Using rammed earth, mud, clay and other natural materials for construction is a practice that has been around for at least 10,000 years. Casa Covida is a unique home that blends these age-old construction practices with the marvels of modern technology like 3D printing to elevate sustainable architecture to a new level!

Even today, earth-based houses are used by almost 30 percent of the world’s population because they are low-tech, affordable, and simple. These are not just tiny huts, they cover everything from hand-made earthen buildings to traditionally modern homes – the binding factor is the use of rammed earth techniques as well as sustainable materials like bamboo or wood. These materials are local and easy to source – what could be easier than to use the earth beneath one’s own feet? While some people might think these techniques are outdated, many designers and architects are experimenting with them by mixing them up with 3D printing technology. Emerging Objects is one of these visionary studios that want to explore more novel ways to use 3D printing. Casa Covida has been 3D printed using soil mixed with straw, sand, and other organic materials – a successful experiment by the California-based studio.

The name Casa Covida refers to both the global pandemic and the Spanish word for cohabitation because it was born during a special time where we dealt with both those things. The organic structure is currently a prototype that can host two people and has been 3D-printed in the desert of San Luis Valley, Colorado, using a three-axis SCARA (Selective Compliance Articulated Robot Arm) that extruded out an adobe mix of sand, silt, clay, and water. The house has three parts – a central space, a sleeping space, and a bathing space. The central space can be accessed via a wooden door which can be left open/closed thanks to an inflatable pink roof that can be deployed during rain or snow, or if the occupants want to keep the heat of the fire from escaping. The roof is one of the most interesting features and has been inspired by a blooming cactus as a nod to the dwelling’s desert location.

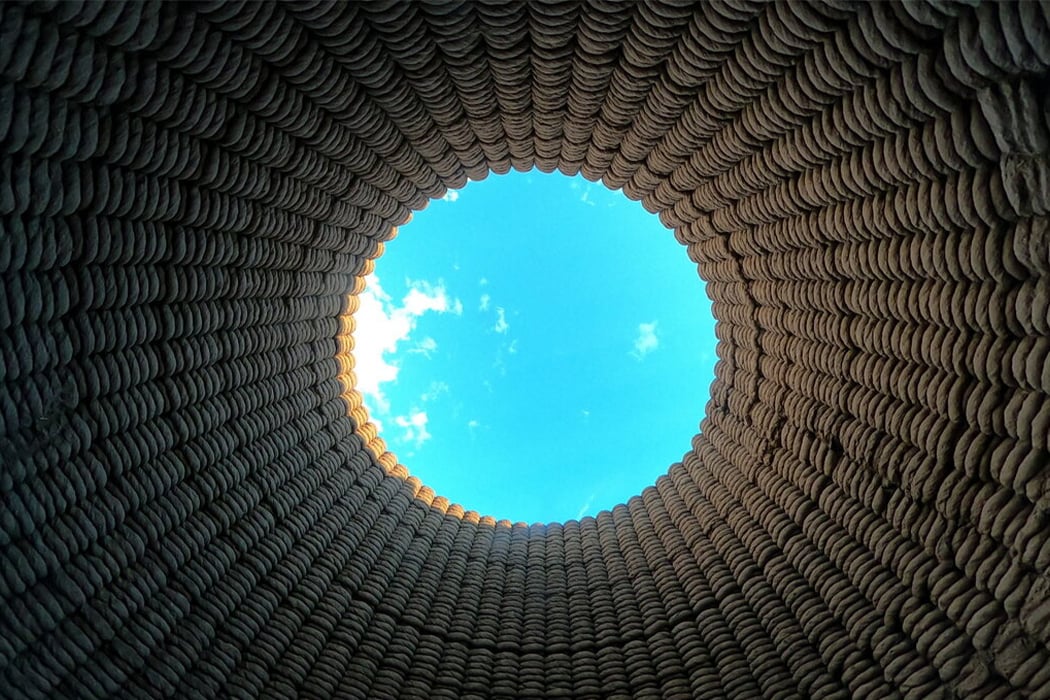

The central space includes the main hearth and two earthen benches called tarima. It also comes equipped with custom-designed earthen cookware which was also 3D-printed using locally sourced micaceous clay. The sleeping space includes a platform made from beetle kill pine (basically wood reclaimed from trees that have been killed off by mountain pine beetles – a big problem in Colorado) and is softened up for comfort with textiles made by local artist Joshua Tafoya. The bathing space has a metal soaking tub embedded into the ground and surrounded by river stones – straight up making you feel like you are bathing in a river bed. When you look up from the tub, there’s an open view of the sky above from a circular window.

The smartphone-controlled SCARA robotic printer used in this project is lightweight enough that only two people are needed to operate it. Casa Covida may be an experimental prototype for now, but Rael points out that the goal here is to ask vital questions about the limits of advanced technology and materials, and the possibilities of reviving ancient techniques and materials in a modern context, “In some ways, for me at least, this is a return to a particular origin and we’re taking the most primitive materials and combining them with the most sophisticated technology. But I actually see that in reverse: I see that mankind has been developing the use of mud for 10,000 years — it’s actually our most sophisticated material. And the way it works thermally, and the way it performs, and the way that it works environmentally is extremely sophisticated. The robotic arm is a crotchety, weird thing that’s always breaking down — that’s only existed for two years. It’s the least sophisticated technology we have for making a building. So the way I look at it is that we’re returning to a higher level of construction system by simplifying.” Reverse engineering the use of sustainable materials!

Designer: Emerging Objects