The Greek civilization achieved significant progress in the fields of philosophy, science, art, architecture, and education alongside sports, mathematics, and theatre. These advancements have left a significant mark in shaping society and cultural evolution. This civilization, spanning from mainland Greece to Mediterranean regions, produced precise and monumental buildings that have shaped architecture for millennia. Their focus on perfection over novelty led to elegant and enduring structures that continue to inspire modern design.

Image courtesy of: Andy_Dean_Photog

What is the Greek architecture?

In broad terms, Greek architecture encompasses the ancient constructions devised and crafted by the various Greek cities and civilizations, spanning regions like the Greek mainland, Peloponnese, and Aegean Islands alongside Greek colonies in Anatolia and Italy. The architecture of Greece can be subdivided into distinct periods.

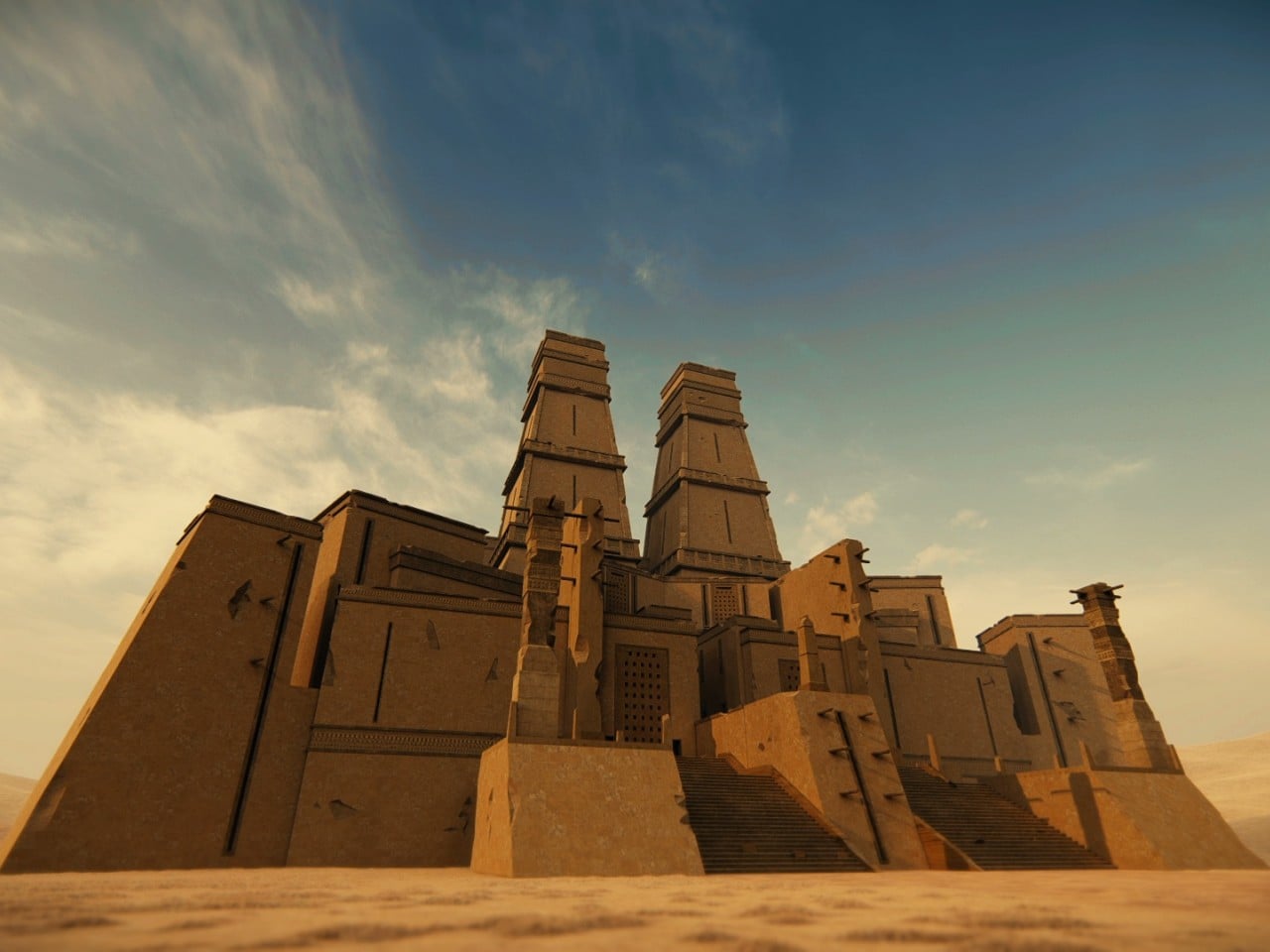

Image courtesy of: Dmitry_Rukhlenko

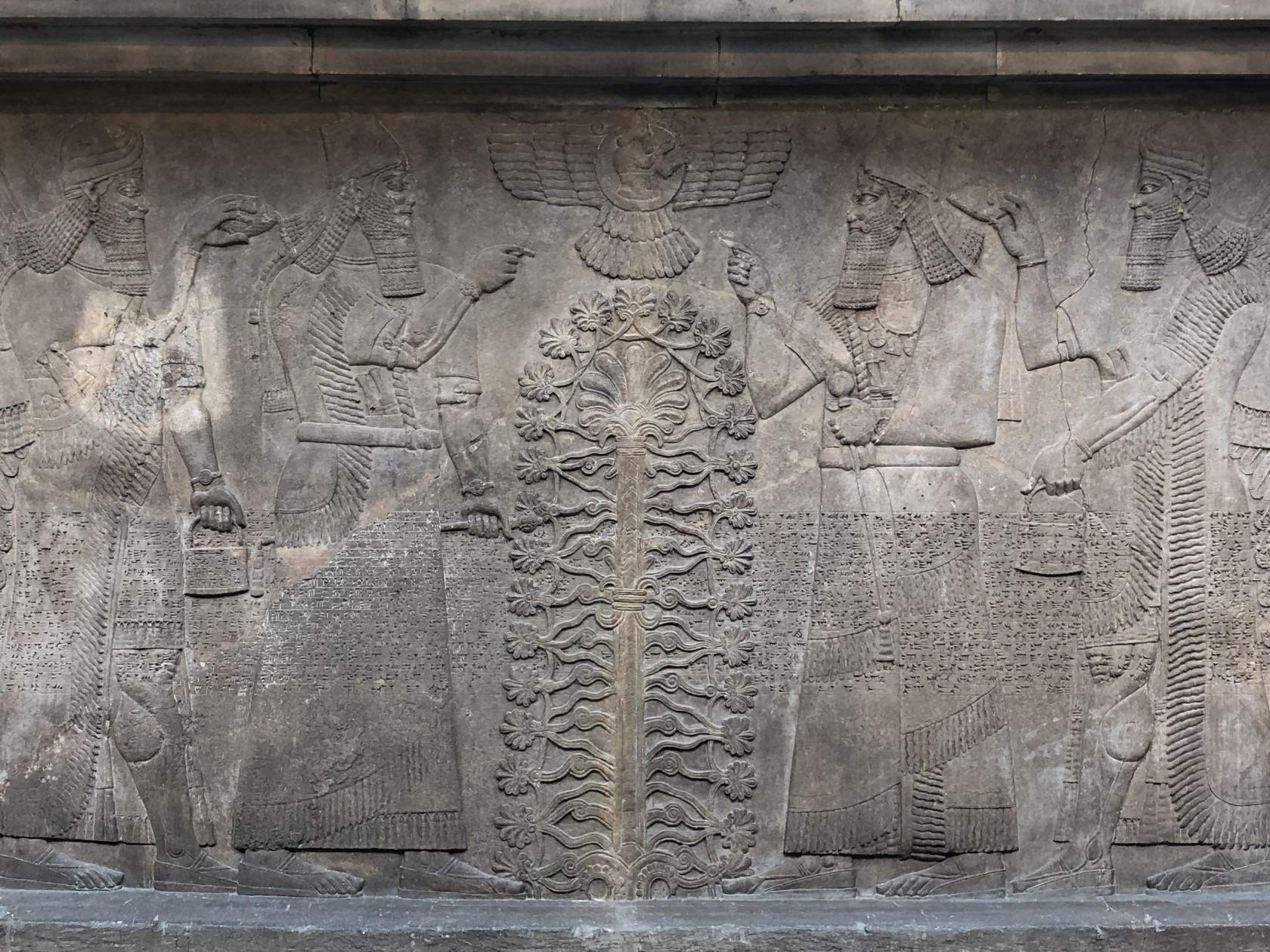

Mycenaean Age (1750 to 1050 BC)

Mycenaean Greece, the final phase of Ancient Greece’s Bronze Age featured palatial states, urban structures, artistic achievements, and a written language. Mycenaean Greeks brought innovations in engineering, architecture, and military infrastructure, relying on Mediterranean trade for their economy.

