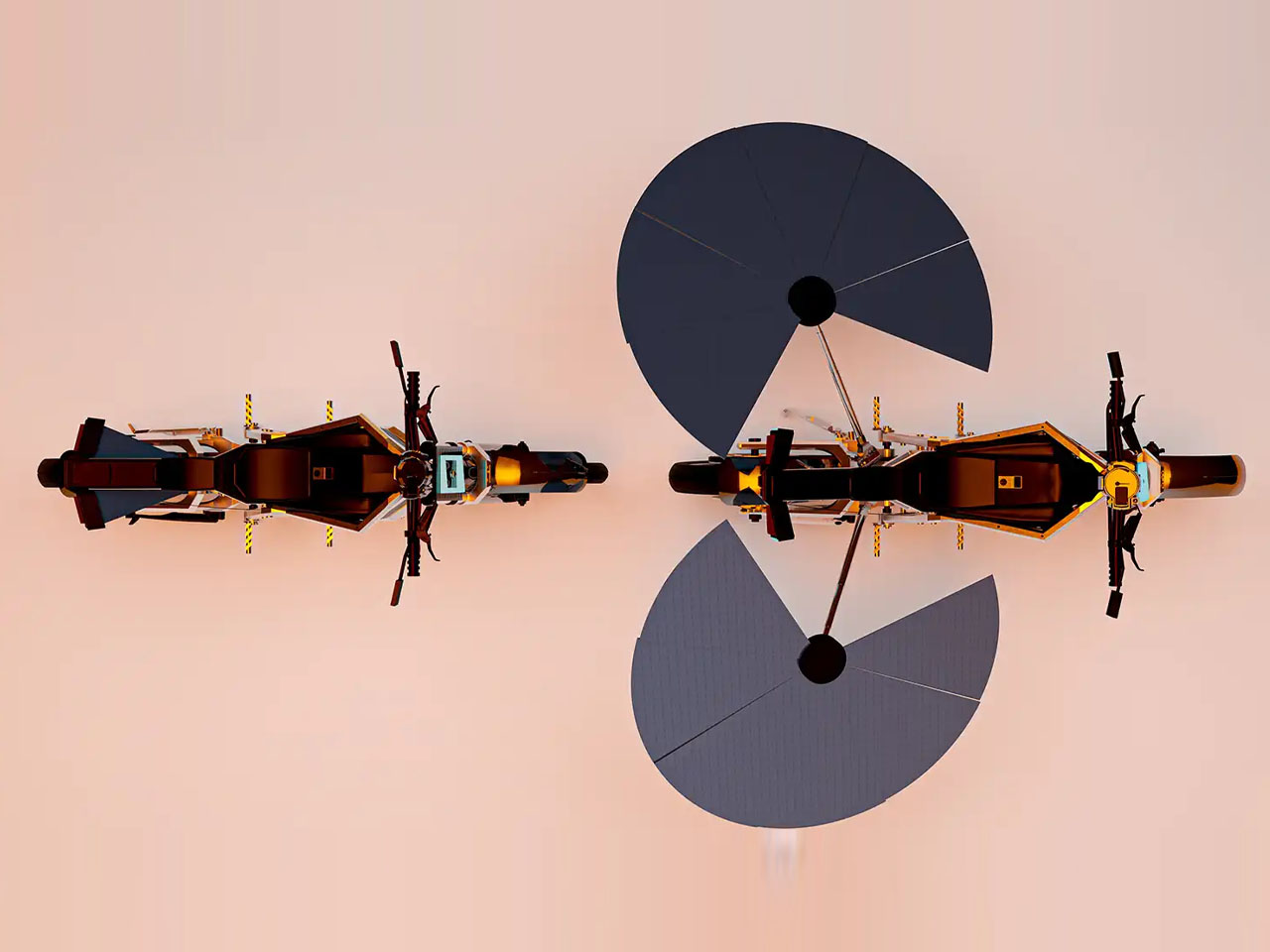

Apple’s shift to 3D-printed titanium marks a turning point, not just for wearables, but for how material innovation becomes the foundation for meaningful design change. Every Apple Watch Ultra 3 and titanium Series 11 case now emerges from additive manufacturing using 100 percent recycled aerospace-grade titanium powder. The process cuts raw material consumption in half and saves over 400 metric tons this year alone.

Designer: Apple

The mirrored polish catches light like traditionally forged luxury timepieces. The featherweight durability feels indistinguishable from cases that started as solid titanium blocks. But these surfaces hide a manufacturing revolution that transforms waste into possibility, turning production constraints into design advantages Swiss watchmakers using forged steel never imagined.

