Like precaution is better than cure in everyday life, warmup and recovery before and after a strenuous workout or competition are equally important. Nike has over decades made life immensely comfortable for athletes with the most relaxed footwear options. Now, it is tying up with Hyperice to ensure that the warmup and recovery phases in a player’s life are also taken care of by the Swoosh brand with equal prowess.

To that accord, in collaboration with Hyperice, – a name providing athletes with innovative technology during recovery to improve the performance of muscles and joints – Nike is working on developing a pair of boots and vest that would “help athletes perform at their best throughout training and competition.”

Designer: Nike

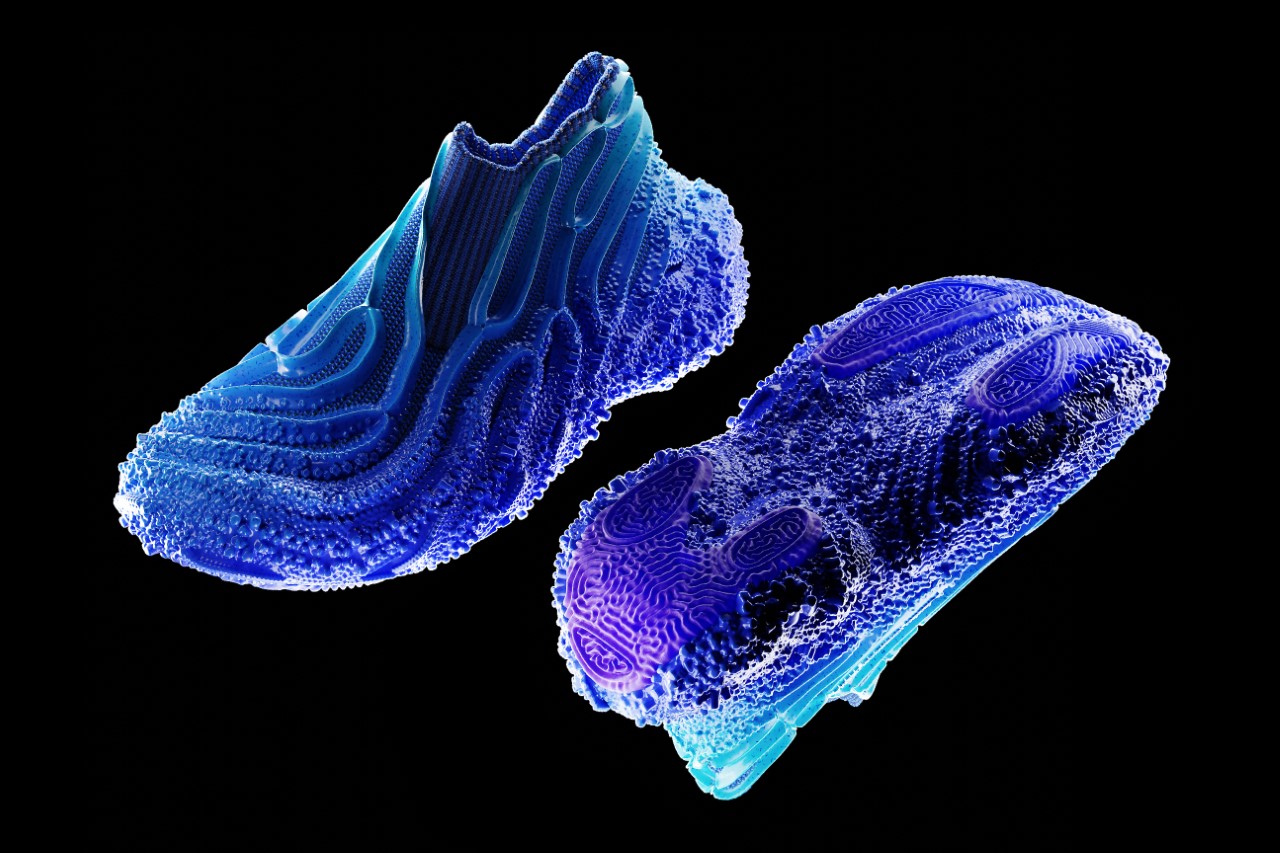

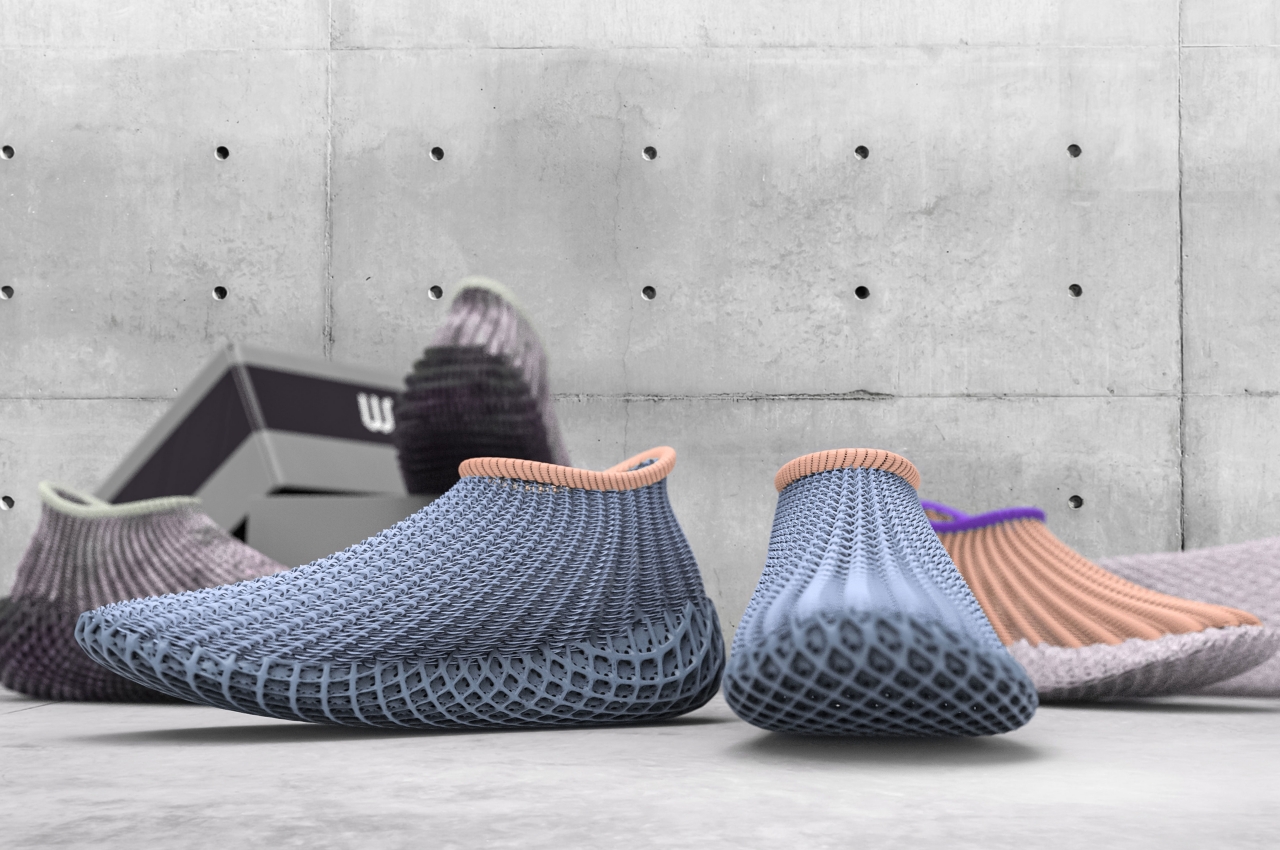

Nike and Hyperice boot and vest, Tobie Hatfield, Senior Director, Nike Athlete Innovation informs, “get the body ready for activity, whether you’re playing for a title or you’re on your feet a lot at work.” An extension of Nike’s focus on the integration of wearable technology in its products, these pair of boots would provide the wear with heat and dynamic air compression at the feet and ankle, which feels like a foot massage. This prepares the body before a workout and can relax the feet after a long stressful game or if the person has been on the foot for too long.

The Nike and Hyperice vest is designed to monitor and maintain the body temperature of a player. For this, the vest is integrated with thermal modules and pressure sensors that work in tandem to ensure effective heating and cooling of the body. Both the vest and the shoes are still under development and will be launched at a “later date,“ Nike confirms.

The pair of high-top shoes, push the boundary of what’s possible for today’s athletes, with air Normatec bladders and warming elements. The air bladders inflate and deflate – what feels like a massage – and allow the heat to distribute evenly and deep in the feet and ankle to provide soothing comfort to the wearer’s feet. Of course, the shoes are primarily targeted at the athletes, with the likes of LeBron James testing them, the adaptation of technology could be beneficial for people whose work requires them to stand and walk too much.

“From the moment I tried the Nike x Hyperice boots and vest while they were still in development more than a year ago, I knew they were going to change the game for athletes’ warm-up and recovery,” LeBron James notes. It is worth noting that the heat and air compression in the Nike x Hyperice boots are customizable. The user can synchronize the heat and compression with the push of a button (at the control panel placed on the midsole), and can even choose to run different settings on individual shoes, if required.

The post Nike and Hyperice boots use air compression to massage athlete’s feet, a boon for warmup and recovery first appeared on Yanko Design.