Amidst global concerns of exceeding the Earth’s capacity, upcycling has gained prominence as a solution, driven by conscious consumption and the circular economy’s principles. Upcycling helps reduce the amount of waste that would have made it to the landfills and repurposes items that would have been discarded, giving them a second life without degradation. It facilitates two out of the three Rs of recycling: REDUCE and REUSE.

Designer: FabBrick

Upcycling vs Recycling

Contrary to common belief, upcycling differs from recycling in that it repurposes materials without sacrificing their original quality. While recycling breaks down materials like plastic, paper, glass, and metal to produce new items, typically of inferior quality, upcycling maintains the integrity of the original materials, providing limitless opportunities to breathe new life into old items.

Upcycling

Upcycling involves gathering products or waste to repurpose or reuse, enhancing their value without breaking them down, thus maintaining their original characteristics, strength, and durability. This approach avoids any degradation of the material or product. Materials such as rubber and denim lend themselves well to upcycling, showcasing their versatility and potential. For instance, turning old jeans into patches for a blanket maintains the integrity of the denim, showcasing upcycling’s creative potential.

Recycling

Recycling involves gathering products or waste for breakdown and transformation into new items, requiring a specific process that can alter the original characteristics of the material or product. Each recycling cycle diminishes the material’s strength, and only certain materials are suitable for recycling; for instance, rubber presents challenges in the recycling process.

What are the different categories of upcycled products?

1. Electronics

Designer: Think Tank Team

Mobile devices like smartphones and tablets are now ubiquitous, yet their disposal poses environmental risks due to improper handling. Project Afterlife offers a solution by upcycling old smartphones instead of recycling them. This concept transforms devices into kinetic art objects, enhancing ambiance while conserving energy and resources. The product, resembling a taco-shaped crescent made from recycled plastic, provides an interactive platform for repurposed smartphones. With Project Afterlife, simply tilt the device to switch between different modes, like the “Endless Clock” and the “Timeline” photo stream, without touching the screen. This shows how upcycling helps the environment and makes everyday objects more valuable.

2. Textile

Designer: IKEA

In recent years, there has been a surge in supporting brands that prioritize sustainability, including upcycling and recycling materials. Ikea is joining this trend with their new collection, VÄXELBRUK, made from recycled coworker uniforms. This innovative line features 16 textile-based items, blending old uniforms with recycled materials like polyester from PET bottles. By repurposing these materials, Ikea reduces waste and offers stylish, eco-friendly products. The collection showcases how sustainability and style can go hand in hand.

3. Wood Waste

Designers: Michael and Mariel Upton

Recycling reduces landfill waste but can be energy-intensive and alter original designs. Upcycling offers a more efficient option, yet not all materials suit it. For example, discarded skateboard decks are transformed into stylish wall lamps named Heru, Cuna, and Mara. Reshaped into shorter ovals, paired with lighting hardware, and adorned with original artwork, these lamps emit a warm glow, serving as both illumination and minimalist decor, defying their original purpose.

4. Old Furniture

Designer: Christoph Kurzmann

During renovations, some opt to discard furniture instead of considering recycling. However, awareness of consumption and disposal is growing, leading to projects that repurpose items. Oxford Brookes University planned to landfill furniture during dorm renovations, but a student proposed the Upscaling Upcycling project. Disassembling existing furniture, Kurzmann created new designs, such as stackable stools and chairs from old bedframes and drawers. These pieces are well-designed and practical, showcasing the potential of upcycling to save resources and create useful furnishings.

5. PET Bottles

Polyethylene terephthalate (PET) plastic, known for its durability and lightweight nature, is commonly utilized in manufacturing containers for the food and beverage, pharmaceutical, and personal care sectors.

