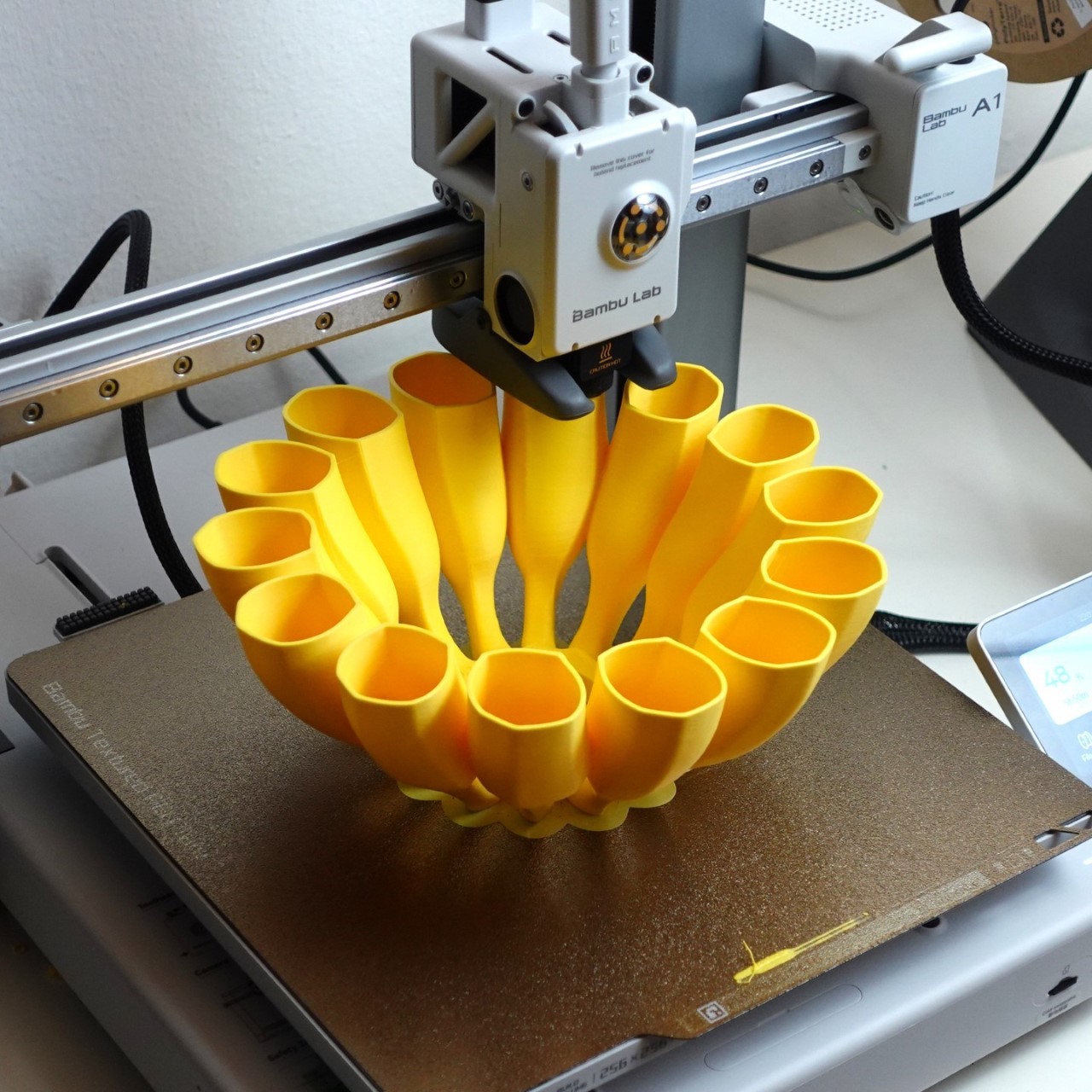

There’s something deeply satisfying about watching a potter’s wheel spin, the way human hands coax wet clay into form. But what happens when you hand that craft over to a robot? Designers Yutao Chen and Yiwen Gu asked that question, and their answer is CeraShingle, a façade system that’s reimagining what ceramic can do for architecture.

