Traditional wooden cellos and violins are exquisite but fragile. They crack in dry weather, warp in humidity, and require constant environmental monitoring. A professional instrument can cost tens of thousands of dollars, yet one bad flight or unexpected temperature change can cause irreversible damage. This vulnerability has long kept quality instruments out of reach for traveling musicians, students in varied climates, and performers who need reliability above all else.

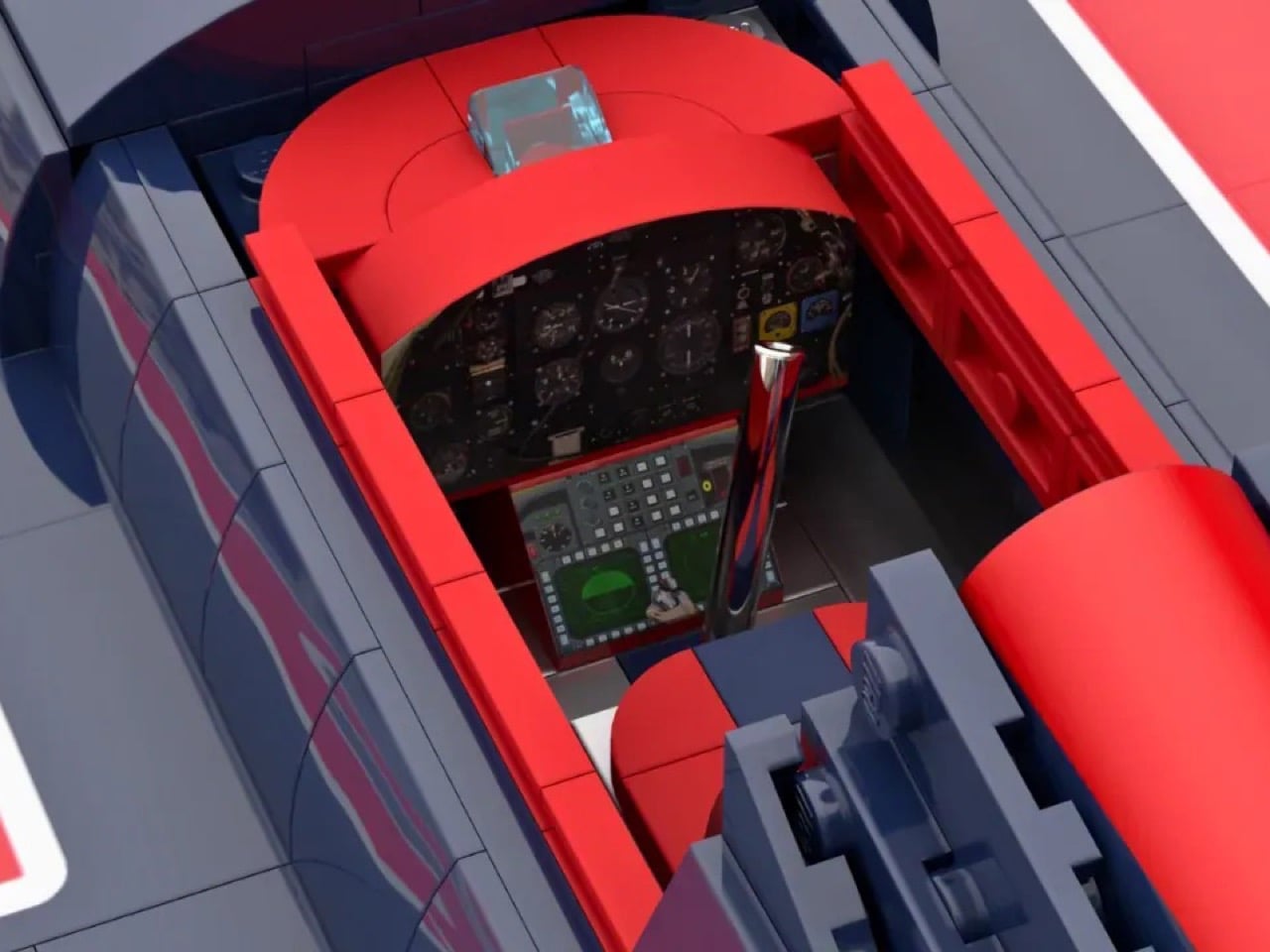

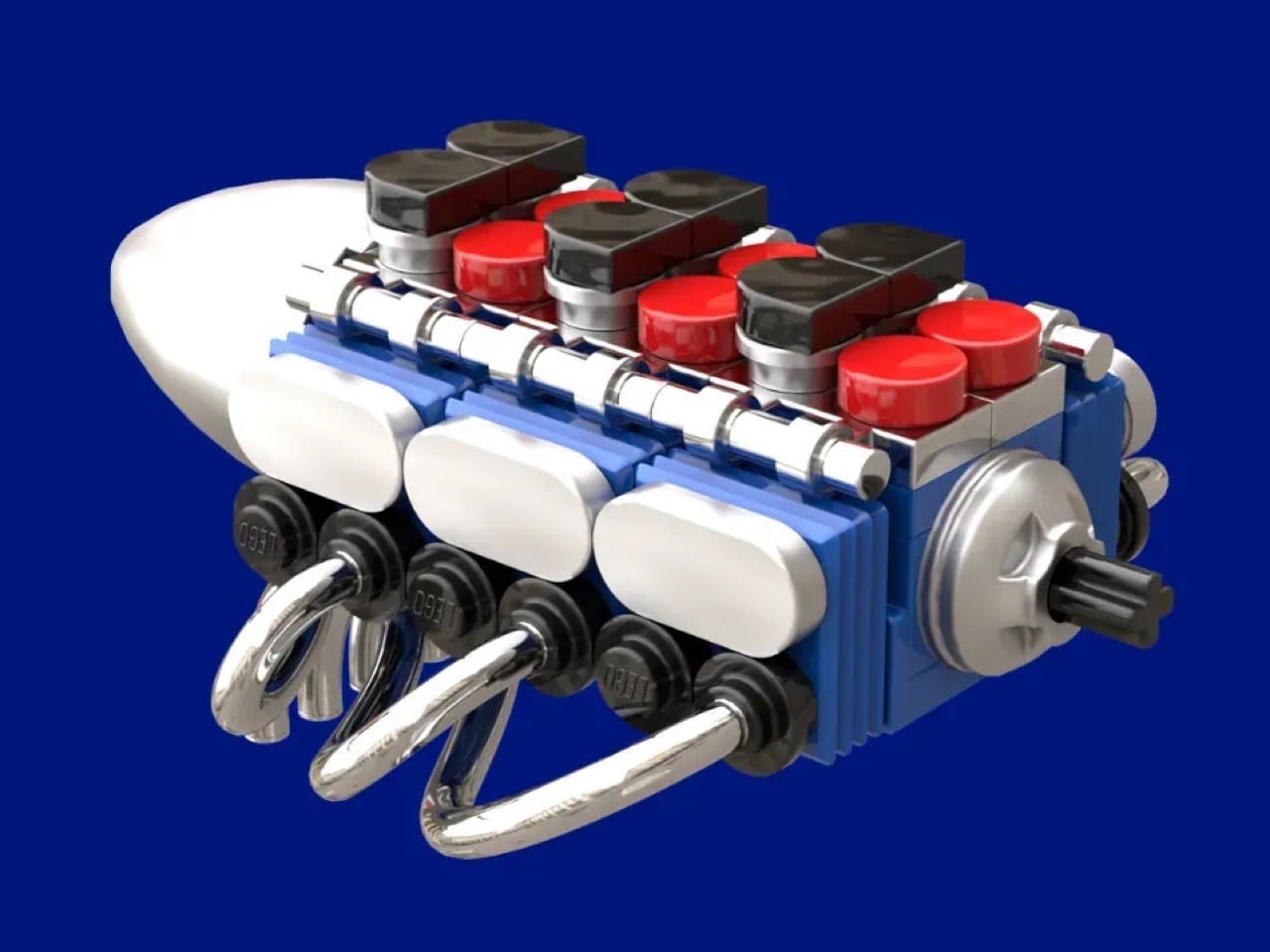

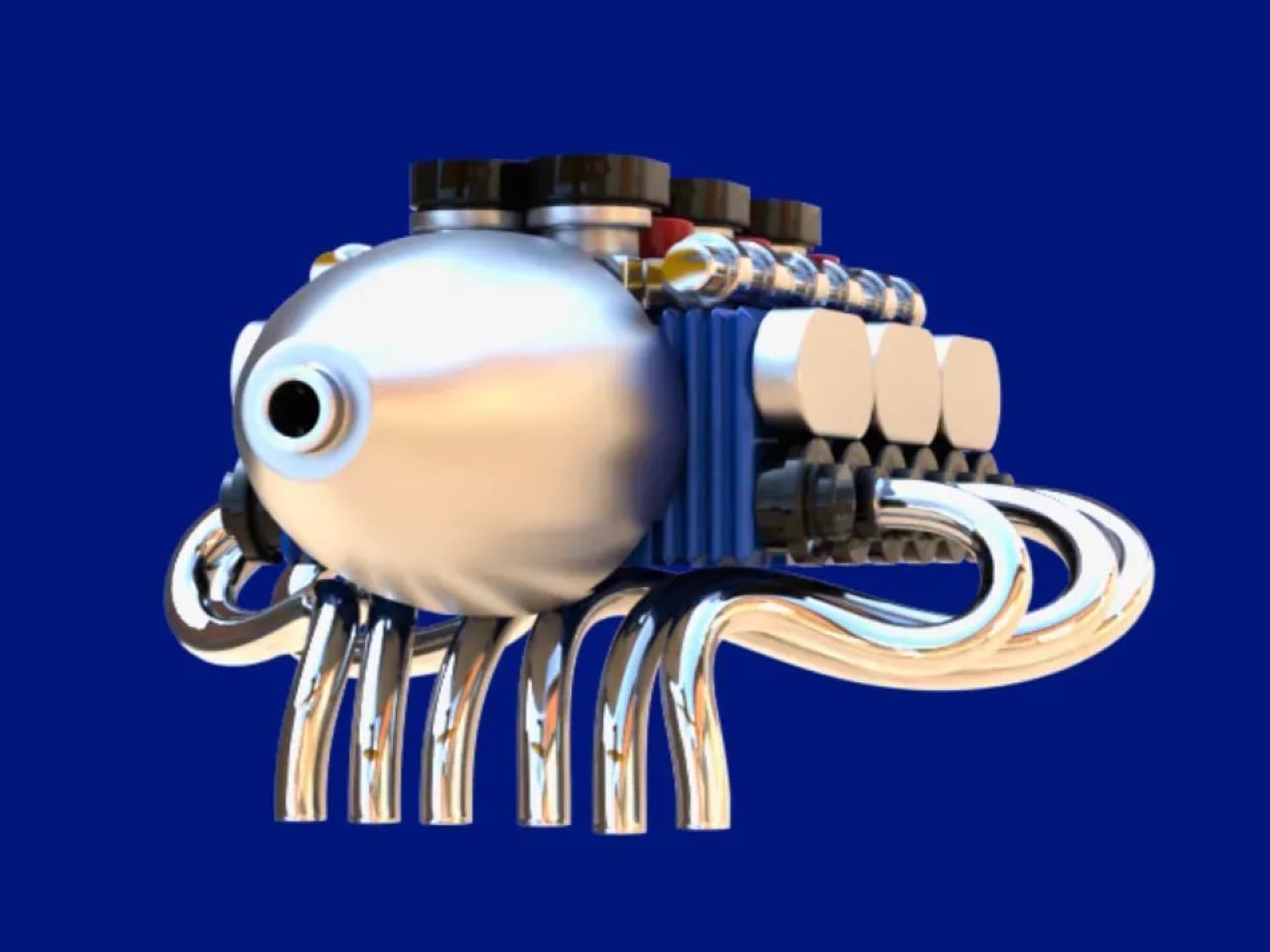

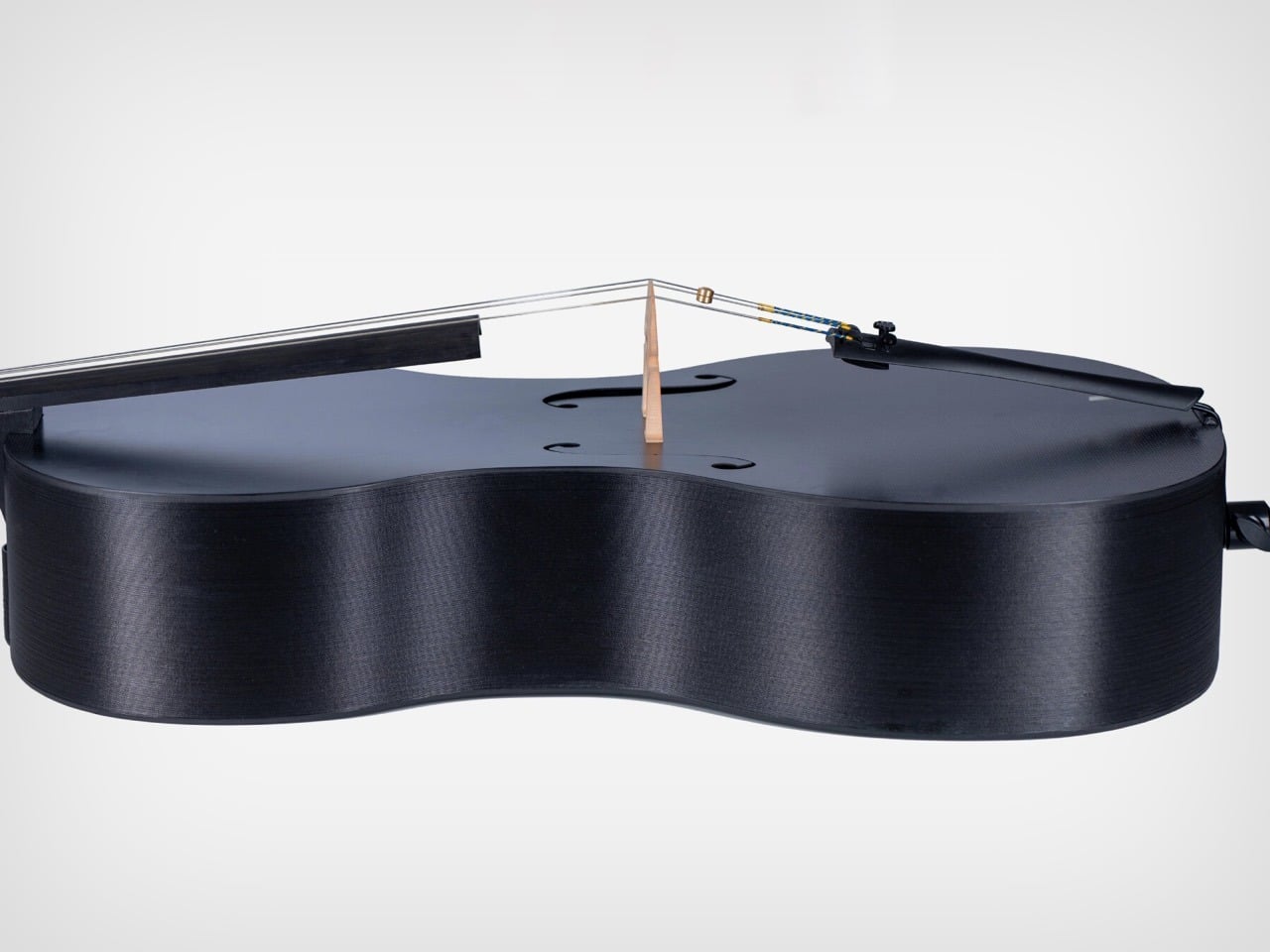

Forte3D’s answer combines 3D printing technology with carbon fiber construction. The team, led by Yale student Elijah Lee and co-founder Alfred Goodrich, created instruments with flat carbon fiber panels and 3D printed polymer components that maintain their shape regardless of environmental conditions. The sound quality matches traditional instruments because the team used computer-aided design to control every structural element and dial in the acoustics precisely. These instruments also include adjustable string heights and smooth tuning mechanisms, making them accessible for players at different skill levels.