Greek Dark Age (1100 to 900 BC)

The prehistoric Dark Age followed the collapse of Mycenaean society, which lacked civilization and literacy erasing civilization and leaving a society without even rudimentary features like pottery. Lasting roughly 200 years, the Dark Age plunged society into obscurity, extinguishing all signs of civilization, including literacy. The Greek Dark Ages witnessed the transformation of farming villages into city-states, marked by the creation of agora (marketplaces) and central communal spaces, while people lived in primitive huts, had limited interaction with the outside world, and lost the ability to produce art, sculpture, or stone structures.

Greek Archaic period (800 to 479 BCE)

During the Archaic period, significant architectural advancements occurred as local communities expanded their territories to acquire additional farmland and resources, resulting in the creation of grid-planned settlements centered around temples and markets. This era introduced features like covered porticoes, sloped roofs, and stone column shafts. The most notable architectural innovation was the development of distinct column styles, known as the orders of architecture which included the Doric, Ionic, and Corinthian order.

Greek Classical Age (500-336 BCE)

Classical architecture, originating in ancient Greece emphasized columns and pediments and utilized a post-and-beam system with columns as load-bearing elements marking a transition from timber to marble and stone construction. The Doric order, remained popular in the Greek mainland and western colonies, while the Ionic order emerged in the east and was used for smaller temples and interiors.

Hellenistic period (336 to 146 BCE)

Hellenistic architecture emphasizes dramatic theatricality and viewer experience, with public spaces and temples designed on a grand scale, featuring an increased prevalence of the Corinthian order, reflecting the dramatic tendencies seen in Hellenistic sculpture.

Imagge courtesy of Diego Delso

Characteristics of Greek Architecture

Greek architecture is an integral part of classical architecture, including Roman architectural styles, characterized by its emphasis on uniformity, simplicity, proportionality, and harmony. Greek architecture is characterized by its tall columns, adherence to symmetry, square or rectangular floor plans, and the prevalent use of stone in its structures. Many iconic structures from this era were crafted from stone, although materials like wood and brick were occasionally used. Greeks constructed various public buildings, such as theatres and stadiums, but the most renowned achievements were the temples dedicated to the Olympic gods.

