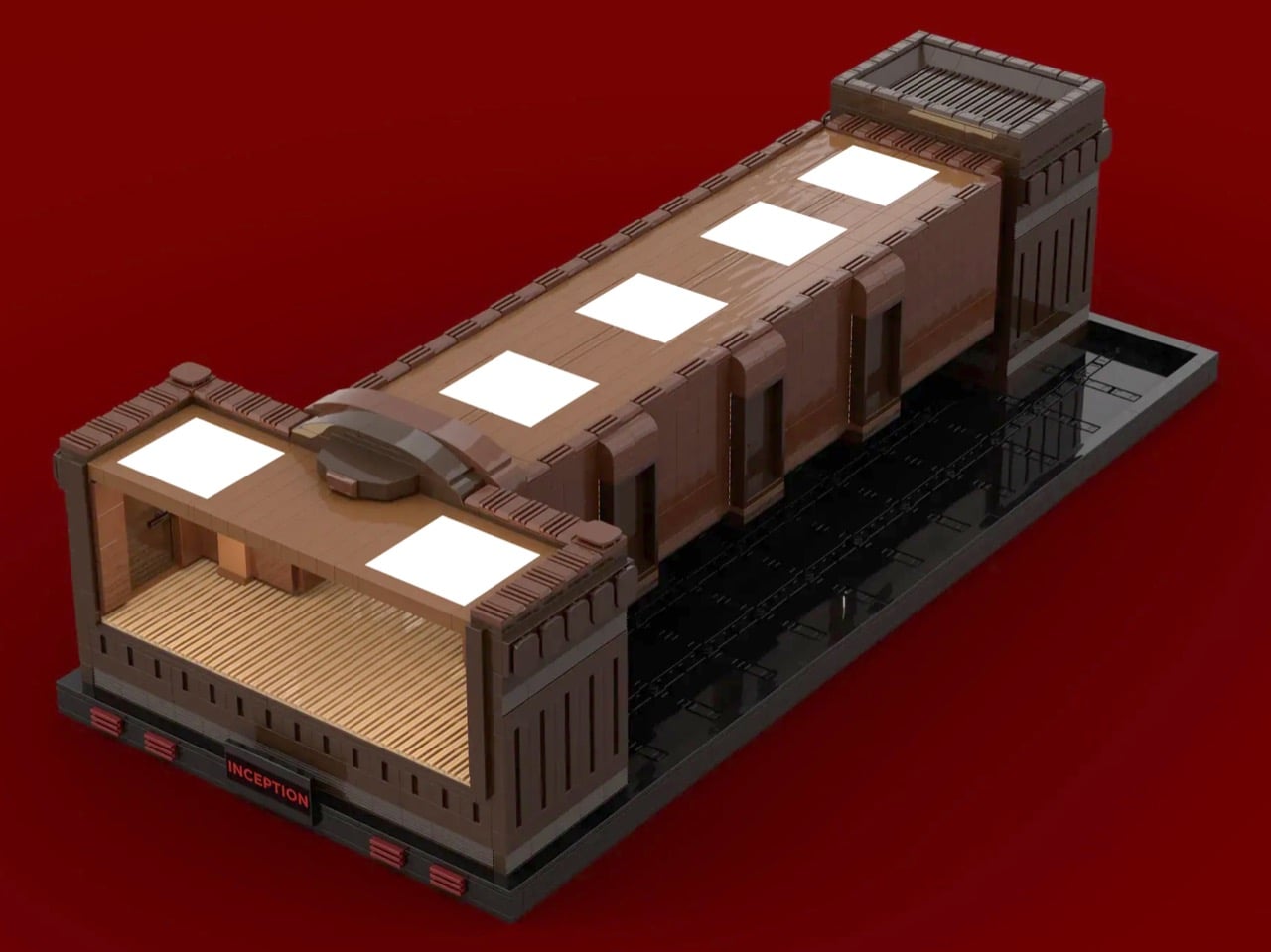

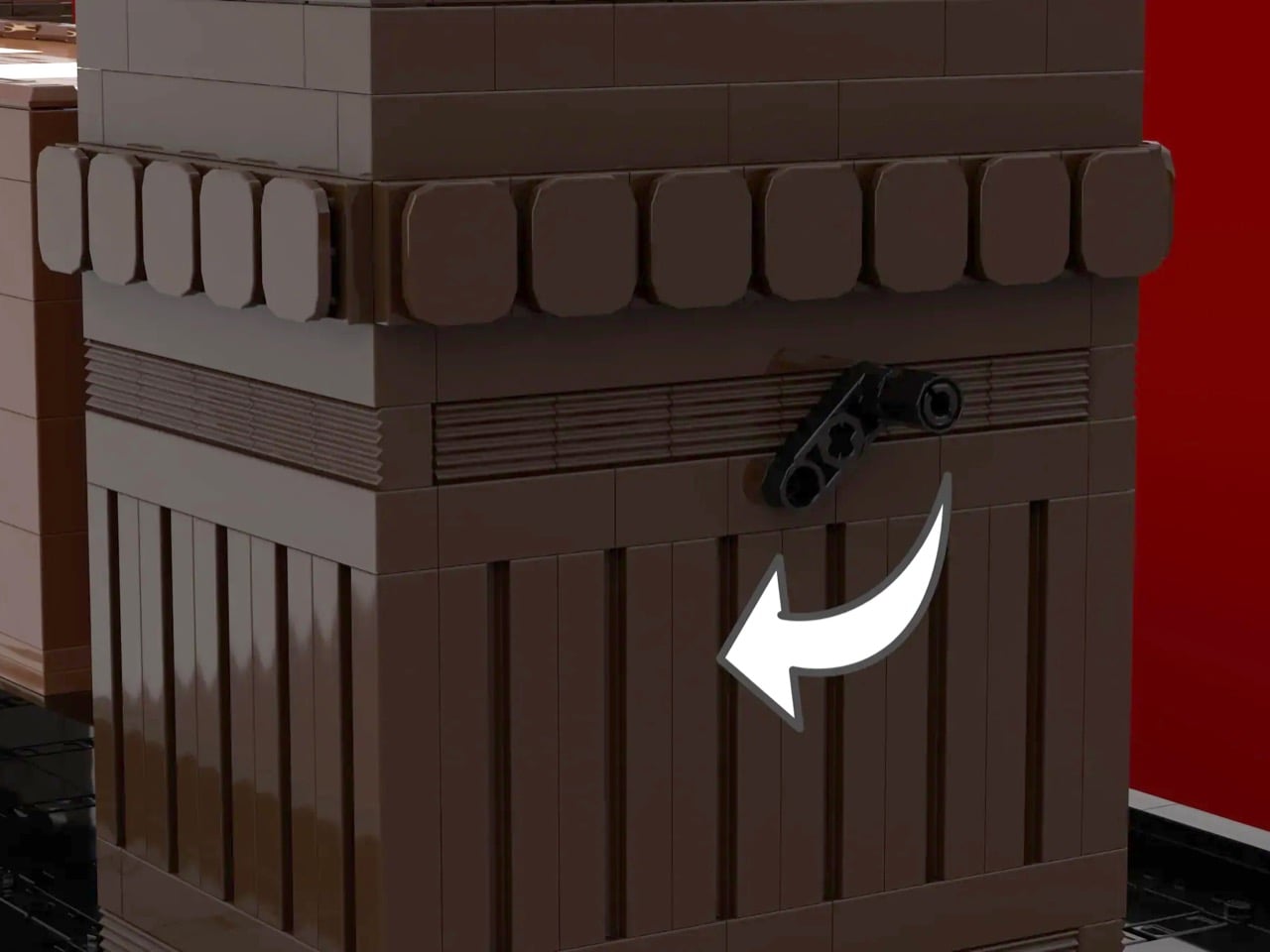

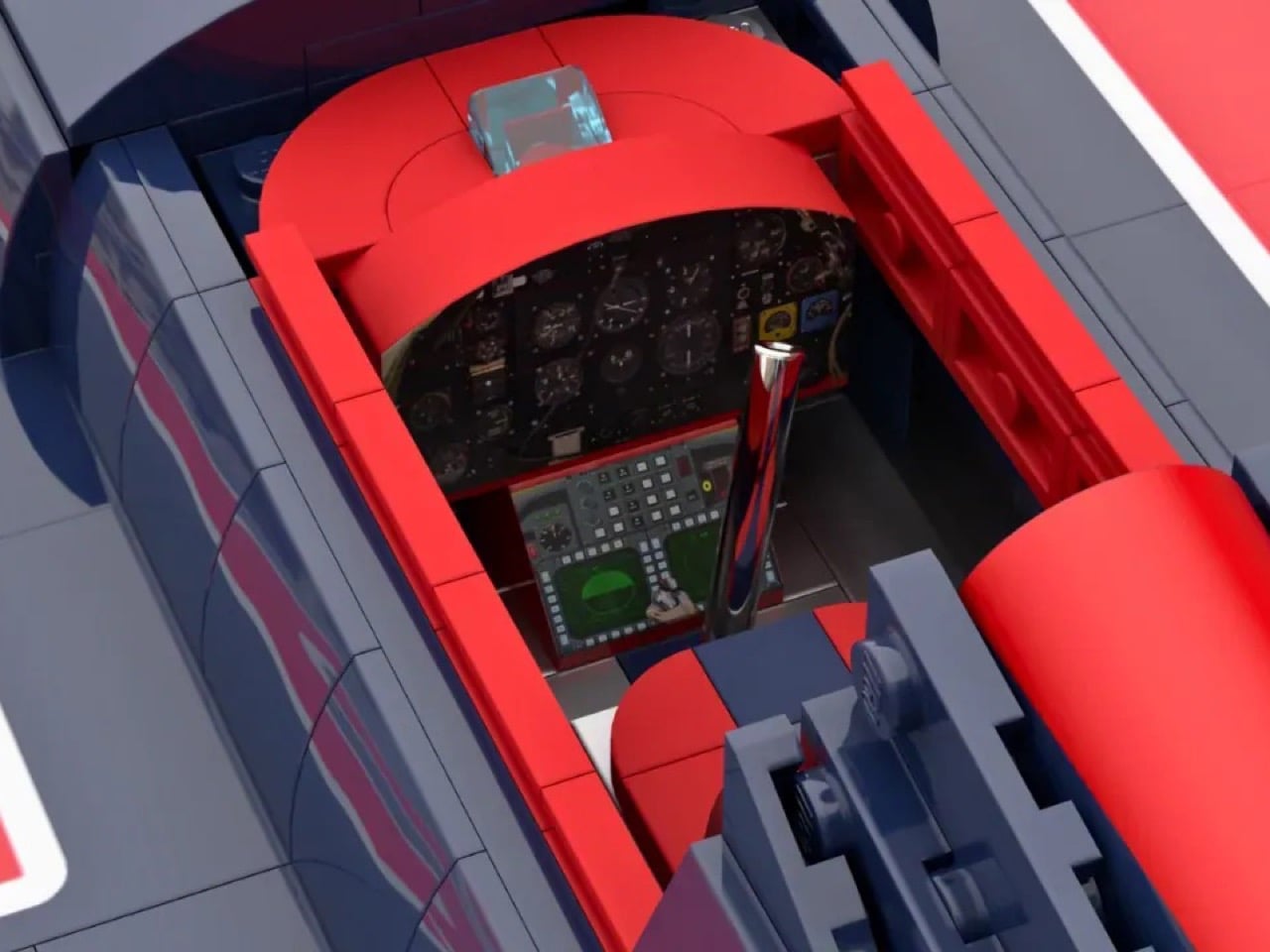

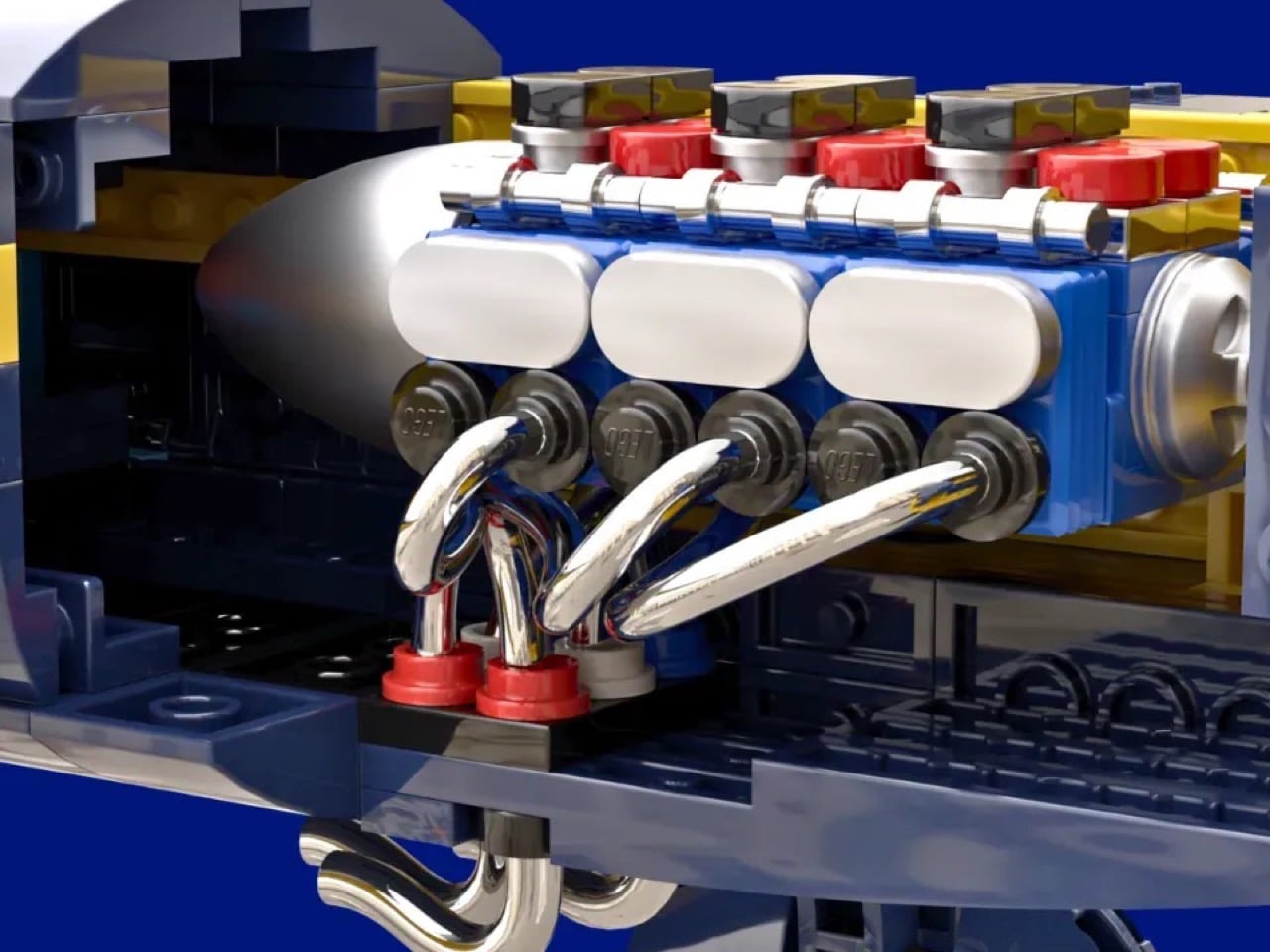

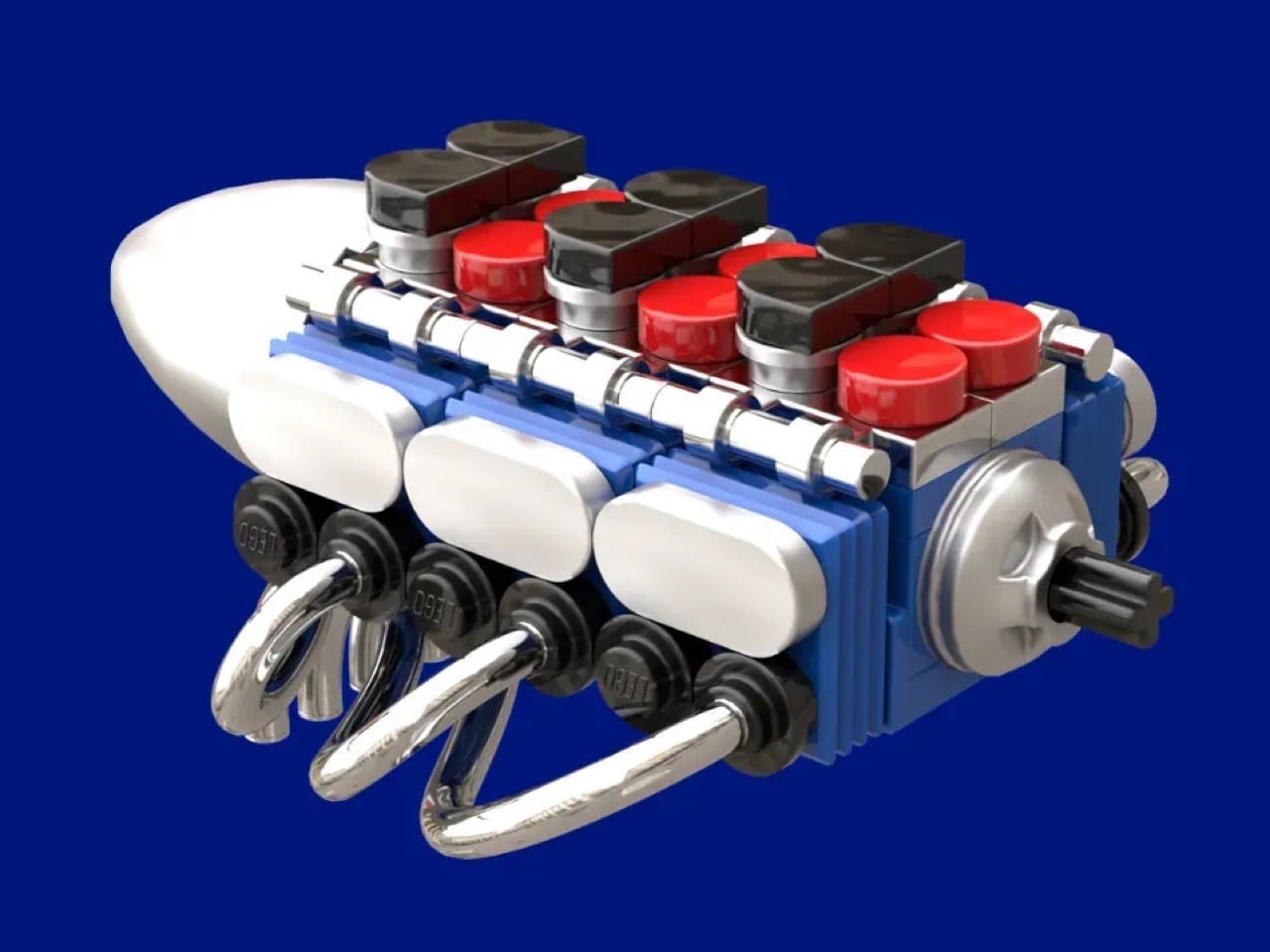

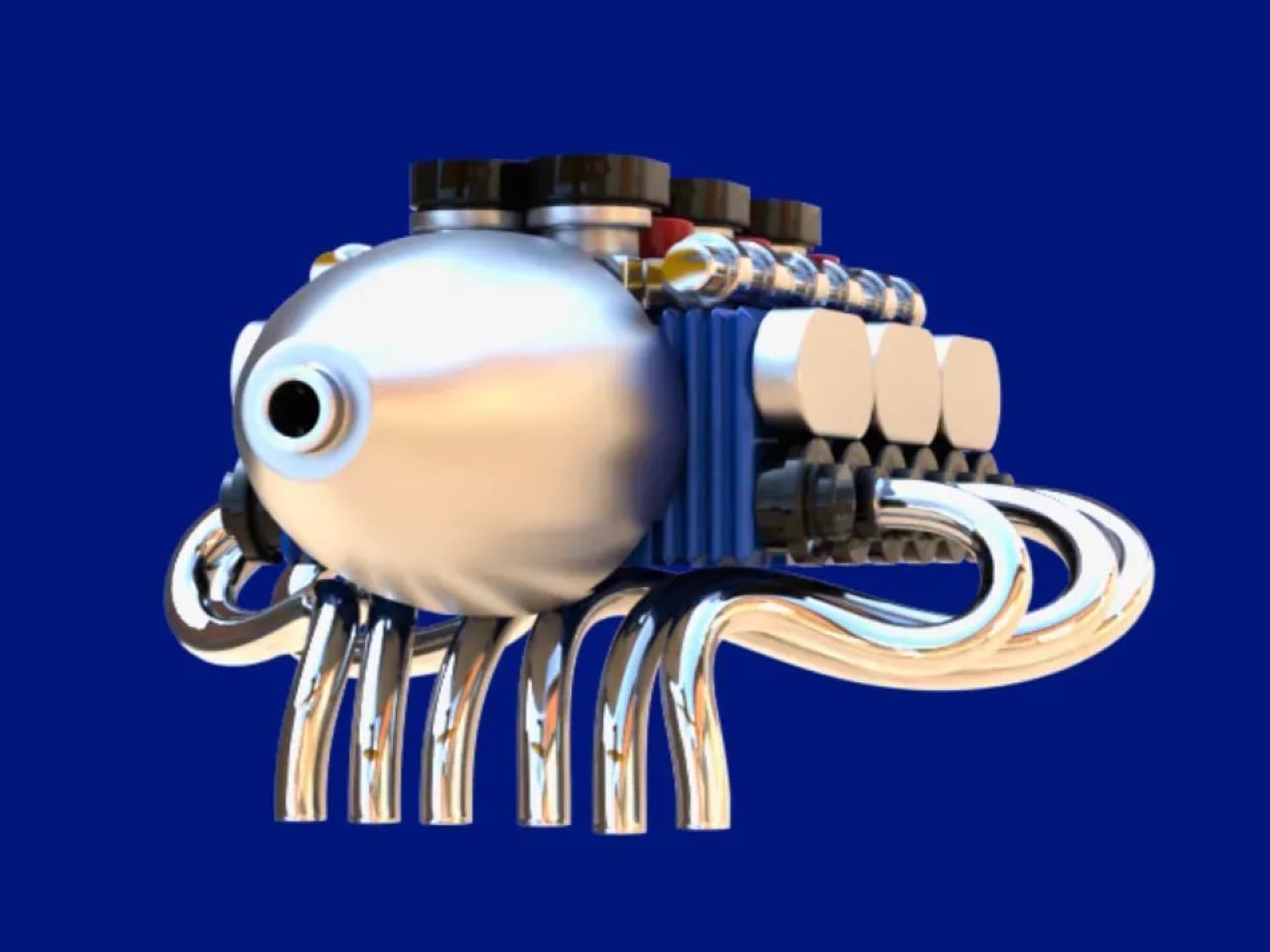

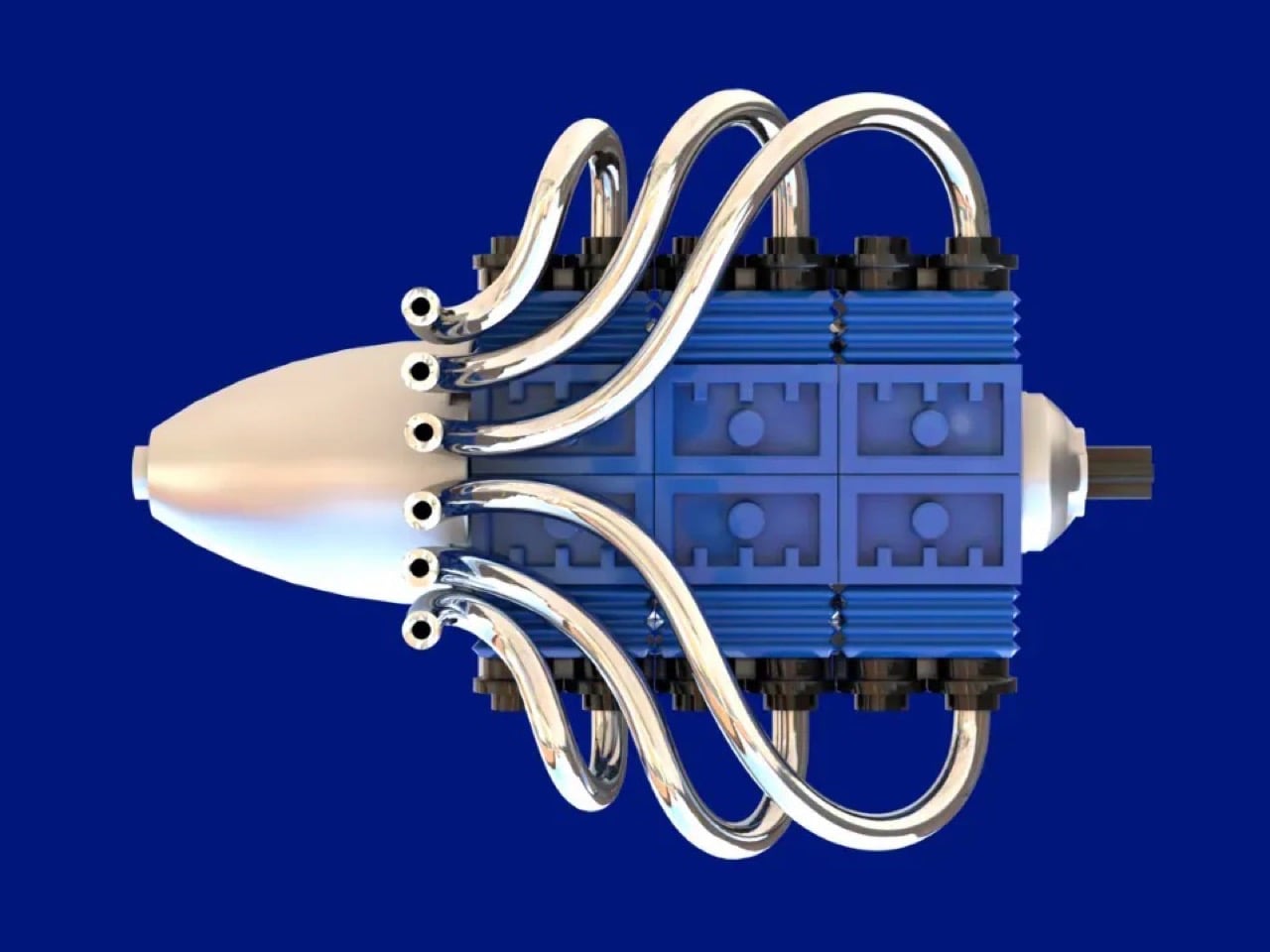

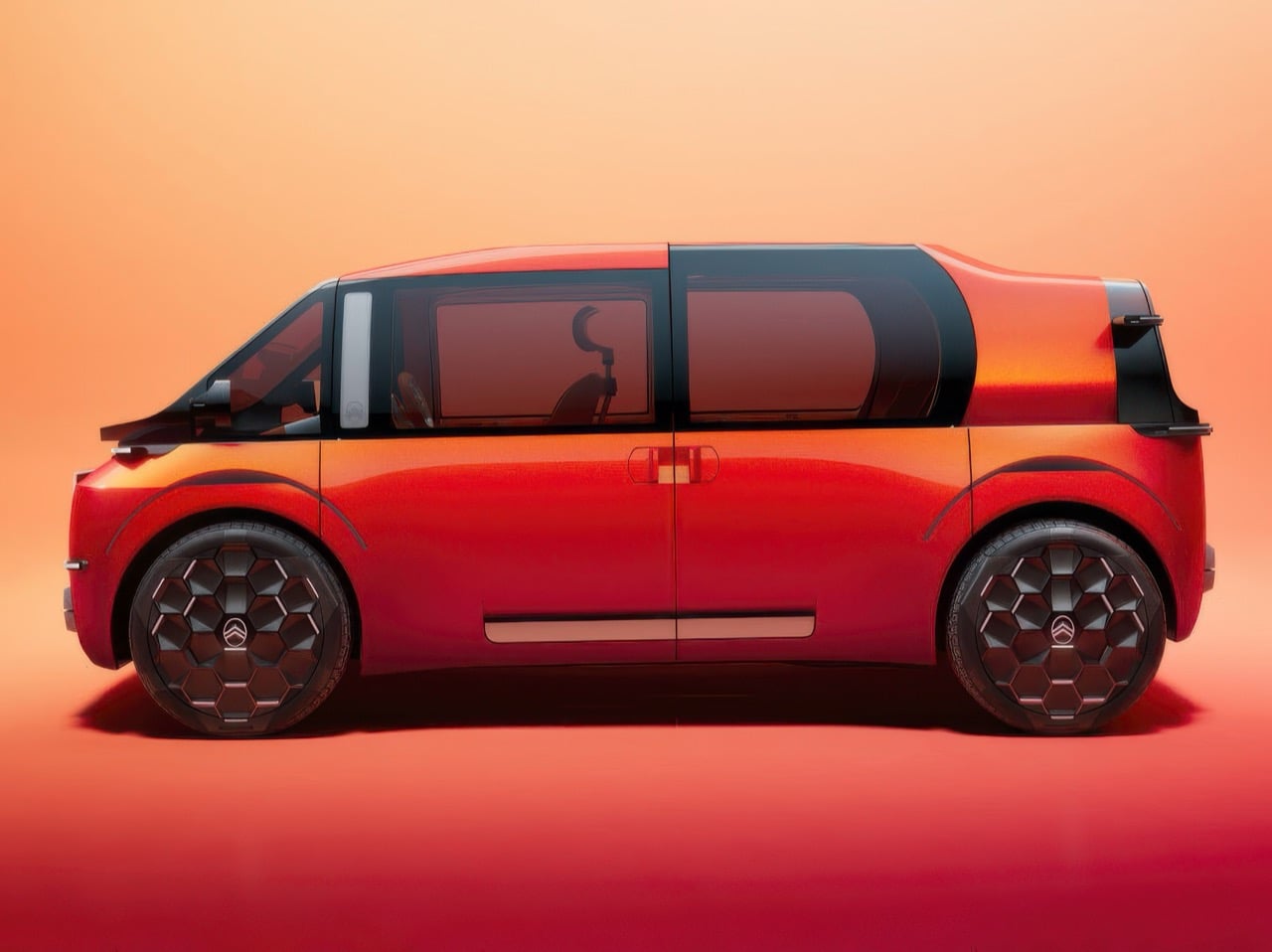

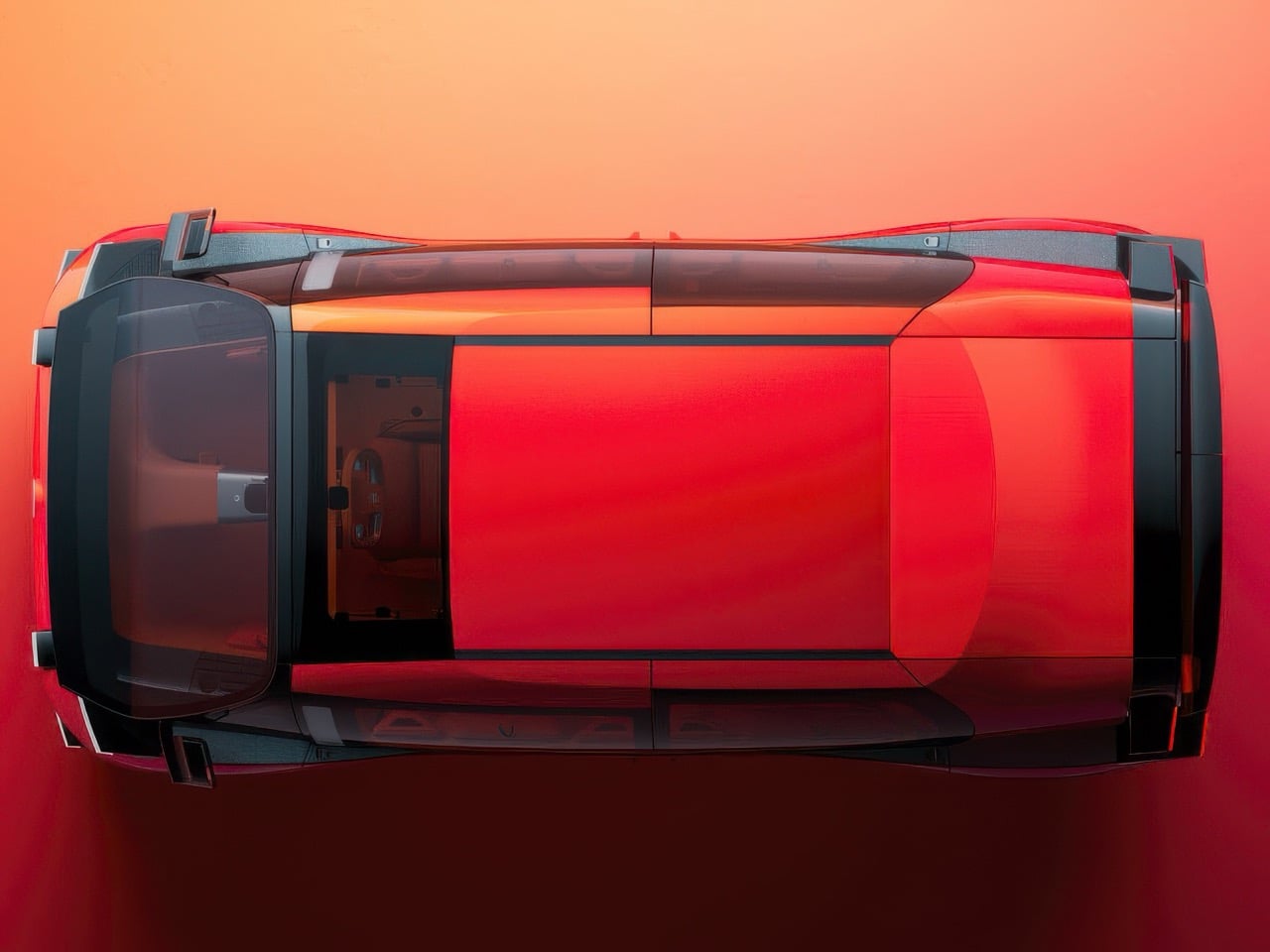

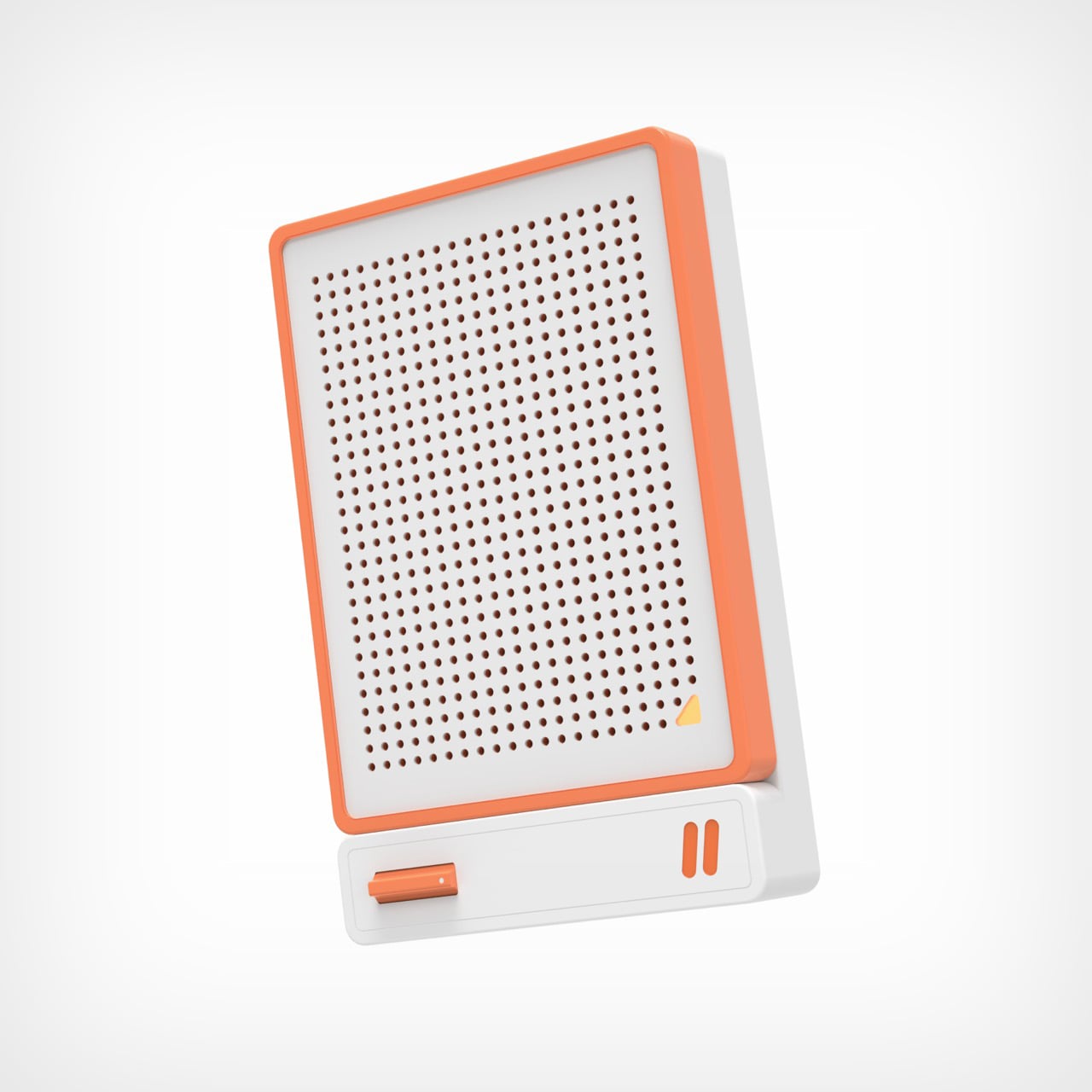

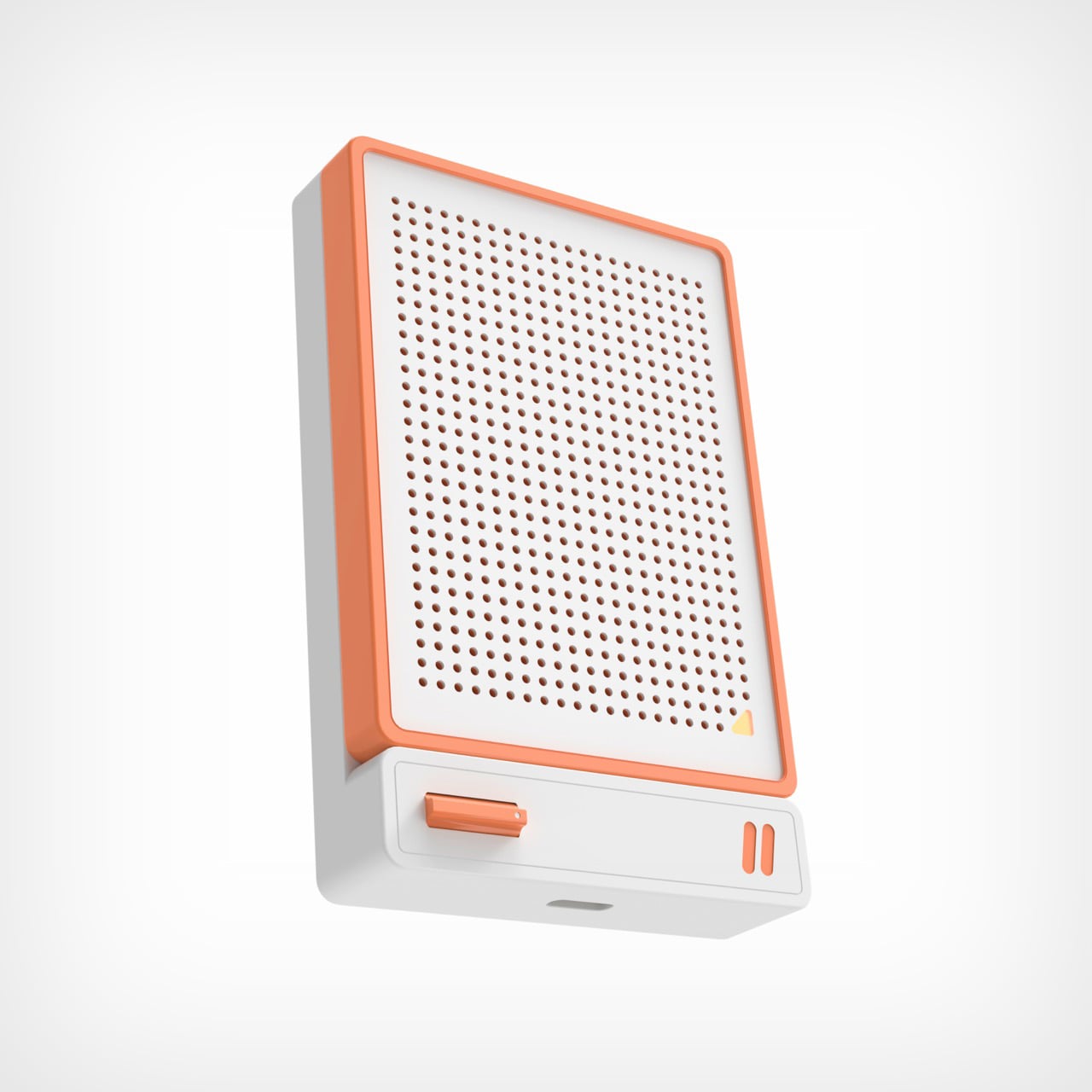

Show me another MagSafe breadboard. I’ll wait. Kevin Yang’s Commi Board is the only one, and