Photo: Audi

How Audi’s Formula 1 entry rewrites the visual rules of motorsport

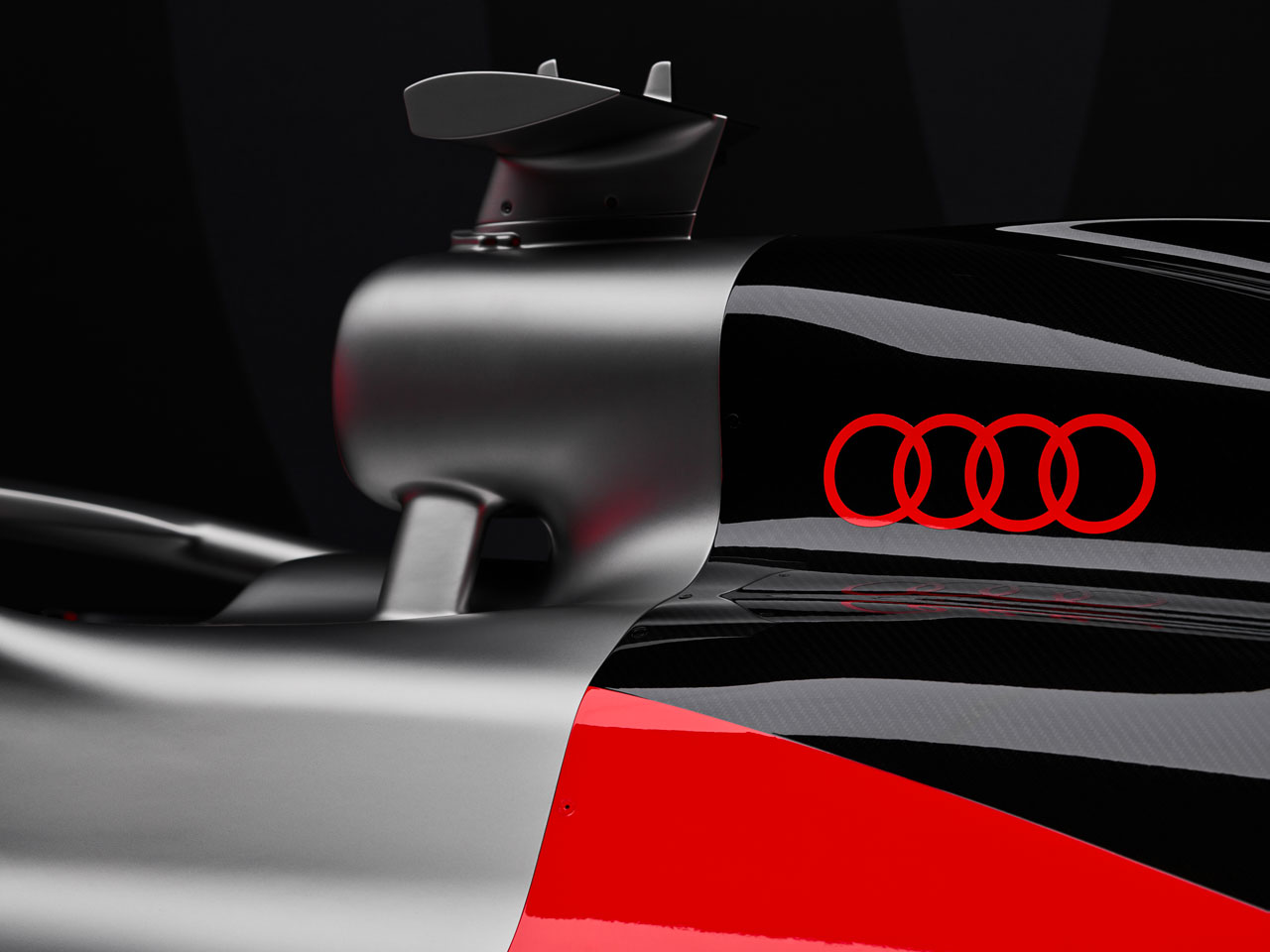

On November 12, 2025, Audi unveiled the R26 Concept at its Brand Experience Center in Munich. I was there, and the first thing that strikes you when you see the car in person is how clean it looks compared to every other F1 car. Where competitors plaster every surface with sponsor logos and complex graphics, Audi went the opposite direction: radical minimalism driven by four design principles that treat the race car as architecture.

