Designers working across product design and interior architecture view the Amazon not as a backdrop, but as a lesson in how materials, forms, and systems perform under real conditions. Designing in this context means moving away from rigid objects and fixed layouts, and learning from the forest’s logic of layering, adaptation, and response to heat, moisture, and constant change. From furniture to spatial planning, every decision must align with the environment rather than resist it.

This mindset shapes interiors and products that prioritize durability, comfort, and reduced environmental impact. Light is softened through screens, textures, and surfaces that gently diffuse glare, while materials are selected for resilience and tactile warmth. Let’s understand how strong design is defined by solutions that behave like living systems, adaptive, efficient, and quietly luxurious in harmony with nature.

1. Layered Roofs Inspired by the Canopy

In the Amazon, a roof is more than just a cover. It must work like the forest canopy, using layers to control heat and handle heavy rainfall. Instead of a single surface, a layered roof helps reduce heat build-up and protects the interior from extreme weather, creating a naturally cooler living environment.

This can be achieved through a double-layer roof system, with an outer protective layer and an inner insulated ceiling. The space between them allows hot air to escape, improving natural ventilation. Deep roof overhangs further protect interiors by blocking harsh midday sun while letting in soft morning light, creating comfortable, shaded spaces that feel connected to nature.

Tucked deep within Ecuador’s Amazon rainforest, A Lodging in the Pigüe is a 484-sq-ft cabin that forges an intimate dialogue between architecture and nature. Designed around a pre-existing Pigüe tree, the structure gently rises around it, allowing the tree to remain untouched while becoming a living component of the home. Located near El Calvario, the cabin seamlessly blends industrial and organic materials, drawing inspiration from tree houses to create a quiet retreat immersed in the forest landscape.

Elevated on stilts made from recycled metal pipes, the home appears to float among the trees, protecting it from ground moisture while preserving natural water flows and encouraging the growth of vegetation below. This raised design also enables bio-filters for wastewater treatment. Inside, a warm, earthy palette dominates, with gabion stone walls, locally sourced bamboo and wood, and polished timber floors. Living spaces extend outdoors through a terrace and net balcony, while floor-to-ceiling glass in the bedroom, along with a compact kitchen, bathroom, and semi-outdoor shower, deepens the connection to nature.

2. Water-Smart Design from Leaf Patterns

In the Amazon, water shapes every design decision. Instead of fighting moisture, buildings should work with it. Surfaces and details must guide rain away quickly, reducing damage while improving long-term performance in a high-humidity climate.

Drainage systems can take cues from leaf veins, where water flows naturally and efficiently. Gutters and channels are integrated into the structure, turning heavy rainfall into a controlled, visible flow rather than a problem to fix later. Materials also matter as moisture-friendly woods and modern bio-based materials perform better in damp conditions, aging slowly and beautifully while reflecting the climate they belong to.

