Remember when camping meant wrestling with tent poles at dusk while mosquitoes feasted on your ankles? Or trying to decipher those cryptic instruction diagrams that somehow never matched the pile of canvas and metal at your feet? Well, South African brand Alphago just released something that makes all that struggle feel wonderfully obsolete.

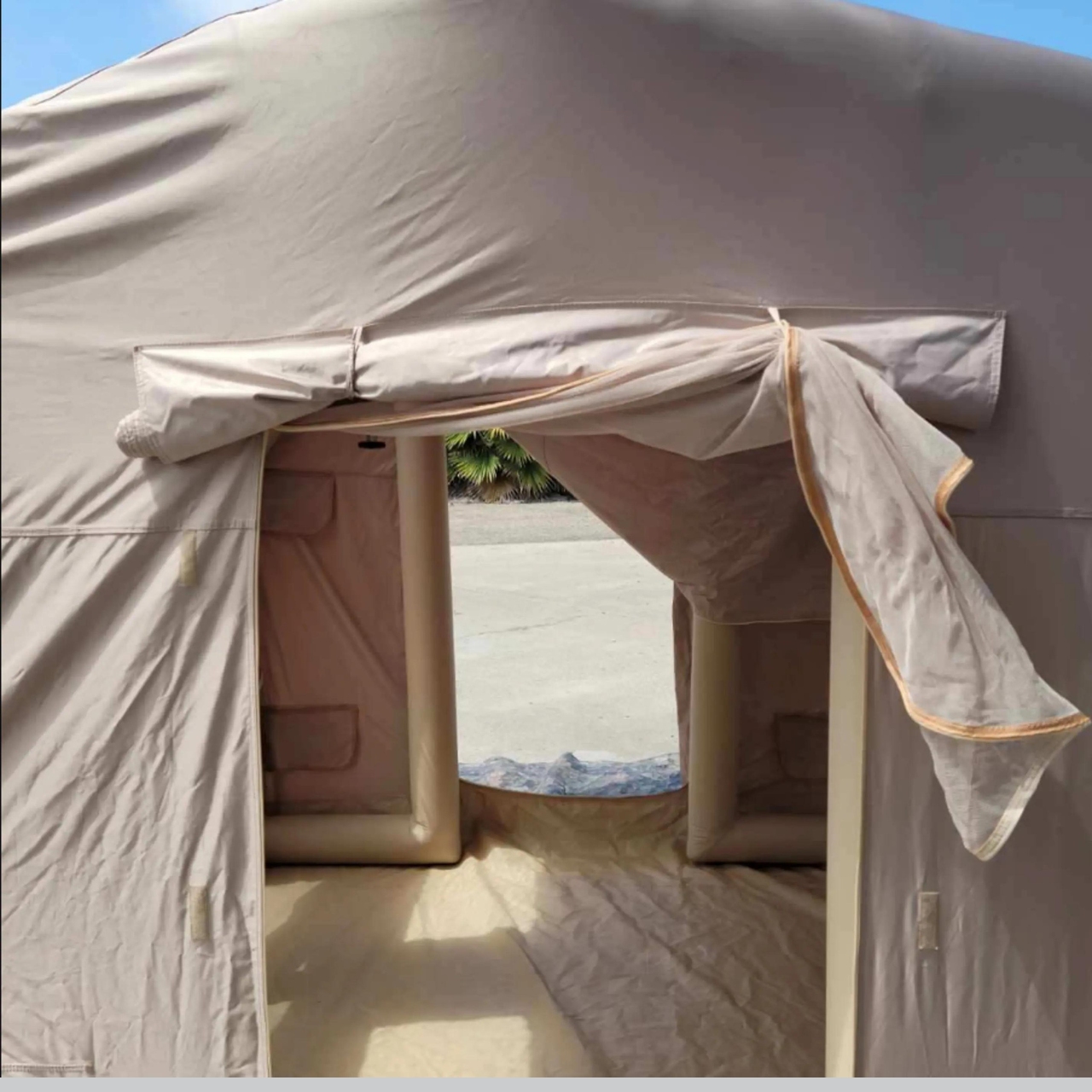

Meet The Cube, an inflatable tent that basically sets itself up while you crack open a cold drink and enjoy the view. We’re talking four minutes from bag to fully erected shelter, and the only tool you need is your finger to press a button.

Designer: Alphago

Here’s how it works: instead of traditional poles, The Cube uses an air tube frame system that inflates via a wireless electric pump. One button press, and the tent whooshes to life like some kind of architectural magic trick. No hammering stakes at odd angles, no accidentally threading poles through the wrong sleeves, no arguments with your camping buddy about which end is the front. Just push, wait, and watch your home away from home take shape.

But what really sets The Cube apart isn’t just the speed. It’s the fact that this thing is actually designed for comfort, not just survival. The stretched, oversized design puts this firmly in glamping territory rather than roughing-it camping. We’re talking about a spacious interior that doesn’t force you to hunch over or play tetris with your gear. The modular design means you can customize your setup depending on whether you’re solo adventuring or bringing the whole crew.

Weather resistance is where The Cube really flexes. The tent features an ultra-rigid airframe that stands up to wind and rain, with a WeatherTec system that includes welded floors and inverted seams to keep you dry even when the weather turns nasty. Both the front and back come with three layers: privacy screening, mosquito netting, and weather panels, so you can adjust your exposure to the elements based on conditions and mood.

The attention to practical details is impressive. Some versions come with camping tables, side tables, and even storage solutions like cupboards with plates, bowls, cups, and cutlery drawers. It’s like someone actually thought about what you need when you’re living outdoors for a few days, rather than just providing a roof over your head. Now, is this traditional camping? Absolutely not. If your idea of connecting with nature involves minimalist gear and earning your shelter through physical labor, The Cube probably isn’t for you. But if you’re someone who loves being outdoors without sacrificing comfort, or if you’ve been put off camping by the sheer hassle of setup and teardown, this is a game changer.

The design also speaks to a broader shift we’re seeing in outdoor recreation. As remote work becomes more normalized and people seek experiences beyond traditional tourism, there’s growing demand for gear that bridges the gap between adventure and comfort. The Cube fits perfectly into this zeitgeist of “soft adventure,” where the goal is experiencing beautiful places without the suffering that used to be considered mandatory. From a design perspective, there’s something satisfying about how elegantly The Cube solves a genuine problem. Traditional tent design hasn’t changed much in decades, but by borrowing from inflatable architecture and modern materials science, Alphago created something that feels genuinely innovative rather than just incrementally better.

Is it affordable? That depends on your camping commitment level, though Alphago has offered specials with significant discounts. Think of it less as a tent and more as portable architecture, an investment in stress-free outdoor experiences for years to come. The bottom line: The Cube represents where outdoor gear is heading. Smarter, faster, more comfortable, and designed for people who want nature without the nature-induced backache. Sometimes innovation isn’t about reinventing the wheel. Sometimes it’s about admitting that tent poles were kind of a pain, and maybe we can do better.

The post This Tent Just Solved Camping’s Most Annoying Problem first appeared on Yanko Design.