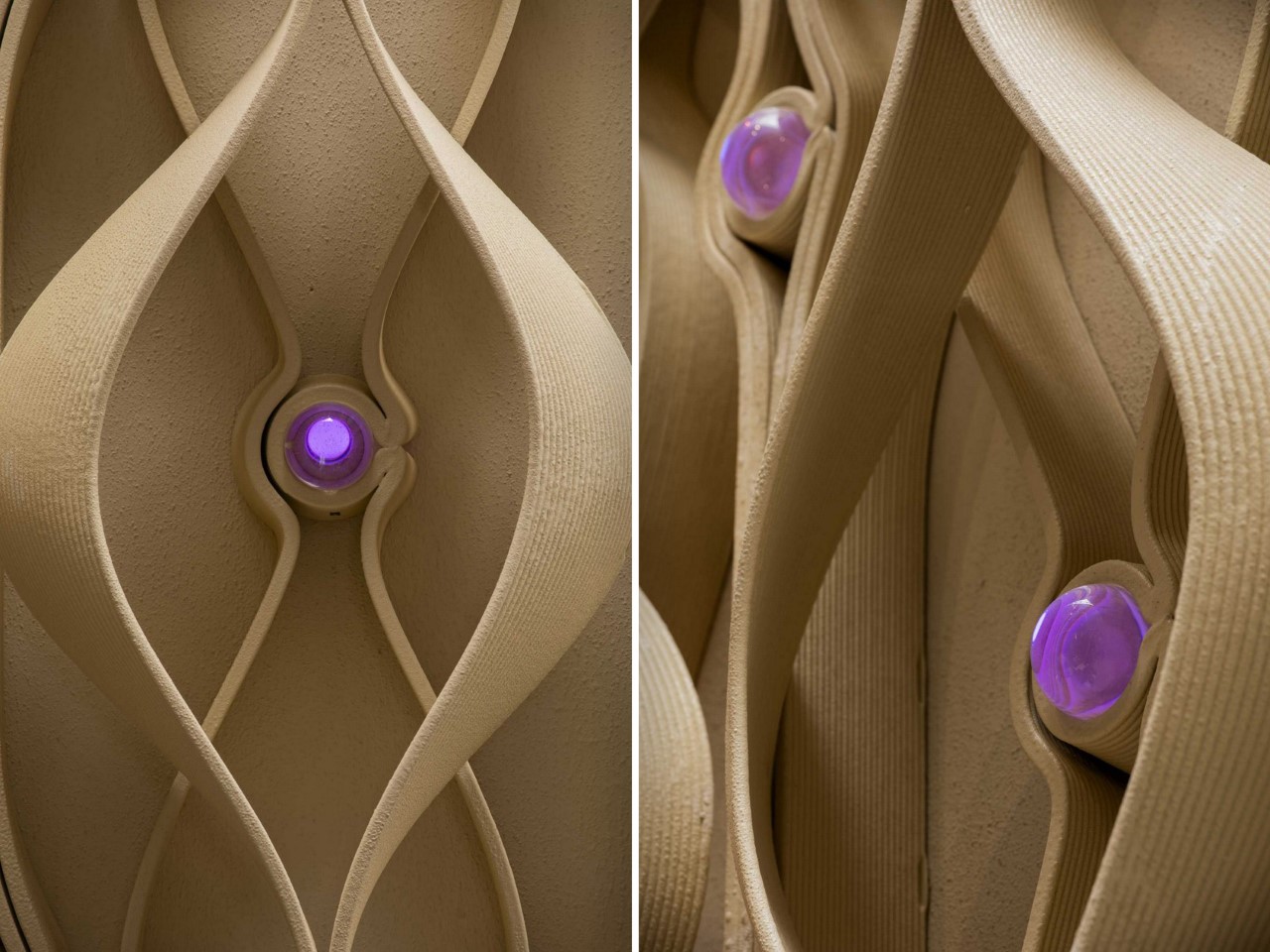

Image courtesy of: Prodronemovie

Image courtesy of: Saffron_Blaze

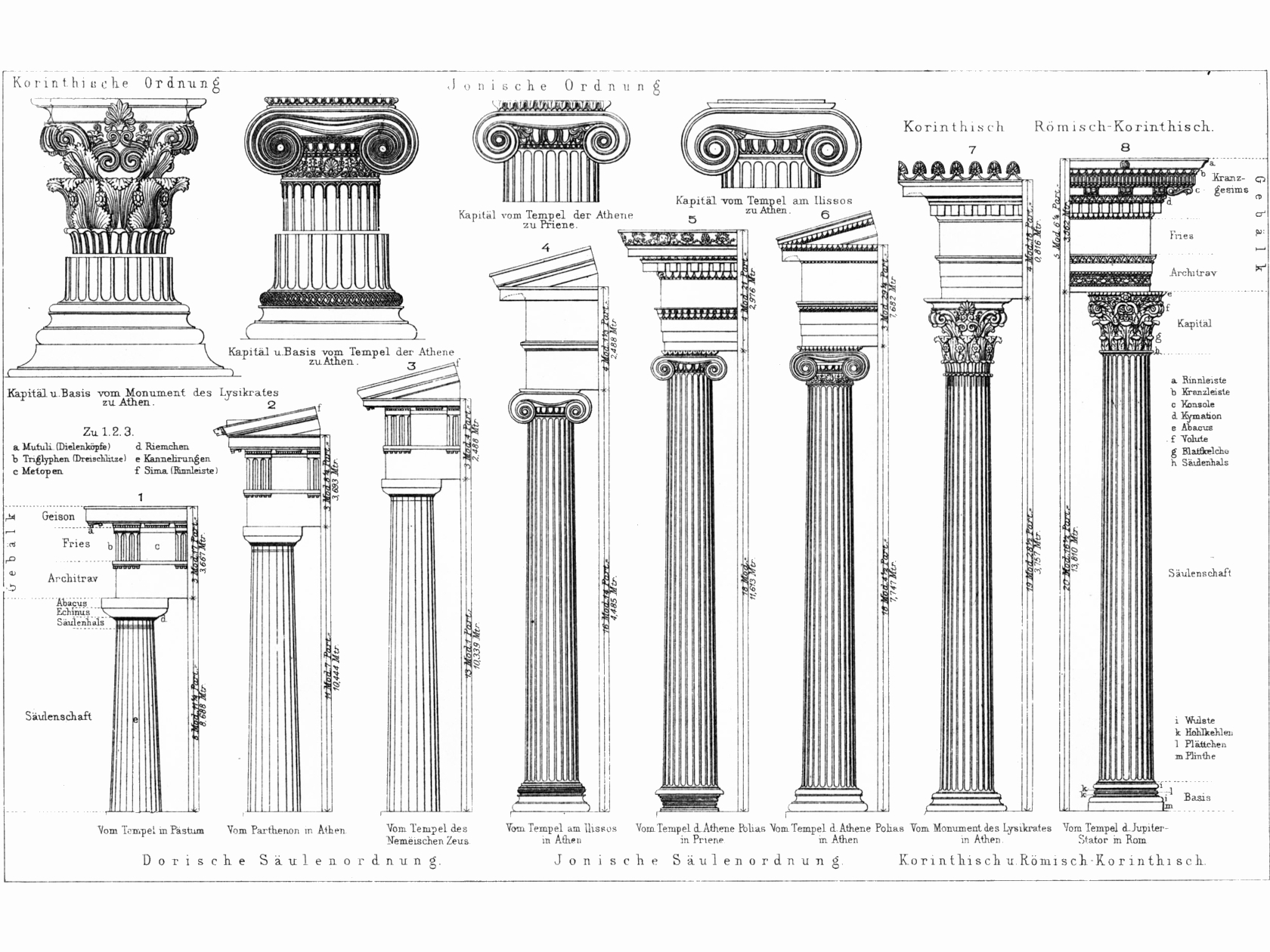

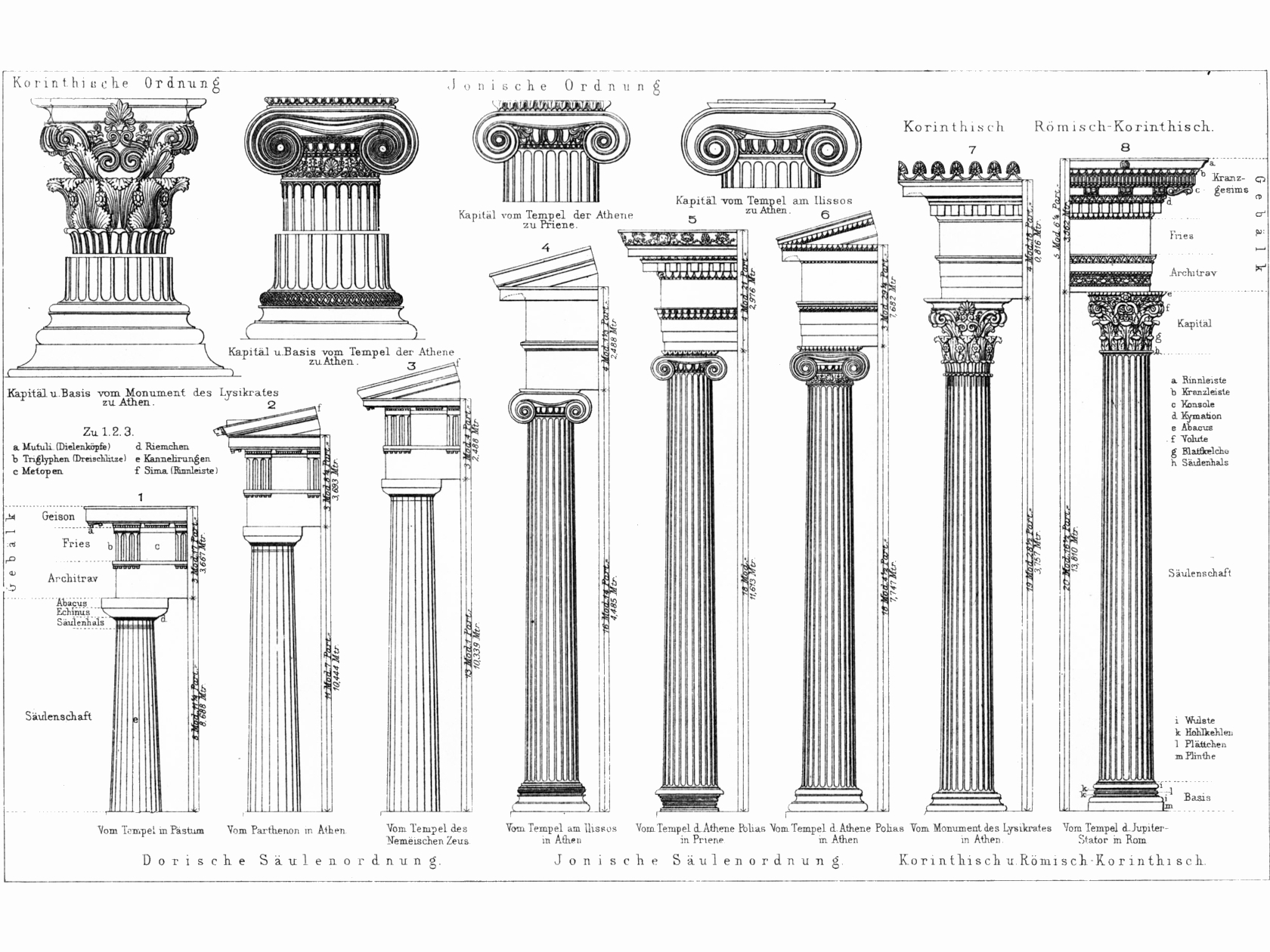

What are the Greek Classical Orders?

The architectural orders represent classical architectural styles, with each order defined by its specific proportions, distinctive profiles, and notable details, and they are most easily identified by the particular type of column they use. These three architectural orders of Greek architecture include the Doric, Ionic, and Corinthian orders.

The primary method for distinguishing architectural orders is through the analysis of their column styles and the entablature, which consists of moldings and bands positioned horizontally above the columns. The entablature can be subdivided into three parts: the architrave (a lintel or beam atop the columns), the frieze (a decorative band usually located in the middle of the entablature), and the cornice (a horizontal molding that crowns the structure).