that alone tells you something about how design students occasionally see opportunities that entire industries miss. The engineering is smarter than it looks: instead of embedding a full microcontroller and battery into a phone accessory, Yang uses GPIO communication to let your smartphone handle the processing. Your phone already has more power than an Arduino Mega, better connectivity than most dev boards, and a screen you actually want to look at. Commi Board just provides the physical interface for components and the software to make it work. You get four programming methods ranging from conversational AI to a proper IDE, real-time circuit validation, and a small display that shows execution status. Dimensions are tight: 62mm by 98mm when installed, with the board itself at 62mm by 82mm when detached.

The color scheme gives strong Flipper Zero vibes, but there’s a key difference between that infamous pen-testing tool and this humble breadboard. Flipper wants to be everything: NFC reader, IR blaster, sub-GHz radio, GPIO interface, and more. Commi Board has a tighter scope and probably benefits from that focus. It’s specifically for prototyping circuits and validating code, not for pentesting your neighbor’s garage door. The modular design splits into the breadboard surface and a MagSafe mounting frame with that distinctive ring cutout for phone cameras. Everything connects through USB-C 3.2, BLE, or Bluetooth, and the cloud storage means you can start a project on your phone and pick it up later without dealing with local file management. Yang has a working theoretical PCB prototype with tested connectivity, though the full API integration is still in mockup phase. For a student project that started in June 2024, this is surprisingly far along.

Designer: Kevin Yang

Most IoT hardware tries to do everything and ends up mediocre at all of it. You get a device with its own processor, battery, screen, and connectivity stack, essentially rebuilding a worse version of the phone already in your pocket. Yang went the opposite direction. Commi Board is parasitic by design, borrowing your phone’s computational power, display, internet connection, and power management. What remains is pure interface: holes for components, GPIO pins for communication, and minimal onboard electronics to translate between physical circuits and software. This approach means lower weight, cheaper manufacturing, and no battery degradation to worry about in three years. After 3 years, swap your phone, but continue your tinkering. Sounds almost revolutionary, no?

You can tell Yang actually built and tested this thing because of how the modular split works. Sometimes you want the board magnetically stuck to your phone for portable testing. Other times you need it detached because your circuit blocks the camera or needs more space to breathe. The MagSafe frame has that circular cutout positioned exactly where iPhone camera arrays sit, which matters more than it sounds. Misalign that by a few millimeters and the magnetic connection feels sketchy. The orange border serves double duty as brand identity and a visual indicator of where the two pieces separate. Good industrial design makes functional divisions obvious without needing instruction manuals, and this pulls it off cleanly.

