![]()

In most concept cars the paint is just a color. On the Mercedes-Benz Vision Iconic, the paint is a powertrain component. Beneath that mirror black surface lies solar paint, a wafer thin photovoltaic skin that turns every curve and contour into an active energy source, capable of adding thousands of miles of range each year under ideal conditions. The result is a car that charges itself while it poses, while it cruises, even while it sleeps in a garage flooded with sunlight, generating a mind-boggling 7,450 miles of range annually based on ideal conditions.

That technology wraps a body shaped like a vintage dreamscape. Mercedes pulled proportions from its 1930s icons, with a near vertical grille, extended hood, and fastback silhouette that hides the electric skateboard underneath. The grille glows with animated pixels, the hood star lights up, and the entire form is finished in reflective black that emphasizes sculptural surfaces over character lines. Inside, the cabin becomes a velvet lined theater with brass accents, floating glass displays, and neuromorphic computing that makes autonomous driving 90 percent more efficient. Solar energy meets Art Deco in a manifesto for sustainable luxury. Chief Design Officer Gorden Wagener created the concept as his creative conclusion before leaving the company, ensuring his “Sensual Purity” philosophy persists beyond his tenure. The strategy acknowledges that luxury customers buy emotional experiences rather than mere transportation. Technology serves that experience instead of overwhelming it.

Designer: Mercedes-Benz

![]()

This car is essentially Wagener’s mic drop, a final, definitive statement on his “Sensual Purity” design philosophy before his departure in January 2026. For years, he’s talked about this bipolarity of emotion and intelligence, and the Vision Iconic is its physical manifestation. The emotion comes from the sheer presence of the thing, its sculptural surfaces and historical nods. The intelligence is the bleeding-edge tech humming beneath the surface. It’s a perfect symbiosis. This concept cements his legacy, proving that his focus on physical clay modeling to perfect proportions and surface language can produce something that feels both classic and futuristic. It’s a powerful farewell that will shape the company’s aesthetic for years to come.

![]()