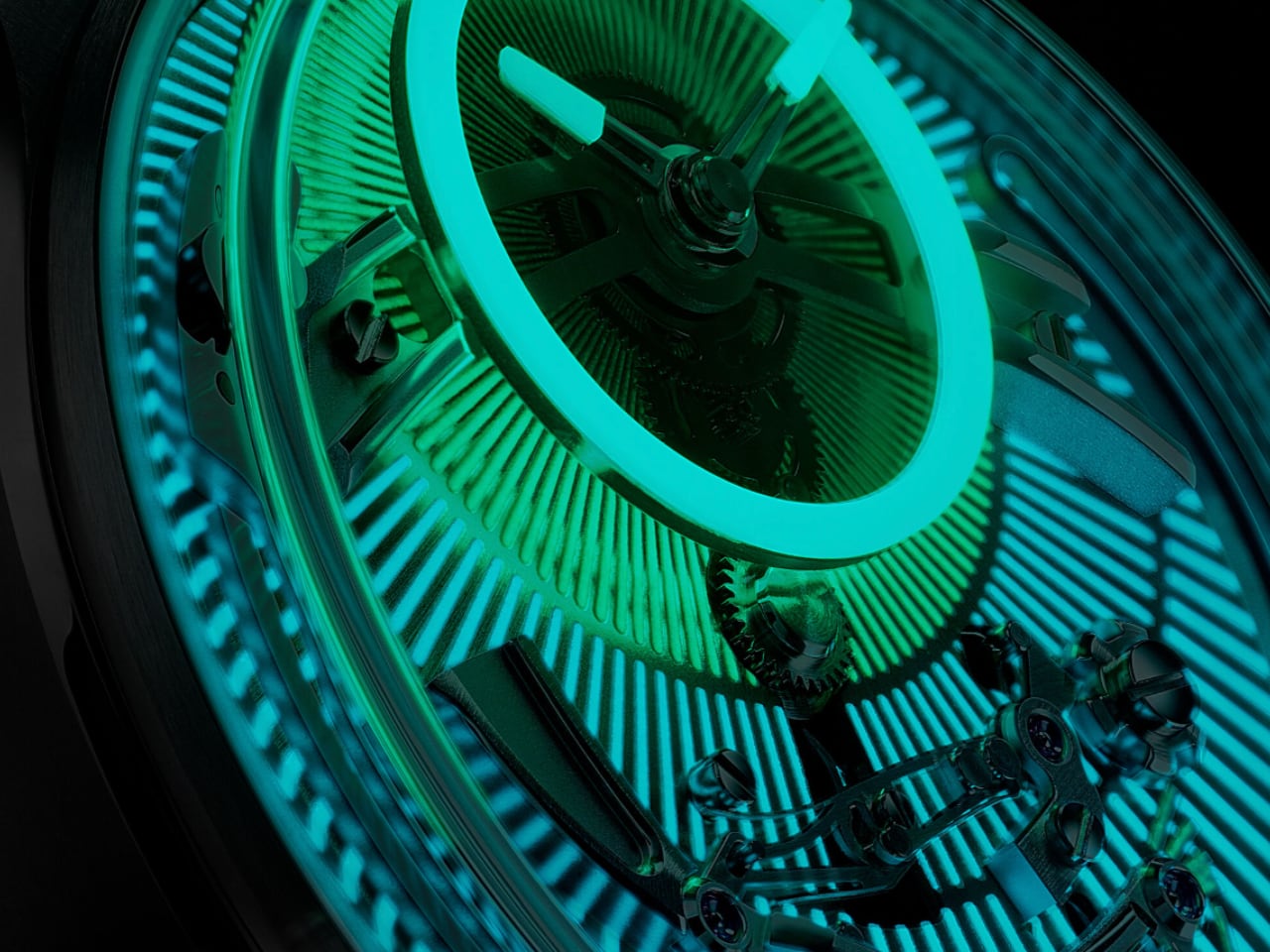

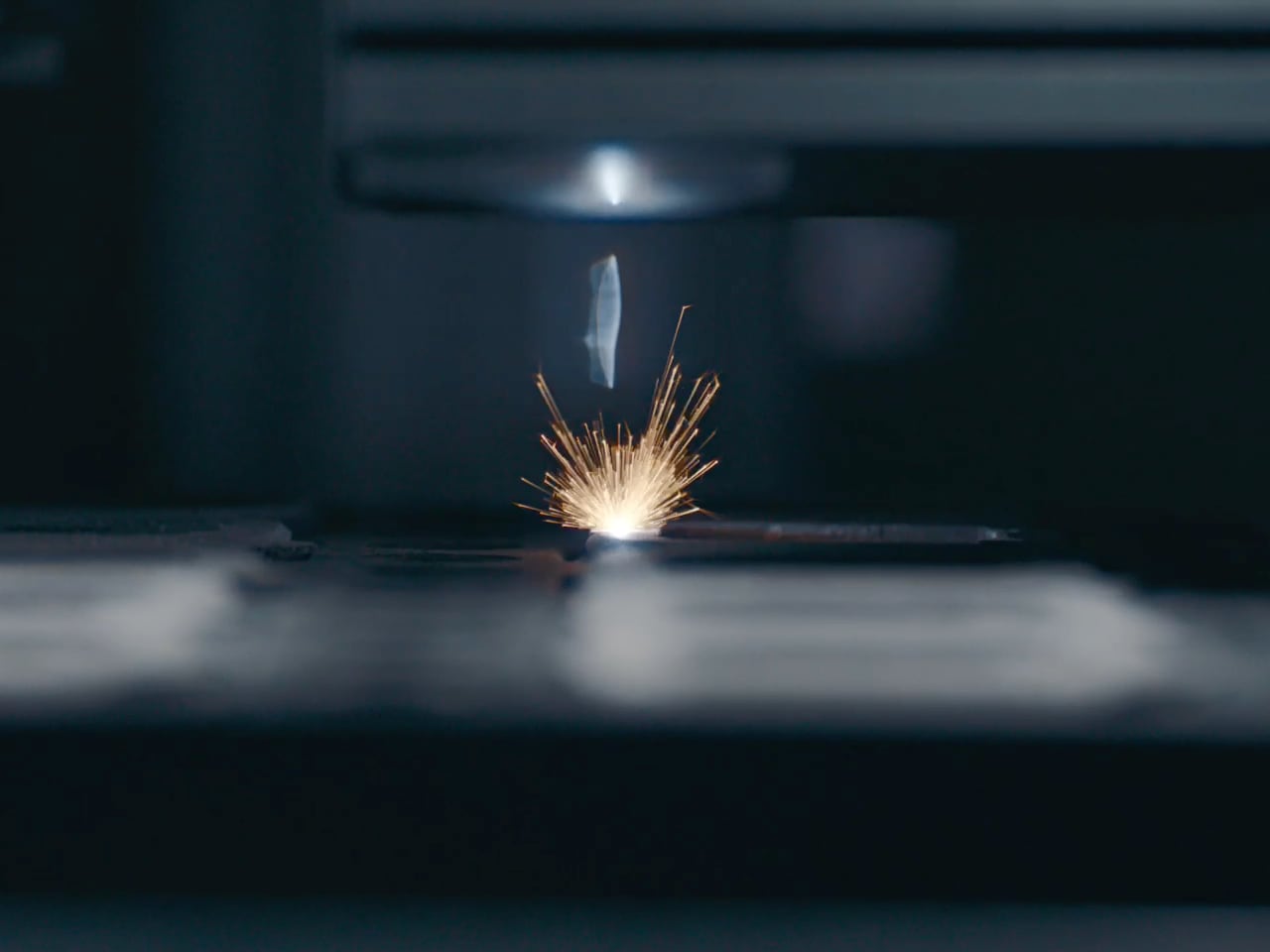

The R26 sat under bright reveal lighting at the Brand Experience Center, and the titanium finish showed its full reflective quality – a light, warm silver with subtle gold undertones. Move around the car, and you see how metallic finishes shift depending on viewing angle and light direction. That dynamic quality is something photos struggle to capture.

