PROS:

- Massive 10,001mAh battery with 80W wired fast charging

- Bright and vibrant display

- Solid mid-range performance

CONS:

- Slightly heavier and chunkier compared to many mid-range devices

- Ultra-wide and front-facing cameras are only average for the price

RATINGS:

SUSTAINABILITY / REPAIRABILITY

EDITOR'S QUOTE:

Realme P4 Power proves that killing battery anxiety is more useful than chasing benchmarks, wrapping a 10,001mAh cell, tough IP69 shell, and smooth performance into an honest mid‑range package.

Realme has built a reputation for pushing smartphone battery tech forward, from faster charging to bigger and more efficient cells. Instead of treating battery life as an afterthought, the brand has consistently tried to make it a headline feature that changes how often you actually need a charger. That focus has turned power and charging from a boring spec line into one of Realme’s main selling points.

The Realme P4 Power is the clearest expression of that idea so far. It packs a massive 10,001 mAh battery into a phone that still looks and feels familiar, then backs it up with 80W fast charging, 27W reverse charging, a bright 144Hz AMOLED display, and 5G performance aimed at everyday users and gamers alike. More than just another mid‑range phone with a slightly bigger battery, it’s a device built around the promise that you should be able to forget about battery anxiety for days at a time.

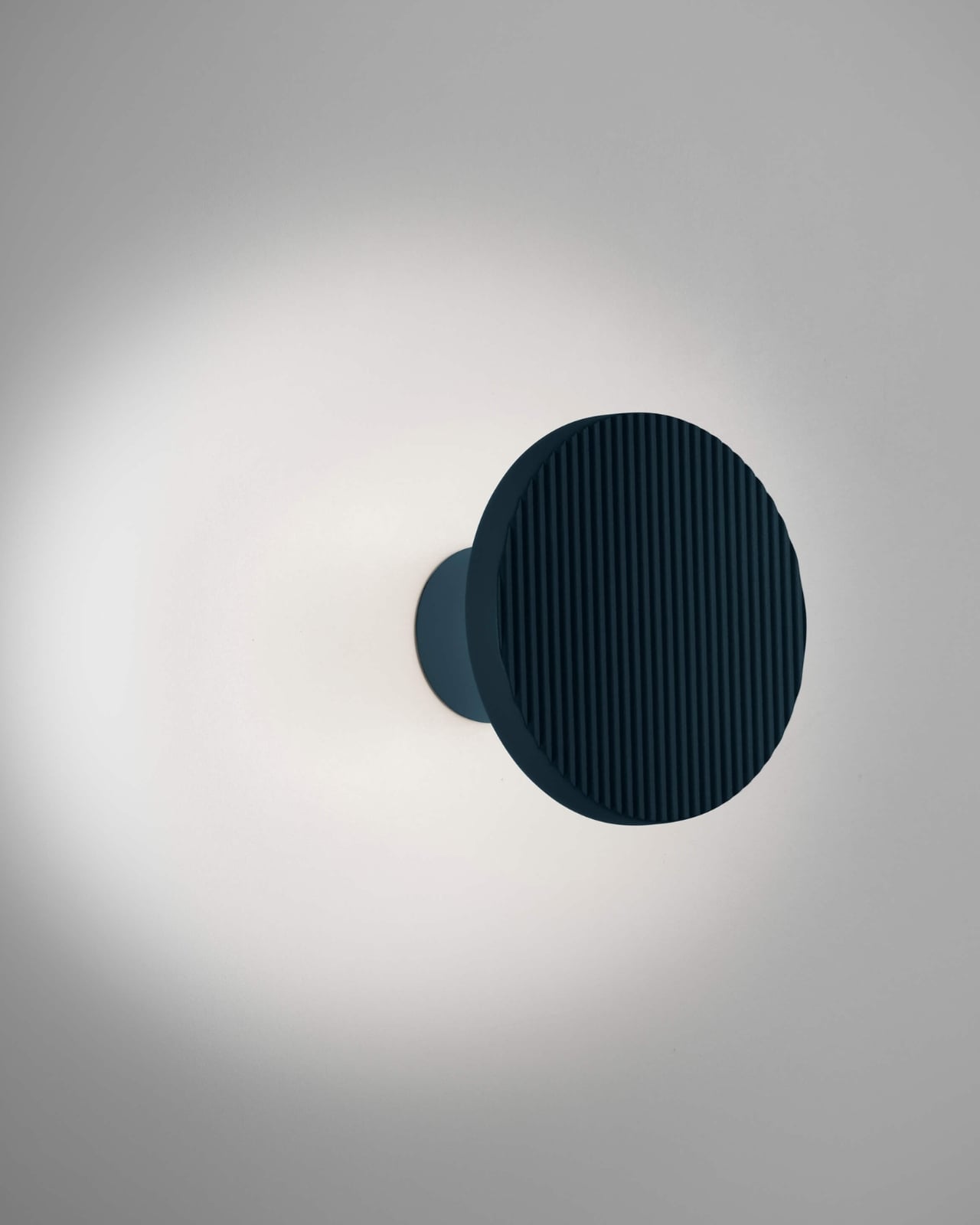

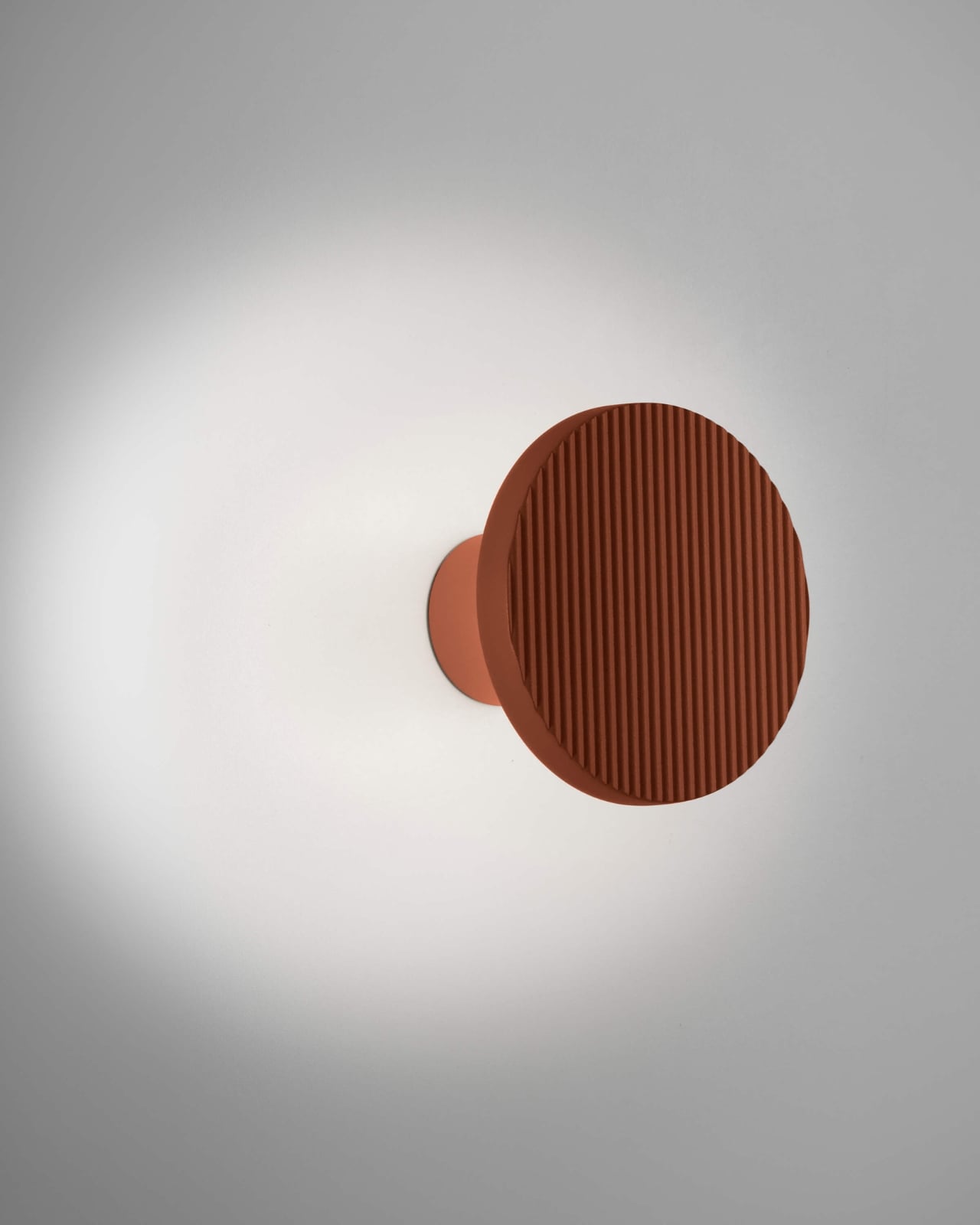