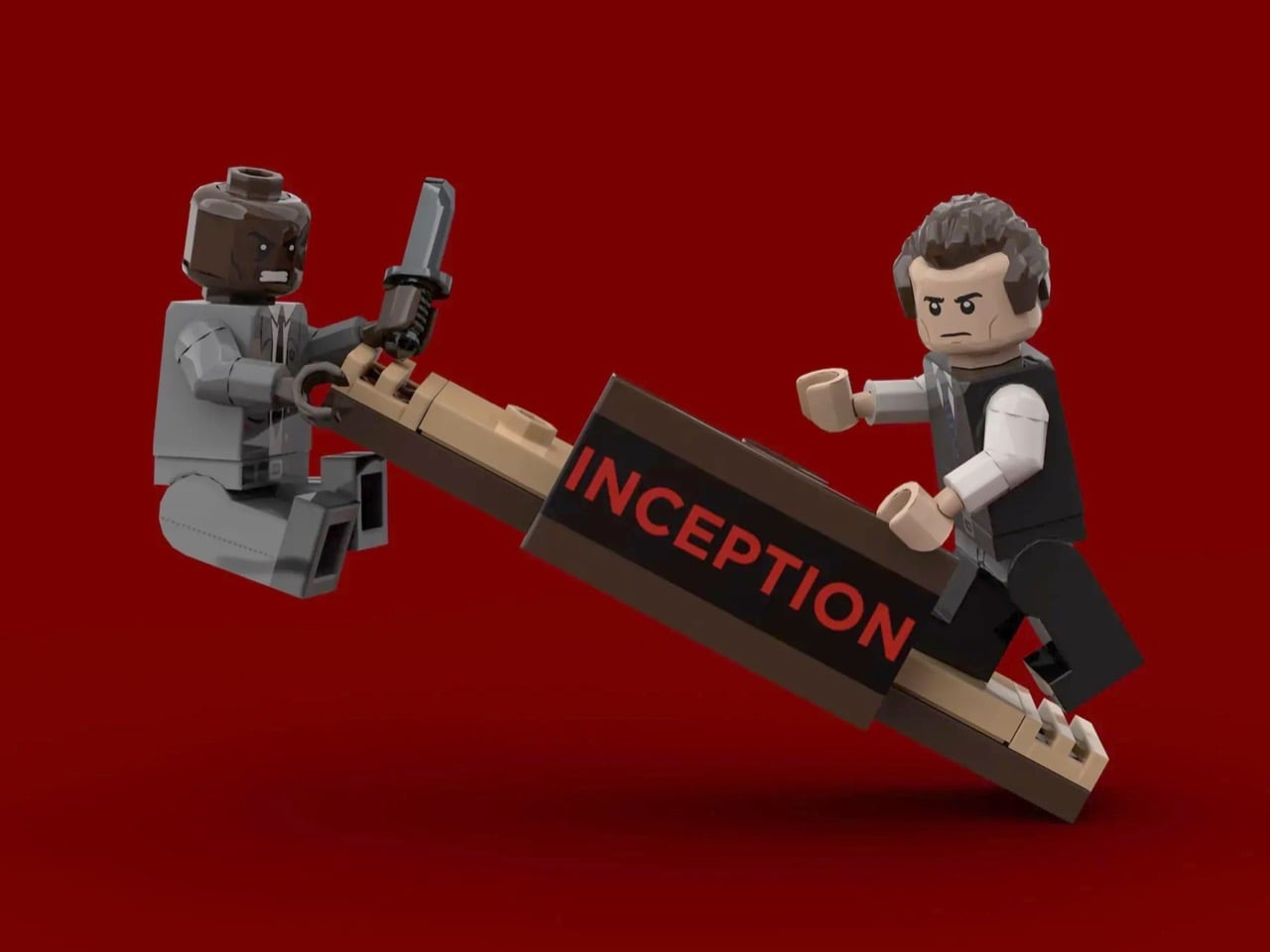

Four programming methods cover a wide range of experience levels, from ‘never touched circuitry in my life’ to ‘I ship builds and hardware for a living.’ Beginners can type “make an LED blink every second” and watch AI spit out working code. That builds intuition about syntax without requiring fluency first, which is how people actually learn instead of how computer science departments think they should learn. Visual block programming handles the intermediate phase where you understand logic flow but typing semicolons still feels unnatural. Puzzle-piece interfaces work surprisingly well for teaching conditionals because the physical constraints mirror logical ones. Then there’s the full IDE for anyone comfortable with text editors or shipping actual products. Most educational platforms force you to switch ecosystems as you level up, losing all your previous projects in the migration. This keeps you on the same hardware using the same project files, just changing how you communicate with the circuits.

Yang claims GPIO communication lets the phone simulate most microcontrollers, which holds up for Arduino-class applications but gets questionable under pressure. Smartphones have absurd amounts of raw compute, but they run full operating systems with schedulers and background processes that introduce latency. Blinking LEDs and reading sensors? Totally fine. Tight timing loops or bit-banging niche protocols? You’ll probably hit walls. The spec sheet lists USB-C 3.2 alongside Bluetooth and BLE, which tells me Yang ran into exactly these problems during development. USB-C handles the demanding stuff while Bluetooth covers casual wireless control. That’s the kind of tiered connectivity you see from someone who tested their assumptions and had to architect around reality.

And the Commi Board comes with cloud storage too, allowing you to save your projects/builds/experiments in a secure place that isn’t bound to your phone. Imagine the alternative – you get inspired, start wiring something up, then life happens and three weeks later you can’t remember which transistor you needed or where you saved that working code. Friction kills momentum harder than technical difficulty does. Being able to pull up a half-finished project on your phone while standing in a component aisle trying to remember your parts list solves a real problem. The project-sharing community is obviously coming next, which transforms this from a standalone product into a platform. If Yang opens the API properly for third-party development, this could turn into something way bigger than a thesis project. Right now there’s a working PCB prototype with tested connectivity, which means the core tech functions. Let’s hope Yang gets to a point where he can take this to a startup level, or even crowdfunding. I know I’d have my money ready.

The post MagSafe Breadboard Turns Your iPhone Into a Circuit Prototyping Lab first appeared on Yanko Design.