This isn’t a livery. It’s a visual system.

First Impressions: Seeing the R26 in Person

The R26 Concept sits on a raised platform at the Brand Experience Center, and from the moment you walk in, you understand what Audi means by “clarity.” The car reads as a single sculptural object. Your eye doesn’t jump between different graphic elements or sponsor logos fighting for attention. Instead, you follow the car’s form.

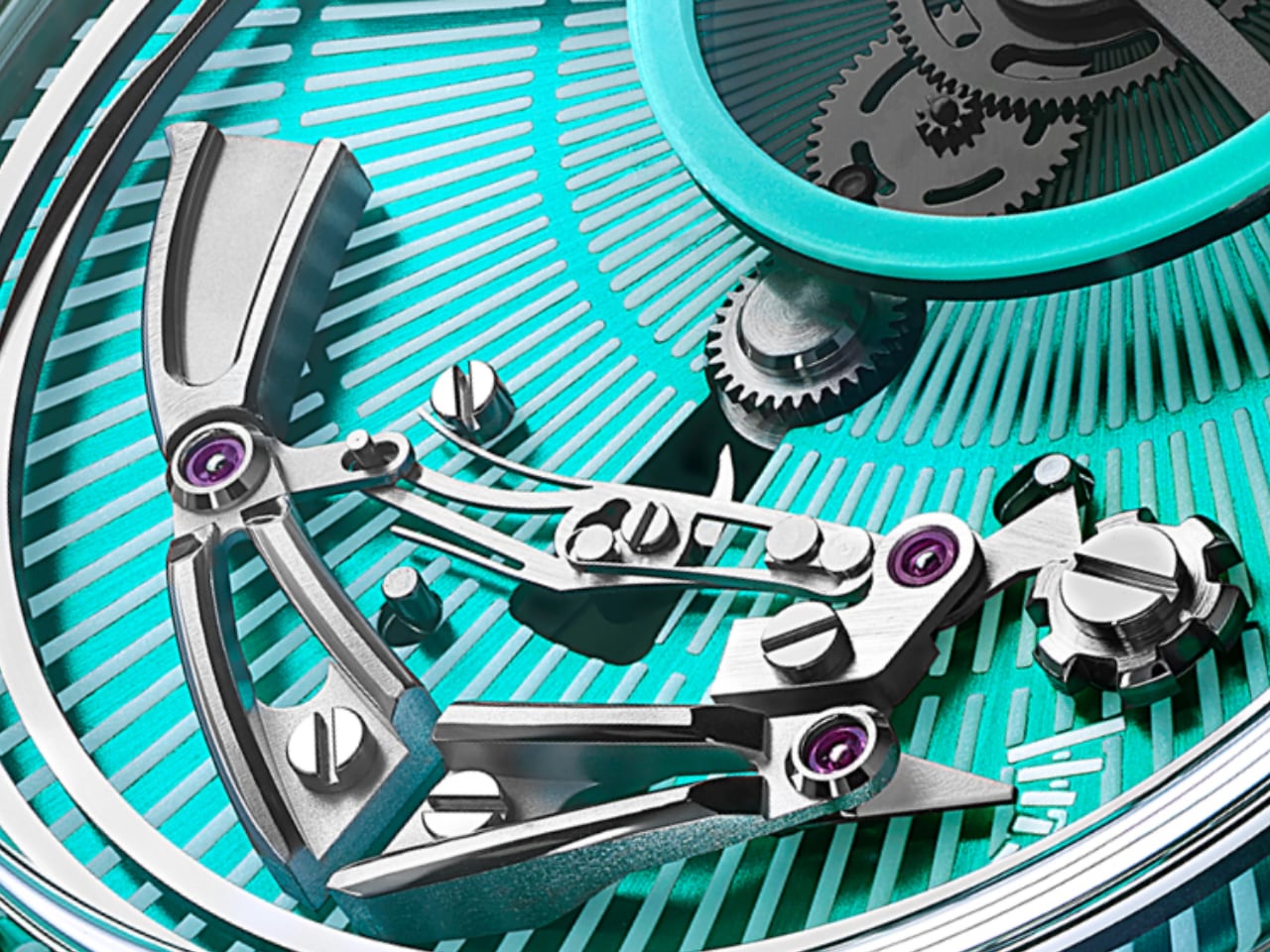

The red rings dominate immediately. Against the titanium and carbon, the red pops in a way that silver rings never could. Standing about 10 feet from the car, the rings are the first thing you see. Move closer, and the geometric cuts become visible. Move to the side, and you see how those cuts follow the sidepod’s compound curve.

The carbon fiber is particularly striking in person. It’s not painted black. It’s actual woven carbon, clear-coated to bring out the texture. Under the reveal lighting, you can see the individual weave pattern. It creates this organic texture against the precision geometry of the titanium panels. The contrast between smooth metal and textured carbon adds depth that flat paint never could.

The proportions feel different from current F1 cars. The R26 looks smaller, more compact, almost delicate. The narrow track width and reduced wheelbase make it look more like a classic Grand Prix car than a modern F1 machine. The minimalist graphics amplify this effect. Without visual clutter, the car’s actual shape becomes the dominant element.

Walking around the car, the geometric cuts reveal their logic. Each cut aligns with a structural element or airflow path. On the front wing, the titanium and carbon transition follows the wing’s compound curve. On the sidepods, the geometric division marks the break between the upper and lower airflow paths. These aren’t arbitrary design choices. They’re the car’s engineering made visible.

The Four Principles: Clear, Technical, Intelligent, Emotional

Audi’s design team built the R26 around four foundational principles: Clear, Technical, Intelligent, and Emotional. Each principle shapes specific design decisions.

Clear means eliminating visual noise. The R26 uses minimalist graphic surfaces with precise geometric cuts that follow the car’s structural lines rather than fight them. Where most F1 liveries wrap graphics over complex 3D surfaces, Audi’s design integrates with those surfaces. The result: a car that reads as a single visual object rather than a collection of stickers.

Technical drives the material expression. Exposed carbon fiber, metallic titanium, functional air intakes: every surface communicates its engineering purpose. The design doesn’t hide the technology; it celebrates it through selective color application and geometric clarity.