The Material Challenge That Changed Everything

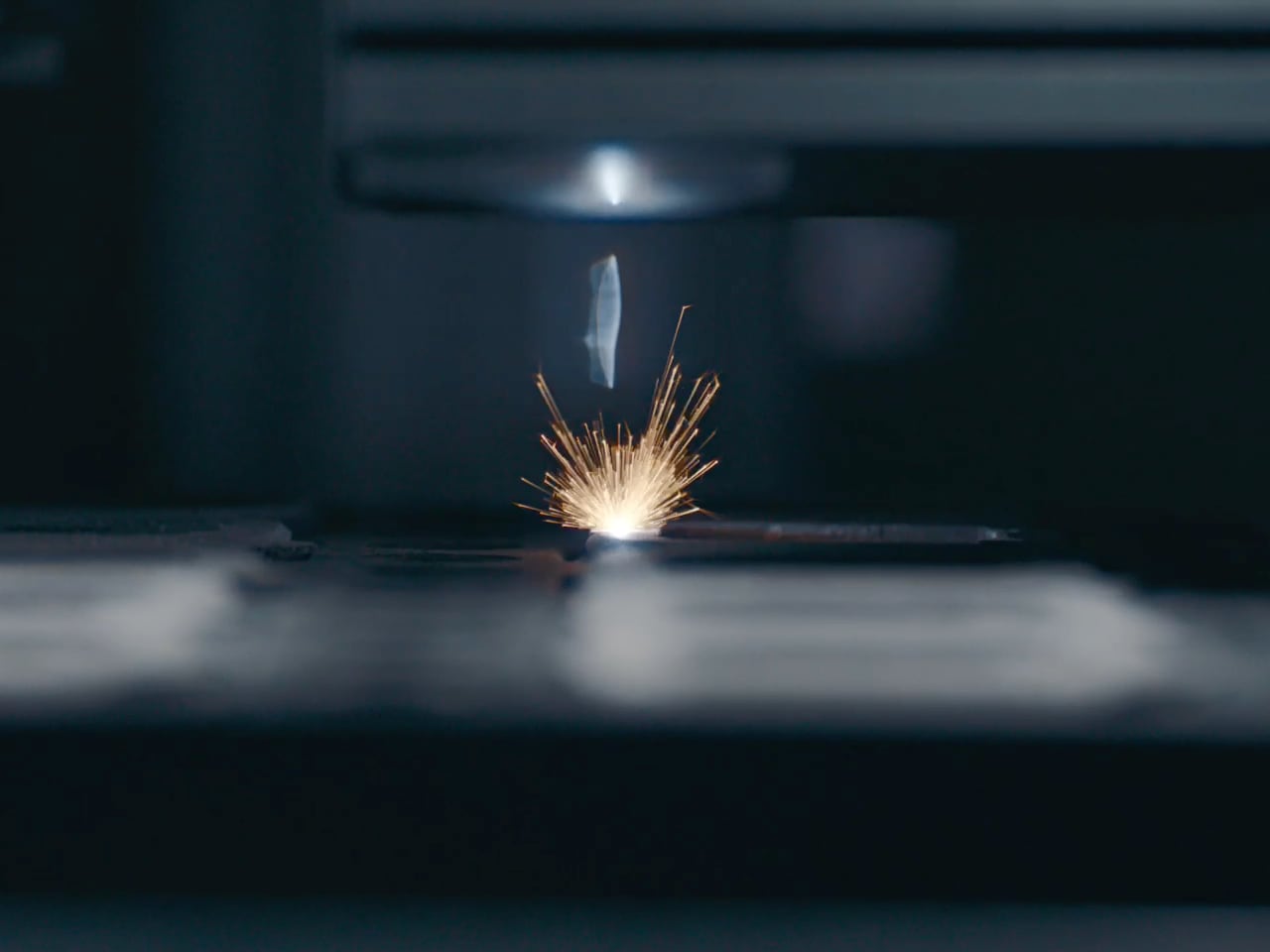

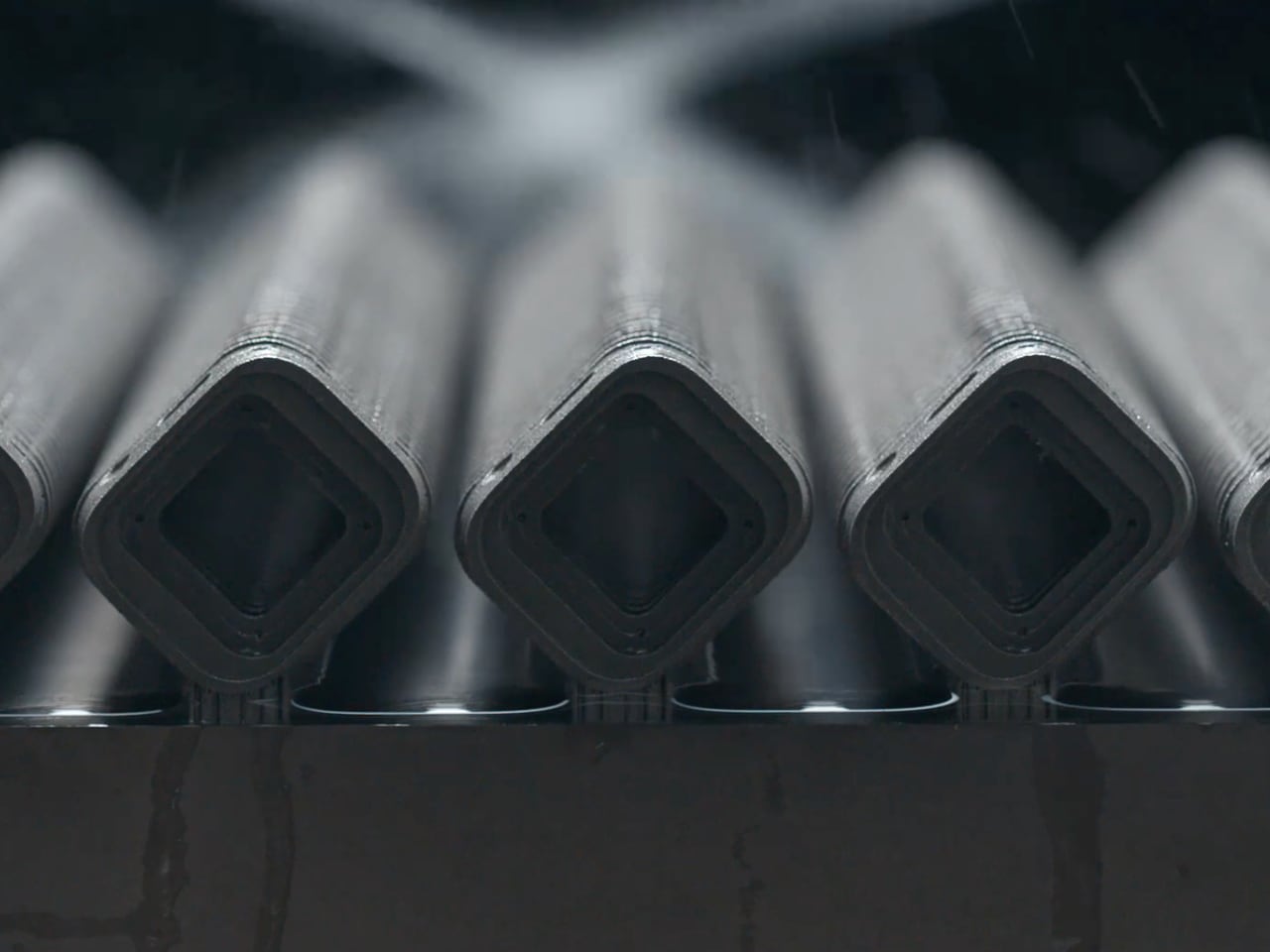

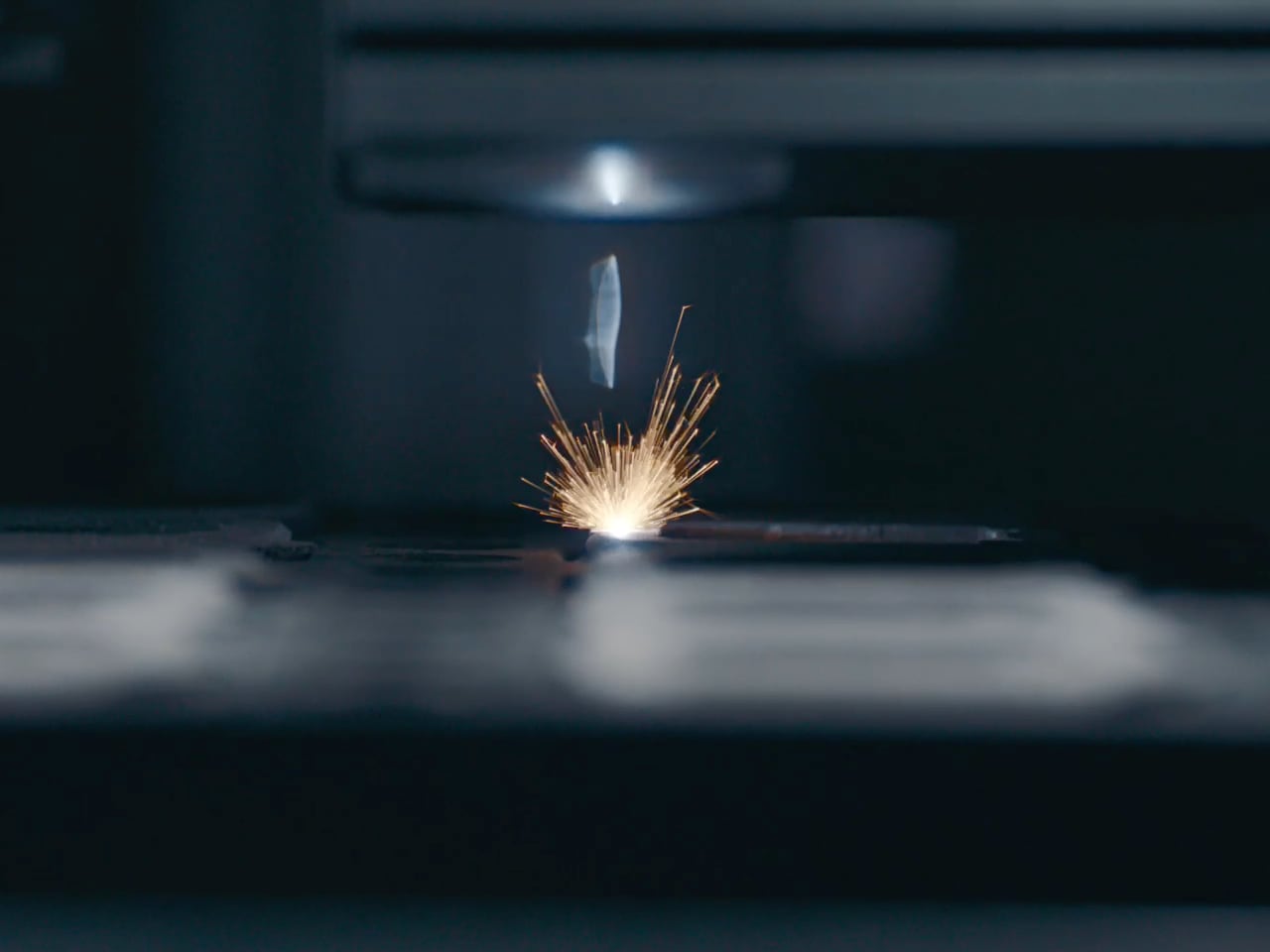

Traditional watch case manufacturing works subtractively. Large titanium blocks get machined down until the case emerges, with excess material becoming waste. 3D printing reverses this entirely. Six lasers build each case layer by layer, over 900 times, until the form reaches near-final shape using only what the design actually needs.

“It wasn’t just an idea: it was an idea that wanted to become a reality,” Kate Bergeron, Apple’s vice president of Product Design, explains. The team spent over a decade watching 3D printing mature across industries. Hospitals printed prosthetics. Astronauts manufactured tools aboard the International Space Station. But cosmetic parts at consumer electronics scale remained impossible until Apple solved the titanium puzzle.

