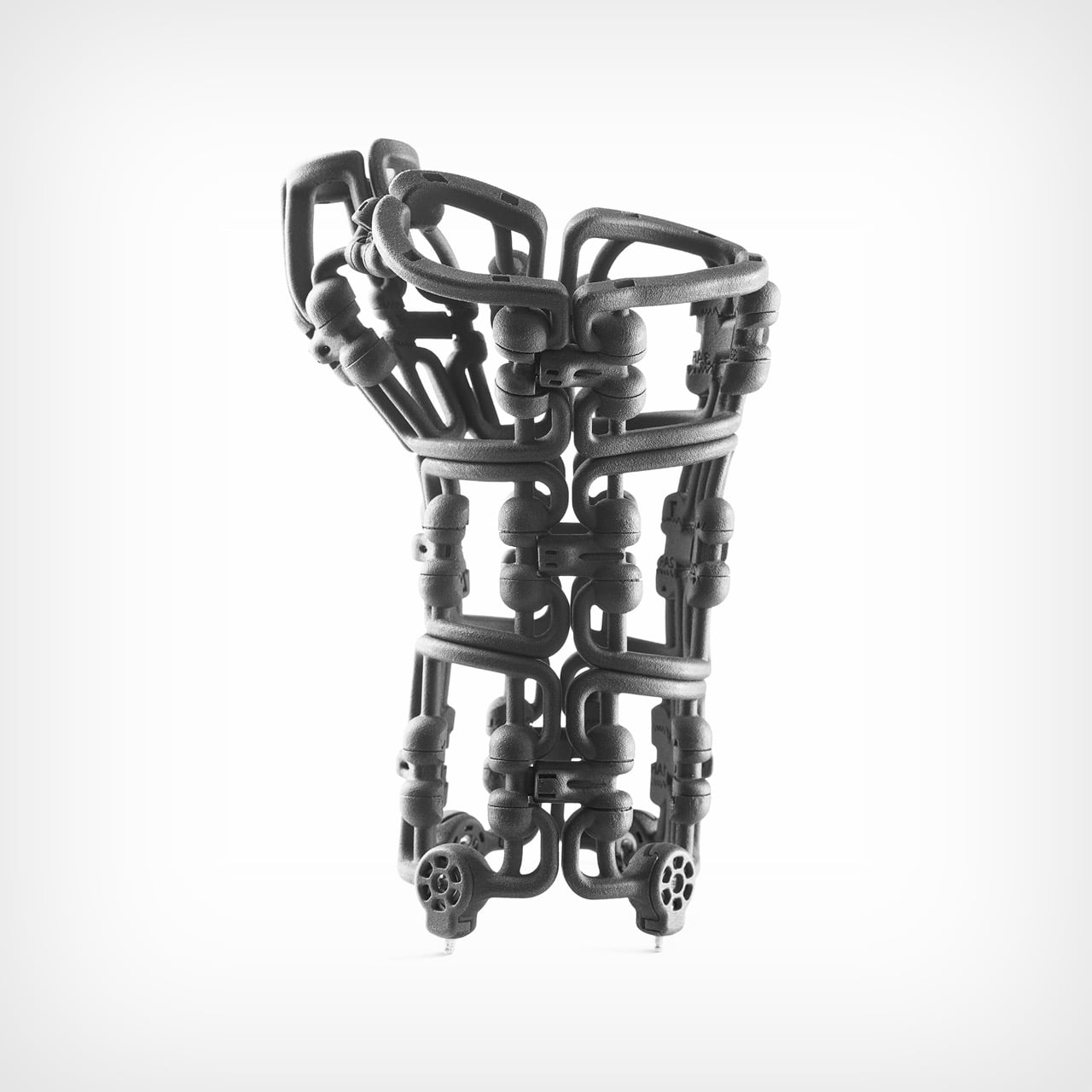

What do Swiss timepieces and sailing rigging systems have in common with orthopedic braces? More than you might think. The engineers at Osteoid drew inspiration from these precision mechanical systems to create Bracesys, a revolutionary approach to fracture immobilization that challenges everything we thought we knew about medical casts.