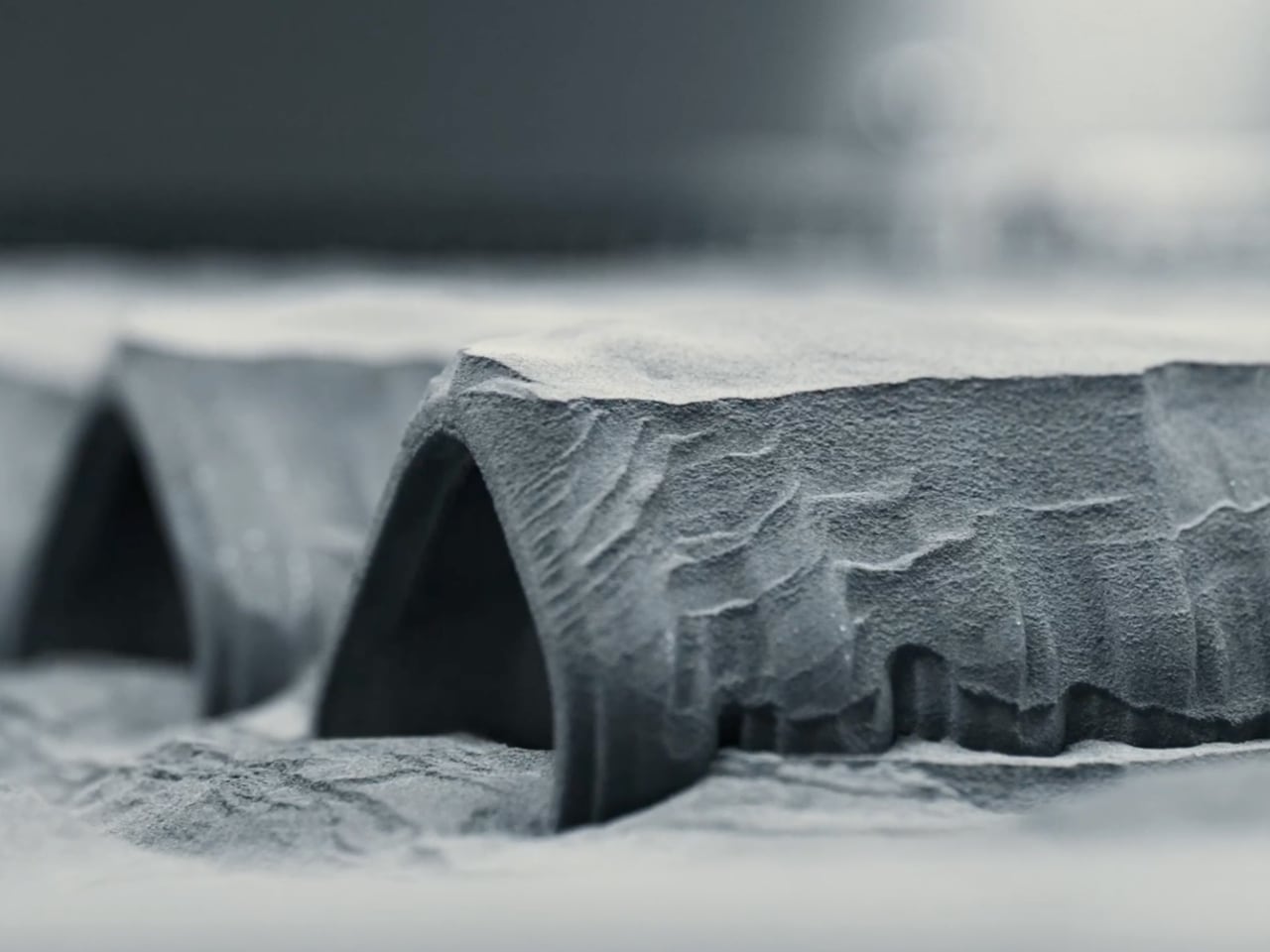

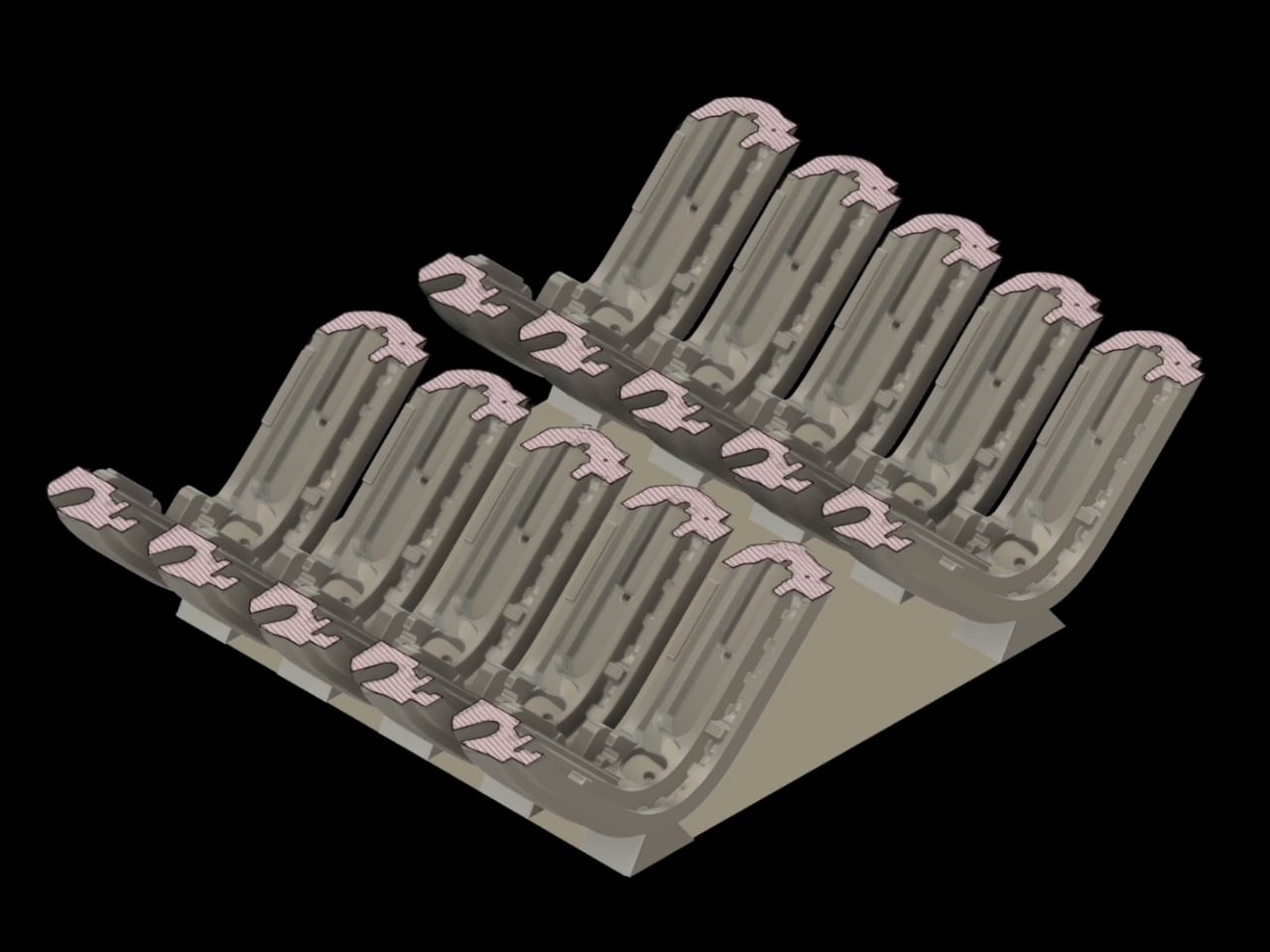

Intelligent governs the systematic application of design elements. The geometric cuts aren’t random. They map to structural stress points, airflow paths, and regulatory panel divisions. Audi’s designers worked directly with the engineering team to map every cut to the car’s invisible architecture: stress points where forces concentrate, airflow boundaries where high and low-pressure zones meet, load paths where structural members transfer energy. The visual geometry reflects forces you can’t see but that define how the car works. Function dictates form, but beauty emerges from the constraint.

Emotional brings the selective use of Audi red. While the base palette stays monochromatic (titanium and carbon black), red appears at key moments to create visual punctuation. The red rings replace Audi’s traditional silver exclusively for F1, marking a historic brand departure.

Color as Communication: The Three-Color System

Audi developed an entirely new color palette for F1, and each color has specific purpose:

Titanium: The Foundation

Titanium is Audi’s new performance color, first introduced on September’s Concept C. It’s a warm metallic that reads differently depending on light conditions. In bright sun, it appears almost white with a subtle gold undertone. In shadow or under track lighting, it shifts to a deeper, cooler gray with bronze highlights.

Photo: Audi

The Concept C introduced titanium as part of Audi’s production car transformation. The R26 adapts that same color for a radically different purpose. Where Concept C uses titanium to signal elegance and precision in a road car, the R26 deploys it for instant recognition and competitive differentiation in racing. Same color, different mission. The R26 doesn’t copy Concept C. It translates Concept C’s design language into motorsport clarity.

The warmth differentiates it from traditional racing silvers. Where chrome and aluminum feel cold and industrial, titanium conveys technical sophistication with organic warmth. It’s the color of aerospace-grade materials, of precision engineering, of expensive watches.

Titanium also solves a practical problem: visibility. On modern F1 broadcasts with complex camera angles and varying light conditions, many cars become visually similar. Titanium’s warmth and unique reflective properties create immediate visual differentiation.