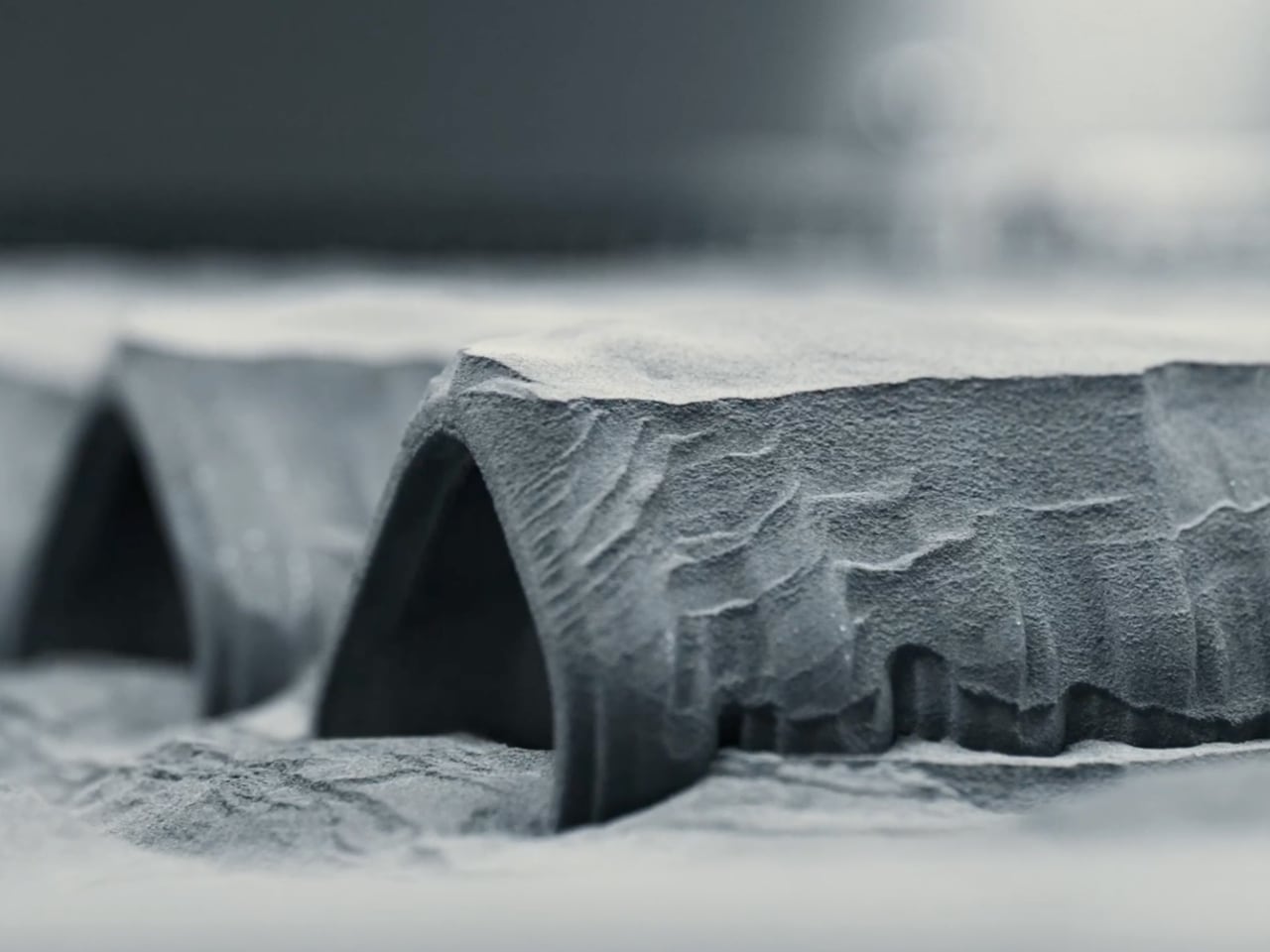

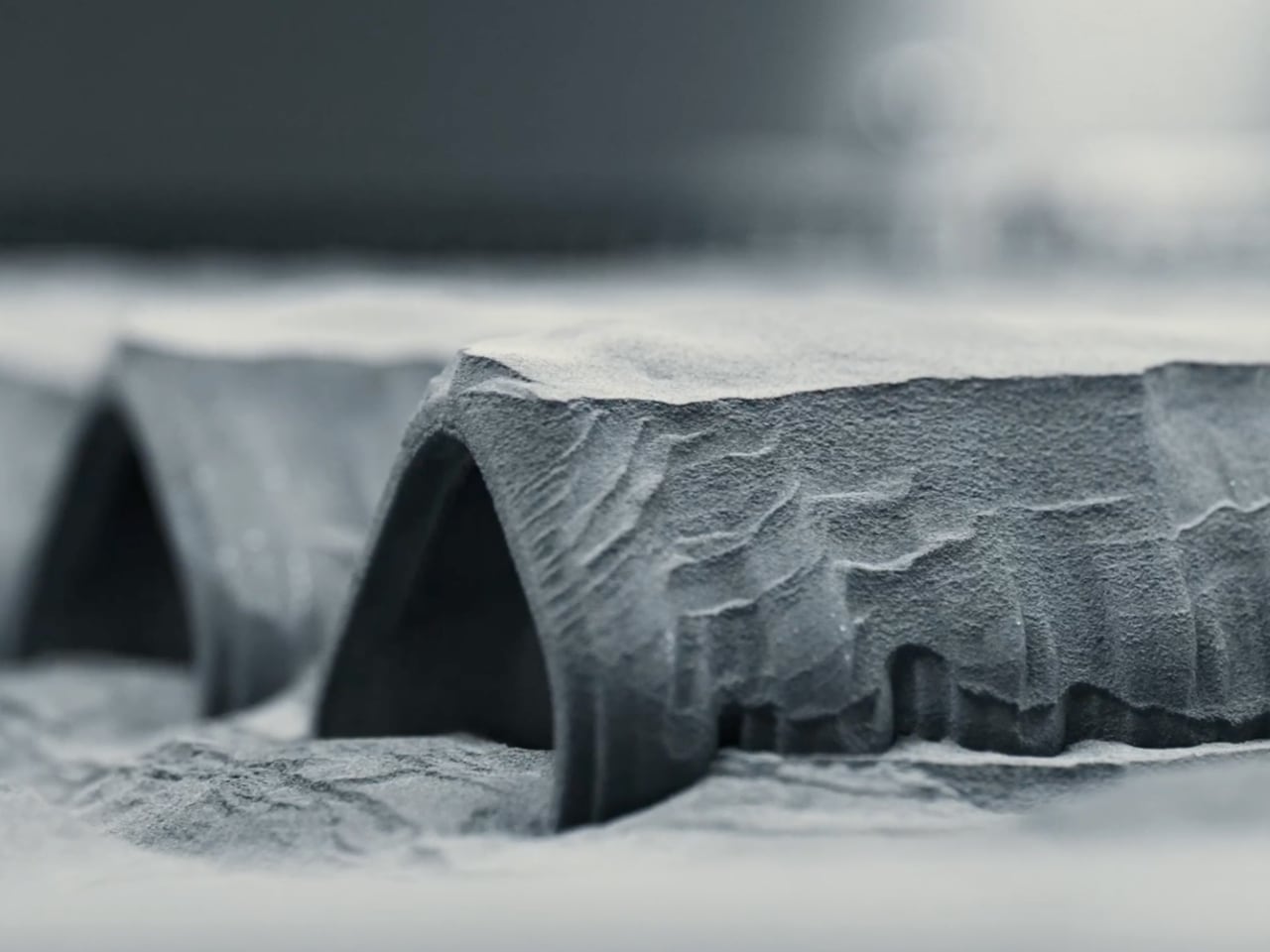

The material itself fought back. Titanium powder needs atomization to 50 microns, like sifting ultra-fine sand. But at that scale, oxygen content becomes critical. Too much oxygen, and hitting the powder with lasers risks fireworks instead of precision manufacturing. The materials science team engineered a low-oxygen titanium powder that could withstand six simultaneous lasers without compromising aerospace-grade quality.

