The more buildings we put up to address the growing needs of our civilization, the more materials and energy are consumed along with a rise in waste. And these structures don’t last forever, so the unsustainable process happens over and over again. The need for more sustainable alternatives to building materials has never been greater, especially at the rate that we’re building, tearing down, and rebuilding structures. This new kind of cinder block alternative is trying to be that answer, and it’s notable not just for its composition but because of the interlocking design that makes it easy to build a wall and, when the time comes, take it down again and reuse the blocks for some other building.

Designer: Dustin Bowers

Although your typical cinder block isn’t completely harmful to the environment, they are simply wasteful and inefficient. Putting together a wall requires a lot of time, effort, and materials like mortar to give it strength, and even then it’s not that strong anyway. And if you have to, say, move the wall or remove it completely, there’s no other method other than demolishing that wall and then building a new one from scratch.

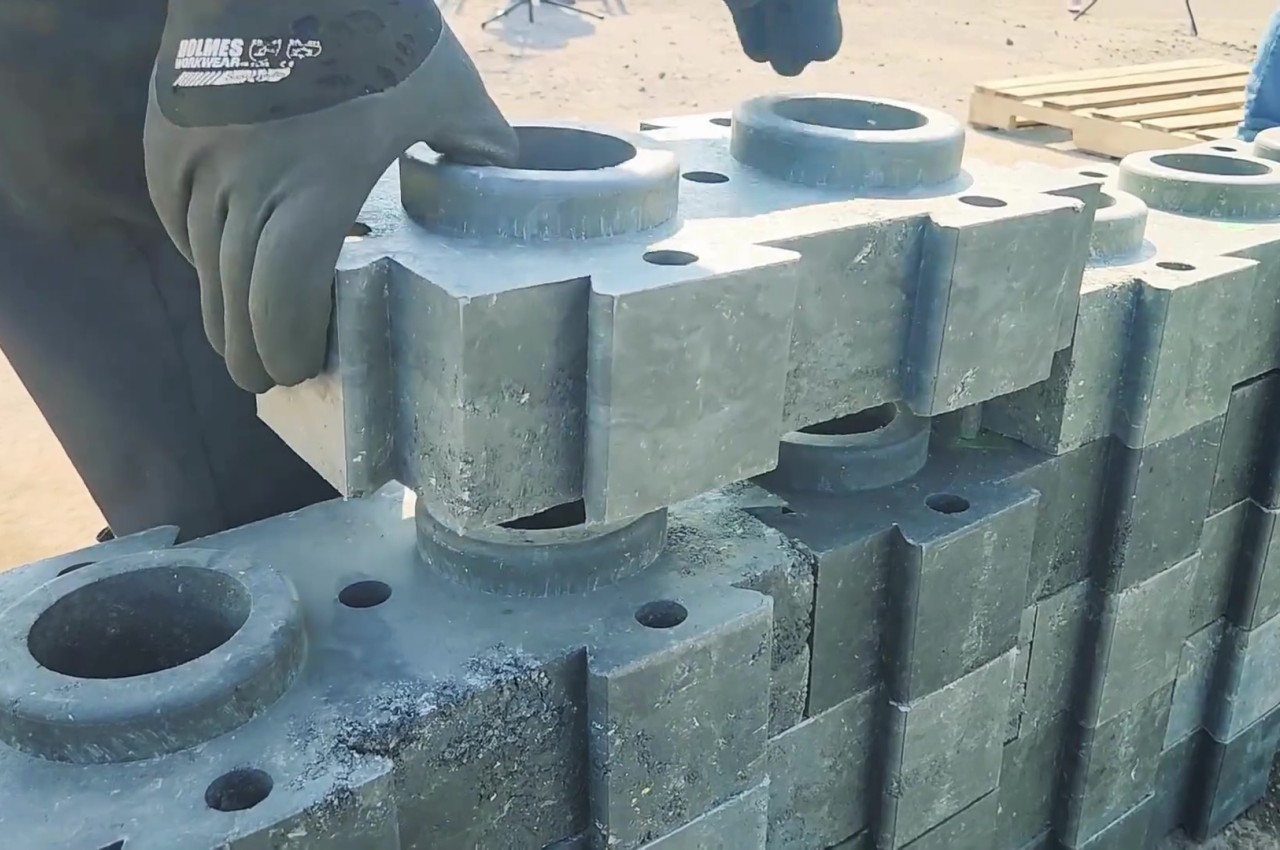

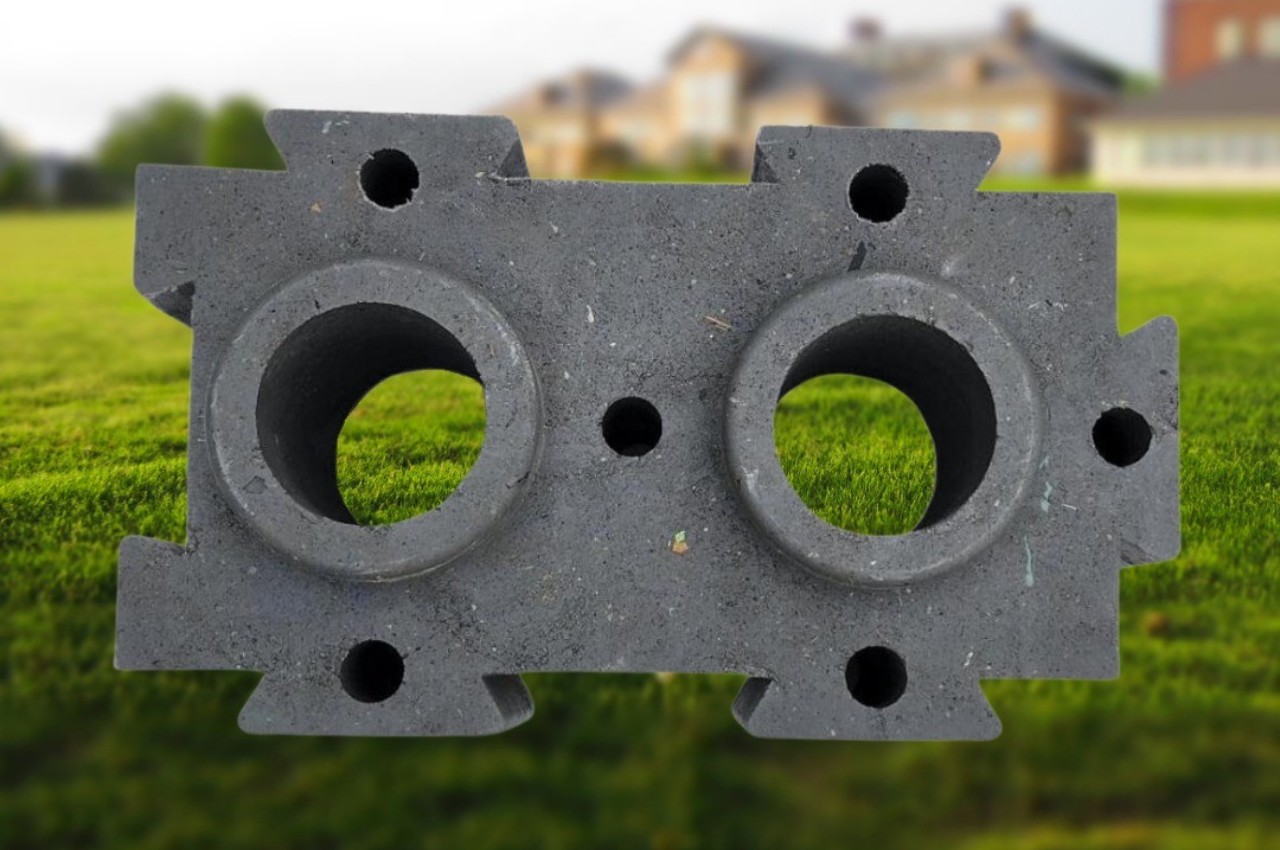