Designer: Forte3D

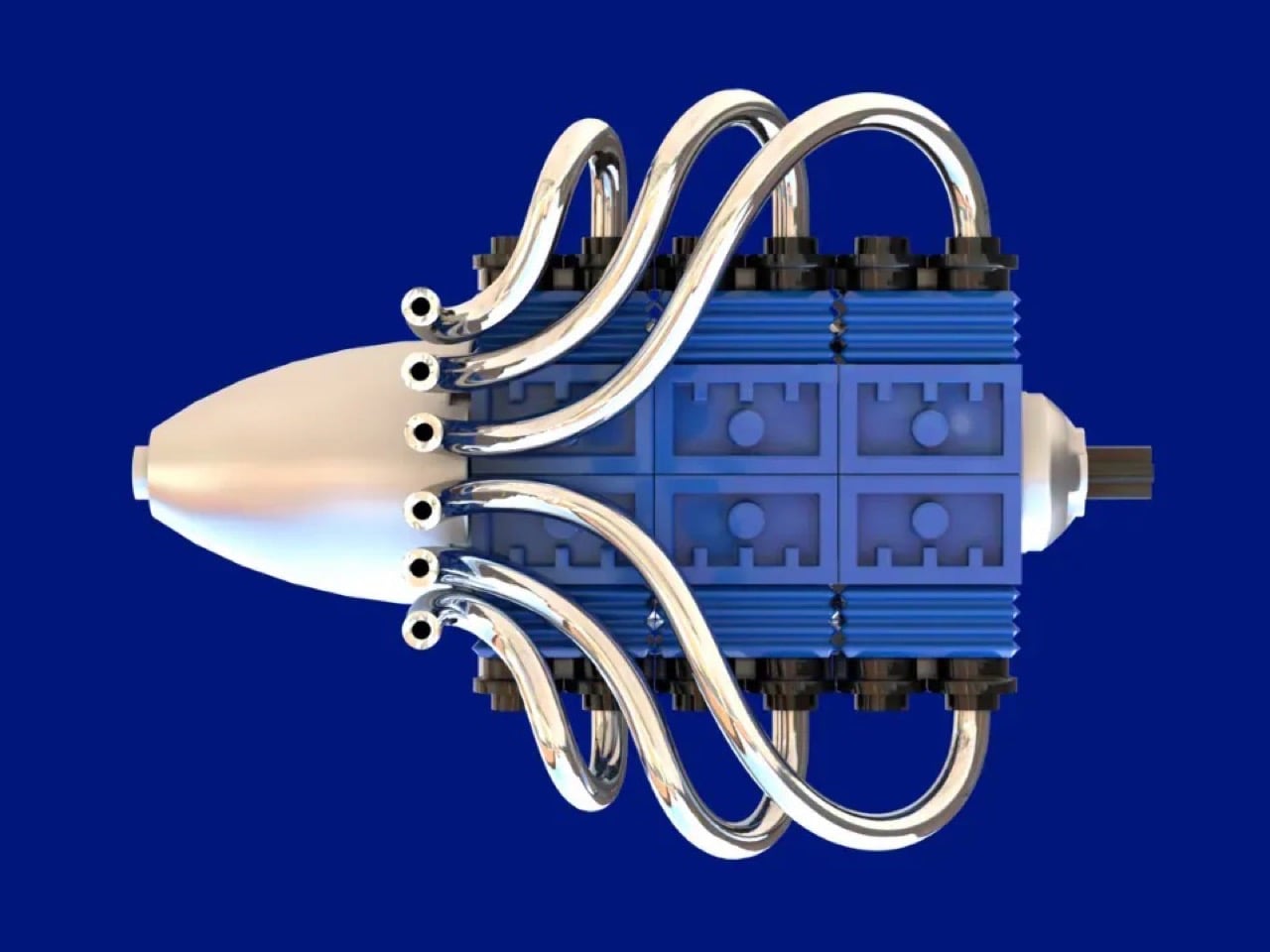

The project originated from a practical challenge. Lee’s orchestra director asked if he could use his early 3D printing skills to design a cello that was strong, low cost, and easy for more people to use. Rather than simply replicating traditional designs in new materials, Lee and Goodrich rethought the entire structure. They tested different thicknesses and configurations using computer-aided design tools, discovering they could shape the sound in more controlled ways than traditional luthiers. This digital precision allowed them to dial in the acoustics by controlling every part of the structure.