Design Unlocked Through Process

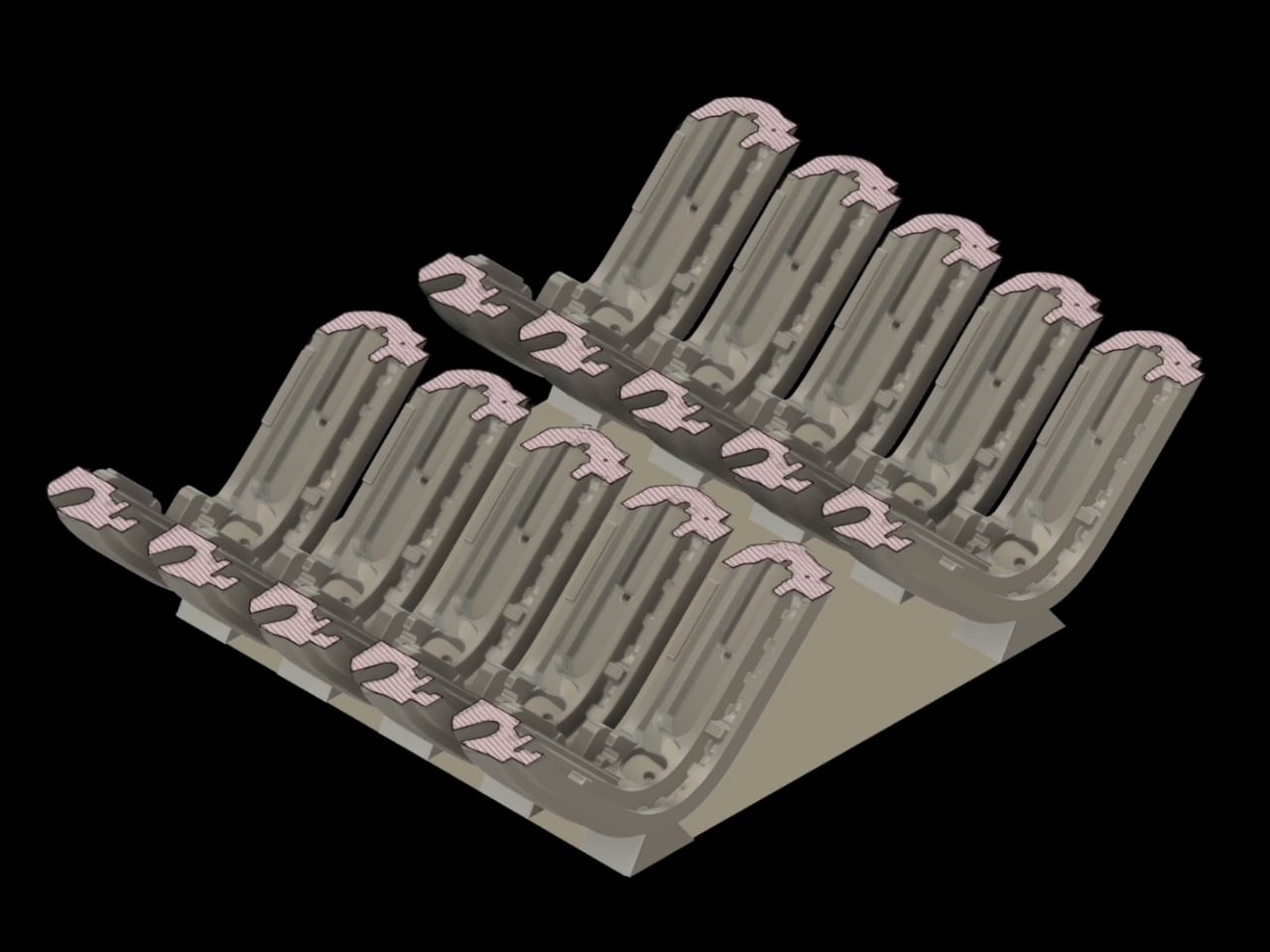

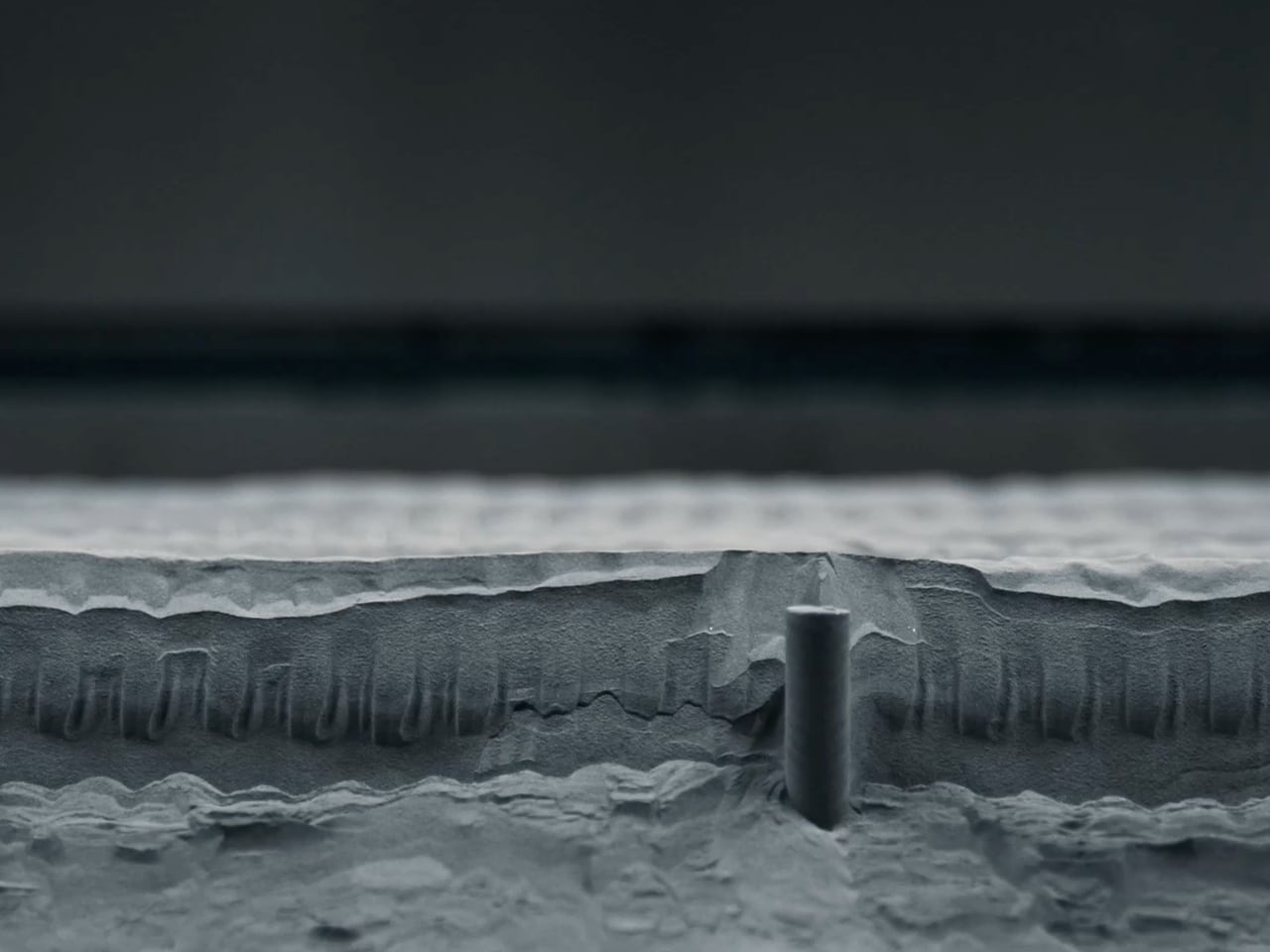

The 3D printing breakthrough delivered benefits traditional forging never could. The process enables texture printing in locations previously inaccessible during manufacturing. For cellular Apple Watch models, this solved a critical waterproofing challenge.

