3D printed architecture is slowly but surely gaining a lot of popularity and momentum. This emerging trend is paving a path for itself in modern architecture. And I mean, no wonder, it has a ton of benefits! It’s a simple, efficient, and innovative technique that lowers the risks of errors, and also manages to save on time! 3D printing eradicates a lot of tedious steps during the construction process and simplifies it. It is being used to build homes, habitats on Mars, and even floating islands! The potential and possibilities of 3D printing in architecture are endless and mind-blowing. We’ve curated a collection of 3D-printed architectural structures that are our absolute favorites – from floating office pods to an underwater skyscraper, every single one of these designs unleashes the magic and potential of 3D printing!

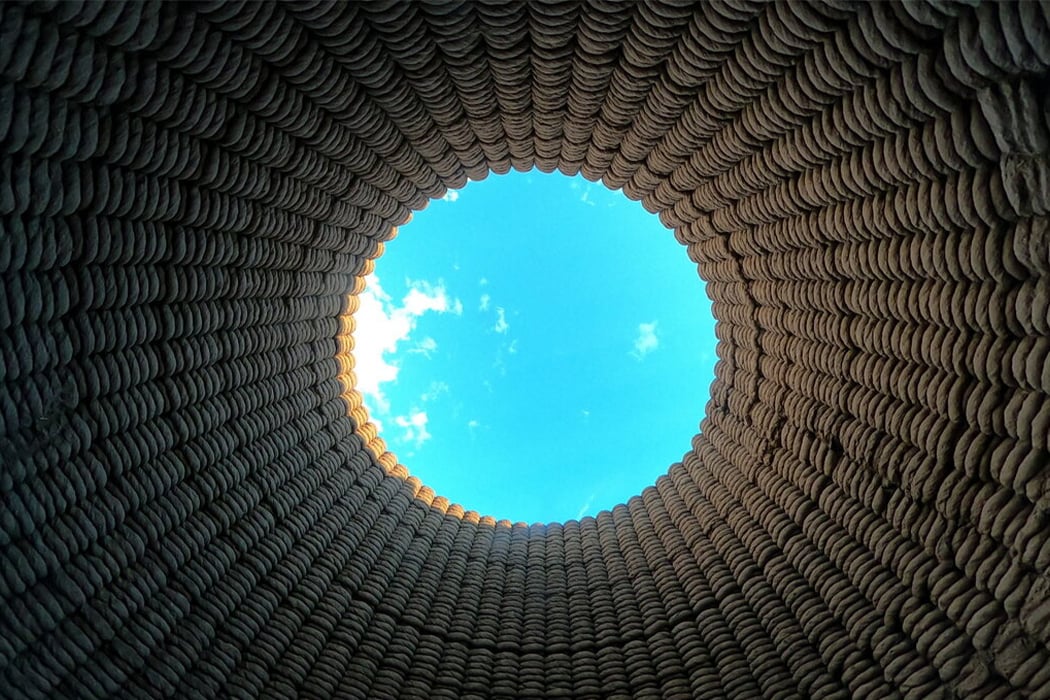

TECLA is a completely 3D printed global habitat based on natural materials. TECLA’s construction started as a prototype in 2019 near Bologna, Italy as a response to pressing societal issues of explosive population growth which inevitably led to a lack of affordable accommodation. TECLA is created using entirely reusable, recyclable materials taken from the local terrain – it aims to be a model for circular housing as well as eco-housing. The habitat has been designed by Mario Cucinella Architects and brought to life by WASP’s engineering and printing tech. TECLA is set to be the first house to be entirely 3D-printed using locally sourced clay which has been used for centuries in countries like India as a cost-effective and environmentally friendly alternative to cement – clay is a biodegradable and recyclable material that will make the building a zero-waste structure.

