Picture this: four robotic arms working in perfect harmony, tracing circular patterns like some kind of futuristic dance performance. But instead of creating art, they’re printing the walls of an actual farm. Welcome to Itaca, a project that just wrapped up its construction in the hills of Northern Italy, and it’s changing how we think about building homes.

WASP, the Italian company behind this audacious venture, just finished printing the walls of what they’re calling the first certified 3D-printed construction in Italy. Located in their Shamballa open-air laboratory, Itaca isn’t just a quirky experiment. It’s a fully functional, self-sufficient farm designed to house a family of four while producing its own food and energy.

Designer: WASP

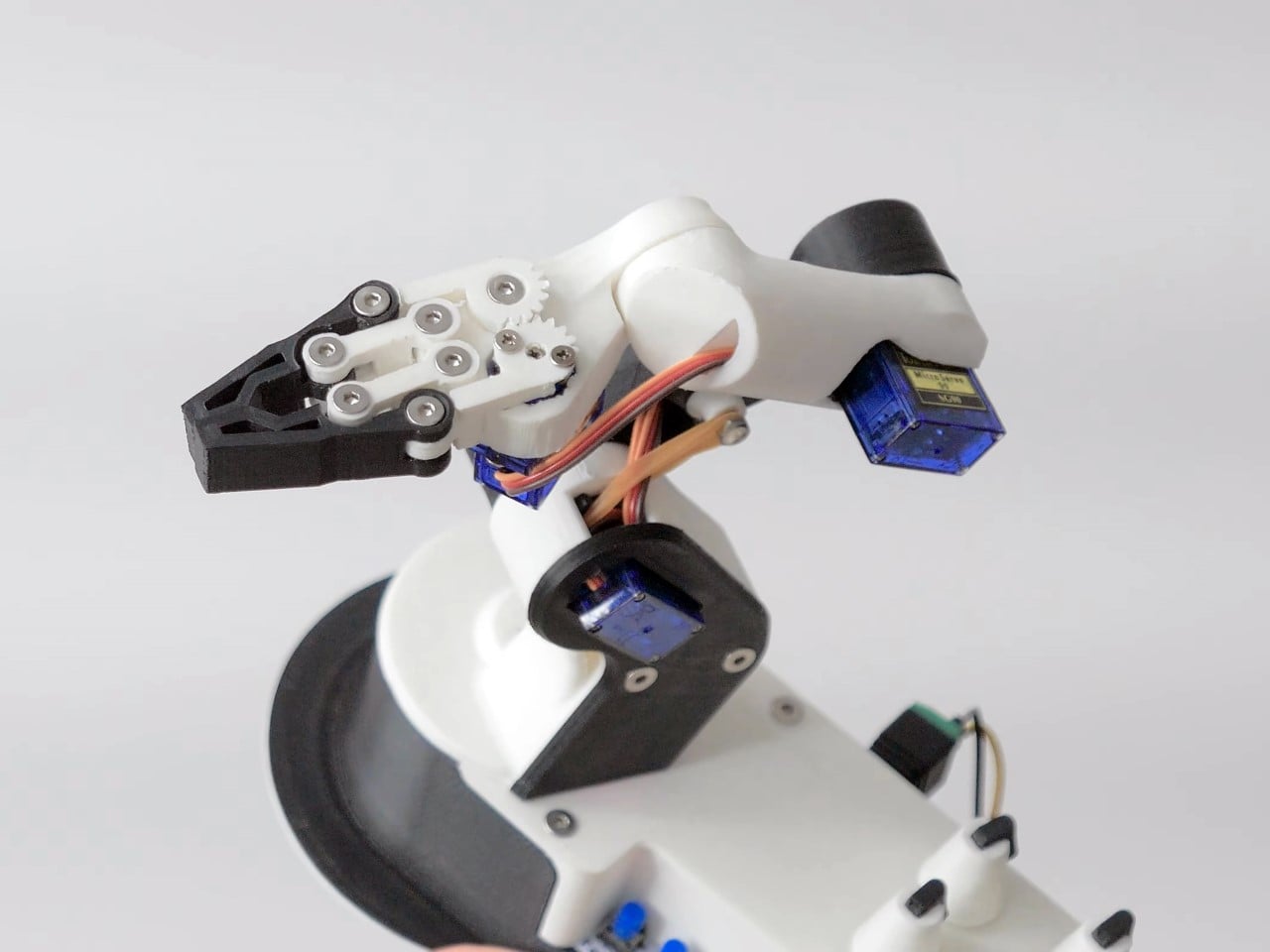

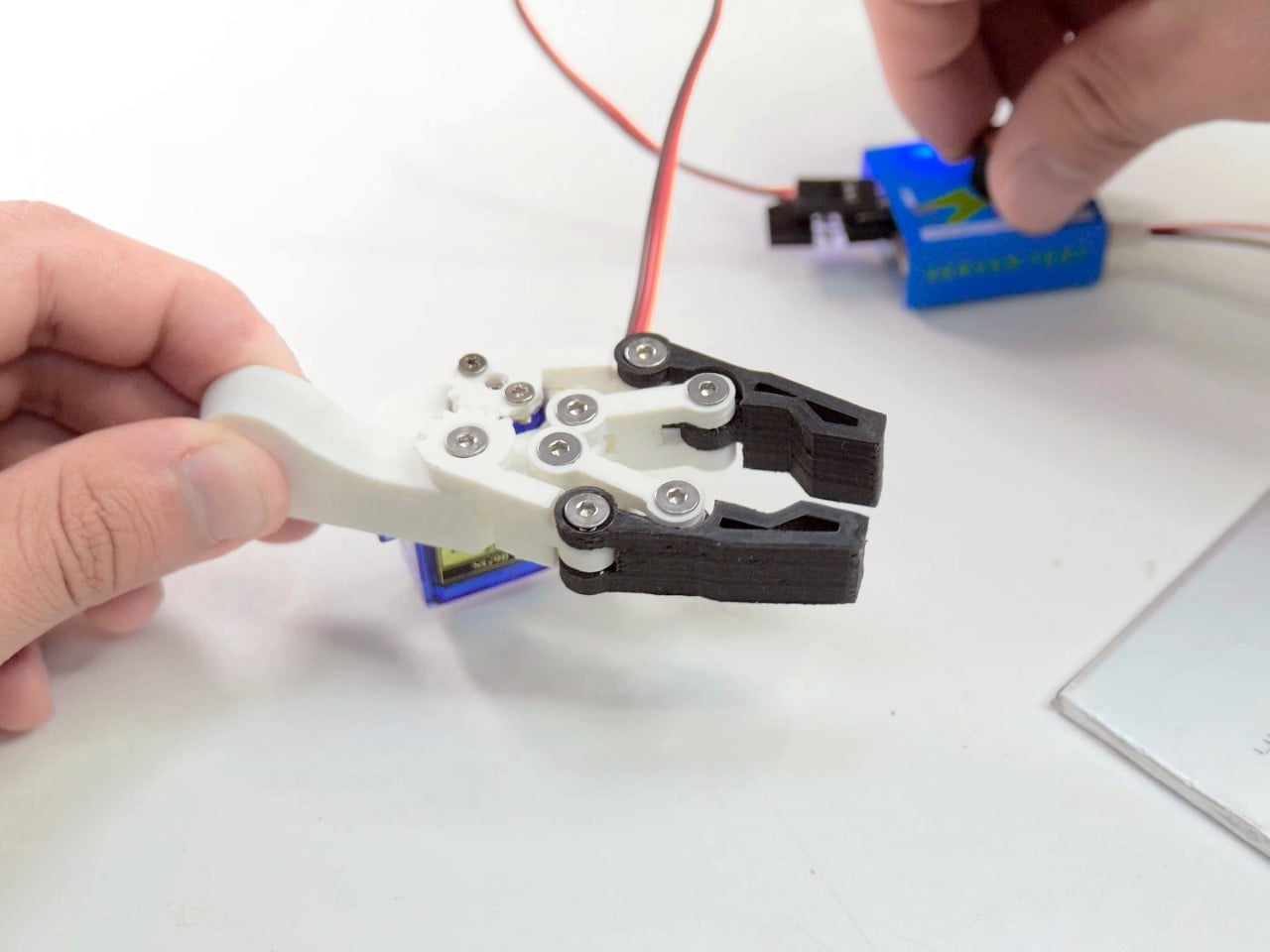

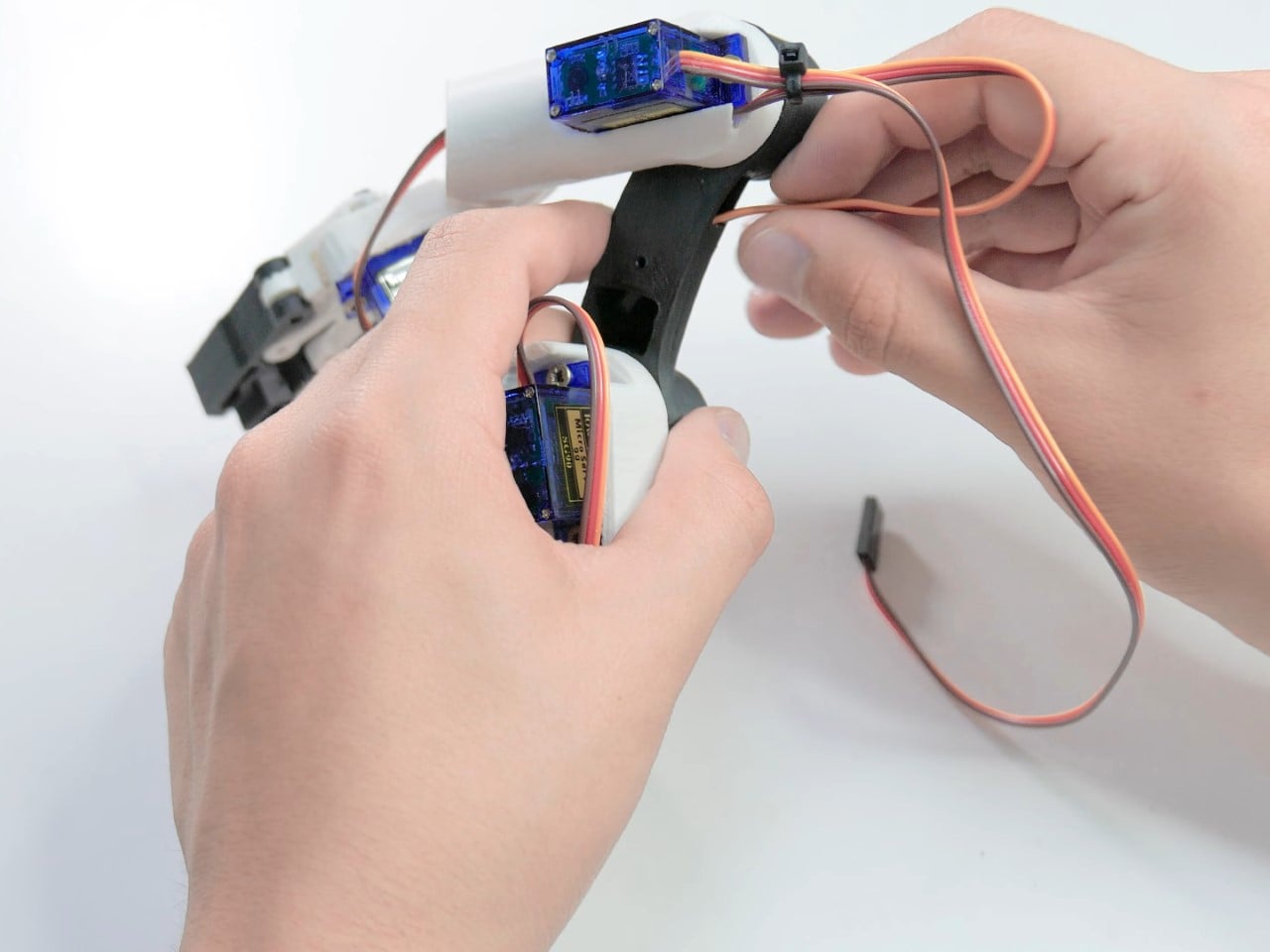

The whole concept sounds like something from a sci-fi novel, but the execution is surprisingly grounded in ancient wisdom. The farm’s design takes inspiration from mandala geometry, with four robotic arms positioned at the vertices of a hexagonal structure. These machines use a lime-based printing material that allows the facades to regulate their temperature naturally, breathing like a living organism. No air conditioning required.