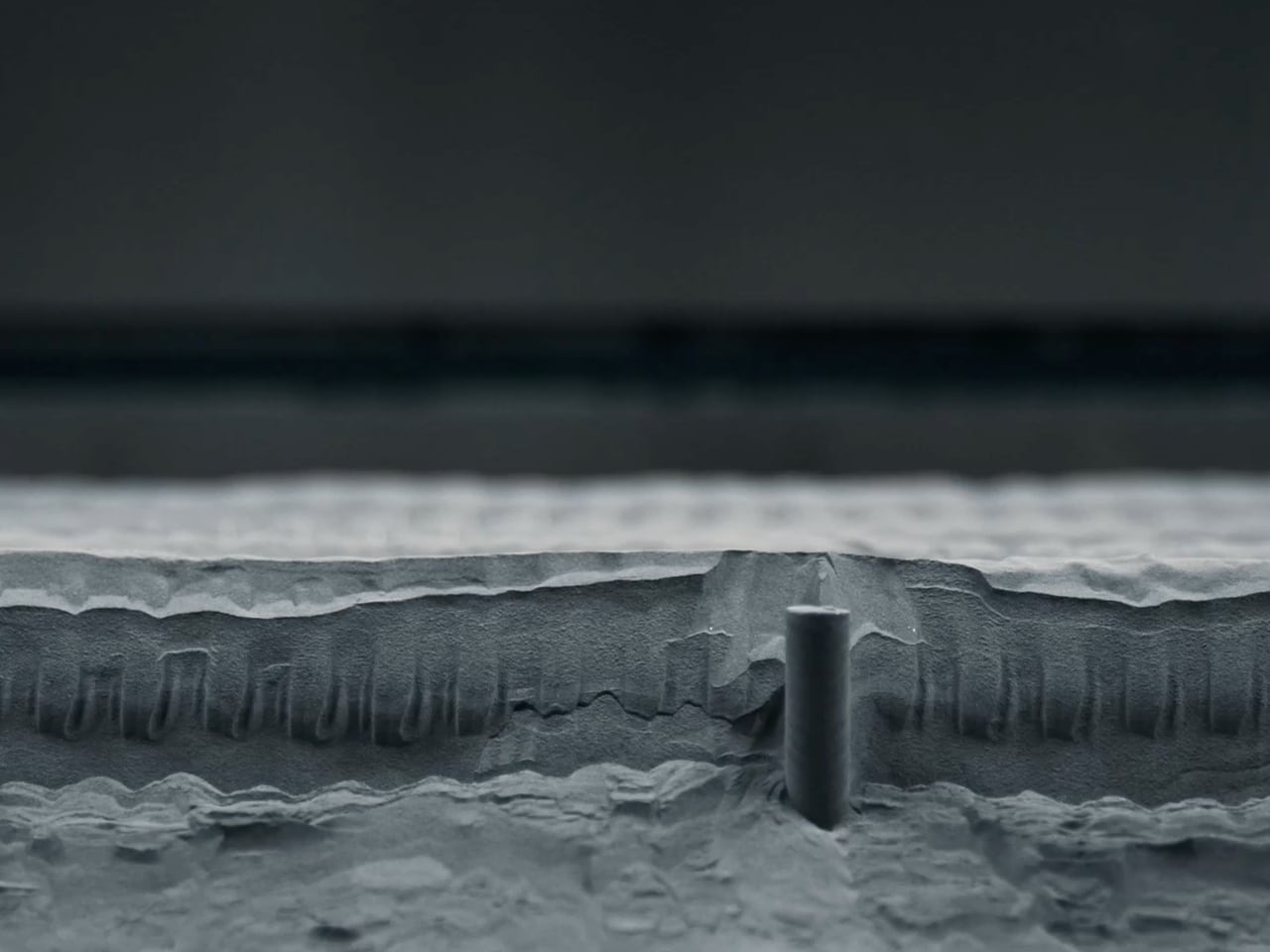

Cellular cases require a plastic-filled split to enable antenna functionality. The bonding between metal and plastic determines water resistance performance. 3D printing allowed Apple to print specific textures on the inner metal surface, dramatically improving how plastic bonds to titanium.

