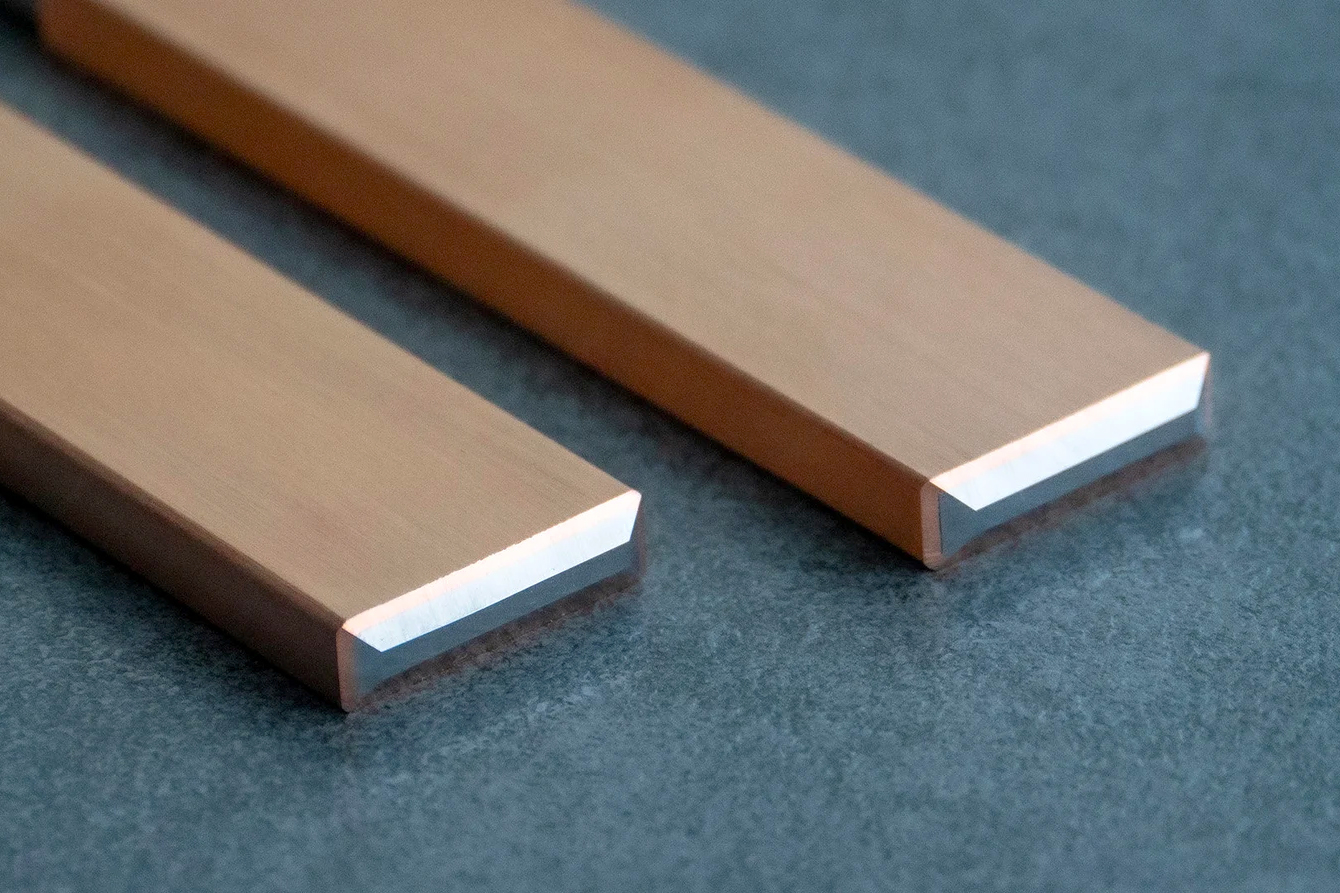

A closer look at the carbon-steel blade and the fuller groove running from tip to grip.