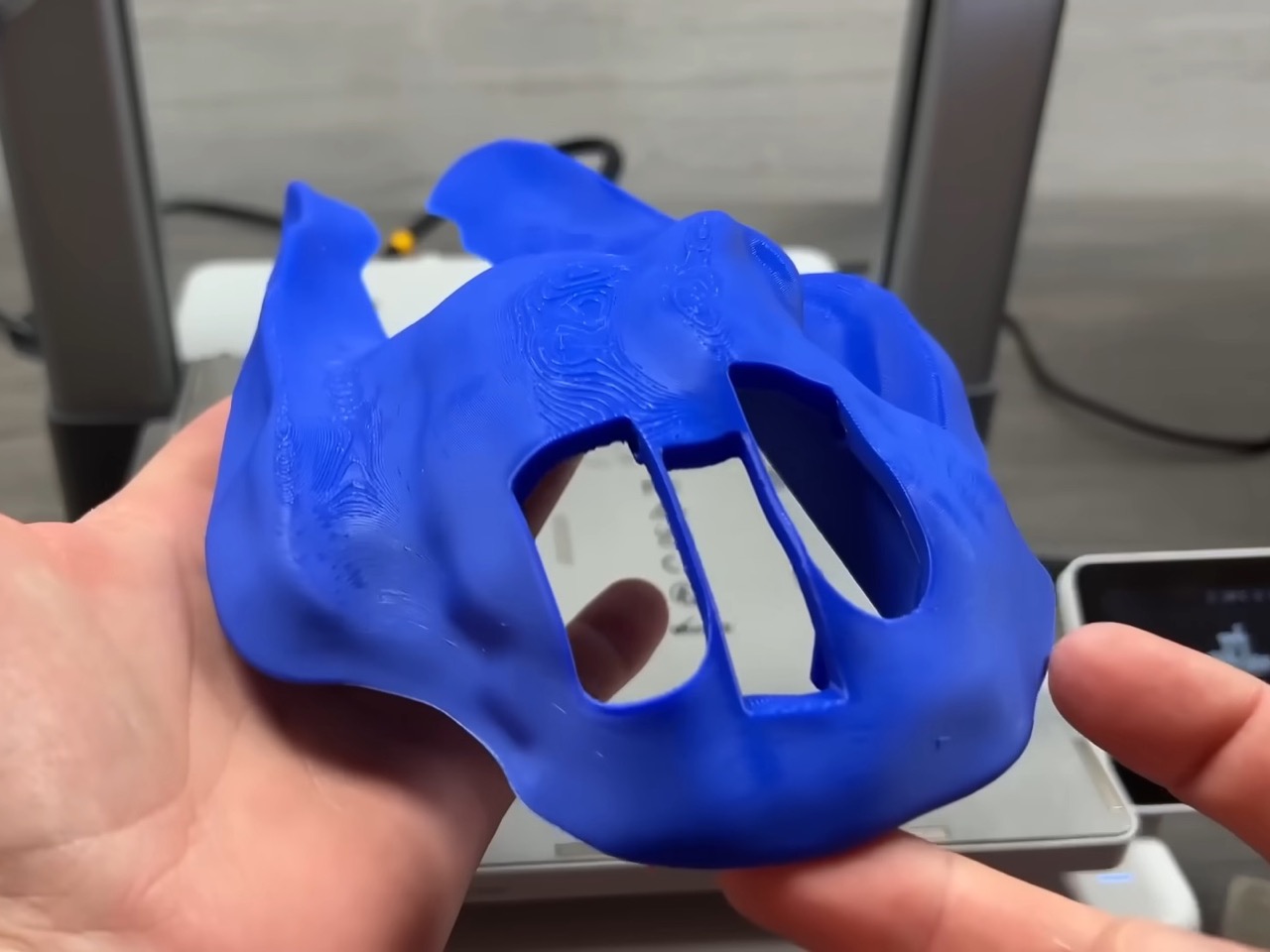

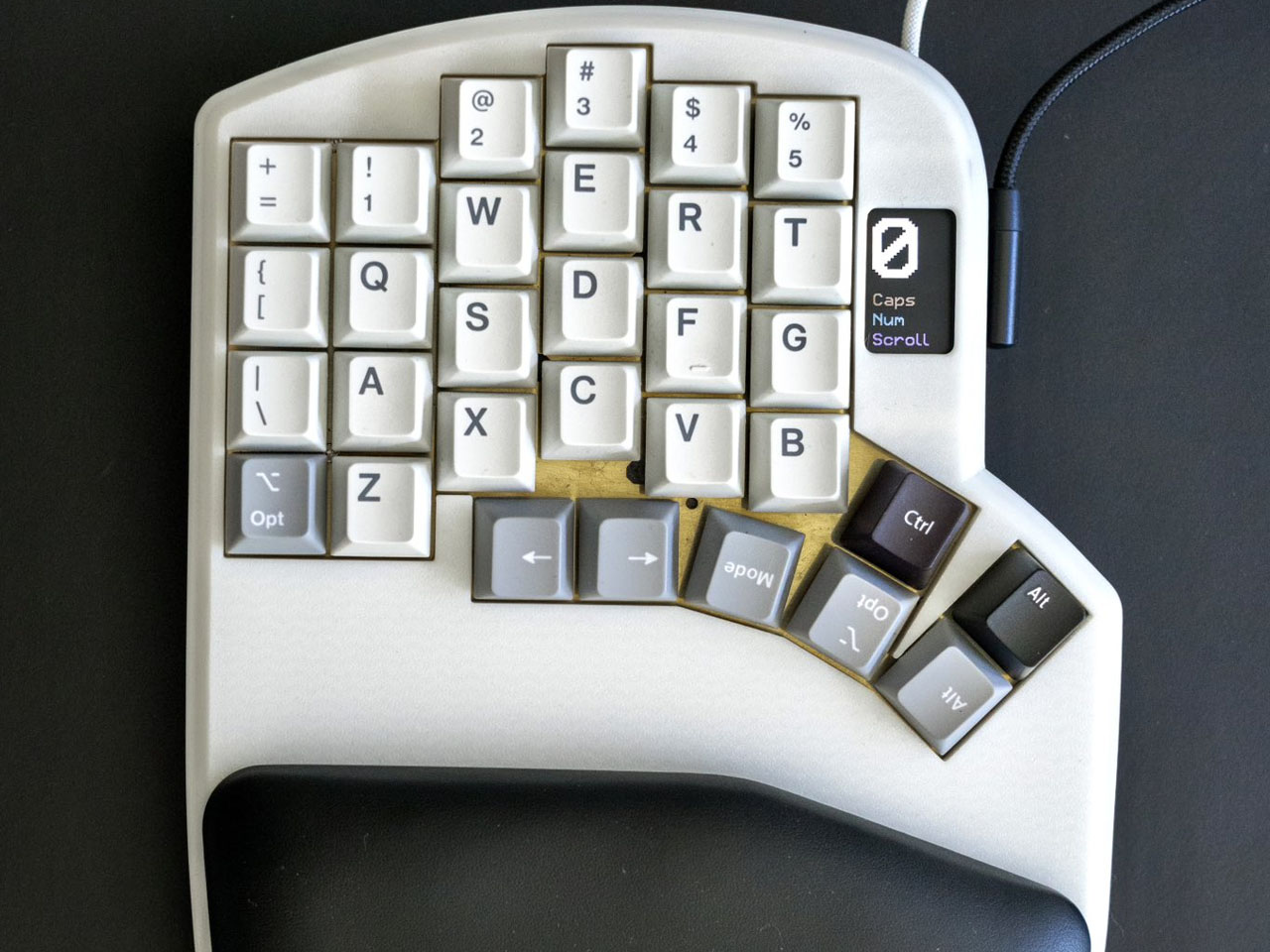

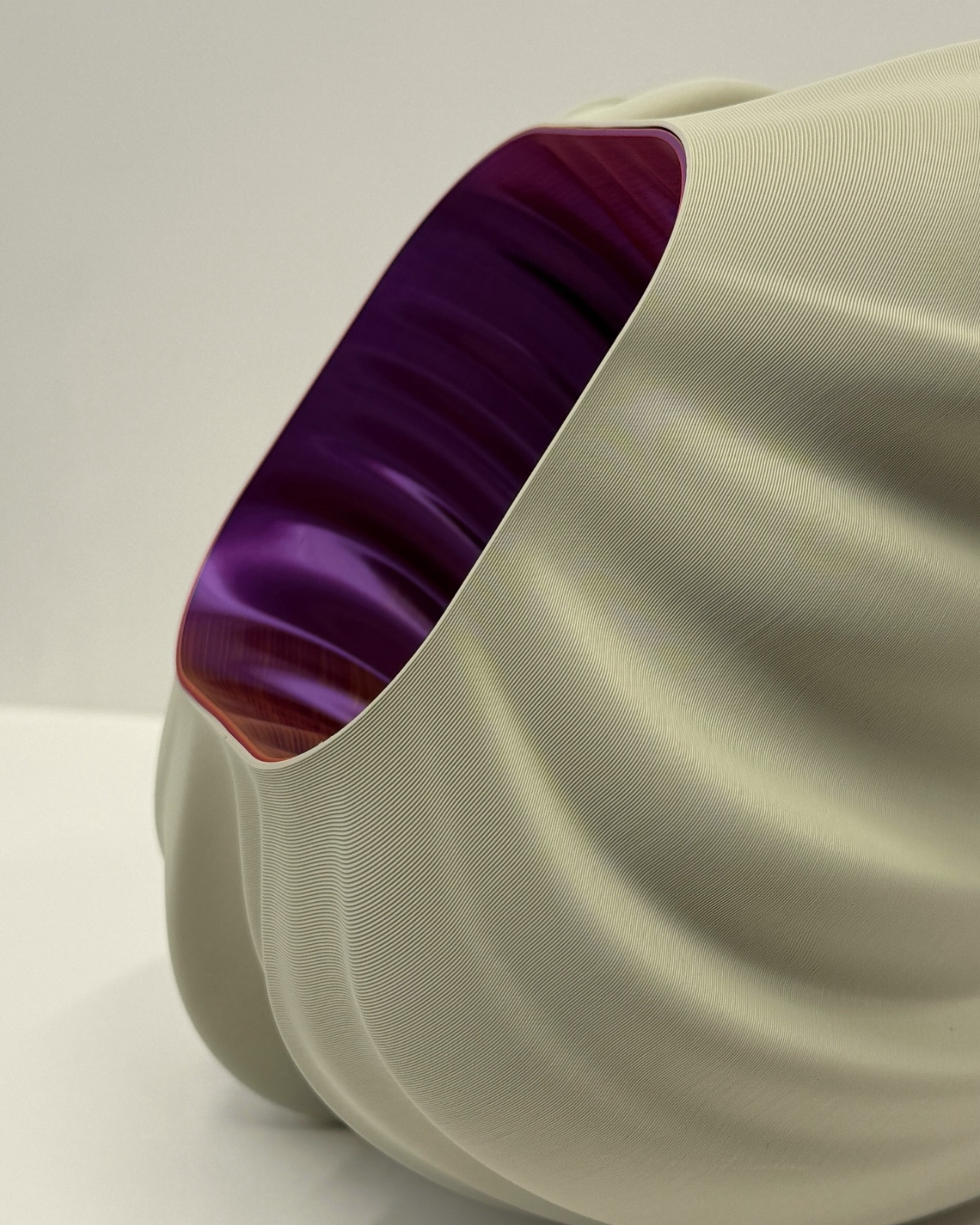

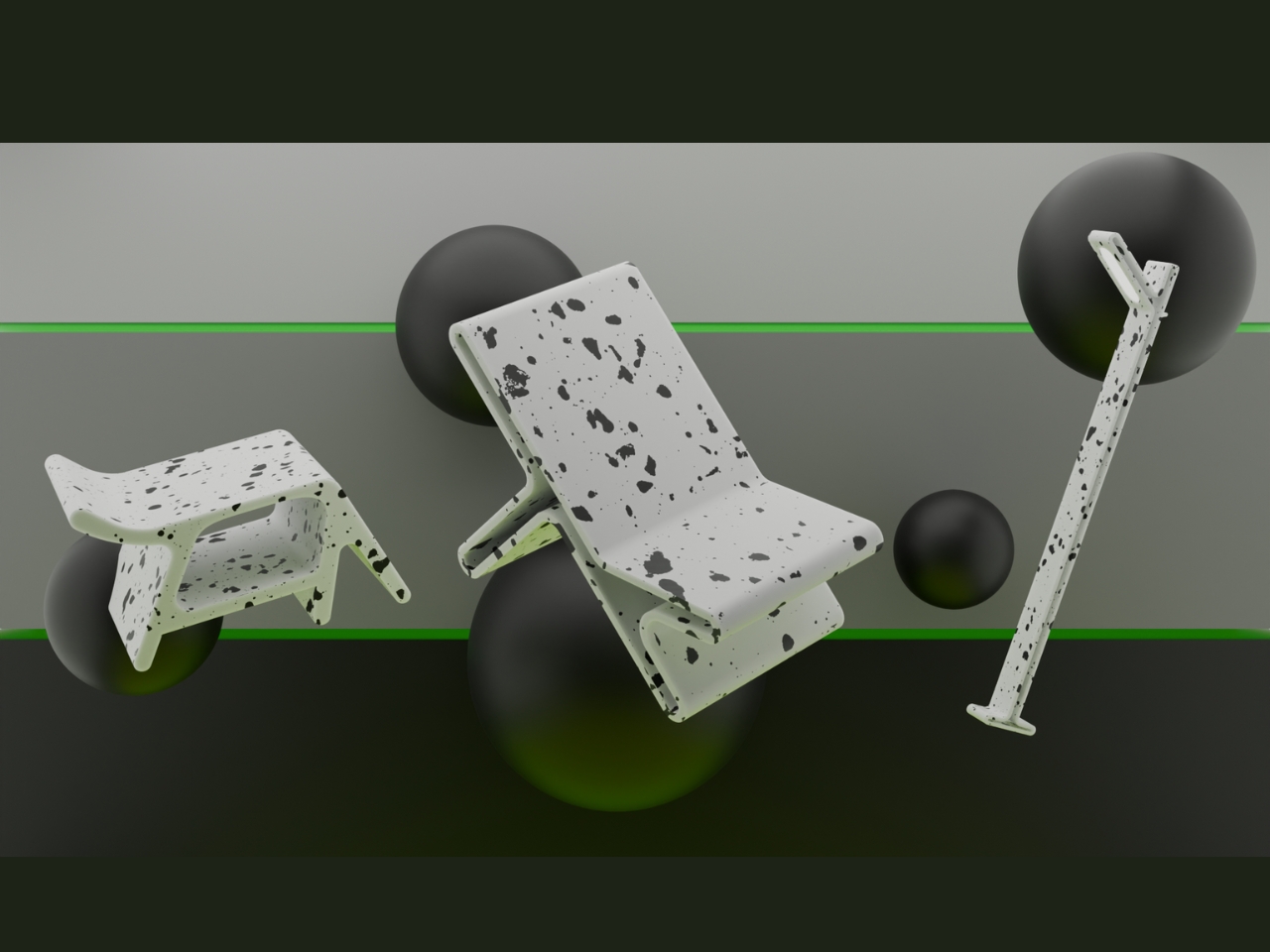