For swimmers doing open-water laps, athletes training in downpours, or anyone caught in unexpected rain, that improved bonding translates to confidence the watch survives submersion without compromise. Better waterproofing emerges without adding bulk or sacrificing the slim profile that keeps the watch comfortable through 14-hour days.

“This has now opened up the opportunity for even more design flexibility than what we had before,” Bergeron notes. That flexibility already extended beyond Apple Watch. The new iPhone Air’s USB-C port features a titanium enclosure 3D-printed with the same recycled powder. The incredibly thin yet durable design only became possible through additive manufacturing.

Sustainability as Systems Change

The environmental mathematics tell a compelling story. Apple’s additive process uses half the raw titanium compared to subtractive machining of previous generations. That 50 percent reduction translates to two watches from material previously required for one.

“We’re extraordinarily committed to systems change,” Sarah Chandler, Apple’s vice president of Environment and Supply Chain Innovation, states. “We’re never doing something just to do it once: we’re doing it so it becomes the way the whole system then works.”

This aligns with Apple 2030, the company’s goal to achieve carbon neutrality across its entire footprint by decade’s end. All electricity powering Apple Watch manufacturing already comes from renewable sources like wind and solar. The 3D printing advancement represents another major step toward eliminating waste throughout the production chain.

The process preserves material quality without compromise. Ultra 3 maintains its durability and lightweight form for everyday adventurers. Series 11’s polished mirror finish stays pristine. Both deliver better environmental performance using the same or superior materials compared to traditionally machined cases.