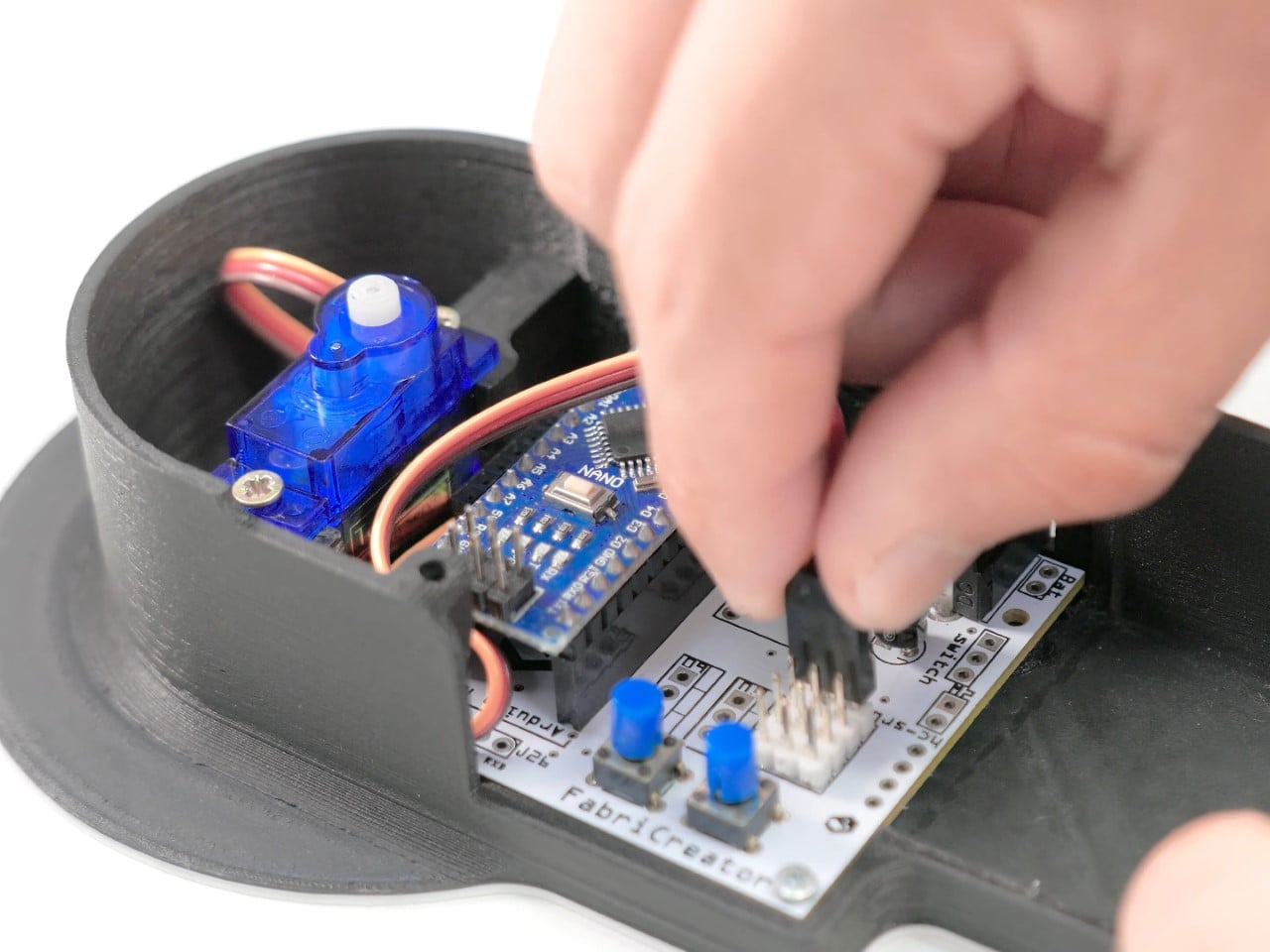

What makes Itaca genuinely fascinating is how it challenges our assumptions about both technology and sustainability. The walls aren’t just printed and left hollow. They’re packed with rice husks sourced from agricultural waste, creating natural insulation that keeps the interior comfortable year-round. The radiant heating systems and electrical installations are embedded directly during the printing process, which means less construction time and fewer workers needed on site.

But WASP didn’t stop at the structure itself. They’ve integrated 3D-printed vertical hydroponic systems that ensure fresh vegetables all year round using minimal water. The entire setup operates on a circular micro-economy model, where waste from one system becomes fuel for another. It’s the kind of closed-loop thinking that environmentalists have been advocating for decades, finally made tangible through advanced manufacturing.