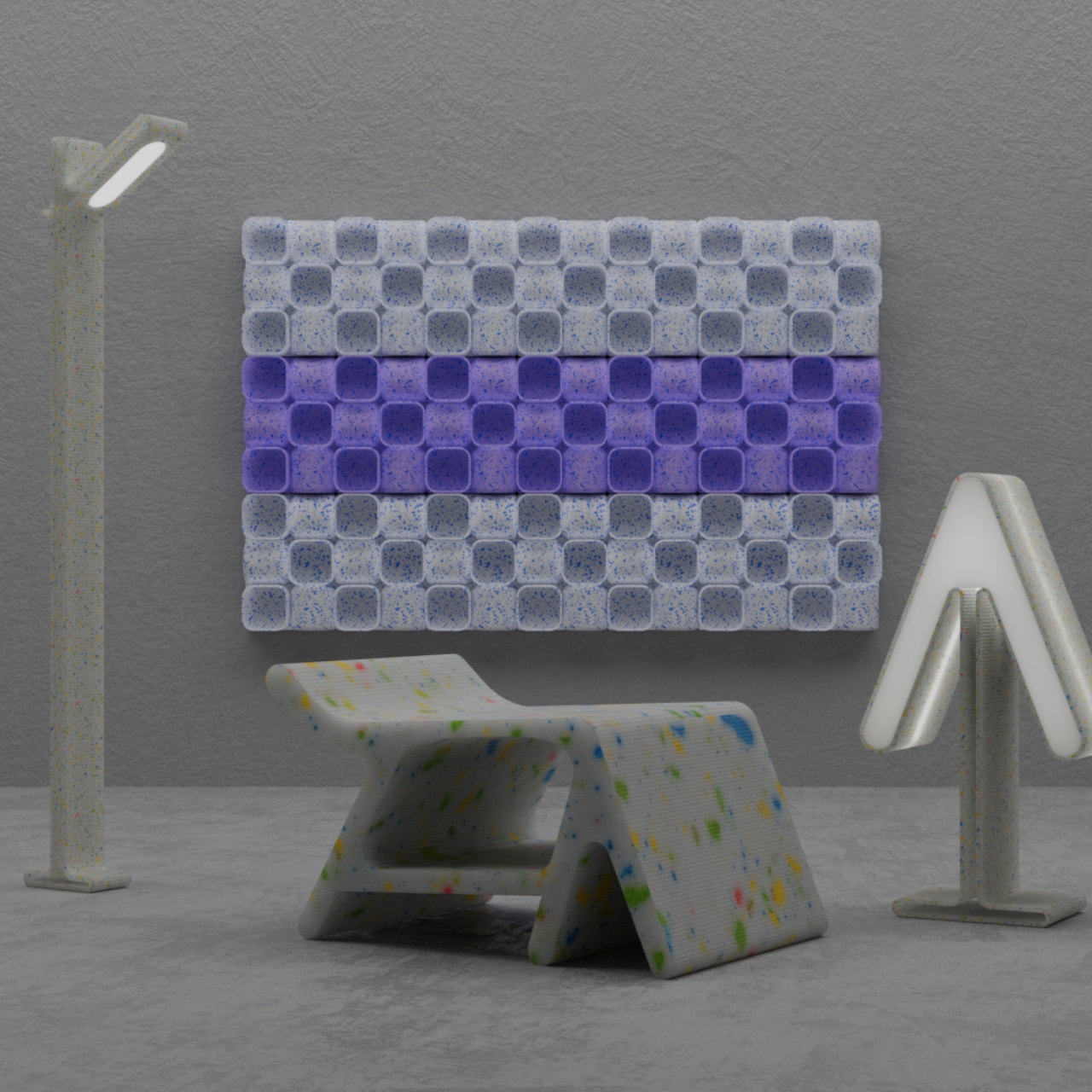

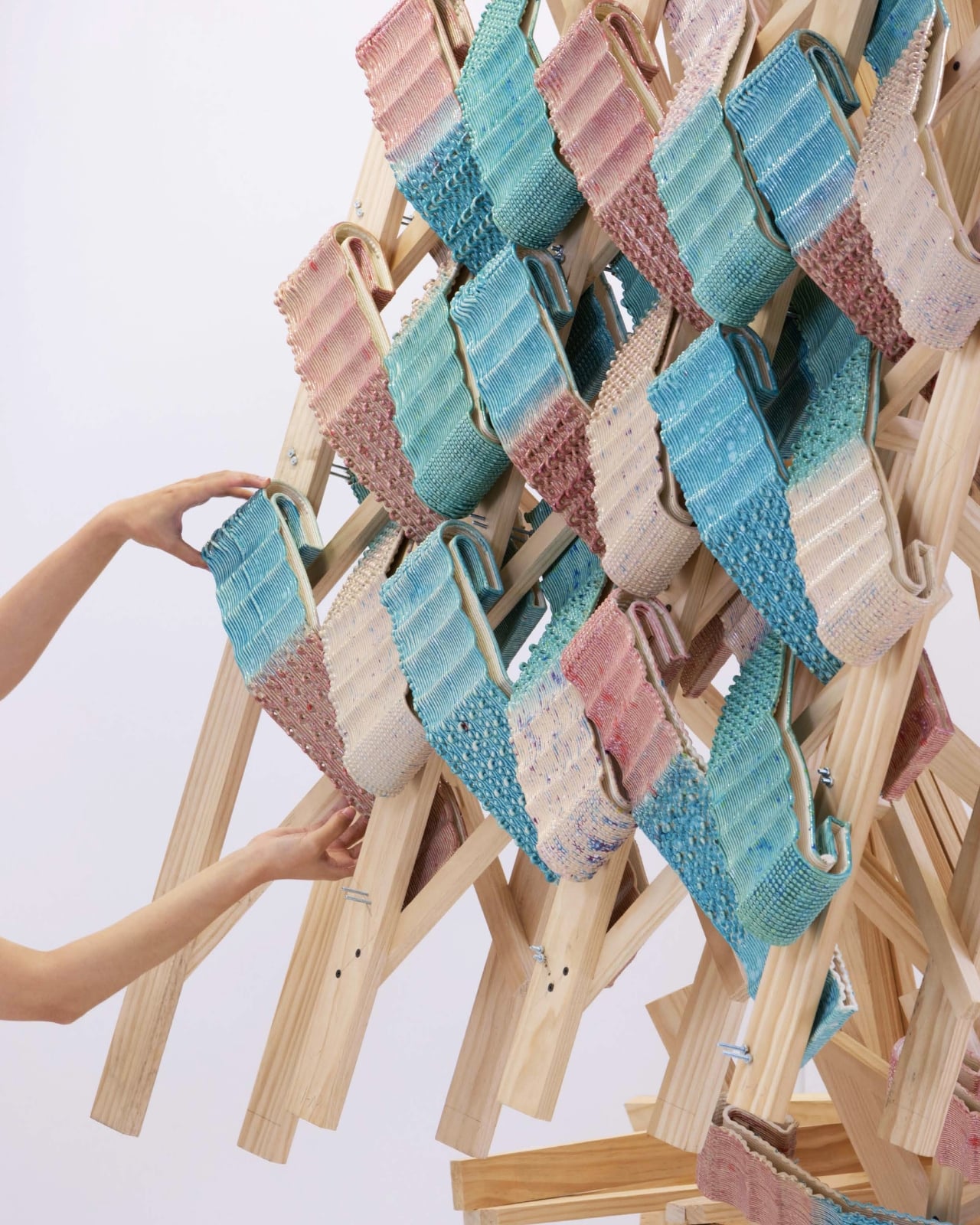

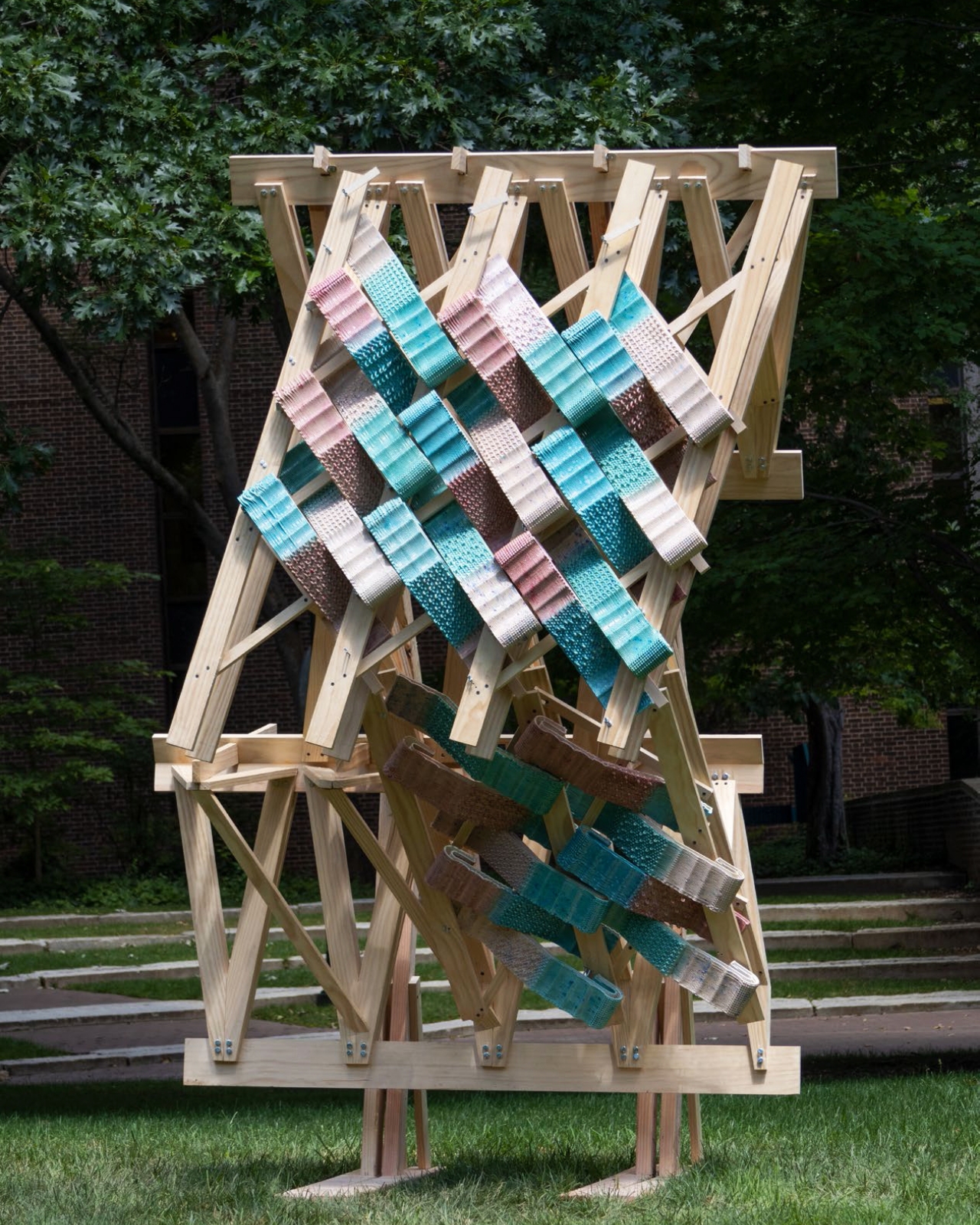

Picture a building wrapped in ceramic tiles, but not the flat, uniform squares you’re used to. CeraShingle modules are 3D-printed clay shingles with intricate textures, delicate perforations, and color gradients that flow across the surface like watercolor on paper. Each piece measures roughly 400 by 130 millimeters and weighs just over a kilogram, light enough to handle but substantial enough to feel real. When you install them with calculated overlap, they create a skin that seems to breathe with the light, shifting appearance as the sun moves and as you change your viewing angle.