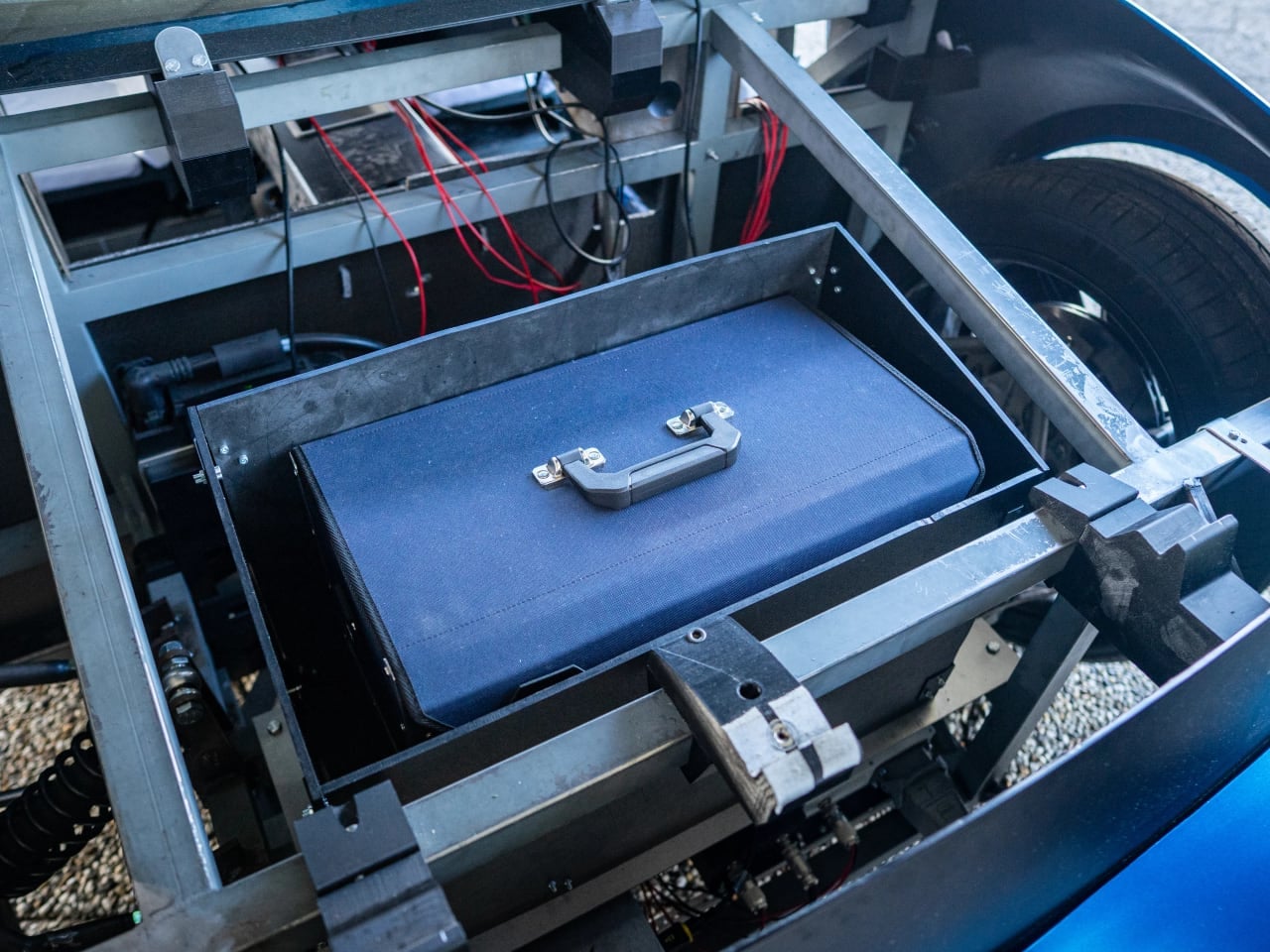

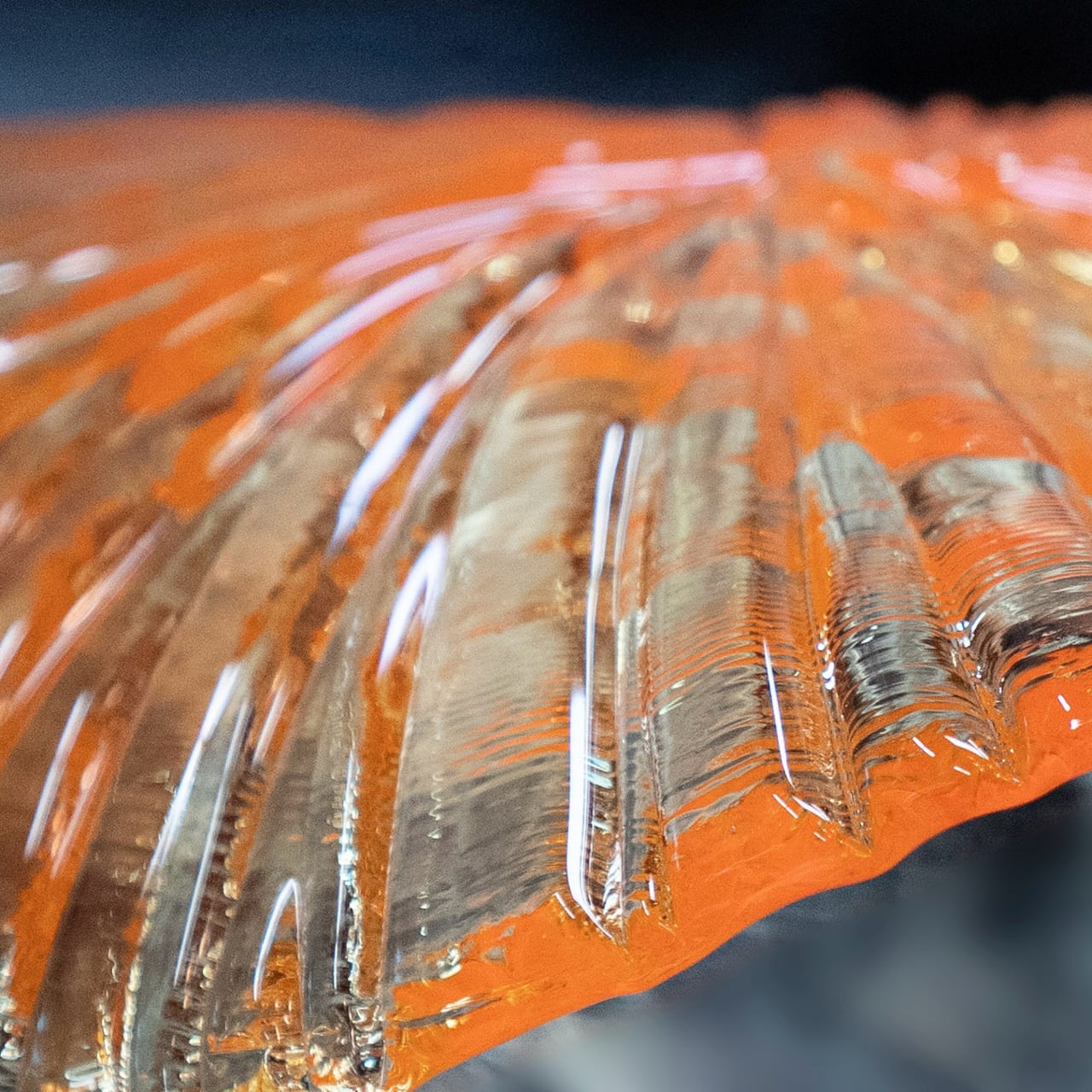

The final design breaks from tradition in significant ways. The top and back panels are made from carbon fiber and shaped as flat and concave surfaces rather than carved forms. The ribs and neck come from 3D printed polymer material. However, certain classical elements remain unchanged because they work perfectly as they are. The sound post, fingerboard, and bridge are still made using traditional methods and materials, creating a hybrid that respects acoustic principles while embracing modern durability.

Carbon fiber’s core advantage is its stability. Unlike wood, which expands and contracts with atmospheric changes, carbon fiber maintains its dimensions regardless of humidity or temperature. This means musicians can bring their instruments to outdoor performances, different climates, or even extreme environments without worrying about structural damage. The material also eliminates the need for specialized maintenance products. A simple cloth and common household cleaners are sufficient to keep these instruments in excellent condition.