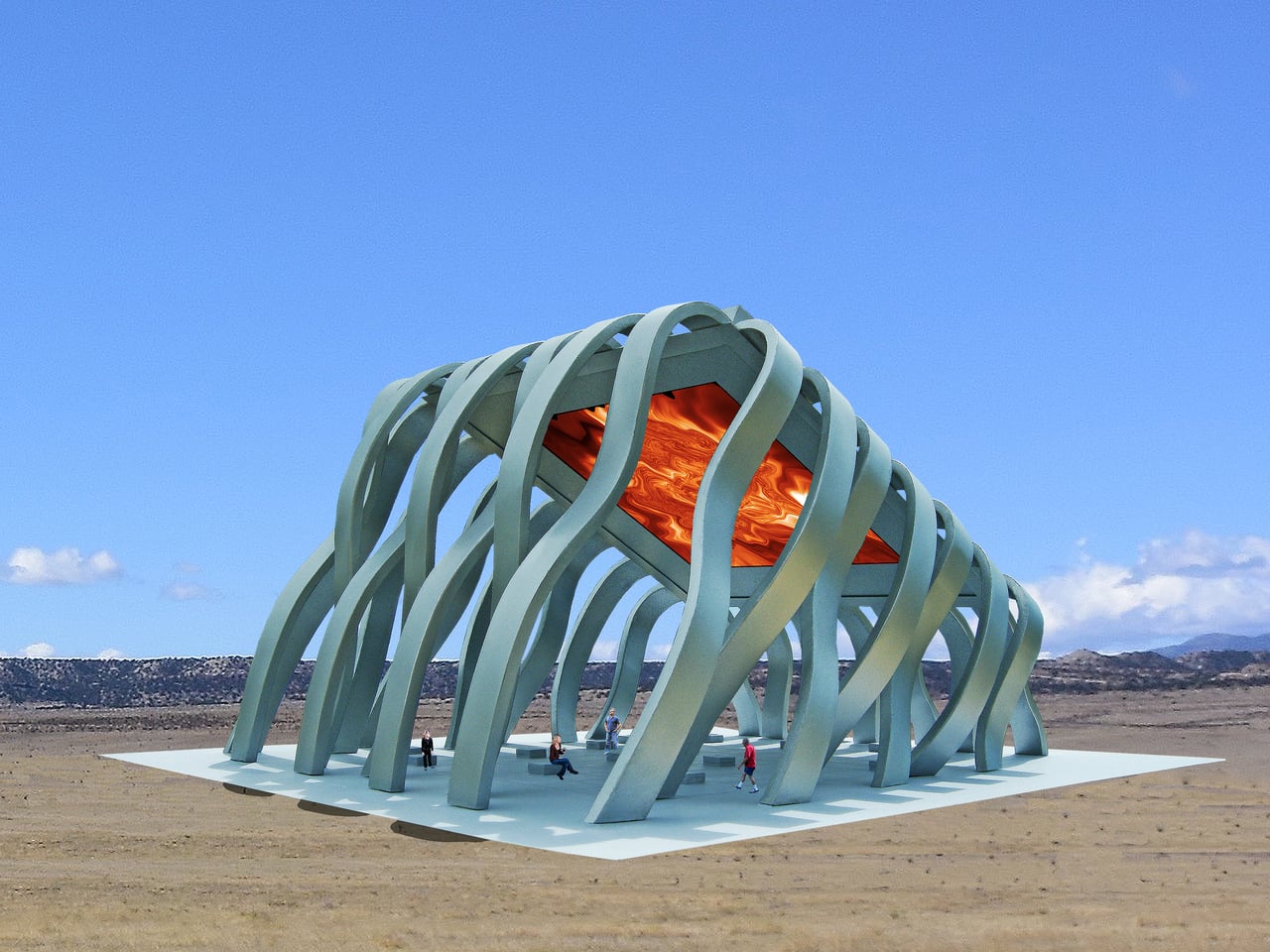

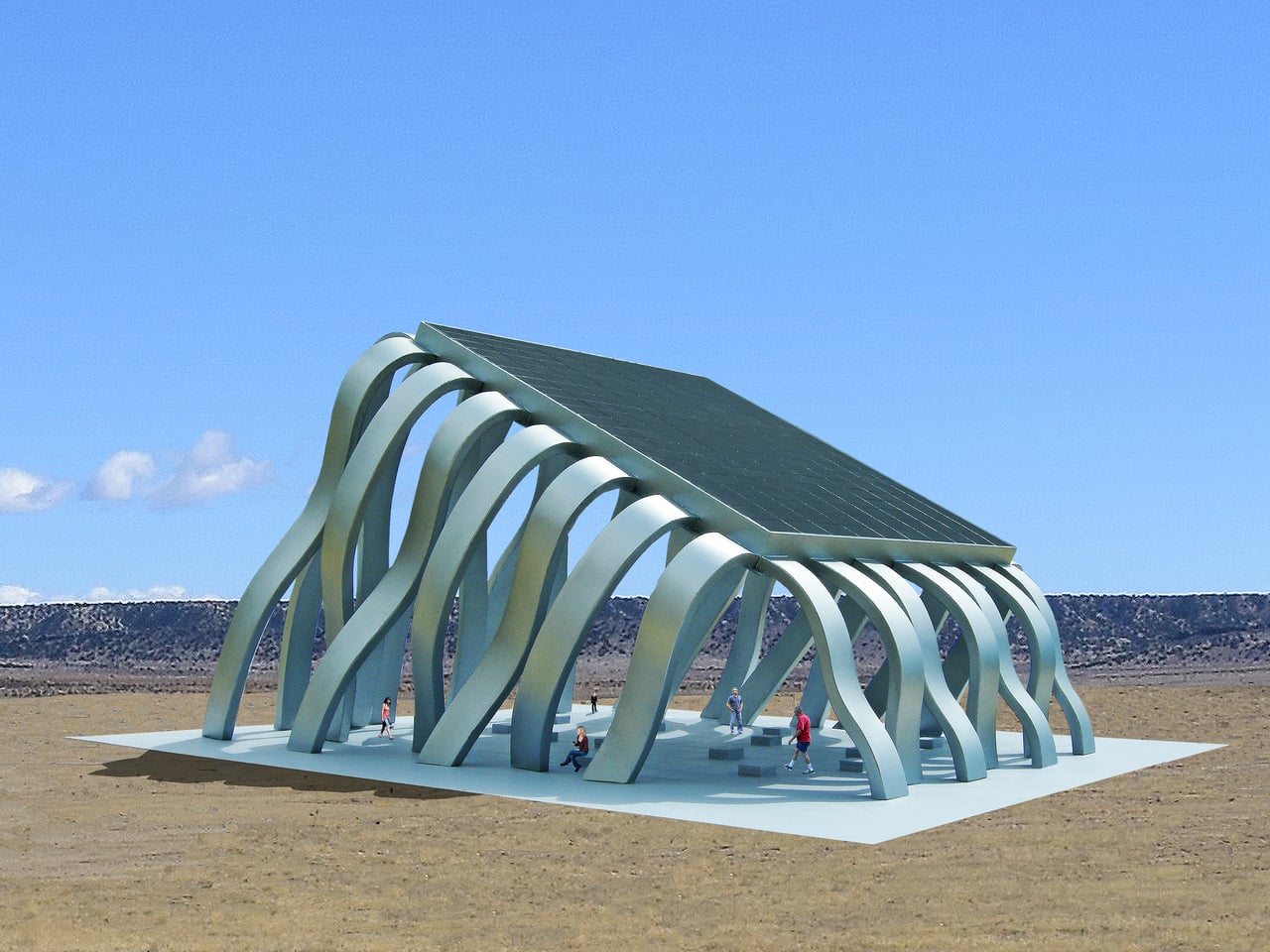

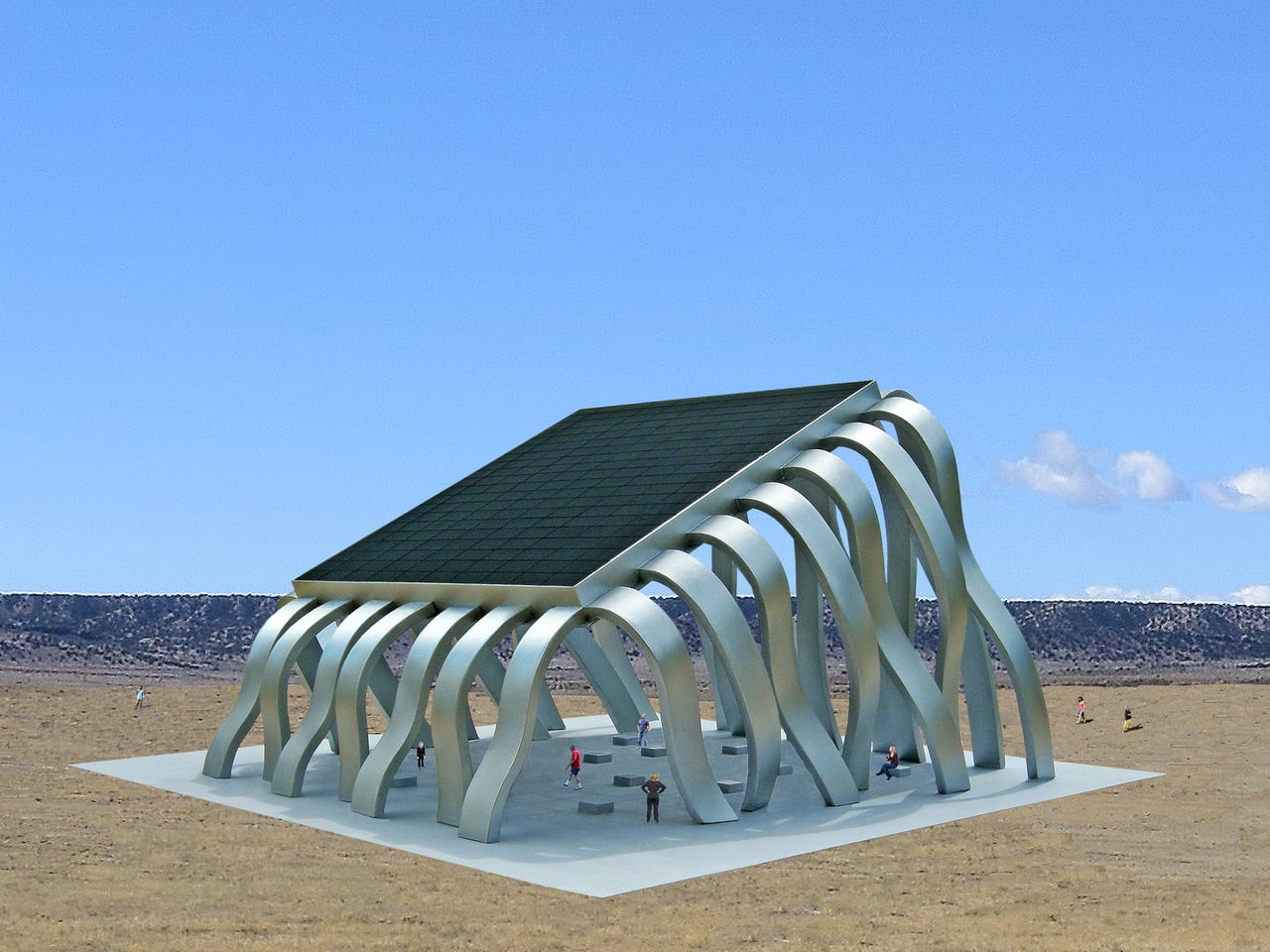

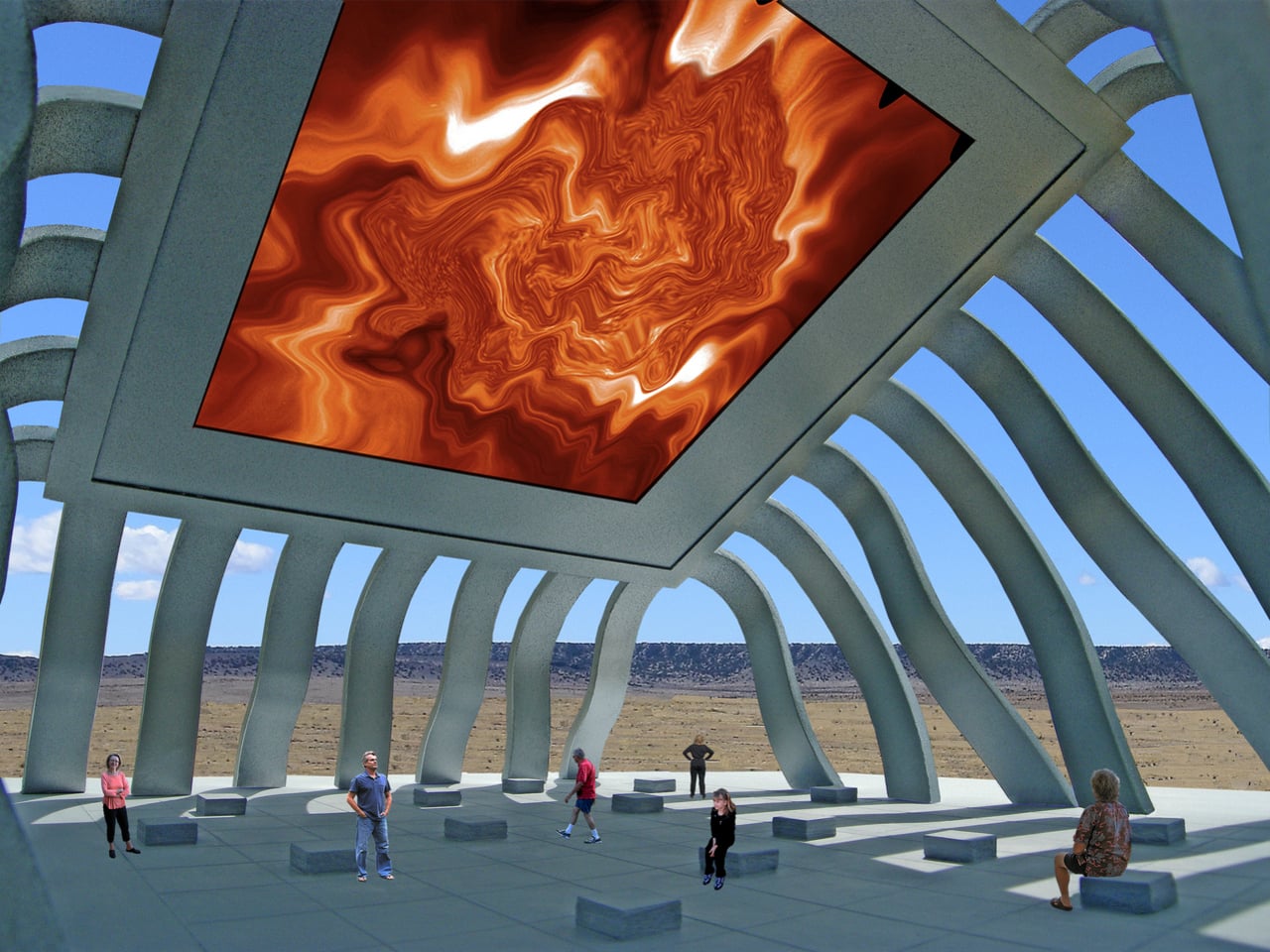

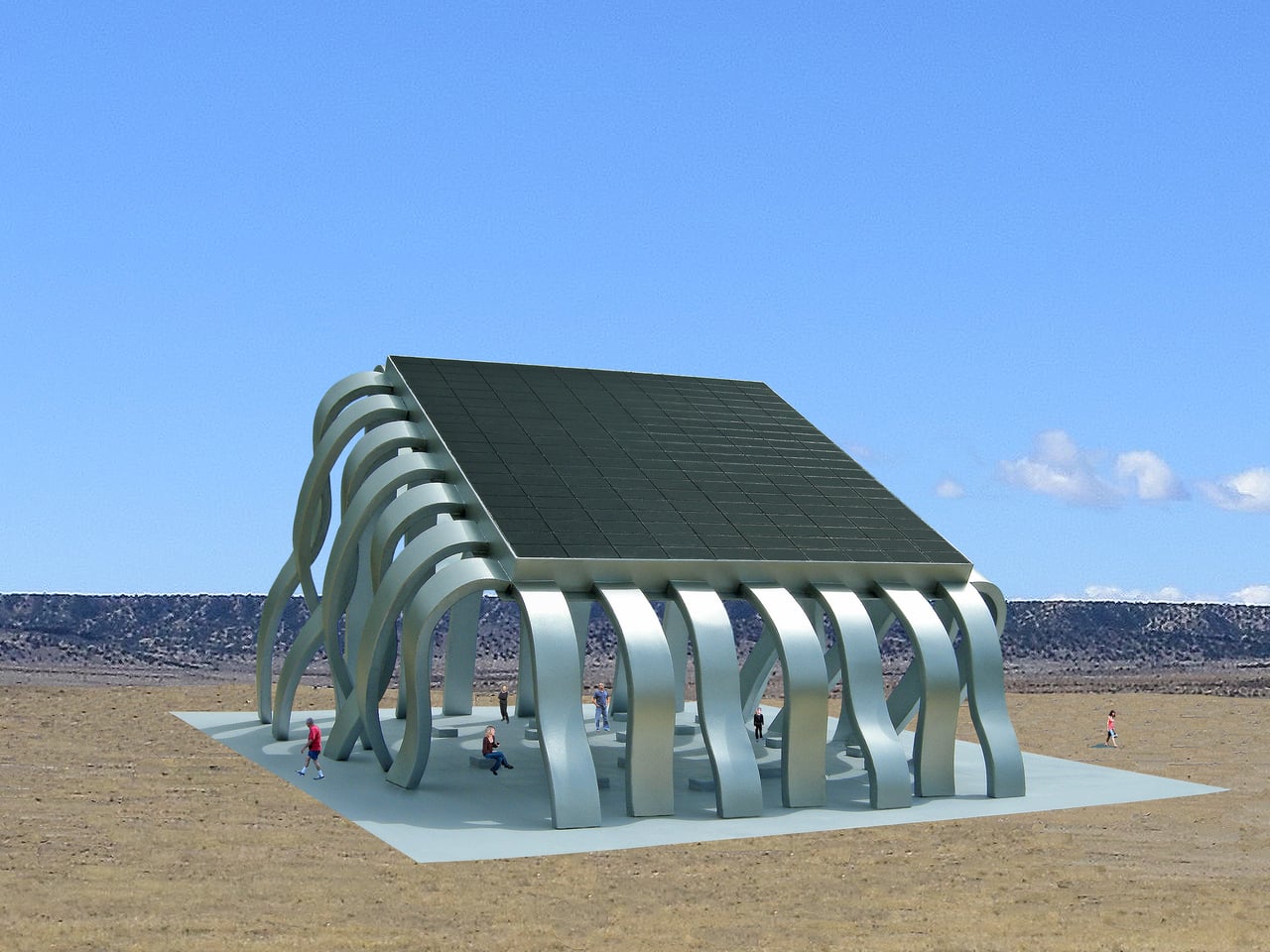

As technology-driven lifestyles pull people further from nature, the Amazon Immersion Pavilion is imagined as a quiet architectural counterpoint rooted in presence and ecological respect. Conceived as a conceptual project for Iquitos, Peru, the pavilion invites visitors to experience the rainforest through sound, light, texture, and movement. Rather than treating the Amazon as a backdrop, the design approaches it as a living partner, encouraging deliberate sensory engagement. Shaped by biomimicry and local ecological understanding, the pavilion uses bamboo as its primary material, reflecting regional building traditions while supporting low-impact construction and environmental responsibility.

The spatial journey unfolds across two levels, creating a clear emotional progression. The lower level offers an introspective, cocoon-like atmosphere, where filtered daylight, flowing water, and dense vegetation heighten sensory awareness. As visitors move upward, the pavilion opens toward expansive views of the Amazon River, allowing the architecture to recede in favor of the landscape. Passive ventilation, natural light, and low-impact assembly techniques enable the structure to align quietly with the rhythms of the forest.

3. Floating Floors That Respect the Ground

In sensitive ecosystems like the Amazon, real luxury means building without disturbing the land. Lifting structures above the forest floor allows natural water flow, plant life, and biodiversity to continue untouched. The building becomes a guest, not an intruder.

Raised floor systems on stilt-like foundations let air move freely beneath the structure, improving cooling while protecting interiors from moisture and insects. This approach also draws from regional building traditions, where homes are elevated to adapt to the climate and terrain. By combining this wisdom with modern design, architecture stays rooted in culture while meeting contemporary performance needs.