Carbon Black: The Contrast

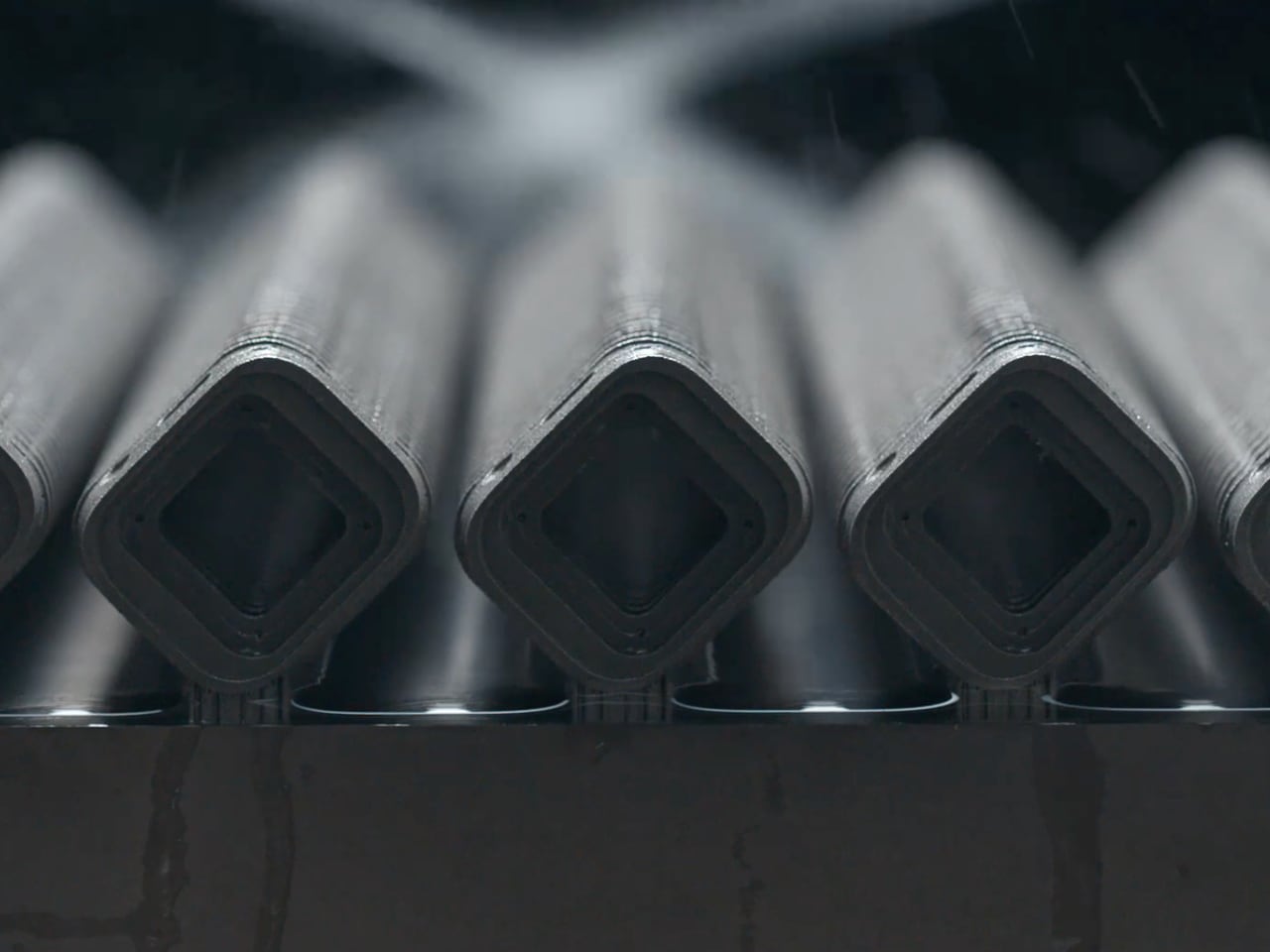

Carbon black isn’t paint. It’s exposed carbon fiber, finished to showcase the material’s woven structure. The decision to leave carbon exposed rather than painted communicates technical transparency.

Carbon black creates depth through texture. Where titanium reflects light, carbon absorbs it. The contrast between the two materials creates visual drama without graphics. The eye follows the transition between reflective and absorptive surfaces, mapping the car’s complex 3D geometry.

The exposed carbon also references Audi’s motorsport heritage. The Auto Union Silver Arrows pioneered lightweight construction in the 1930s. The R18 e-tron quattro showcased carbon monocoque technology at Le Mans. Exposed carbon fiber connects past to present through material honesty.

Audi Red: The Punctuation

Audi red exists nowhere else in the brand’s history. Created specifically for F1, it’s a pure, saturated red without orange or blue undertones. Think Rosso Corsa (Ferrari’s racing red) but slightly cooler in temperature.

Red appears selectively. It doesn’t flood the car. Instead, it marks specific moments: the halo structure, certain wing elements, brake cooling ducts. Each red application draws the eye to a functional element. Red becomes a visual guide to the car’s critical systems.

The red rings replace Audi’s silver rings exclusively for F1. Four red rings against titanium and carbon create instant recognition. From any angle, any distance, you know it’s Audi. The red rings also solve the challenge of brand visibility on a minimalist design. Without busy graphics, the rings need to work harder. Red makes them unmissable.

Geometric Language: Precision Cuts and Surface Integration

The R26’s most striking design element is its geometric surface treatment. Rather than applying graphics to the car’s complex 3D forms, Audi’s designers created precise cuts that follow the car’s structural geometry.

Think of it as subtractive design. Instead of adding visual elements, they’re revealing underlying structure through selective color application. A titanium surface might have a carbon black geometric cut that follows the bodywork’s compound curve. The cut isn’t arbitrary. It maps to an internal structural member, an airflow path, or a regulatory panel division.

This approach requires understanding the car’s architecture at a deep level. The design team worked directly with engineers to map stress points, airflow boundaries, and load paths. The visual geometry reflects the invisible forces acting on the car.

The geometric cuts also solve a challenge unique to F1: active aerodynamics. The 2026 regulations allow adjustable front and rear wings. The R26’s design maintains visual consistency whether wings are deployed or stowed. The geometric language works in multiple configurations because it follows the car’s core structure rather than any single aerodynamic state.

Proportion and Geometry: Working with the 2026 Regulations

The 2026 regulations give Audi’s designers opportunities unavailable with current F1 cars. The new cars are smaller (3.40m wheelbase vs. 3.60m), narrower (190cm vs. 200cm), and lighter (768kg vs. 798kg).