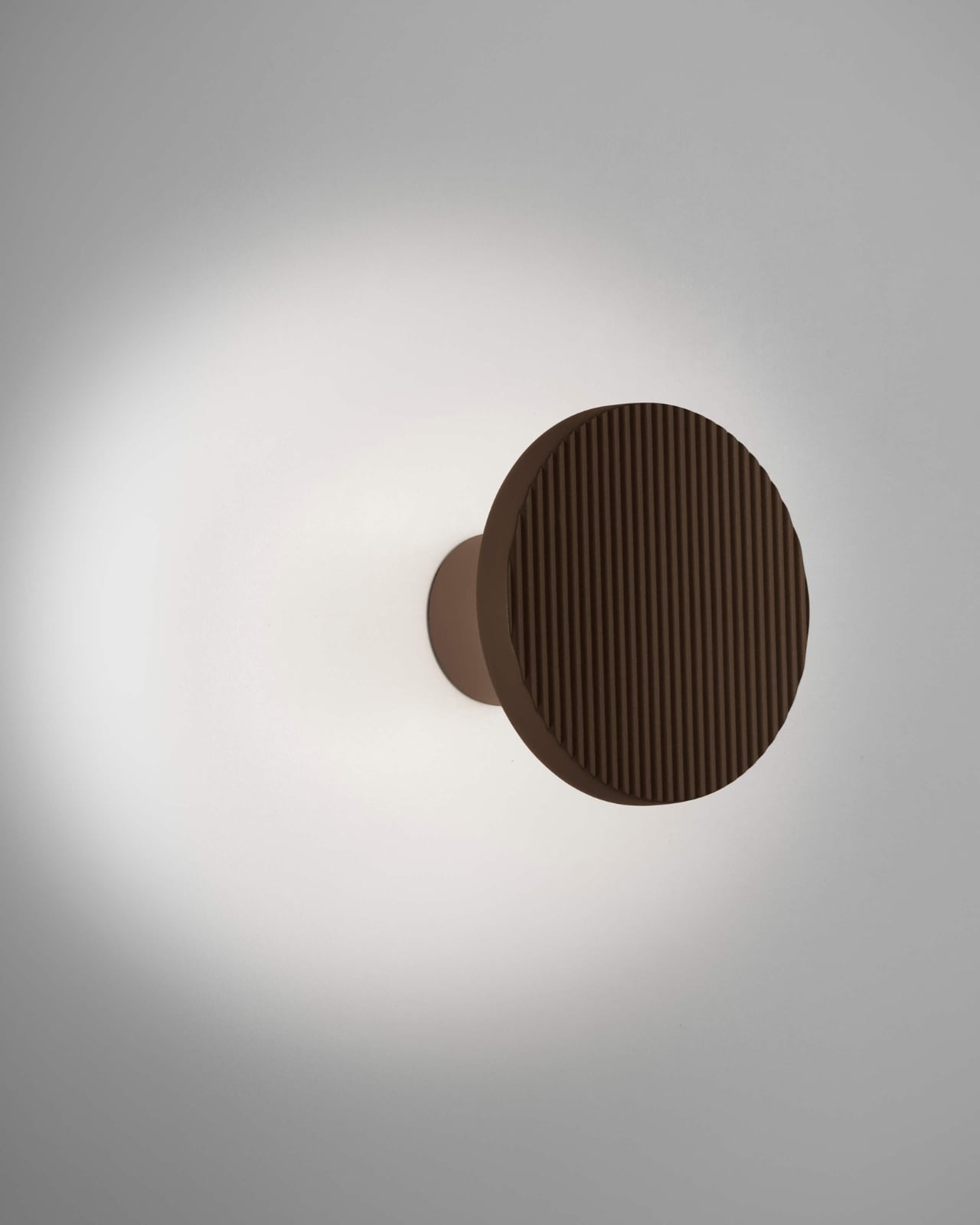

Aesthetics

The Realme P4 Power is a battery‑first phone that does not look like one at first glance. On the table, it reads as a modern, fashion‑driven slab rather than a chunky endurance tool, which is exactly what Realme is going for. It comes in two color variations, Flash Orange and Power Silver.

The upper third of the back panel has a distinctive pattern that creates an almost translucent effect, playing with reflections and depth when light hits it. The rectangular camera island is neatly integrated, with a clean ring‑based layout that avoids the oversized, fussy modules you see on some rivals. The overall look feels intentional and confident, not like a normal phone that accidentally got thicker to fit a bigger battery.