Designers: Yutao Chen, Yiwen Gu

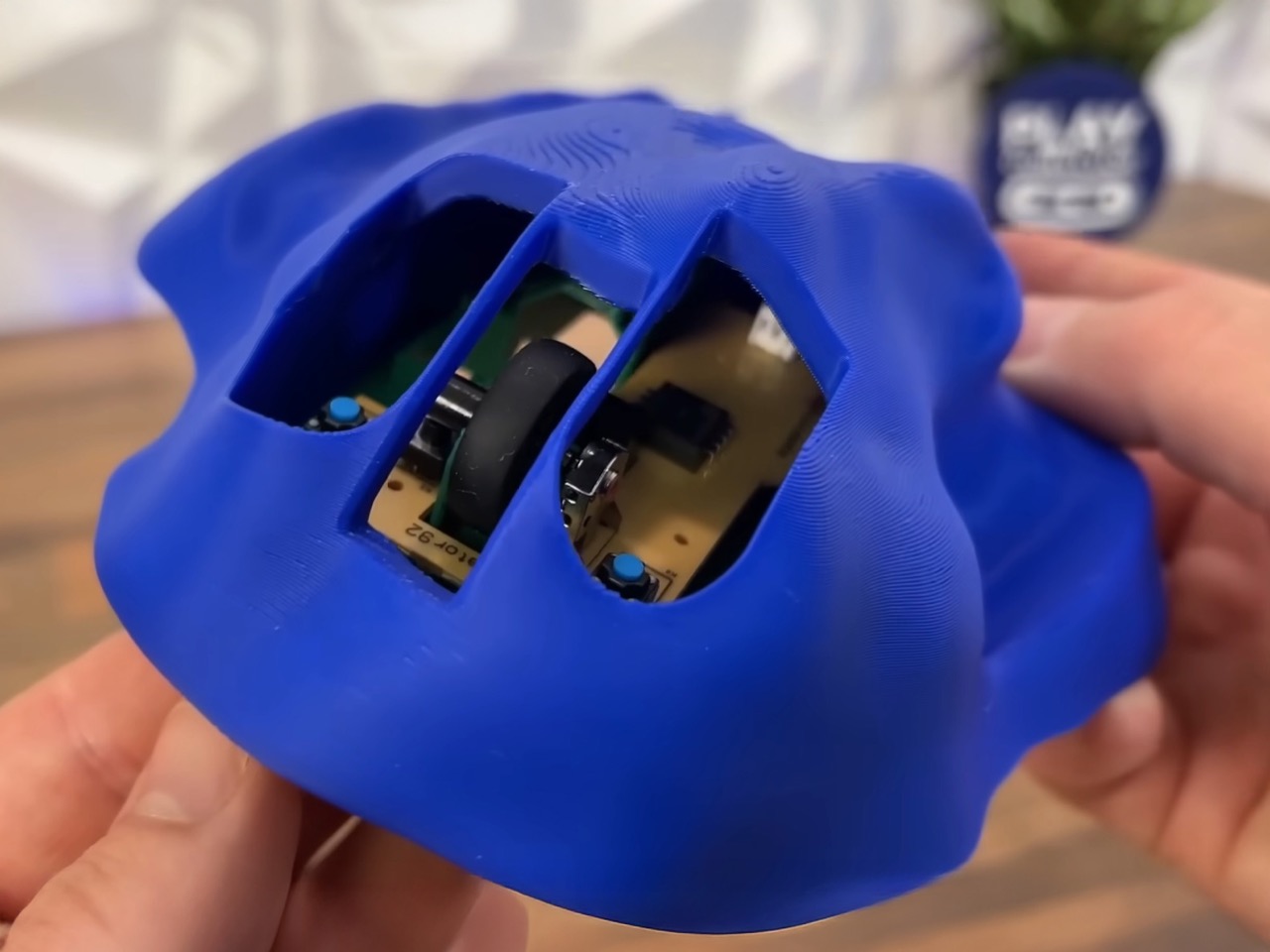

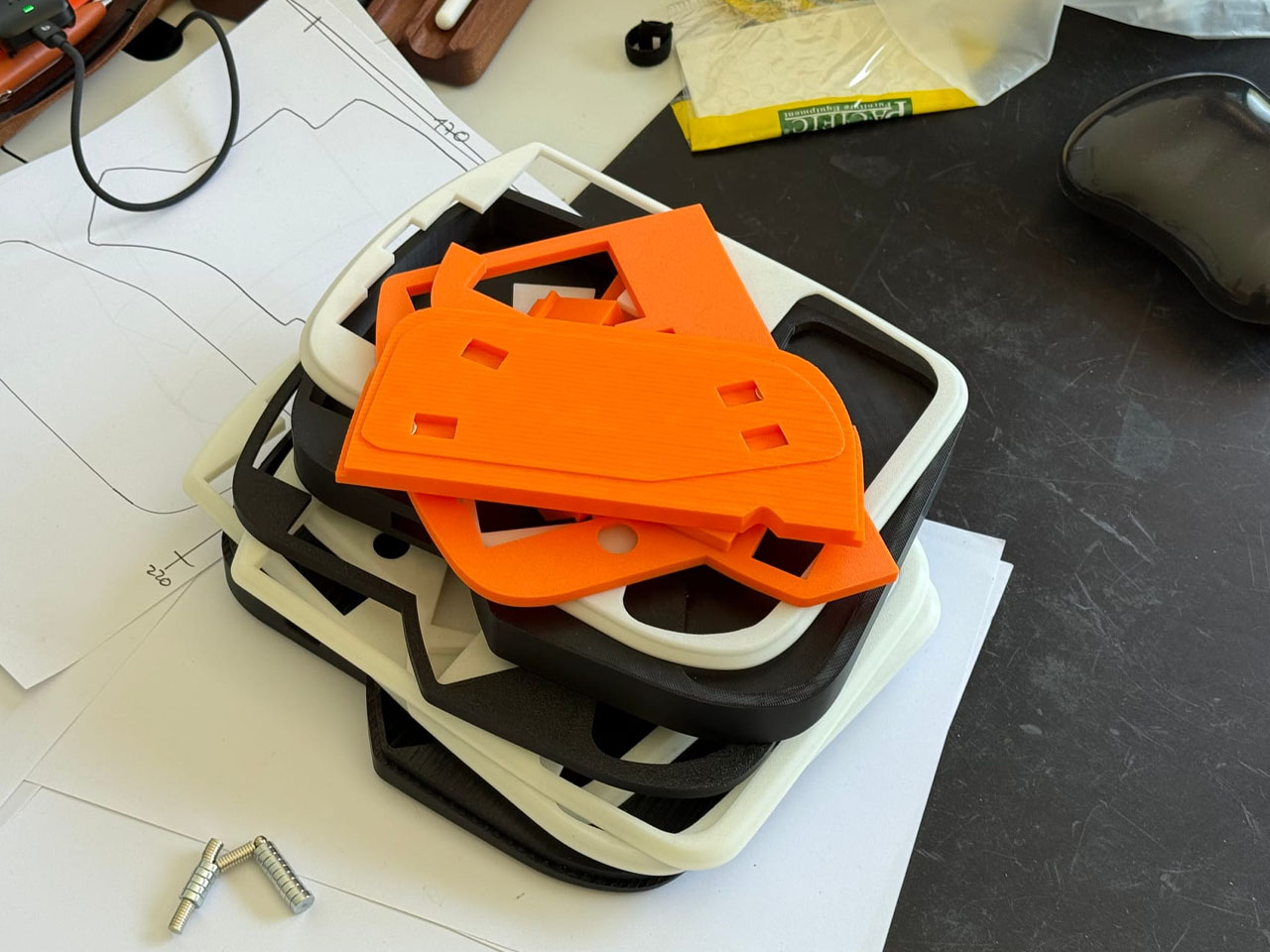

The magic happens in the making. Robotic arms deposit clay layer by layer, building up surface details that would be impossible with traditional molds. Think micro-ribs that catch shadows, patterns that emerge only at certain times of day, gentle curves that couldn’t be pressed or cast. It’s precision meets poetry. The parametric design workflow means each shingle can be unique while still fitting together on site, varying in thickness, texture, and shape within families of compatible parts.

What strikes me most about CeraShingle is how it refuses the usual digital-versus-handmade debate. Instead of replacing the warmth of craft with cold precision, it uses computational tools to amplify what makes ceramics special. The robot doesn’t erase the human touch; it extends what human hands can achieve. You get the intimacy of clay with possibilities that would make traditional ceramicists weep with joy.