Manufacturing Precision at Scale

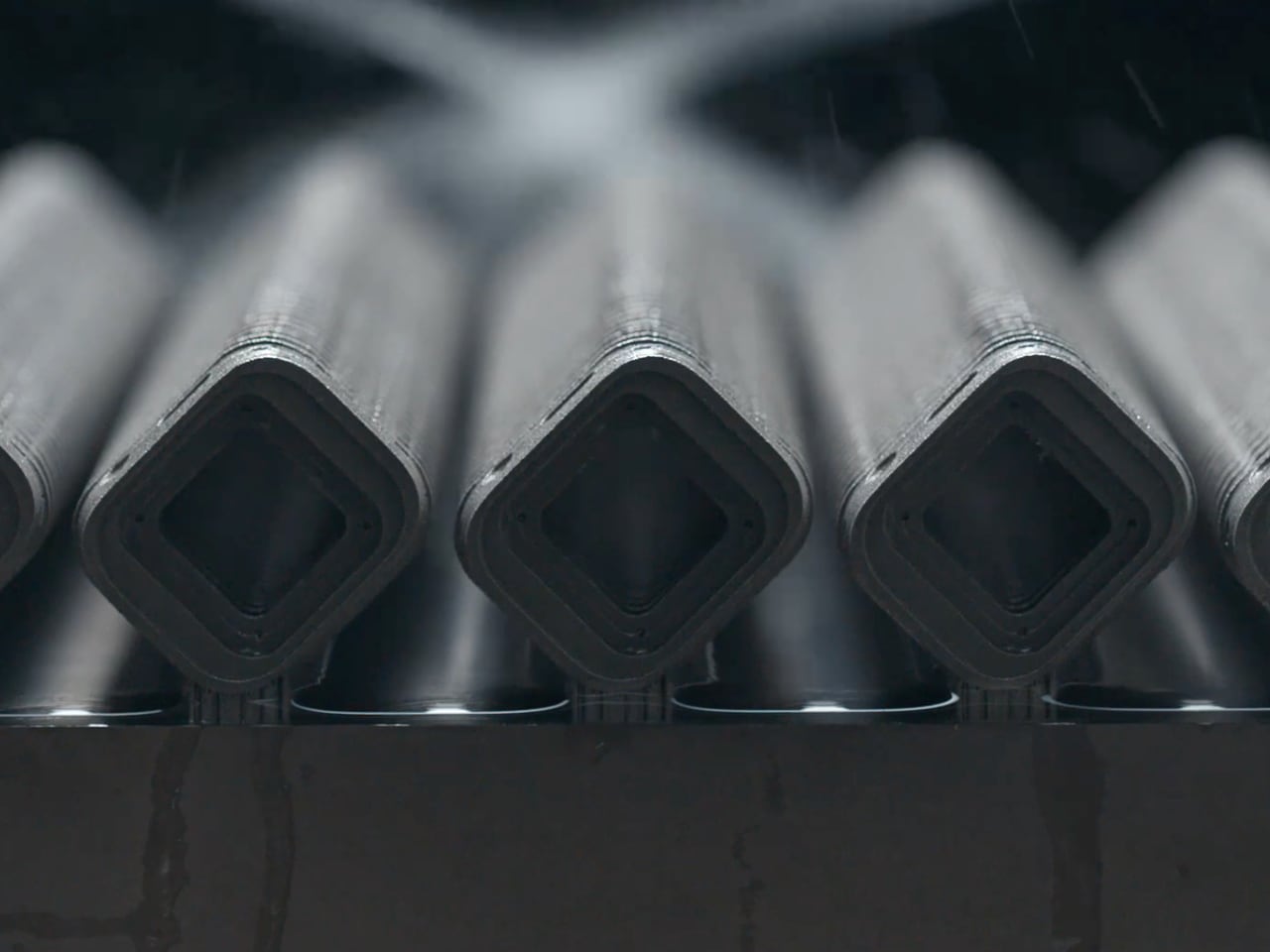

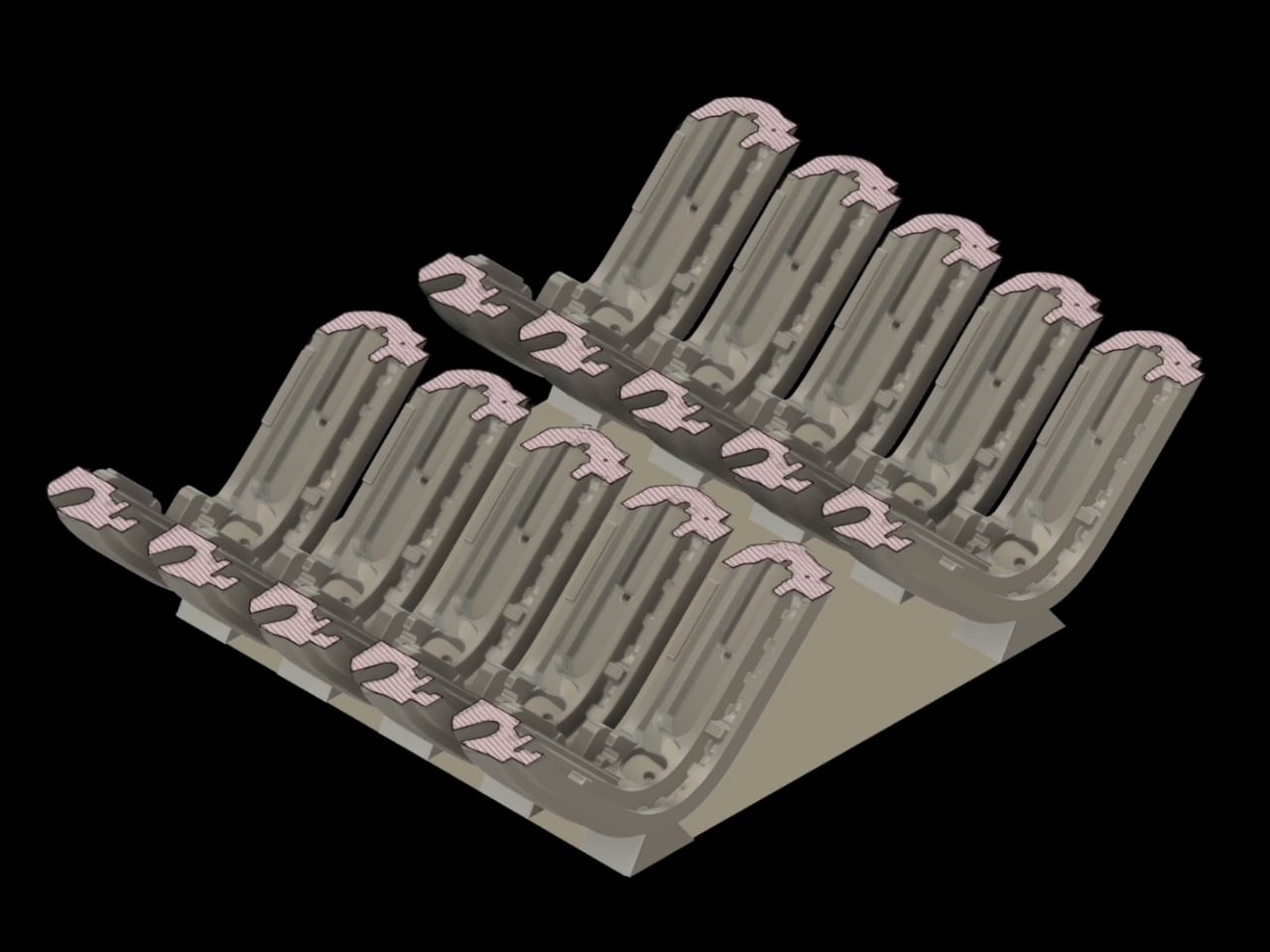

Each 3D printer houses a galvanometer with six lasers working simultaneously. Layer thickness must hit exactly 60 microns. A precision squeegee spreads powder at microscopic tolerances. Speed matters for scalability, but precision matters for design standards.

“We have to go as fast as we possibly can to make this scalable, while going as slow as we possibly can to be precise,” Bergeron explains. After printing completes, operators vacuum excess powder during rough depowdering. An ultrasonic shaker removes powder trapped in case interlocks during fine depowdering. A thin electrified wire saws between each case during singulation while liquid coolant manages heat. Automated optical inspection verifies dimensions and cosmetics before cases move to final processing.

The multiyear journey started with demos and proofs of concept. Apple tested 3D printing at smaller scales in previous product generations before committing to this titanium breakthrough. Each incremental step validated the next possibility. The specific alloy composition, the printing process itself, the quality control protocols, all required continuous optimization to meet Apple’s exacting standards.

Design Philosophy Meets Environmental Imperative

What makes this achievement remarkable isn’t just the technical complexity. It’s how Apple made sustainability inseparable from design excellence. The polished titanium finish looks identical whether machined or printed. Performance remains unchanged or improves. Durability meets or exceeds previous generations.

According to Apple, environment is a core value for every team. The 3D printing technology offered material efficiency critical for reaching Apple 2030 goals. But the team refused to compromise aesthetics or functionality to hit environmental targets. Instead, they engineered a solution delivering all three simultaneously.

The manufacturing breakthrough also demonstrates how production constraints can drive design innovation rather than limit it. Printing textures in previously inaccessible locations improved waterproofing. Additive manufacturing enabled thinner, more durable USB-C ports. Material efficiency created new design possibilities instead of restricting existing ones.

“When we come together to innovate without compromise across design, manufacturing, and our environmental goals, the benefits are exponentially greater than we could ever imagine,” Chandler adds. By merging manufacturing efficiency with environmental responsibility, Apple turns sustainability into a creative asset rather than a corporate checkbox.

“We’re only beginning to imagine where additive manufacturing can take us,” Bergeron notes. The 3D-printed titanium Apple Watch cases prove manufacturing processes can become design philosophy. When production efficiency, material sustainability, and aesthetic excellence align, the result transcends simple environmental compliance. It becomes a new standard for what responsible design looks like at scale.

Key Takeaways

Manufacturing becomes design opportunity: 3D printing shifts titanium production from wasteful subtraction to efficient addition, cutting material use by 50 percent while enabling new design possibilities.

Sustainability unlocks features: The additive process allowed texture printing in previously inaccessible locations, directly improving waterproofing performance for cellular models without adding bulk.

Scale meets precision: Apple’s approach sets a manufacturing precedent, proving consumer electronics can achieve millions of identical premium-quality cases through 3D printing with 100 percent recycled materials.

Cross-product innovation: Breakthroughs developed for Apple Watch extended to iPhone Air’s impossibly thin USB-C port, demonstrating how solving constraints for one product unlocks possibilities across entire product lines.

The post Apple’s 3D-Printed Titanium Apple Watch: When Manufacturing Becomes Design Philosophy first appeared on Yanko Design.