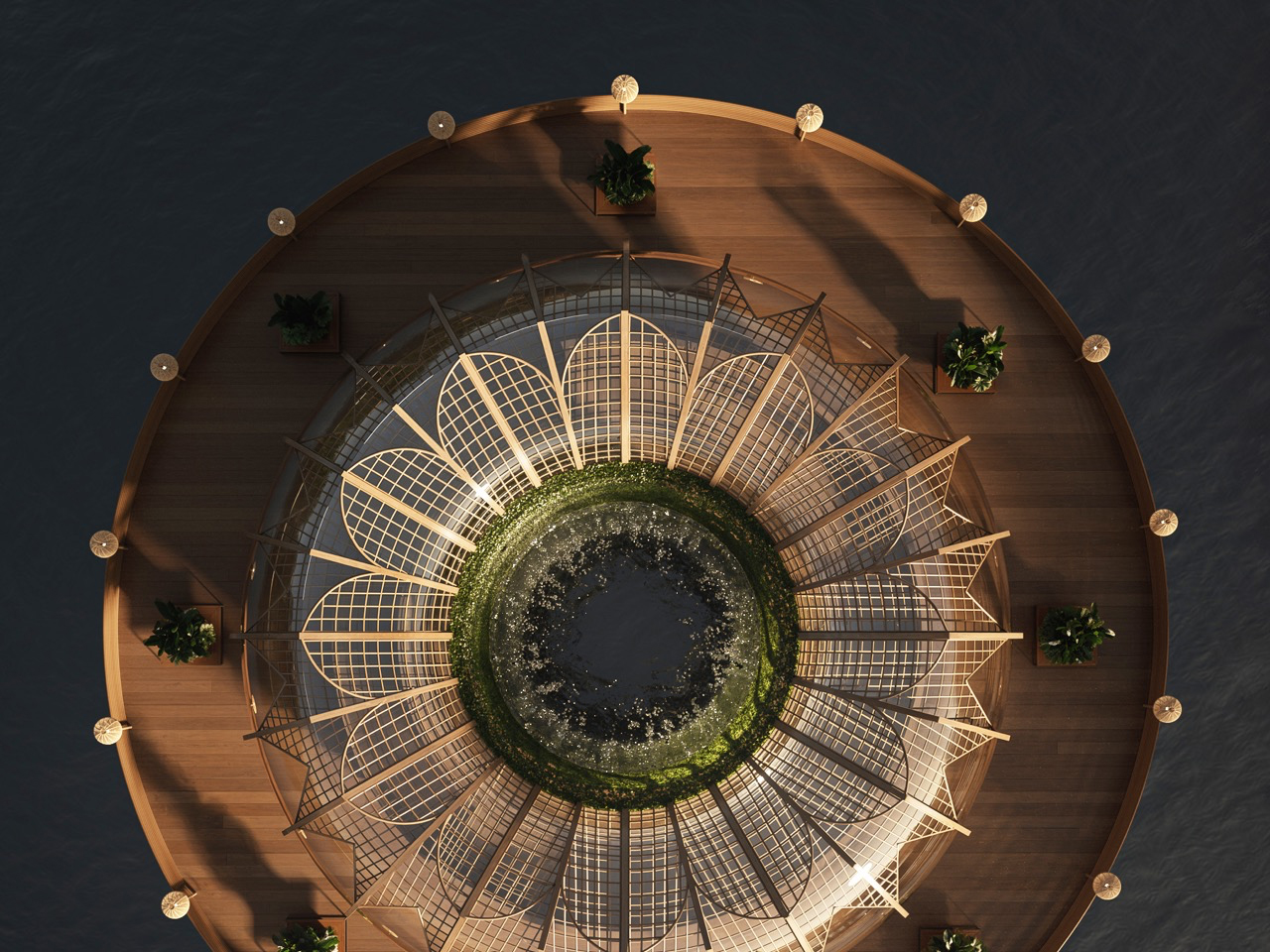

AquaPraça is a floating public square that responds directly to tidal movement, rising and falling with the water. Unveiled at the UN Climate Change Conference COP30 in Belém, Brazil, the 400-square-metre platform is conceived as a permanent cultural and civic space rather than a temporary installation. Designed by CRA–Carlo Ratti Associati in collaboration with Höweler + Yoon, the structure is anchored in Guajará Bay and adapts to daily tidal variations of up to four metres through buoyancy-based engineering. By positioning visitors at eye level with the river, the project transforms environmental change into a perceptible spatial experience.

First presented at the Venice Architecture Biennale, AquaPraça later arrived in Belém as part of Italy’s pavilion at COP30 and will be donated to Brazil for continued public use. Its sloped surfaces respond in real time to shifting water levels, offering a physical demonstration of sea-level rise. Located at the confluence of the Amazon River and the Atlantic Ocean, the project exemplifies adaptive architecture that aligns environmental responsibility with long-term cultural engagement.

4. Breathing Buildings for Tropical Comfort

In the Amazon, sealed glass buildings simply do not work. The forest itself breathes, and architecture must do the same. Instead of airtight enclosures, buildings should allow air to move naturally, responding to heat, humidity, and daily climate shifts.

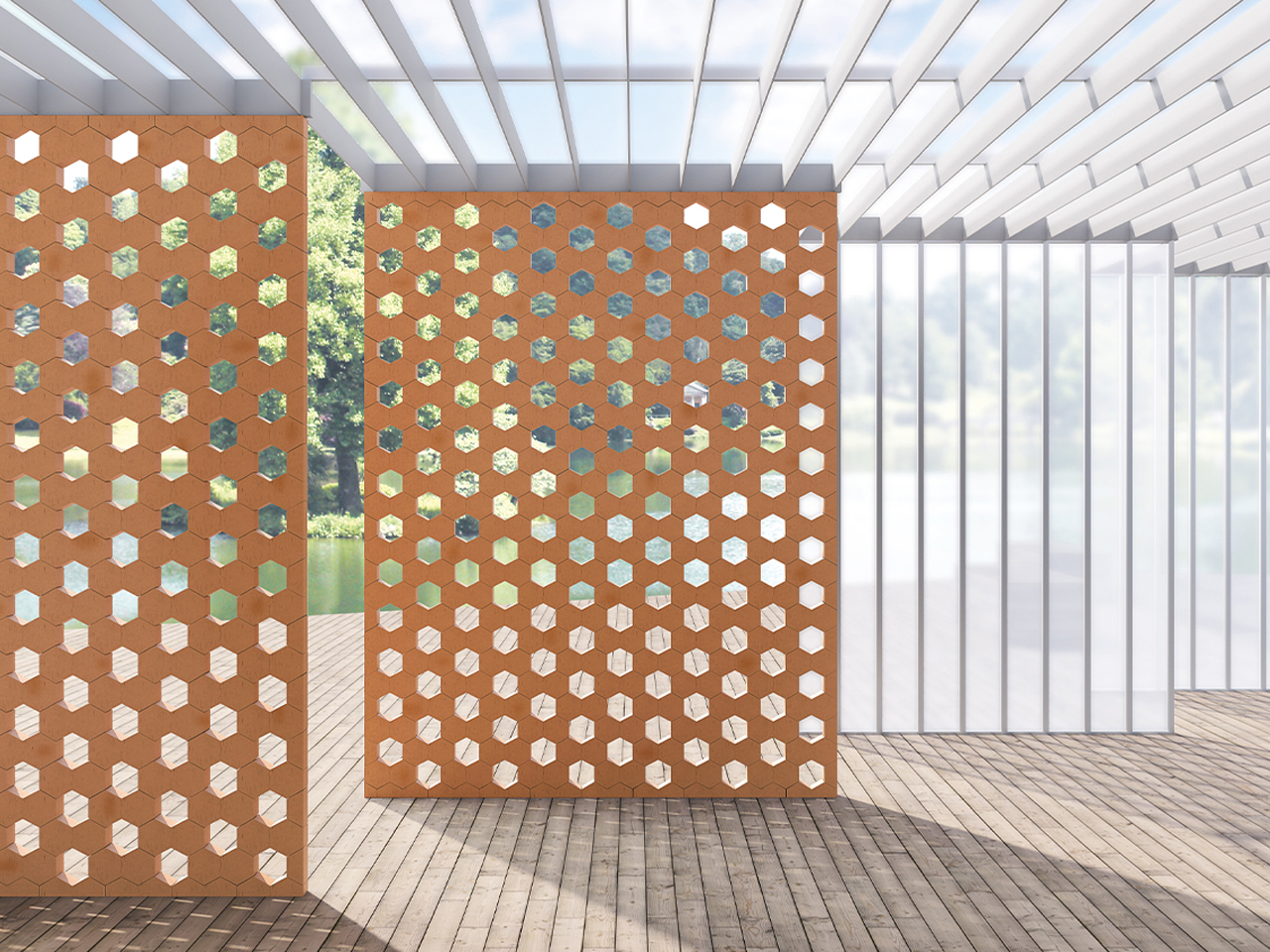

Walls can be designed as adjustable layers using louvers made from sustainable wood, perforated brick walls, or recycled metal. These openings act like breathing pores, letting fresh air flow through while maintaining shade and comfort. Compared to fully air-conditioned spaces, breathable facades consume less energy and create a stronger connection to the surroundings, allowing occupants to experience natural airflow, sounds, and scents of the forest.