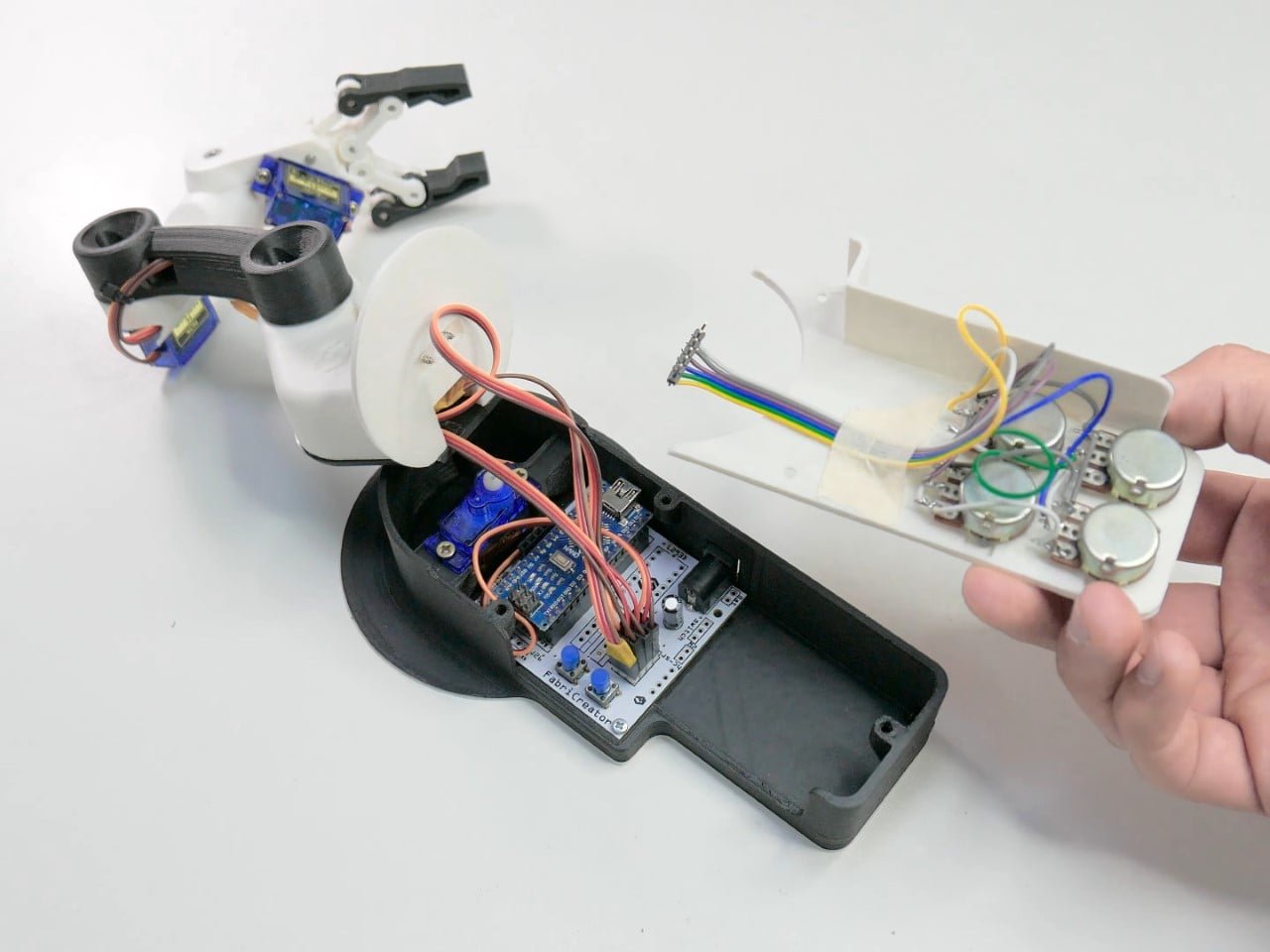

Massimo Moretti, WASP’s founder, first unveiled Itaca at Italian Tech Week in Turin as part of the company’s broader vision to democratize sustainable housing. The real genius here is accessibility. The Crane WASP system used to build Itaca is designed to operate even in remote areas, making it possible to replicate this model worldwide. You don’t need massive infrastructure or armies of specialized construction workers. Just the machine, locally sourced materials, and the digital blueprints.

This approach to construction could be transformative for communities dealing with housing shortages or natural disasters. Traditional building methods require extensive supply chains, skilled labor, and months of work. With 3D printing, the timeline compresses dramatically, and the environmental footprint shrinks considerably. Using local materials means less transportation, fewer emissions, and buildings that are naturally suited to their climate. The ventilation system deserves special attention too. It’s designed to allow air to flow through the interior spaces continuously, transforming Itaca into what WASP calls a living house. This isn’t just clever branding. The structure literally responds to environmental conditions, adjusting naturally without mechanical systems that consume energy and break down over time.

What’s striking about Itaca is how it sidesteps the typical debate between high-tech solutions and traditional wisdom. It’s both. The robotic arms and digital design tools represent cutting-edge technology, while the materials and principles draw from centuries of vernacular architecture. Rice husks and lime have been used in construction for millennia because they work. WASP 3D Build, the startup within WASP dedicated to printed construction, executed the project using technology that’s already proven and available. This isn’t a prototype languishing in a research lab. It’s a real building that people will actually live in and farm around. That’s the difference between innovation theater and genuine progress.

The implications extend beyond individual homes. If this model scales, it could reshape how we approach rural development, affordable housing, and disaster relief. Instead of shipping prefabricated structures across continents, communities could print buildings on demand using materials from their own backyards. The rapid transmission of information through digital files means a successful design in Italy could be adapted and printed in Peru or Indonesia within weeks. Itaca represents something rare in architecture: a project that’s simultaneously visionary and practical, high-tech and humble. It proves that sustainability doesn’t require sacrifice or compromise. Sometimes it just requires thinking differently about the tools we have and the wisdom we’ve inherited.

The post Four Robot Arms Just Built a Farm House That Prints Its Future first appeared on Yanko Design.