The design is more playful than minimalist, especially in the brighter Flash Orange variant, while Power Silver keeps a slightly more muted but still distinctive character. For a phone whose headline feature is a huge battery, it is surprisingly stylish and clearly aimed at people who care how their device looks on a desk or in a hand. Branding is present but not overpowering, so the rear stays relatively clean even with the layered graphics and that “under‑glass” pattern.

Ergonomics

Even when you pick it up, the P4 Power feels a little deceptive. This is not a featherweight device, coming in at about 219g and measuring 162.26 x 76.15 x 9.08mm. The large 10,001 mAh battery and sturdy build give it noticeable heft in the hand, and you will feel that if you are coming from a slim device. However, Realme has done a great job of balancing the mass so it does not feel awkward during normal use. For many users, the extra grams will be an acceptable trade‑off for the freedom from constant charging.

The shape helps more than the spec sheet suggests. The slightly curved 6.8‑inch display and curved‑edge back panel let your fingers naturally wrap around the device rather than pressing into a sharp edge. The matte back does a good job of hiding fingerprints and smudges, although it can feel a bit slippery, so a case might still be a smart idea.

The power and volume keys are within comfortable reach on the right side, so you do not have to stretch or shuffle the phone around to adjust volume or wake the screen. The in‑display fingerprint reader, on the other hand, sits quite close to the bottom of the display, which can make quick unlocks feel a bit forced, especially in one‑handed use. Overall, the build quality feels more premium than the price tag suggests, and ergonomics are good for a device built around such a large battery.

Performance

On the front, the P4 Power offers a quad‑curved 6.8‑inch AMOLED display with a resolution of 1280 × 2800 pixels and a maximum refresh rate of 144Hz. In practice, though, only a few native apps, such as Calculator, Compass, and Recorder, actually run at 144Hz, while most of the interface and third‑party apps stick to lower refresh rates.

Realme quotes typical brightness around 600 nits, a boosted mode up to 1800 nits, and a local peak figure of 6500 nits for small areas of the screen. In real‑world use, the display stays readable in harsh sunlight and bright outdoor conditions. The panel supports HDR10+ and 10‑bit color, so compatible streaming content looks rich, punchy, and pleasantly saturated.