The environmental story is equally compelling. The 3D printing process deposits material only where it’s needed, cutting waste dramatically compared to subtractive methods. Chen and Gu specify locally sourced clay and low-temperature glazes, reducing both transportation costs and firing energy. When a module gets damaged, you replace just that piece rather than a whole panel, extending the façade’s lifespan and keeping embodied carbon low. In an era when construction is responsible for nearly 40 percent of global carbon emissions, these details matter.

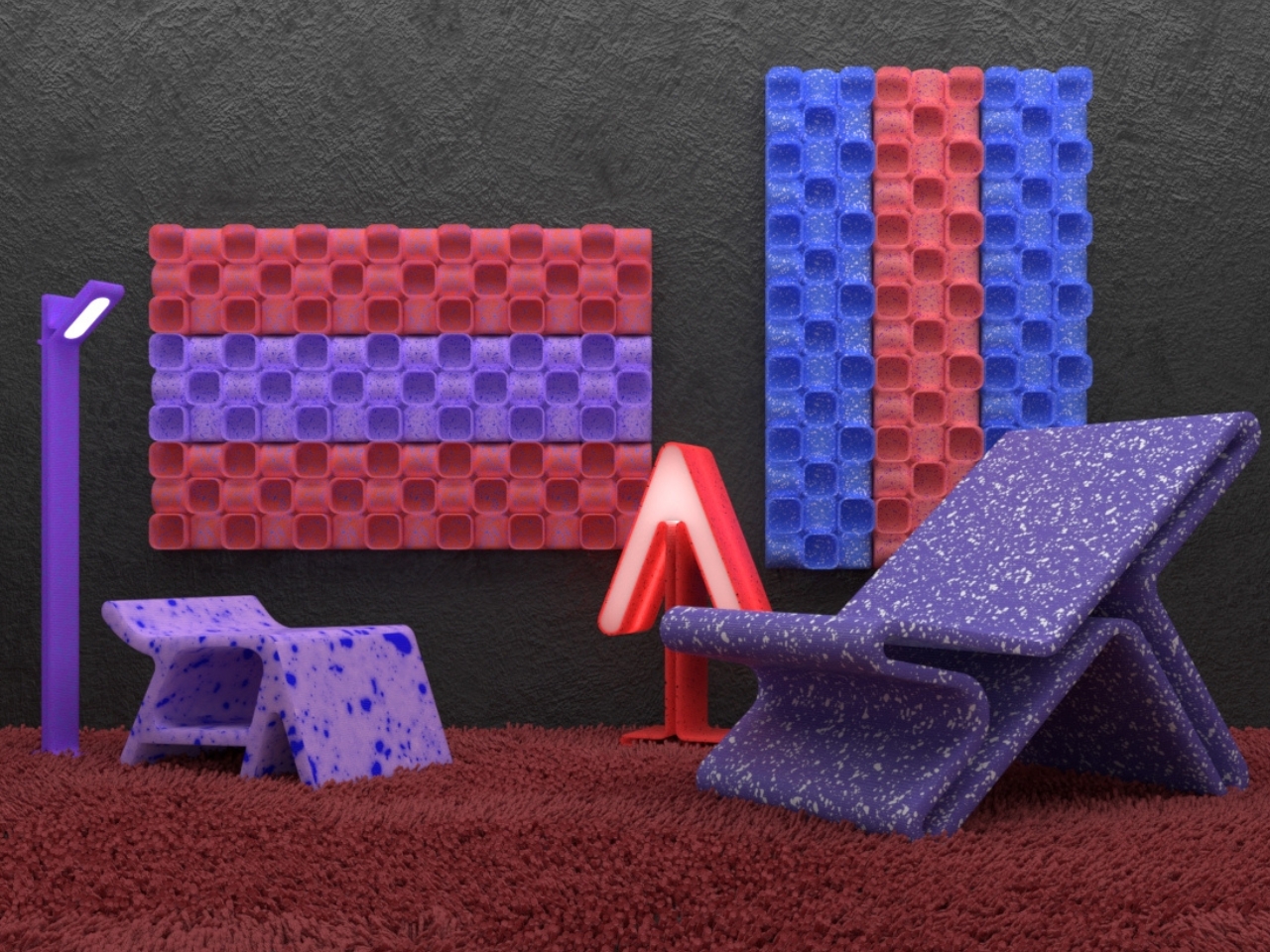

But CeraShingle isn’t just solving problems; it’s proposing a new aesthetic language. Contemporary cladding tends toward two extremes: either sleek industrial materials like glass and metal, or nostalgic brick and stone that look backward. CeraShingle occupies a third space. It’s clearly contemporary, born from digital tools and computational thinking, yet it carries ceramic’s ancient warmth. It’s sculptural without being precious, technical without being cold. The system scales beautifully. You could use it for a small architectural installation, an accent wall, or an entire building envelope. The modular logic means projects can grow organically, and repairs stay simple. For architects tired of choosing between innovation and practicality, that flexibility is powerful.

Set to launch in 2026, CeraShingle arrives at an interesting moment. We’re seeing renewed interest in craft and materiality after decades of smooth minimalism. People are hungry for texture, for surfaces that respond to light and touch, for buildings that feel less like sealed boxes and more like living things. At the same time, climate concerns are pushing architecture toward lighter, more efficient assemblies. CeraShingle threads that needle. It gives you the sensory richness of traditional materials with the performance and adaptability of contemporary systems. It’s a building skin that can think, that can vary and respond while staying grounded in earth and fire.

What Chen and Gu have created isn’t just a clever product; it’s a provocation. It asks what happens when we stop treating digital fabrication as a replacement for craft and start seeing it as craft’s next chapter. The answer, wrapped around a building and catching the afternoon light, might just be the future of how we clad our world.

The post World’s First Robot-Made Ceramic Tiles Change Color With Sunlight first appeared on Yanko Design.