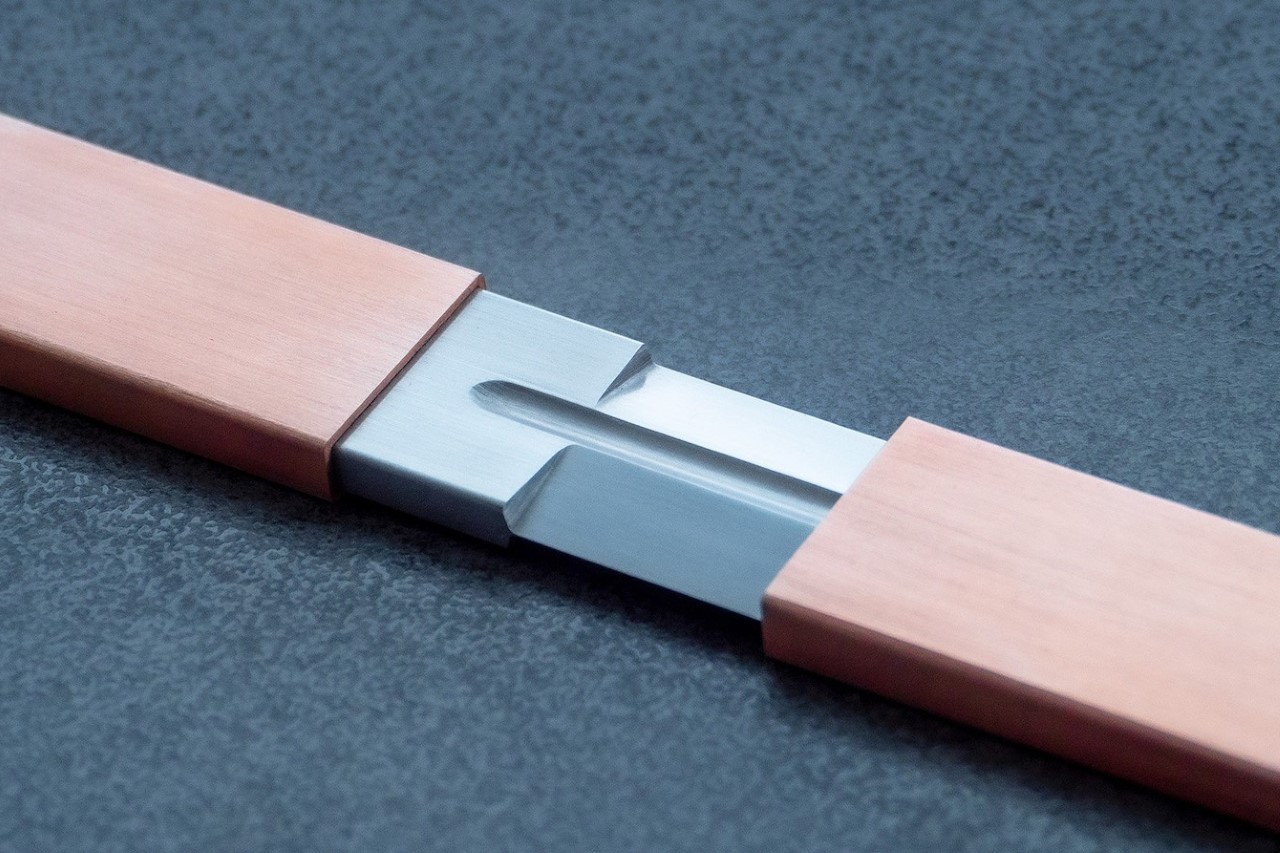

Building the knife is a process that borders on sheer artistry too. Koss starts with a rather rusty-looking billet of steel, which he cuts, machines, sands, and hardens into the blade of the dagger. The dagger’s dimensions are machined to absolute precision, designed to fit snugly into the copper pipe he sourced too. Once ready, Koss soft-hammered the pipe over the dagger, ensuring a tight, glue-less and screwless fit. The full-tang blade then got a bit of sanding done on the back, revealing both the metals with a neat bevel detail.

Sadly, the Copper Dagger didn’t last too long on Koss’ Etsy store. Priced at $420, the dagger saw an immediate buyer who snagged this minimalist beauty. However, if you’ve got the tools and the energy, the YouTube video above should serve as a how-to guide if you want to build your own EDC knife too!

The post This gorgeous Copper and Carbon Steel Dagger is a Masterclass in Minimalism first appeared on Yanko Design.