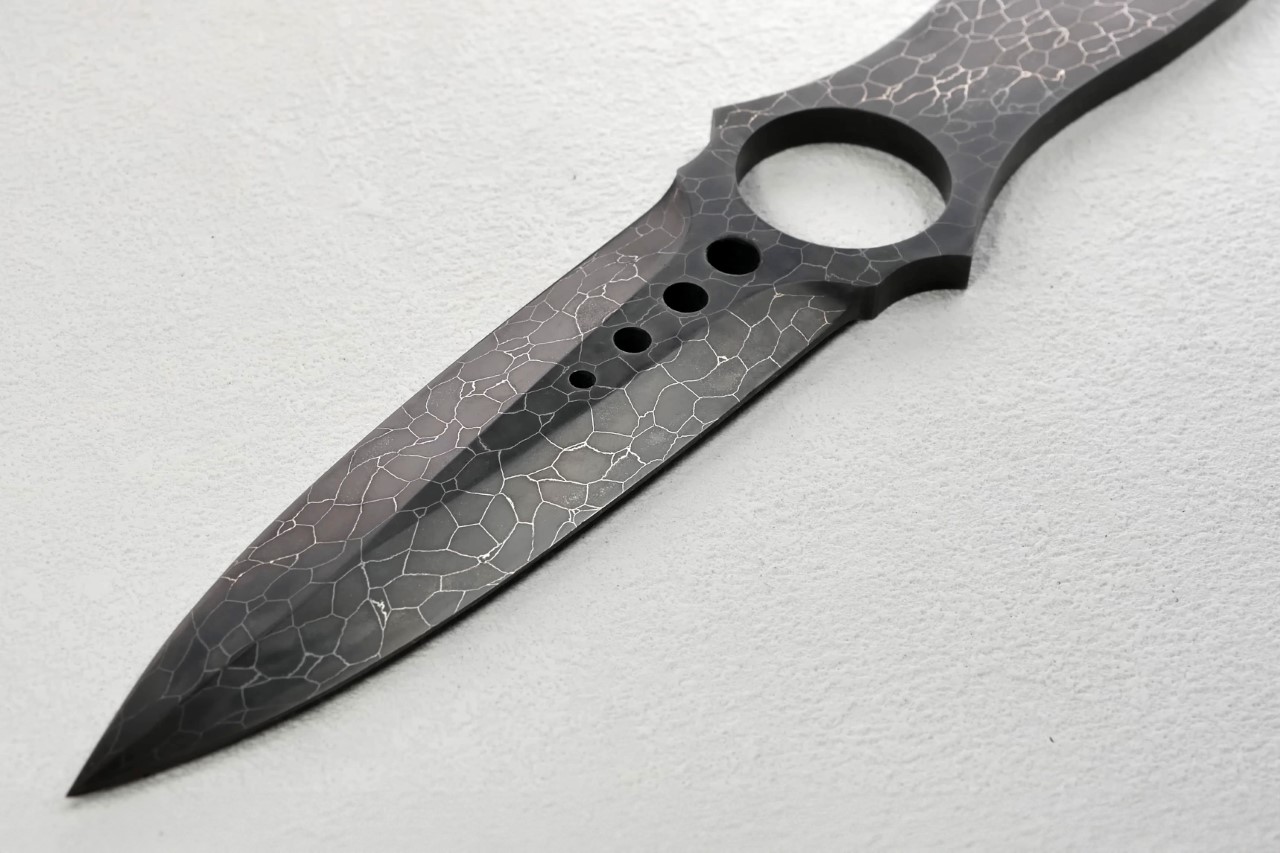

With each knife having a pattern that is unique to it, almost like its own fingerprint, the Greno puts the beauty of hand-forged VG-10 Stainless Damascus steel in your grip, giving you a knife that’s equal parts magnificent and masterful.