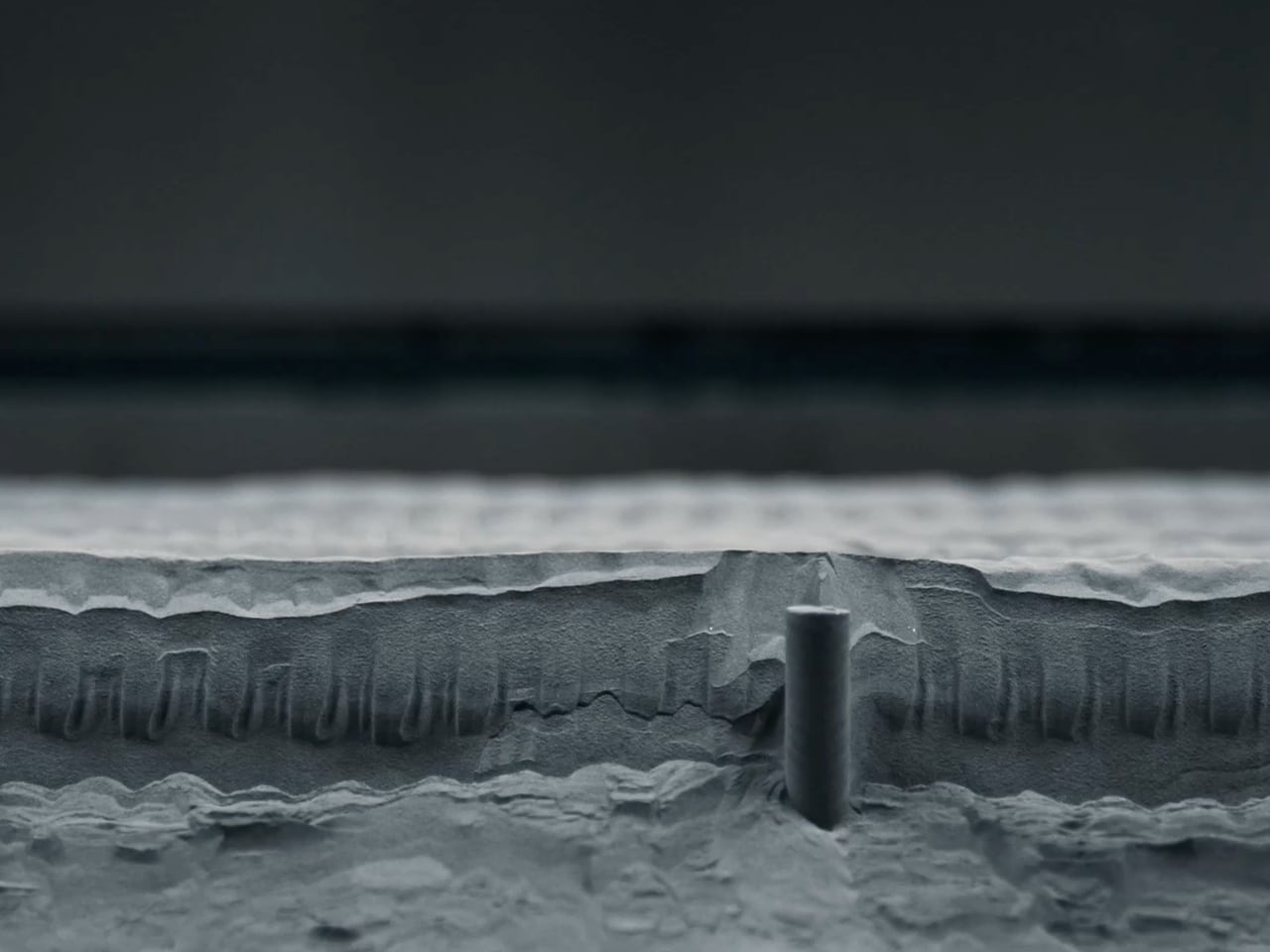

The 2026 regulations also mandate a fundamental powertrain shift: 50% electric power. The MGU-K (electric motor-generator unit) delivers 350kW, roughly matching the combustion engine’s output. This massive increase in electrical power (tripled from current regulations) changes the car’s architecture. The battery, inverter, and MGU-K create new packaging challenges and cooling requirements that directly influence the car’s geometry and surface design.

These reductions change the car’s proportions dramatically. Current F1 cars look big and planted, almost heavy. The 2026 cars will look nimble, almost delicate by comparison. The reduced wheelbase creates a more aggressive front-to-rear ratio. The narrower track width emphasizes vertical elements like the halo and rear wing.

Audi’s design amplifies these proportional shifts. The minimalist graphics make the car look even smaller because there’s no visual clutter to fill space. The geometric cuts emphasize the car’s length and narrowness. The selective red draws the eye vertically, accentuating height.

The overall impression is of lightness and precision: a car pared to its essential elements.

Material Expression: Texture and Finish

Beyond color, the R26 communicates through texture and finish. Audi specifies different surface treatments for different materials:

Titanium surfaces: Semi-gloss finish that balances reflection with depth. Too glossy and the car becomes a mirror, washing out detail. Too matte and the color loses its metallic character. The semi-gloss finish maintains the warm metallic read while preserving surface detail.

Carbon fiber surfaces: Clear-coated to reveal the woven structure but finished smooth for aerodynamic efficiency. The weave pattern creates visual texture without adding surface roughness. Under bright light, the carbon weave becomes visible, adding organic pattern to the geometric precision.

Red also needs high gloss for color saturation. Matte red looks dull and heavy.

These finish differences create a hierarchy of visual attention. Your eye goes to high-gloss red first, then semi-gloss titanium, then matte carbon. The finish strategy guides how you read the car’s form.

Typography and Graphics: When Less Is More

The R26 Concept preview shows minimal typography and graphics. The Audi wordmark appears clean and geometric, likely in a custom typeface that references the geometric cut language. Numbers use a technical, precision-cut style similar to engineering drawings.

Sponsor logos will be present on the final race car but in reduced size and selective placement. Audi’s partnership strategy emphasizes quality over quantity, which extends to livery design. Fewer, larger sponsor placements rather than dozens of small logos fighting for attention.

The lack of visual clutter makes individual elements more impactful. When everything screams, nothing stands out. The R26’s restraint makes each element meaningful.

Beyond the Car: A Complete Visual System

Audi’s design extends beyond the R26 to every touchpoint:

Team clothing (designed with adidas) uses the same geometric cuts, the same three-color palette, the same material contrasts. Driver suits feature titanium and carbon panels with red accents. Engineer shirts use geometric patterns derived from the car’s surface cuts.

Motorhome design applies architectural clarity. Clean white surfaces, geometric titanium accents, selective red details. The hospitality space feels like a contemporary art gallery, not a racing paddock.

Pit garage aesthetics showcase technical precision. Carbon fiber workstations, titanium tool holders, red accent lighting. Every element reinforces the four design principles.

Fan engagement zones reflect the design language through environmental graphics, wayfinding, and spatial organization. The geometric cuts become architectural elements. The three-color palette defines zones and circulation paths.

Digital fan zones and merchandise: The design system extends to Audi’s F1 app, website, and official merchandise. The same geometric patterns, the same three-color palette, the same material language. A fan buying an official team shirt gets the same design experience as someone walking through the paddock.

This comprehensive visual system creates a unified brand experience. Every interaction with Audi F1 reinforces the same design principles, the same aesthetic values, the same material language.

Designing for a New Audience

Audi’s design choices target F1’s demographic shift. The sport has gained 120 million female fans in five years. 44% of on-site visitors are now under 35. This younger, more diverse audience values aesthetics, sustainability, and brand authenticity differently than traditional F1 fans.

The R26’s minimalism appeals to design-conscious audiences who appreciate restraint over excess. The sustainable fuel mandate (part of the 2026 regulations) and 50% electric power align with younger fans’ environmental concerns. The red rings and titanium palette create a visual identity that works across digital platforms where younger audiences engage with F1 content.

Formula 1’s growth among younger demographics isn’t accidental. It’s driven by new media formats, design-forward teams, and visual storytelling that emphasizes aesthetics alongside performance. The R26 positions Audi at the center of this shift.

Design Heritage: From Silver to Red

Audi’s motorsport design history provides context for the R26:

The Auto Union Silver Arrows (1934-1939) pioneered the mid-engine layout, creating an entirely new racing silhouette. They emphasized technical innovation through streamlined bodywork that showcased mechanical complexity.

The Audi quattro (1981-1984) made four-wheel drive visible through aggressive fender flares and functional air intakes. The design communicated the revolutionary drivetrain through proportional shifts.