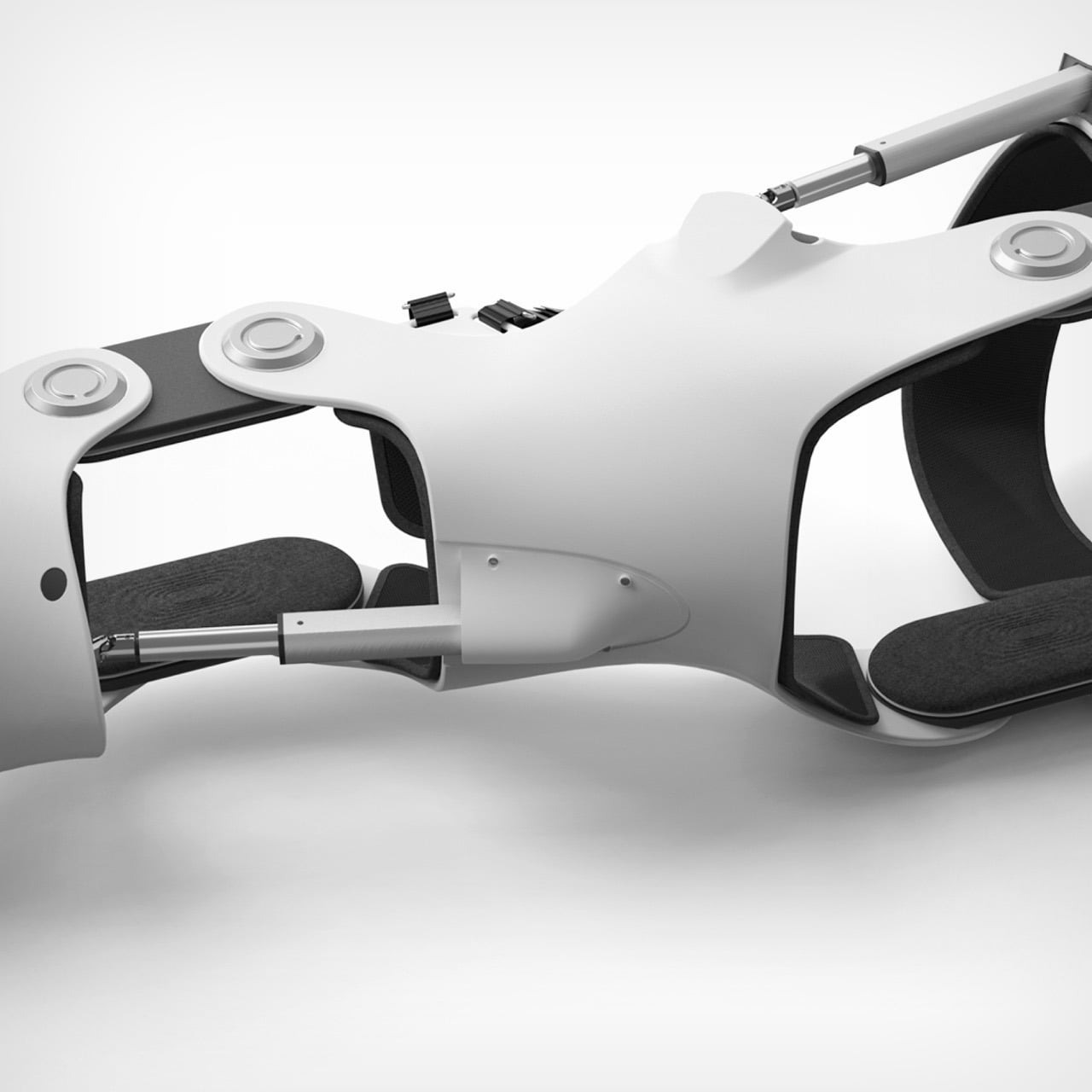

Traditional plaster casts have remained largely unchanged for over a century. Off-the-shelf braces offer convenience but rarely fit properly. Custom 3D-printed alternatives require expensive scanners, lengthy production times, and specialized expertise. Bracesys sidesteps all these limitations with an adjustable framework of segmented units, articulating connectors, and tension dials. The entire system weighs just 150 grams and folds flat into an envelope, yet provides rigid support comparable to traditional casts. More remarkably, clinicians can customize it to each patient’s anatomy in real time, adjusting the fit as swelling decreases and healing progresses.

Designer: Osteoid Design Team

Kevlar cables run through the framework and get tightened via integrated dials, borrowing directly from sailing rigging where distributed tension points create precise control. Yacht rigging achieves massive structural loads through this exact principle. Osteoid just applied it to wrist immobilization. The framework comes from SLS and MJF 3D printing with medical-grade Nylon 12, reinforced at stress points with CNC-machined aluminum and stainless steel. This hybrid manufacturing approach delivers geometric complexity for anatomical conformity while keeping structural integrity where loads concentrate. Pure injection molding couldn’t achieve these organic shapes. Pure 3D printing couldn’t handle the forces.

Over 600 anonymized CT scans went into the sizing methodology, processed through AI-driven segmentation and implicit skinning algorithms that map soft tissue deformation around bone structures. Principal Component Analysis crunched all that data into four standardized sizes covering the 5th to 95th percentile of hand and wrist anatomy. You’re getting semi-custom fit from off-the-shelf components, which anyone in medical device design will tell you is brutally difficult to pull off. Manufacturing needs standardization for scale. Patients need personalization for outcomes. Most companies pick one and live with the compromise.

A typical Colles fracture brace measures 190 x 90 x 115 mm assembled but breaks down completely flat into an A4 envelope. Clinicians wrap it around the limb loose, let the segmented units find their natural anatomical alignment, then use screwdriver-sized tools to adjust connector lengths and tighten the tension dials incrementally. Spring-loaded quick-release pins handle adjustments as swelling changes during recovery. The whole initial fitting takes minutes. I keep coming back to that speed because custom 3D-printed orthotics need weeks of turnaround, and drugstore braces fit approximately nobody correctly. This lands right in the middle with none of the usual tradeoffs.

Every plaster cast is single-use. Every prefab brace eventually becomes landfill. Traditional orthopedic devices generate waste at a scale that should embarrass the industry but somehow doesn’t. Bracesys uses recyclable materials throughout, sterilizes for reuse in clinical settings, and lets you replace individual components rather than trashing the whole assembly. I’m usually cynical about sustainability claims in medical devices because they often conflict with clinical needs or regulatory requirements. This actually works because better economics and better outcomes align with lower waste. Nobody has to sacrifice anything.

We shouldn’t still be using plaster casts in 2026. The technology to do better has existed for decades. The problem has always been the gap between custom fabrication costs and mass production constraints. Most attempts at solving this try to make manufacturing cheaper or faster. Bracesys flips that entirely by making adjustability the core feature and shipping that capability to the point of care. You’re not customizing during manufacturing. You’re customizing during application. That philosophical shift matters more than any individual mechanical innovation. If orthopedic practices actually start using this widely, we might finally kill off a medical technology that’s been coasting on pure inertia since the 1800s. It’s time we ‘brace’ for change…

The post This Kevlar Medical Brace Folds Flat Like Origami and Might Finally Kill the Plaster Cast first appeared on Yanko Design.