PLAEX-crete attacks the problem of concrete blocks from two angles: composition and construction. Unlike other sustainable blocks, PLAEX doesn’t hesitate to get down and dirty, using materials that are considered different to recycle, including agricultural, marine, and industrial plastic waste and aggregate waste from the construction industry. Each block is made up of more than 90% recycled waste but is 33% lighter than traditional cinder blocks while also stronger.

The material alone isn’t enough to radically change the construction industry, though. The second part of the two-hit combo that PLAEX delivers is the shape of the blocks that look like gigantic LEGO blocks. The interlocking mechanism is no joke, however, and allows workers to build up a wall twice the time as regular concrete blocks. Best of all, you don’t even need mortar or other materials to keep the blocks together, and they still end up being more solid, sturdier, and more durable than a cinder block wall.

That same interlocking design makes it possible to disassemble the blocks just as easily so that they can be reused, saving money and resources. A modification of the design has also given birth to the PLAEX LinX which supports connections at different angles for more creative shapes and constructions. At the moment, PLAEX can only be used for non-occupancy walls, but work is underway to make the material certified for homebuilding, at which point it could revolutionize the construction industry with its environment-friendly and convenient design.

The post LEGO-like concrete blocks made from waste are easy to assemble and disassemble first appeared on Yanko Design.