• Doric Order

The emergence of the Doric order in Greek architecture dates back to the early 7th century BCE, leading many to consider it the oldest, as well as the most straightforward and imposing architectural style. Doric columns featured unadorned and uncomplicated smooth, round capitals and were more robust compared to their counterparts in the Ionic and Corinthian orders. Some of the examples of Doric columns in Greek architecture include the Parthenon, the Temple of Hephaestus, and the Temple of the Delians.

Image courtesy of: butlerm

• Ionic Order

The Ionic Order finds its origins in Ionia, a coastal region located in what is currently known as Turkey, from which it derives its name. Its distinctive features primarily include the scroll-like decorative elements seen on Ionic column capitals, referred to as volutes, and the presence of column bases, a feature absent in Doric columns. Some of the examples of Ionic columns in Greek include the Heraion of Samos and the Temple of Artemis at Ephesus.

Image courtesy of: Netfalls

• Corinthian Order

The term “Corinthian” pertains to an elaborate architectural column design. The Corinthian style is characterized by its intricacy and complexity, distinguishing it from the earlier Doric and Ionic Orders. In the Corinthian style, the capital, which is the uppermost section of the column, features opulent decorative motifs meticulously crafted to resemble leaves and flowers.

Image courtesy of: elxeneize

Prominent examples of Greek architecture

Temple of Olympian Zeus, Athens

Image courtesy of: staRRush

Image courtesy of: BlackBoxGuild

The Temple of Olympian Zeus also known as the Olympieion or Columns of the Olympian Zeus, stands as a colossal relic at the heart of Athens, Greece. This majestic structure was dedicated to “Olympian” Zeus, a title reflecting his role as the chief deity among the Olympian gods. The construction of this temple started in the 6th century BC during the rule of the Athenian tyrants where their vision was to create the grandest temple in the ancient world. It was only in the 2nd century AD that this project reached completion 638 years after its inception under the rule of the Roman Emperor Hadrian. During the Roman era, this temple comprised 104 massive columns and earned the distinction of being the largest temple in Greece.

Parthenon, Acropolis

Image courtesy of: Bokstas

The Parthenon, initially built to celebrate the Hellenic victory over the Persians, also served as a city treasury. Construction started in 447 BC, completed in 438 BC, with decorative work finishing in 432 BC. It later became the treasury for the Delian League and the Athenian Empire. In the 6th century AD, it became a Christian church, then a mosque after the Ottoman conquest. In 1687, it was damaged during a Venetian attack.

Odeon of Herodes Atticus, Acropolis

Image courtesy of: rawf8

Odeon of Herodes Atticus is a typical Roman theater, that finished sometime between 160 and 174 CE. Erected by the affluent philanthropist Herodes Atticus in honor of his wife, Regilla, this structure, in its initial design, featured a roof constructed from cedar and a front facade adorned with three stories of arches. Carved into the rugged southern slope of the Acropolis hill, this open-air theater stands as one of the world’s most ancient and remarkable. With a seating capacity of around 5,000, it underwent comprehensive restoration in 1952-1953 and now serves as the central location for the annual Athens Epidaurus Festival.

Erechtheion, Acropolis

Image courtesy of: Neirfy007

Image courtesy of: Source

The Erechtheion is an ancient temple that is constructed on the north side of Acropolis and is dedicated to goddess Athena. Built during 421 to 406 BC on an irregular terrain, the temple is an asymmetrical composition that formed a religious center for worshipping the god Hephaistos, Erechtheus, and the hero Boutes, who was Erechtheus’ brother.

The Great Theater of Epidaurus

Image courtesy of: Carole Raddato

Situated in the Greek city of Epidaurs and built in the late 4th century BC near modern Lygourio the ancient Theatre of Epidaurus is dedicated to Asclepius, the ancient Greek God of medicine. This theatre is renowned for its remarkable acoustics and aesthetics and is regarded as the most flawless ancient Greek theater.

Greek architecture successfully combines functionality and artistic expression that is reflected in the construction of public spaces, monumental temples and open-air theatres. Its architectural heritage is still replicated and incorporated into modern architectural designs and interior aesthetics.

The post The Architectural Legacy of Ancient Greece first appeared on Yanko Design.