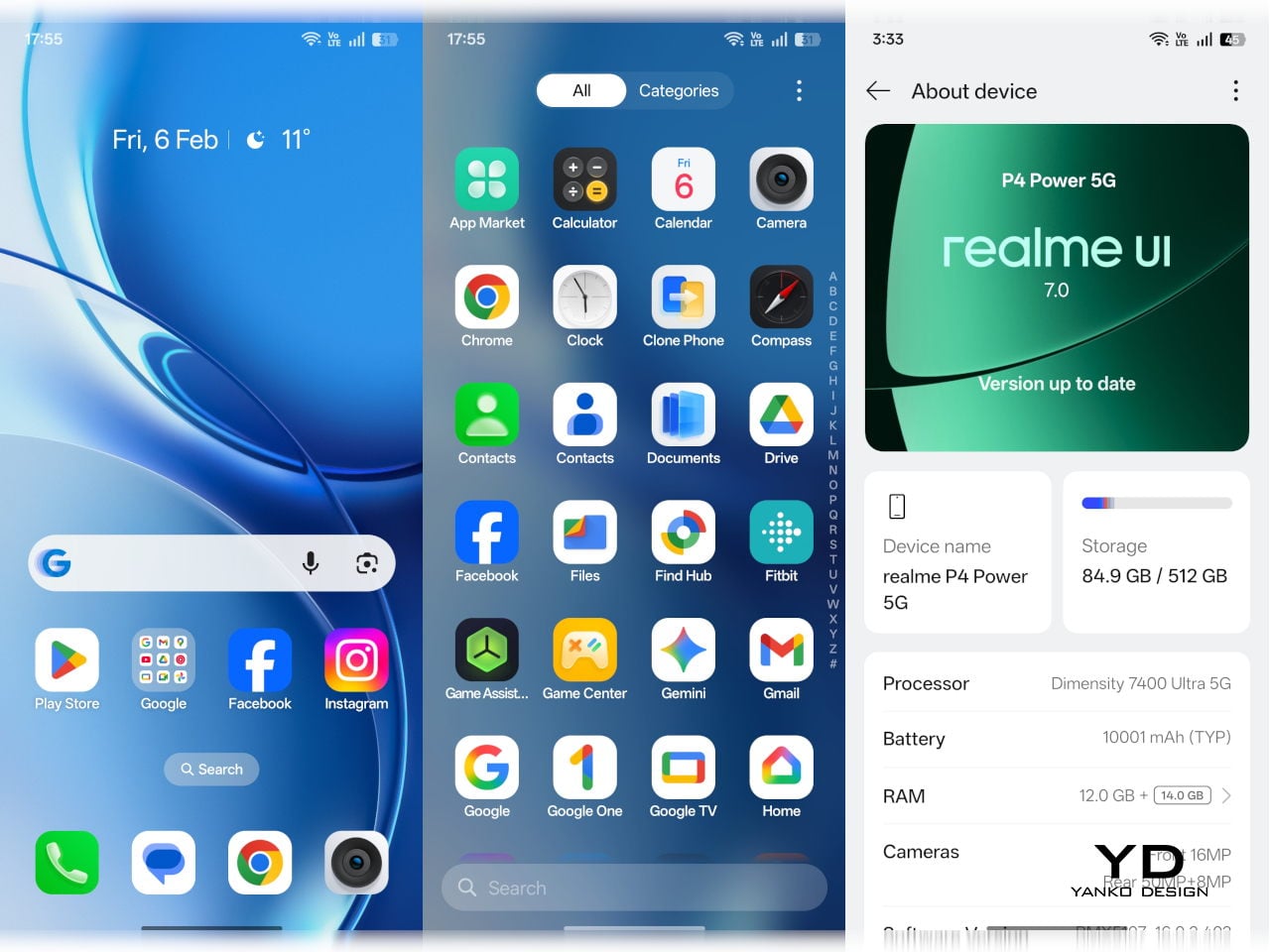

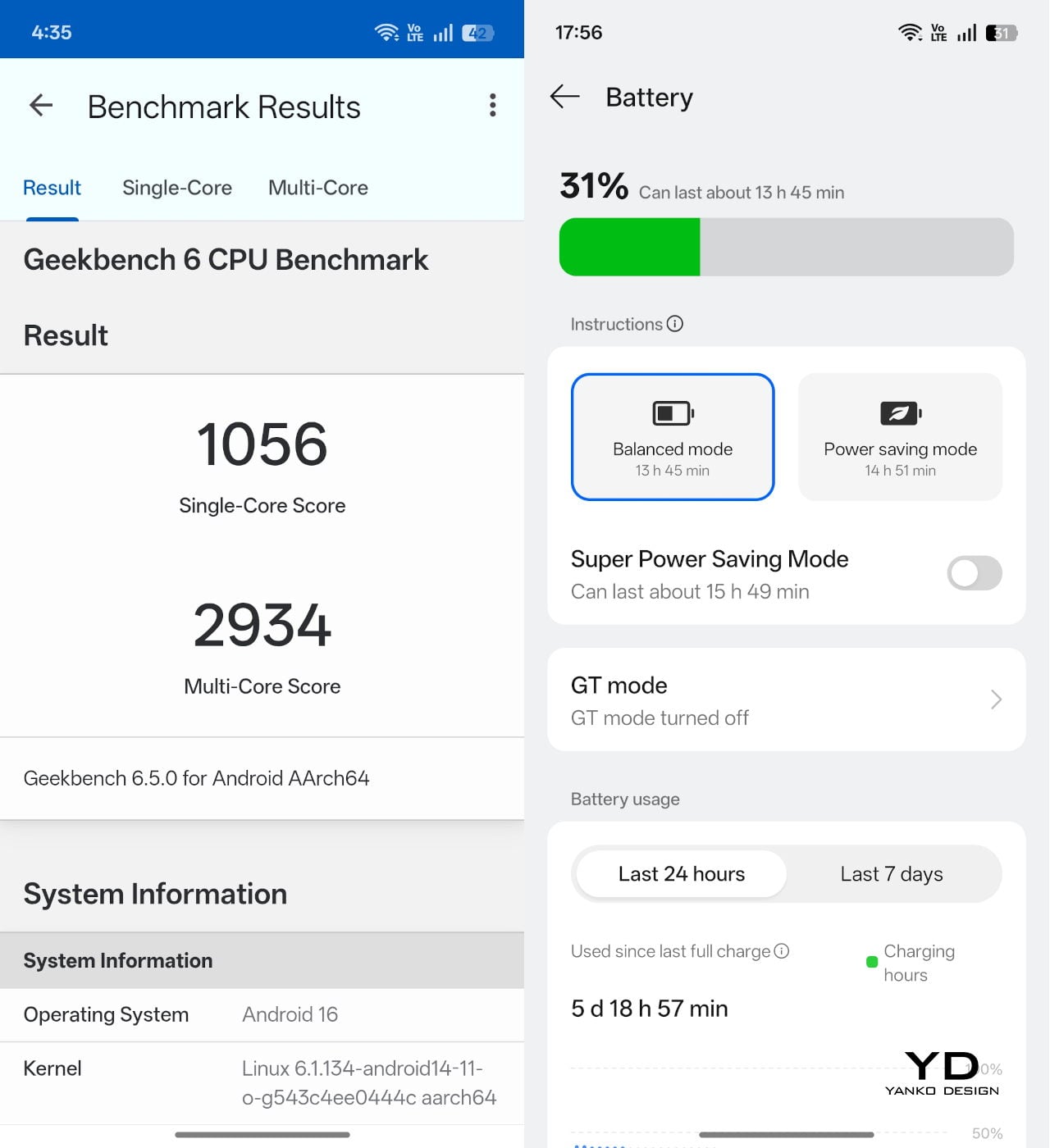

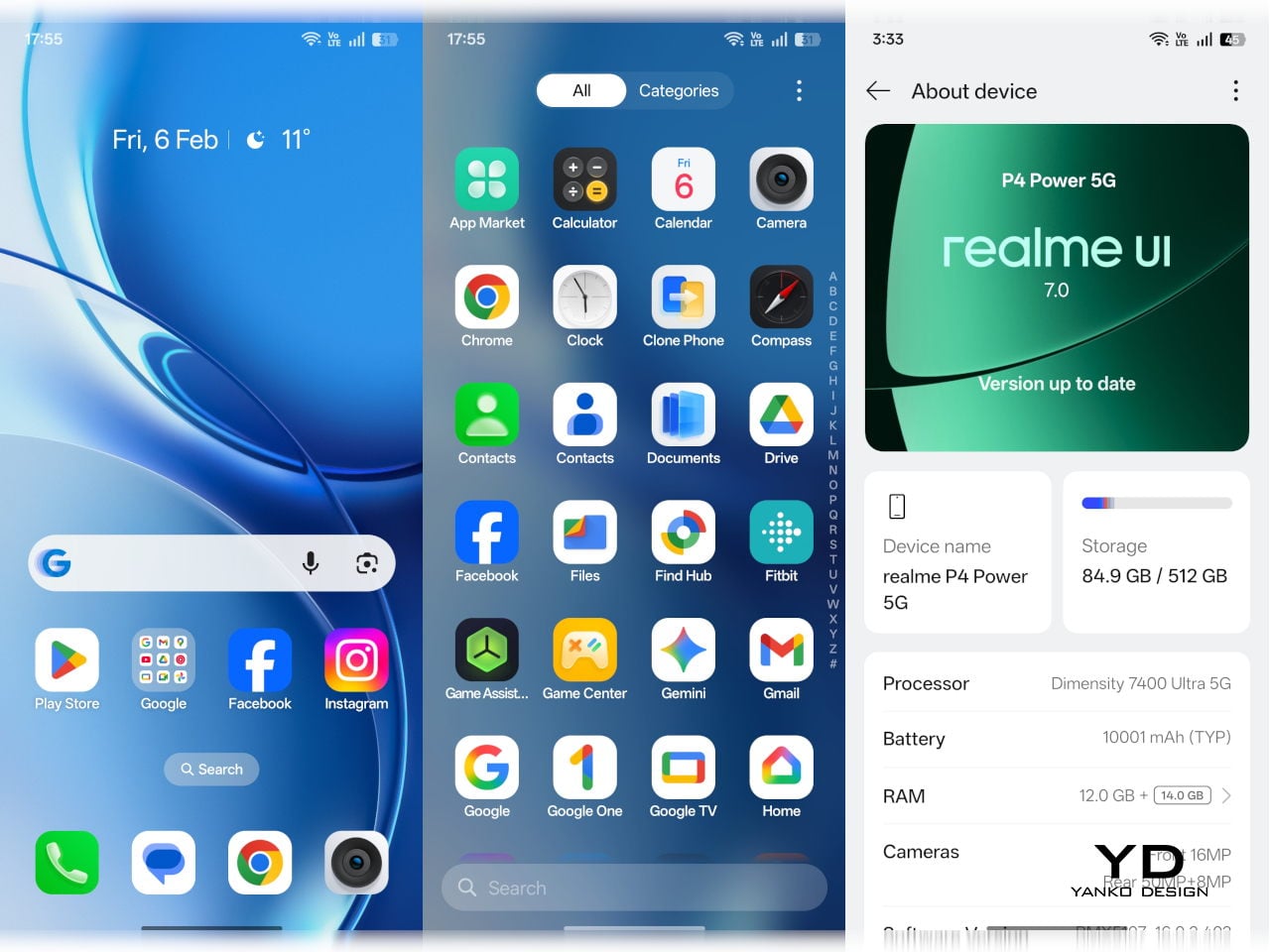

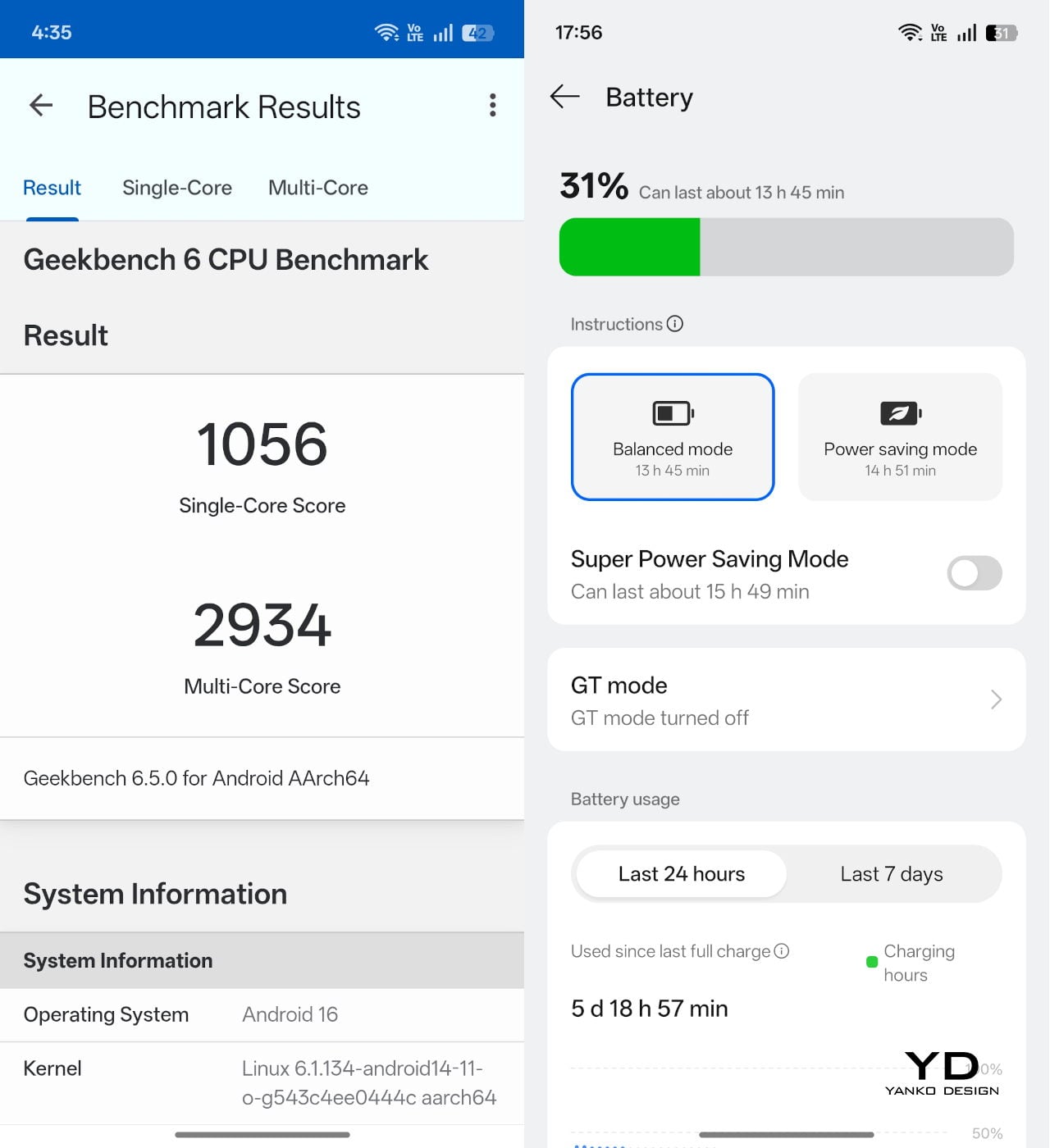

Inside the P4 Power sits MediaTek’s Dimensity 7400-Ultra chipset. It is paired with 8GB or 12GB of RAM and 128GB, 256GB, or 512GB of UFS 3.1 storage. This combination places the phone firmly in the mid‑range. It is not chasing raw benchmark records, yet it is designed to deliver smooth performance in everyday tasks and mainstream games without obvious slowdowns or stutters.