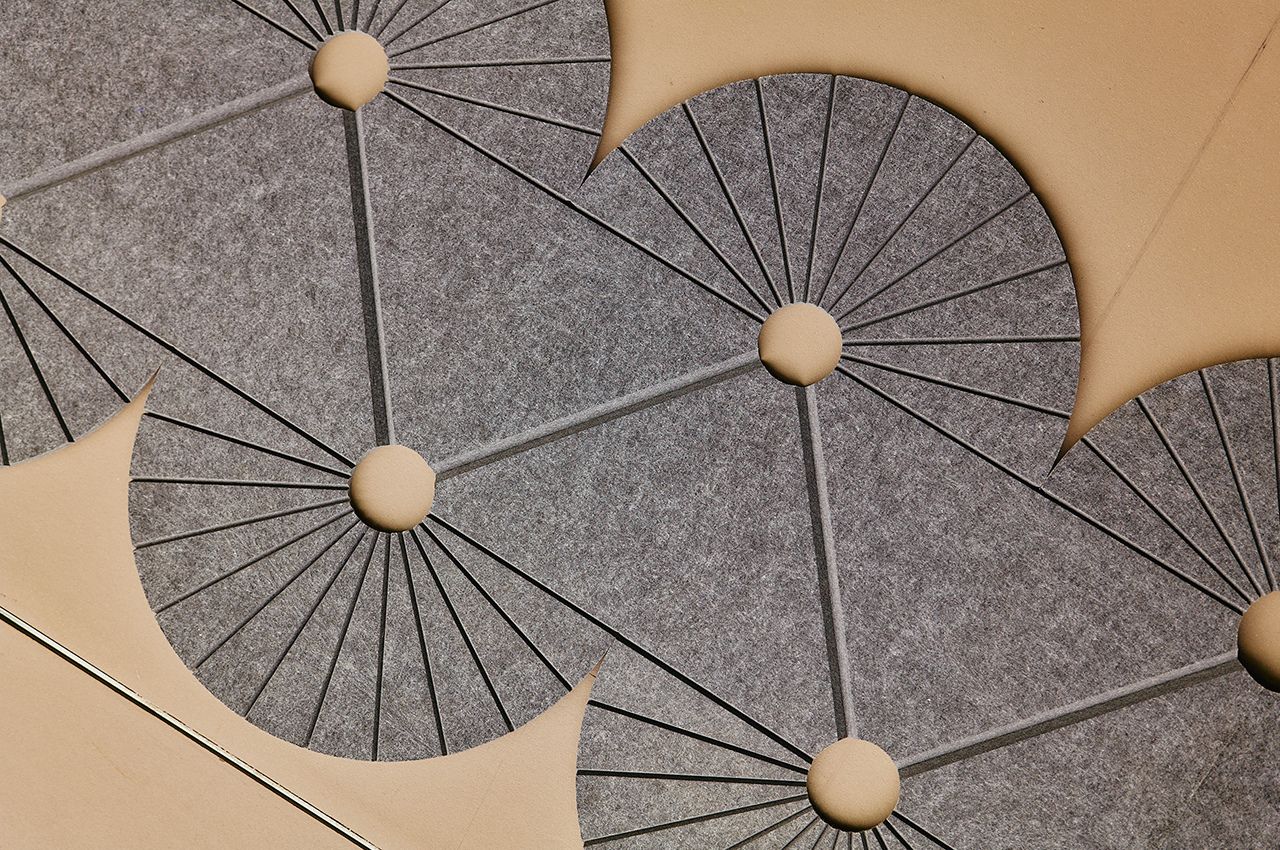

Designer: Impact Acoustic, Atelier oï

At the core of Oloïd’s innovative design is Archisonic Felt, a high-performance sustainable acoustic absorber made from upcycled PET bottles. Crafted from Archisonic Felt, Oloïd, a sustainable acoustic luminaire resulting from the collaboration between Impact Acoustic and atelier oï, exemplifies the fusion of functionality and artistic expression in modern design. This versatile material offers exceptional sound absorption while redefining the interaction between light and sound. Its Cradle-to-Cradle certification and LEED accreditation underscore its eco-friendly credentials. With 32 captivating colors curated from the Archisonic Felt range, Oloïd empowers users to personalize their spaces, seamlessly integrating organic shapes that transform two-dimensional panels into captivating three-dimensional entities. This luminaire not only sets a new standard for sound-absorbing luminaires but also stands as a testament to the potential of sustainable design in reshaping illuminated spaces.

6. Denim

Designer: Jack Spencer (Mosevic)

Researchers highlight that producing a single pair of jeans requires a staggering 7,600 liters of water, prompting global concern among ecologists about denim’s environmental impact. Textile production, notably denim, contributes significantly to water consumption, energy usage, and landfill overflow due to non-biodegradable fibers like synthetics. While recycling remains an underutilized option, upcycling emerges as a promising solution, exemplified by startups transforming old jeans into stylish sunglasses. Mosevic pioneers denim waste reduction by infusing waste denim with bio-resin to craft durable “Solid Denim” sunglasses, adorned with a natural wax finish for longevity. Despite sustainability challenges, initiatives aim to upscale production and inspire similar textile waste solutions.

7. Old Bicycles

Designer: Hyemin Kim

The 2 Stools from 1 Bicycle project repurposes old bike frames to create unique and functional stools. Each stool features a distinctive design with slanted legs reminiscent of the original bike frames, giving them a striking appearance. One stool has three legs, while the other has four, adding to their individuality. The seat is crafted from recyclable cork, in line with the project’s sustainability mission. These stools not only offer practicality and convenience but also allow people to give sentimental objects like old bikes a new lease on life. With their unconventional aesthetics and eco-friendly materials, these stools are both functional and visually appealing additions to any space.

Designer: Roy Sherizly (TOOB)

The growing popularity of bicycles in recent years has brought attention to long-standing environmental concerns associated with their components, particularly inner tubes. Despite being more eco-friendly than cars or motorcycles, bicycles still contribute to pollution due to discarded parts like rubber tires and inner tubes. The TOOB accessories line addresses this issue by repurposing useless inner tubes into practical and stylish products. Handpicked from local shops in Tel Aviv, these inner tubes undergo thorough cleaning and inspection before being transformed into items like TOOB Keychains and TOOB Straps. This upcycling initiative not only extends the lifespan of inner tubes but also supports the local bicycle economy. While inner tubes eventually wear out, TOOB’s efforts help postpone their disposal in landfills, offering a temporary solution until more sustainable alternatives are developed.

8. Cut-Offs

Designers: Anthony Frank Keeler, Sarah Coleman, Wisse Trooster

In manufacturing, there’s often excess material left unused, contributing to environmental concerns. To address this, manufacturers and designers are increasingly focusing on reducing waste and repurposing leftovers. Recycling and upcycling these materials into furniture and lighting fixtures, like Stackabl’s pendant lamps, offer sustainable solutions. Stackabl’s DIY tool allows users to customize their lamps by adjusting parameters such as length and disc diameter, resulting in unique, eco-friendly designs. Incorporating upcycled materials and energy-efficient LEDs, Stackabl emphasizes sustainability while offering personalized lighting solutions.

The post How Does Upcycling Innovate Materials? first appeared on Yanko Design.