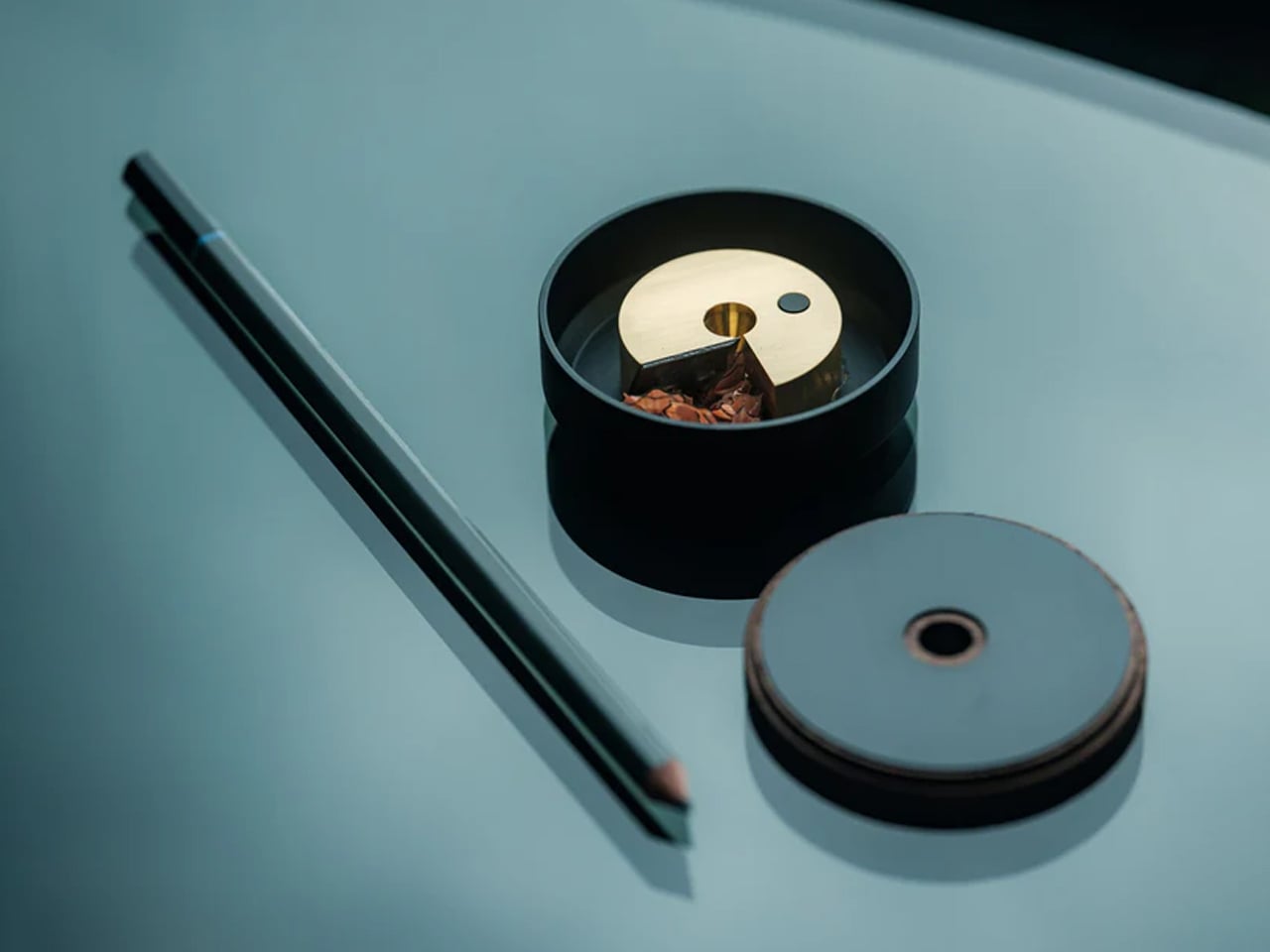

Forte3D also addressed playing comfort, which directly affects technique and long-term health. When strings sit too high or too low, musicians experience hand pain and their personal technique becomes harder to execute. The team built in an adjustable string height system that lets each player move the strings up or down using a small tool that comes with the instrument. The cello also includes smoothly moving tuning pegs and tools for stopping wolf tones, which are unwanted resonances that plague certain notes on string instruments. A printed guide ensures the bridge sits in the correct position, and all these design elements work together to support both playing comfort and sound production.

The violin version carries the same philosophy. Players can adjust string height to match their needs, and the body features a hole at the back to support sound flow. Like the cello, it ships with strings and tuning pegs designed for easier tuning. Both instruments handle weather changes and physical bumps that would damage wooden counterparts. For the Forte3D team, these instruments are not about making a style statement. They focus on what musicians actually need, which means less worry about damage, easier carrying, simpler care, and lower cost. The result is an instrument that honors centuries of acoustic development while finally freeing musicians from the constraints that wood has always imposed.

The post Yale Engineers Created a 3D-Printed Carbon-Fiber Cello That That Never Cracks or Warps first appeared on Yanko Design.