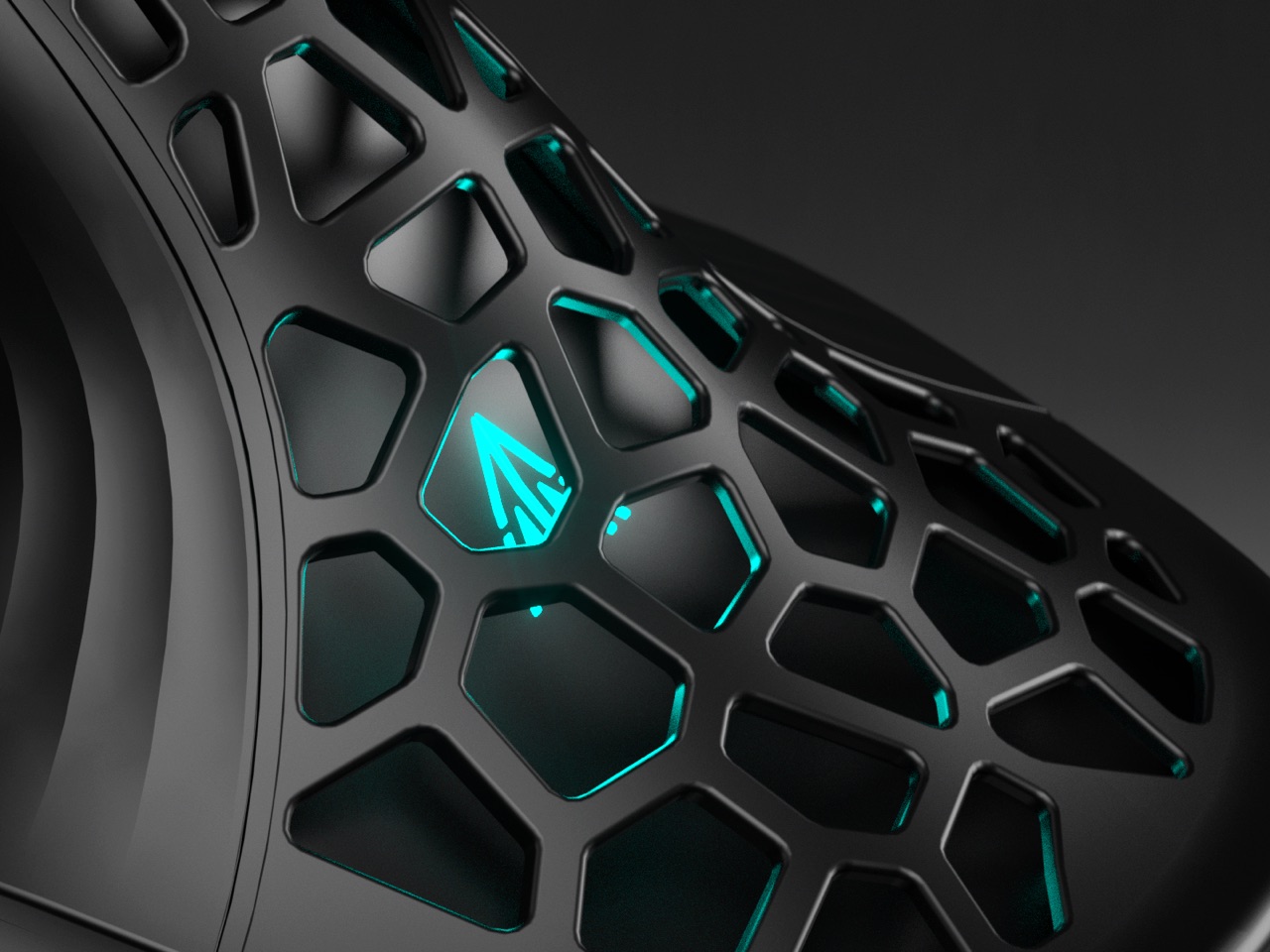

You can’t miss the grille, which is clearly the centerpiece of the new corporate face. It’s a direct homage to the upright, proud grilles of 1960s icons like the W108 S-Class and the W100 600 Pullman, but reinterpreted for the digital age. The structure is built from light, with a pixel-graphic lattice that can animate, giving the car a dynamic presence even when stationary. This isn’t just a styling gimmick; it’s a strategic move to ground the brand’s electric future in its rich heritage, preventing its EVs from looking like generic appliances. The illuminated three-pointed star on the hood reinforces this connection. The rest of the body is a study in minimalism, with clean, flowing lines that emphasize the car’s monolithic, sculptural quality.

![]()

Inside, the team pursued what they call a “hyper-analog” experience, which is a brilliant response to the industry’s obsession with sterile, screen-dominated interiors. The cabin is a lounge, not a cockpit, an idea enabled by its Level 4 autonomous capabilities. A continuous bench seat is wrapped in deep blue velvet, and details are rendered in polished brass. The centerpiece is the “Zeppelin,” a floating glass structure on the dash that houses a mix of analog-inspired instruments and digital displays, creating a layered, artistic effect. It feels opulent and tactile, a reminder that luxury is about materials and craftsmanship, not just pixel density.

![]()

For Wagner and Mercedes-Benz, the Vision Iconic is a manifesto. Mercedes is declaring that its electric future will not be one of compromise. The car’s entire technological ecosystem is built to support its aesthetic ambitions. The neuromorphic computing, which reduces the power needs of autonomous driving tasks by a staggering 90 percent, is what allows for such sophisticated self-driving without a crippling range penalty. The steer-by-wire system frees up the interior packaging, enabling the lounge-like atmosphere and allowing designers to maintain those classic long-hood proportions. Every piece of tech has a purpose that serves the overall vision of creating a desirable, beautiful object that also happens to be a highly advanced electric vehicle.

![]()

The post Mercedes-Benz Vision Iconic: Solar Paint That Generates 7,450 Miles of Range Annually first appeared on Yanko Design.