The Audi R8 LMP (2000-2002) introduced TFSI technology with clean, efficient aerodynamics. The design emphasized airflow management through sculpted surfaces and functional openings.

The R18 e-tron quattro (2012-2014) showcased hybrid technology through distinctive LED lighting and exposed mechanical elements. The design made electrical systems visible for the first time.

The RS Q e-tron (2024) brought electric drive to Dakar with brutal, geometric bodywork that emphasized structure over surface. The design celebrated the mechanical complexity of the electric drivetrain.

The R26 continues this heritage of technical transparency and innovative thinking, but adds a new layer: systematic minimalism. Previous Audi race cars showcased technology through addition: more details, more elements, more visual complexity. The R26 showcases technology through subtraction, revealing essential form through reductive design.

Comparison: How the R26 Differs from Current F1 Design

Current F1 liveries follow predictable patterns:

Busy graphics: Most cars use complex swooshes, gradients, patterns, and layered sponsor logos. Visual complexity becomes visual noise.

Arbitrary color placement: Colors often appear without structural logic, applied to maximize sponsor visibility rather than enhance form.

Surface-level design: Graphics sit on top of the car’s form rather than integrate with it. The 3D complexity of an F1 car gets flattened by 2D graphics.

Brand consistency over innovation: Most teams maintain similar liveries year after year, changing colors but maintaining the same basic approach.

The R26 rejects all these conventions:

Minimalist graphics: Visual restraint creates clarity and impact.

Structural color logic: Color placement maps to the car’s engineering, not sponsor requirements.

Integrated design: Graphics follow and reveal the car’s 3D form rather than covering it.

Visual innovation: The R26 establishes a new aesthetic language for Audi’s F1 era.

The closest comparison might be McLaren’s occasional minimalist liveries or the simple elegance of classic Grand Prix cars from the 1960s. But the R26’s geometric precision and material-driven approach creates something new.

Why Minimalism Works: Function, Not Just Form

The R26’s minimalism isn’t purely aesthetic. It solves practical problems:

Sponsor visibility: Fewer, larger sponsor placements get more attention than dozens of small logos competing for space. The minimalist surfaces make each sponsor location more valuable and more visible on television broadcasts.

Instant identification: Racing fans need to identify cars during chaotic race starts, high-speed overtakes, and wet conditions where spray obscures details. The R26’s distinctive proportions, unique color palette, and bold red rings create instant recognition from any angle, any distance, any lighting condition.

Television clarity: Modern F1 broadcasts use complex camera angles, onboard shots, and aerial views where busy liveries become visual noise. The R26’s geometric clarity reads clearly in every camera position.

Adaptability: The minimalist approach allows the design to work across different configurations (active aero positions) and different lighting conditions (day races, night races, variable weather) without losing visual coherence.

Minimalism becomes a competitive advantage because it makes the brand more visible, not less.

The November R26 Concept preview shows design direction, not final specification. Between now and the January 2026 car reveal, Audi’s design and engineering teams are working through an iterative refinement process:

Color specification: Testing titanium samples under different light sources (daylight, track lighting, television lighting) to finalize the exact metallic formula. Calibrating the red hue for maximum saturation and visibility. Optimizing the carbon fiber clear-coat finish for texture visibility while maintaining aerodynamic smoothness.

Geometric precision: Using CAD models and full-scale mockups to refine the exact placement of every geometric cut. Each cut must align with structural boundaries, airflow paths, or regulatory panel divisions. The design team validates that cuts maintain visual coherence in all wing configurations (active aero deployed and stowed).

Typography: Finalizing the custom typeface design that references the geometric cut language. Testing number legibility at racing speeds and various camera angles. Ensuring consistency across physical car graphics and digital brand materials.

Sponsor integration: Working with partners bp, Revolut, and adidas to position their logos within the minimalist design without disrupting visual flow. Fewer, larger placements that respect the geometric language and three-color palette.

Material transitions: Engineering the physical junctions where titanium panels meet carbon fiber surfaces. Ensuring smooth transitions that don’t create aerodynamic disturbances. Detailing how red elements integrate structurally with the base colors (painted panels vs. vinyl applications).

This refinement process involves constant collaboration between designers in Munich, engineers in Neuburg and Hinwil, and aerodynamicists validating every change in CFD simulations and wind tunnel testing.

The January reveal will show these refinements applied to a competition-ready car. Testing in Barcelona (January 26-30) and Bahrain (February 11-13, 18-20) will reveal how the design works in real racing conditions under television cameras and against competitor liveries. The March 8 Melbourne debut will show the R26 under lights, in competition, against nine other designs.

Strategic Investment: Qatar Backs the Vision

The R26’s bold design vision is backed by equally bold strategic moves. In November 2024, Audi announced that Qatar’s sovereign wealth fund, the Qatar Investment Authority (QIA), acquired a significant minority stake in Sauber Holding AG. This partnership provides financial strength and long-term commitment to the F1 project.

The QIA investment signals confidence in Audi’s approach: minimalist design, technical innovation, and audience transformation. Qatar’s backing allows Audi to execute its vision without compromise, funding the three-location operation, the extensive testing program, and the comprehensive visual system rollout.

Design as Competitive Advantage

“We want to have the most striking car on the grid,” says Massimo Frascella, and the R26’s design might deliver exactly that.

In modern F1, with cars so aerodynamically similar, visual differentiation matters. Fans need to identify cars instantly during chaotic race starts, high-speed overtakes, wet conditions. Television directors need cars that read clearly on screen. Sponsors want immediate brand visibility.

The R26’s minimalism creates instant recognition. The unique proportions, the distinctive color palette, the red rings: you can identify an Audi from any angle, any distance, any lighting condition.

The design also communicates brand values: precision, technical sophistication, innovative thinking. Where other teams shout, Audi whispers. The confidence to do less when everyone else does more.

And that confidence comes from century of motorsport success: 13 Le Mans victories, multiple DTM championships, Dakar Rally wins. Audi earned the right to take design risks.

115 days until the R26 races in Melbourne. 115 days until we see if minimalism can win in motorsport’s most complex, most visible, most competitive arena.

The post Audi R26 Concept: Radical Minimalism Rewrites F1 Design first appeared on Yanko Design.

, brushed and polished

, brushed and polished