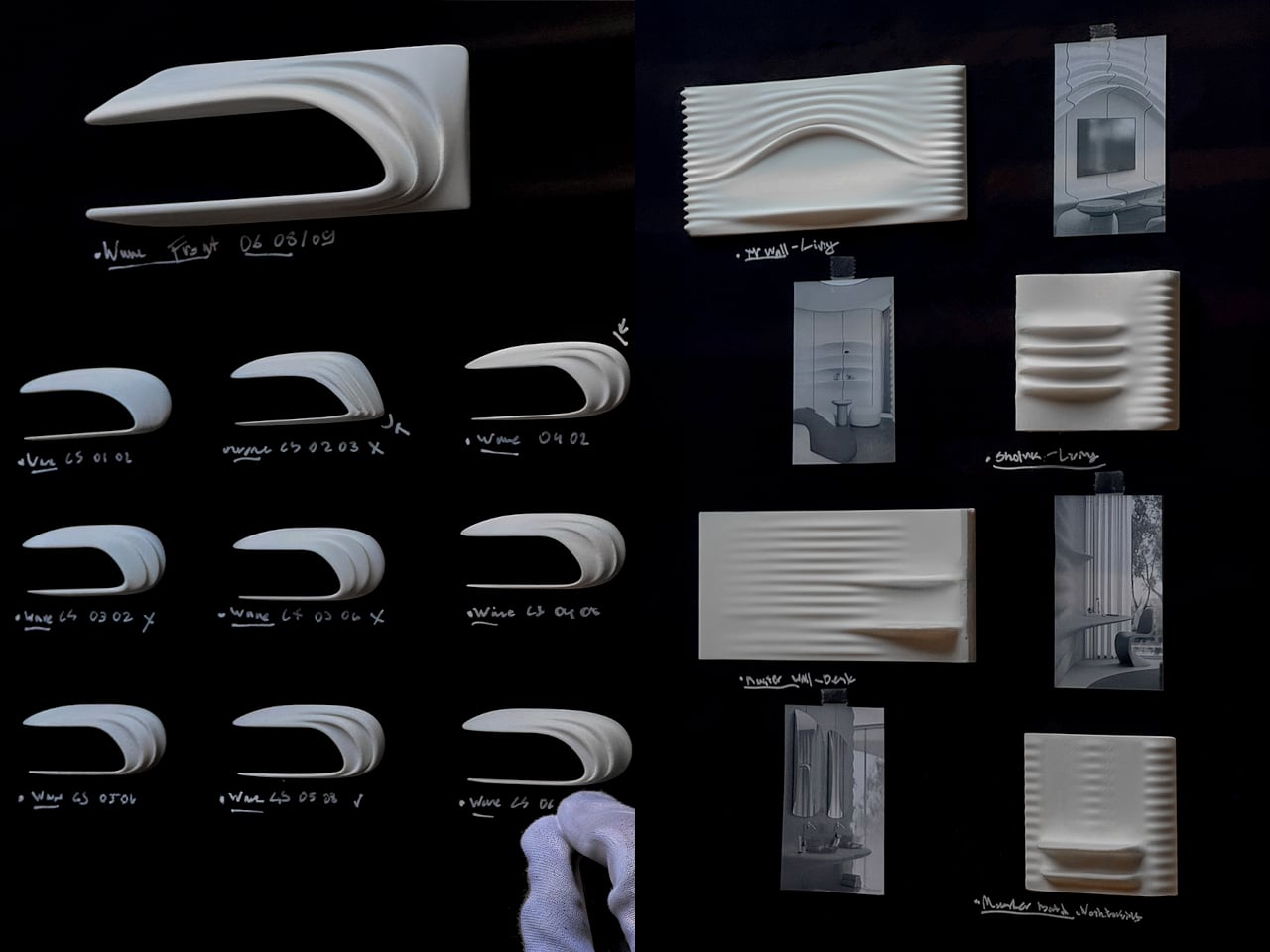

Hives is a modular system of hexagonal terracotta bricks designed to create flexible interior furnishings and architectural structures. Developed for Mutina, the Italian ceramics brand known for collaborating with leading designers, the collection reflects its commitment to material innovation and expressive form. Konstantin Grcic was commissioned to rethink the fixed nature of traditional brick construction, drawing inspiration from the intricate geometry of beehives. Each brick appears as two fused hexagonal units, resulting in a distinctive three-dimensional form that supports a wide range of spatial compositions.

The bricks can be arranged vertically to produce semi-open structures with pronounced cavities, or laid horizontally in staggered or flush patterns to create dynamic, undulating surfaces for columns, walls, and counters. Measuring 13 × 22.5 × 7 cm, the terracotta units offer excellent thermal and acoustic properties alongside durability and tactile warmth.