Out of the box, the phone runs Android 16 with Realme UI 7.0 on top, and Realme also uses a dual‑chip approach. Alongside the main Dimensity processor, there is a dedicated Hyper Vision+ AI chip focused on display and gaming tasks, and there are a handful of AI image features such as AI Perfect Shot and 3D emoji. AI Perfect Shot recognizes faces and can fix closed eyes or awkward expressions by swapping in better face poses from other photos of the same person in your gallery, and AI also helps during gaming by quickly generating message replies in supported messaging apps so you can respond without fully dropping out of your game.

Battery life is the reason this phone exists. The 10,001mAh cell is dramatically larger than the 4,500 to 5,000mAh batteries found in many mainstream phones, and even bigger than the 6,000 or 7000mAh packs in endurance‑focused models. Realme achieves this using a third‑generation silicon‑carbon anode and a compact internal stacking design, which allows more capacity in roughly the same physical space.

In practical terms, this capacity is meant to deliver several days of mixed use. I used the Realme P4 Power as my primary device on a 3‑night, 4‑day scuba trip, with light screen time during the day, and it lasted the entire trip without a charge, still showing around 20 percent battery when I got back home. That kind of real‑world endurance is a clear step up from phones that need a nightly top‑up.

When you do need to charge, the P4 Power supports 80 W wired fast charging. It also supports 27 W reverse charging, so it can basically double as a power bank for your other gadgets when you are on the move.

The camera system on the P4 Power is straightforward. On the back, there is a 50MP main camera using Sony’s IMX882 sensor with optical image stabilization and an f/1.8 lens, paired with an 8MP ultra‑wide camera that offers a 112‑degree field of view. On the front, you get a 16MP selfie camera. For video, the main camera can record up to 4K at 30 fps, while the ultra‑wide and front‑facing cameras are capped at 1080p at 30 fps.

You can choose between Vibrant and Natural color modes. Natural mode is essentially a toned‑down look rather than a more accurate one, so it comes down to preference more than strict realism. The main camera takes good photos with pleasing detail and contrast in daylight, while the ultra‑wide is serviceable but nothing to write home about, with softer detail and more noise. The front‑facing camera delivers decent selfies that are fine for social media, though it does not stand out in this price range.

Natural Color Mode

Vibrant Color Mode

Portrait Mode

Sustainability

The oversized battery also has a clear sustainability angle. Because the 10,001 mAh cell gives you so much headroom, you are less likely to run it close to empty every day or charge it multiple times, which reduces the number of full charge cycles. Realme’s silicon‑carbon chemistry and battery management build on that, and the company claims the battery can retain over 94 percent of its original capacity after three years of typical use and around 80 percent after eight years.

The Realme P4 Power also leans on durability and software support. It is IP69, IP68, and IP66‑rated, so it is tested for dust tightness, high‑pressure water jets, and immersion, making it less likely to die from everyday splashes or rain. On the software side, Realme promises three major Android OS upgrades and four years of security patches, which is fine for a mid‑range phone but not class‑leading, and it slightly undercuts the otherwise long‑term hardware story.

Value

In India, the Realme P4 Power starts at around ₹25,999 (roughly $310) for the 8GB RAM and 128GB storage variant. That pricing puts it in the crowded lower mid‑range segment, where a lot of brands are fighting on specs and features. The Honor Win also features a 10,000mAh battery, but it is officially only available in China, so for most buyers, the P4 Power is the more accessible way to get this kind of battery size.

The phone is aimed at people who value endurance and reliability above camera experience or absolute thinness. That can include gamers, frequent travelers, delivery workers, content creators on the move, and anyone who is simply tired of carrying a power bank. At this price level, the P4 Power tries to stand out by solving a real‑world problem in a very direct way.

Verdict

The Realme P4 Power is a very focused product. It does not try to be the best camera phone or the thinnest fashion accessory. Instead, it aims to be the phone you do not have to think about charging, even on your busiest days. For many everyday users, that single promise can be more valuable than a slightly better zoom lens or a few extra benchmark points.

If your top priority is battery life, with smooth performance and a bright display for gaming and media, the P4 Power is an easy device to recommend in its price range. If you care more about advanced photography features, ultra‑lightweight design, or wireless charging, you may want to look at other options. For everyone else, this is a rare phone that tackles a common frustration head‑on and mostly succeeds.

The post Realme P4 Power Review: Battery Anxiety is Finally Dead first appeared on Yanko Design.