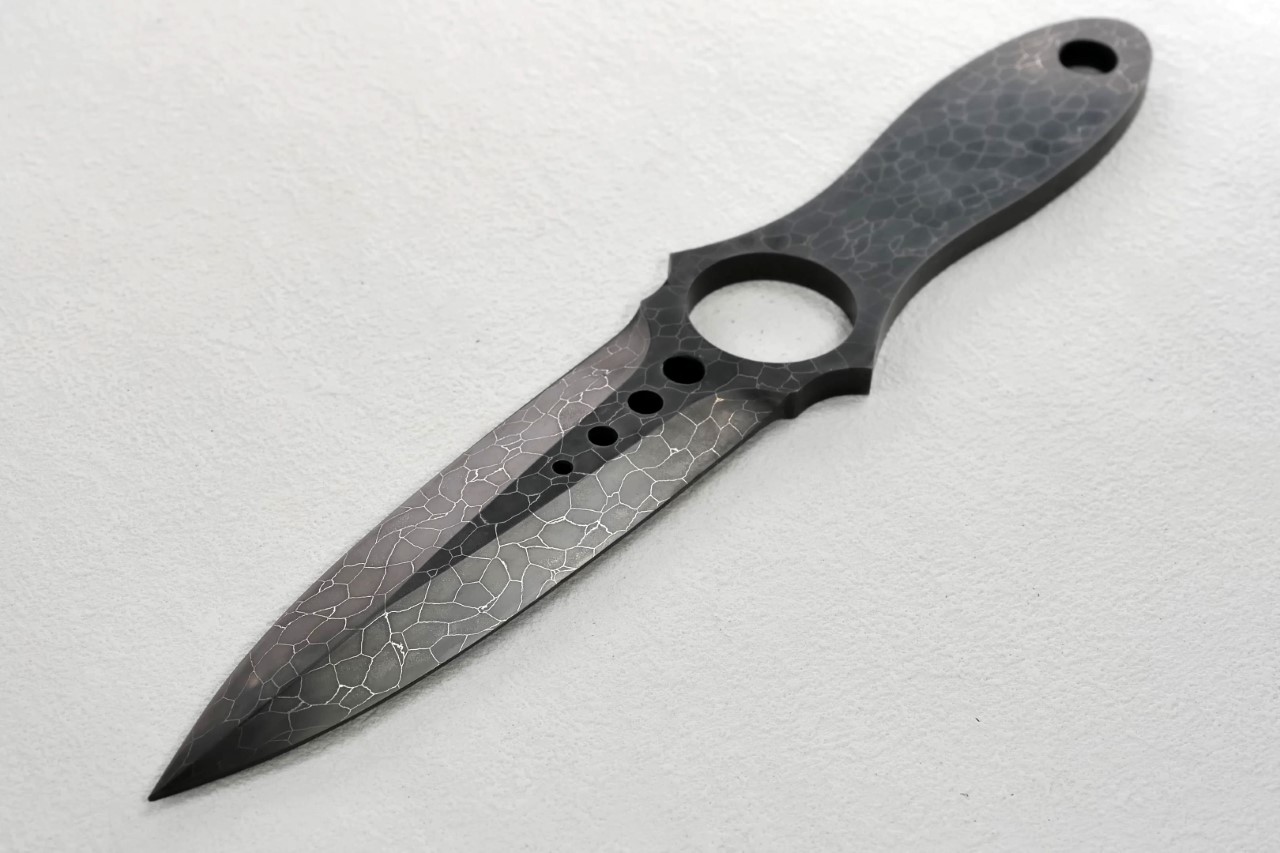

They say that the true process of making Damascus steel was lost to history, although the art has certainly flourished again, with a lot of forgers building their own techniques of making the gorgeously marbled metal. One such creator is Shaggs LLC, the designer and builder behind the Greno – a hand-forged fixed-blade knife with perhaps one of the most unique-looking marbled steel blades we’ve seen. While most Damascus steel blades rely on a dual-color design that highlights the marbling, the Greno is different. It employs VG-10 steel – a premium cutlery-grade stainless steel produced in Japan, which results in a marbling quite like no other. Add that to a 4.5-inch blade with a 4.3-inch handle and you’re left with a knife that doesn’t disappoint. When not in use, the Greno is an art piece, a visual representation of a one-dead handicraft… and when in motion, it’s a knife designed to dominate and get the job done every single time.

Designer: Shaggs LLC

Click Here to Buy Now: $55. Hurry, only a few left!

Measuring a staggering 9 inches from tip to end, the Greno is fairly larger than any of the flippers or folders we feature here. It comes with a fixed blade design too, and ships with a Top Grain Italian cow leather sheath to help you carry it around wherever you go. The knife’s handle comes crafted from green Micarta, used extensively in the knifemaking industry for its durability, balanced weight, and the unique texture it provides to the handle, giving it a superior grip. To supplement this, the Greno’s handle boasts an ergonomic grippy design that’s innately ambidextrous, allowing you to grab it confidently as you maneuver its crown jewel – that spectacular blade.

A self-taught knifemaker, Shaggs managed to master the art of forging Damascus steel, although their experiments with the Greno are different from any other Damascus steel you’d find on the market. To state things plainly, a lot of the Damascus steel you see today is simply a laser-etched marbling pattern on regular steel. True Damascus steel is created by folding and forging two different kinds of steel together, before acid-etching the blade to reveal a zebra-like pattern. Greno’s take on Damascus steel is similar, but the results are stunningly different. The blade shimmers with a chrome-like finish, but instead of being dual-colored, comes with contour lines, almost like the knife has its own fingerprint.

The blade itself has a drop-point design, a very popular template in the knife world. With a long 4.5-inch edge that culminates in a sharp tip, the Greno is perfect for pretty much any indoor or outdoor tasks. Whittling wood, slicing paracord, cutting meat or veggies, and self-defence, the Greno’s blade holds up remarkably well to any form of abuse. The VG-10 steel is inherently corrosion-resistant and has remarkable edge retention, which means spending more time using the knife and less time sharpening it. The rest of the blade travels through the handle, or what the industry calls a ‘full tang’ format. This effectively boosts the knife’s overall durability and allows you to lean into the Greno while using it. The full tang design means being able to apply forward and downward pressure with ease, along with also being able to twist your knife while using it to do things like open metal cans or gut your hunt.

When all’s said and done, the knife slides right into its cowhide sheath, which encases the blade so it doesn’t accidentally hurt anyone. Owing to its large size, the Greno definitely doesn’t come with a pocket clip, but it does boast a lanyard hole at the end of the handle, allowing you to loop a paracord or lanyard through the knife to make it easy to carry around with you on outdoor trips, whether it’s camping, hunting, or even showing off to your EDC-enthusiast friends!

Click Here to Buy Now: $55. Hurry, only a few left!

The post This hand-forged Damascus Stainless Steel Knife boasts a spectacular mirror-finish marbled blade first appeared on Yanko Design.