5. Designing for Circular Living

In the Amazon, nature shows that growth and decay are part of the same cycle. Architecture should follow this logic by using materials that can return safely to the earth over time, without pollution or waste.

Low-impact materials such as mycelium-based insulation and responsibly sourced mass timber help reduce carbon footprint while storing carbon instead of releasing it. Interiors can extend this thinking through natural finishes like local stone, clay plasters, and handwoven elements. The result is a calm, tactile environment that feels connected to the forest, reinforcing the idea of the building as a respectful, temporary presence within a living ecosystem.

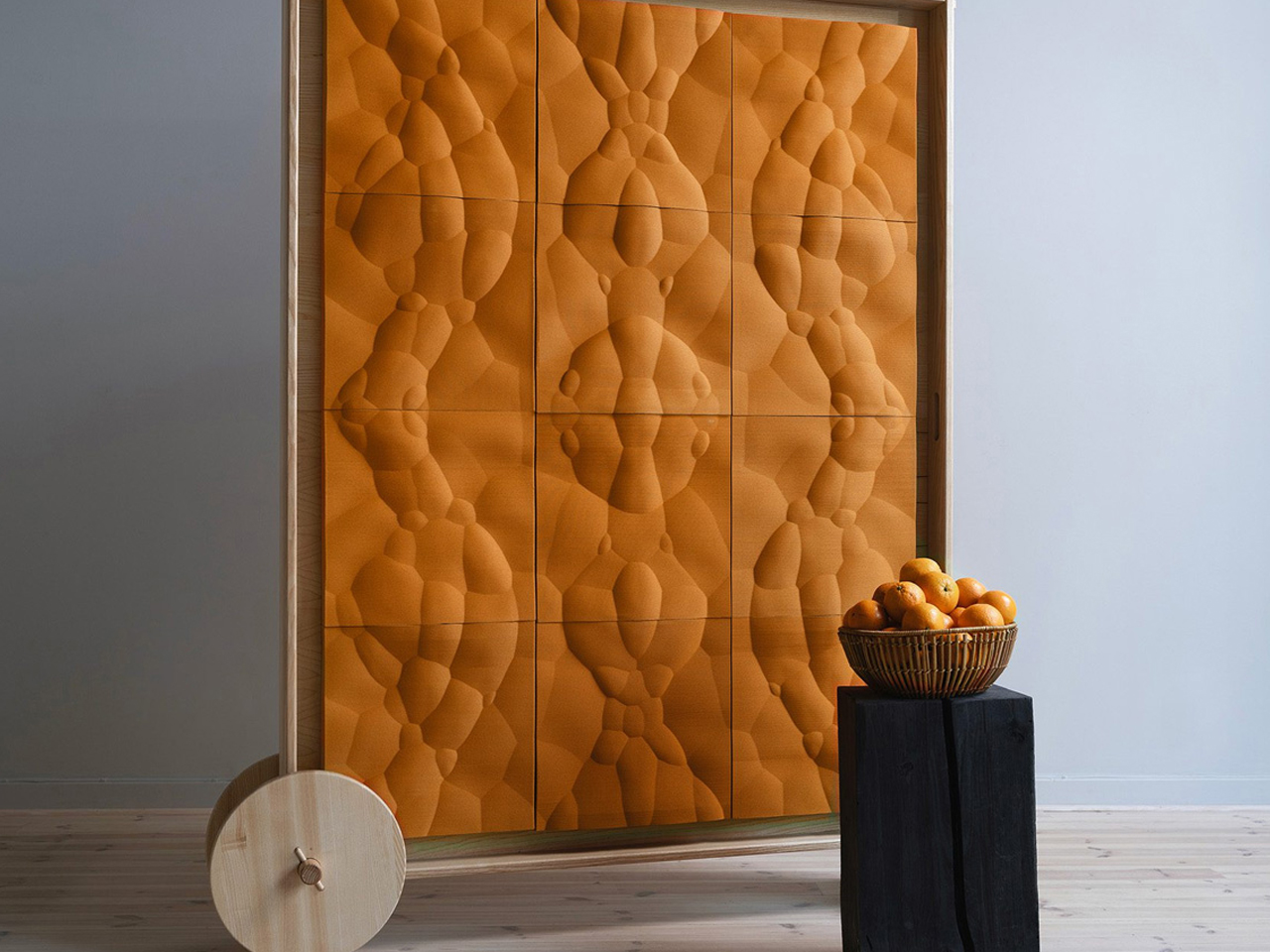

Design studio Interesting Times Gang, in collaboration with cooperative homebuilder OBOS, has introduced Veggro, a collection of sustainable partitions made from biomaterials such as mycelium and orange peel. The Loom design uses mycelium grown on agricultural waste to create textured, mushroom-inspired panels, while Jugoso features 3D-printed orange rinds arranged in geometric patterns shaped by natural fruit vesicles.

Described as a biophilic “wall-as-furniture” concept, Veggro offers acoustic insulation, decorative value, and modular flexibility, representing the first outcome of the partners’ research into low-carbon construction materials.

Designing for the Amazon tests both humility and intelligence. It demands moving away from monumental statements toward buildings that behave like living organisms. By translating rainforest strategies into design, architecture becomes responsive and poetic. This defines a new luxury where spaces that breathe, adapt, and exist in balance with nature.

The post 5 Biomimicry-based Architectural Designs That Copy Nature’s Best Ideas first appeared on Yanko Design.