In making R-IGLO, ArchiTech Company joined arms with Royal 3D to create igloo-like workspaces that are made from recycled PET plastic, a material that can be reused plenty of times over. Currently undergoing redevelopment, an important harbor in Rotterdam called M4H is where the team behind R-IGLO sources all the material used during the 3D printing process. Once the materials needed for printing are acquired, the construction of each R-IGLO workspace takes place in M4H as well. The R-IGLO units are built by linking together 3D-printed panels that can later be disassembled, stored, and transported just as easily as they were put together. Since each R-IGLO structure comprises several modules, owners can decrease or increase the size of their R-IGLO by swapping out different sized modules.

Casa Covida has been 3D printed using soil mixed with straw, sand, and other organic materials – a successful experiment by the California-based studio. The name Casa Covida refers to both the global pandemic and the Spanish word for cohabitation because it was born during a special time where we dealt with both those things. The organic structure is currently a prototype that can host two people and has been 3D-printed in the desert of San Luis Valley, Colorado, using a three-axis SCARA (Selective Compliance Articulated Robot Arm) that extruded out an adobe mix of sand, silt, clay, and water. The house has three parts – a central space, a sleeping space, and a bathing space.

Designed by Dutch architects Houben & Van Mierlo, this boulder-shaped home in the Netherlands had its tenants move into it on 30th April, making it the first lived-in 3D printed house in the country! The single-story home was built as a part of a 3D printing scheme called Project Milestone. It is supposed to be the first 3D printed home in Europe where people actually reside! The tenants say the house has the feel of a bunker and feels safe. With curved sloped walls and floor-to-ceiling windows, the home is an open and warm living space.

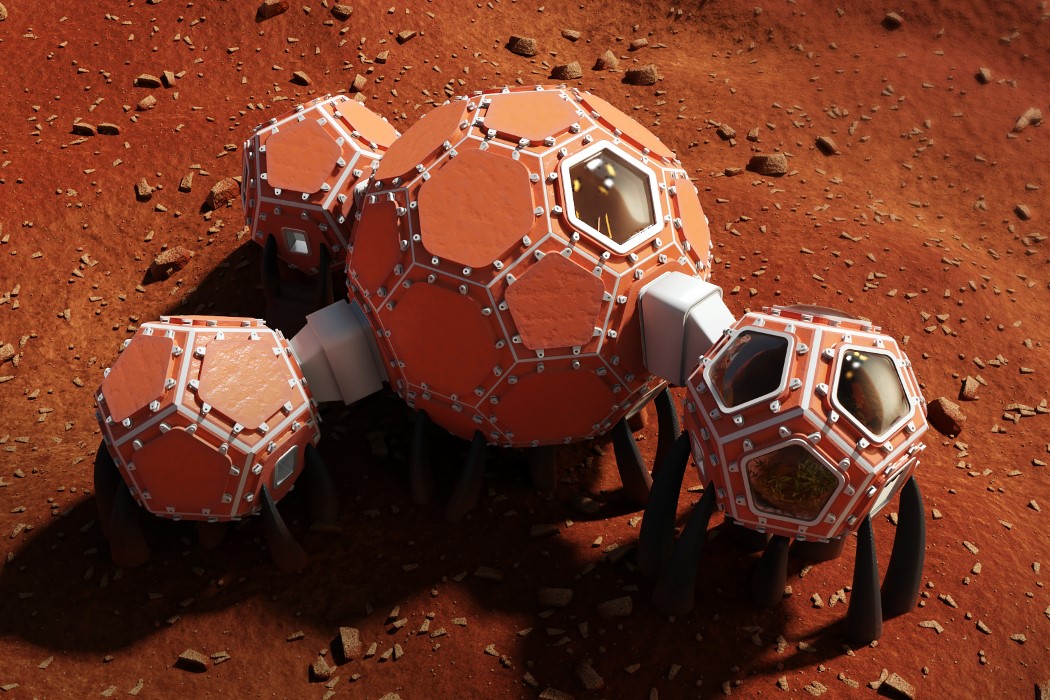

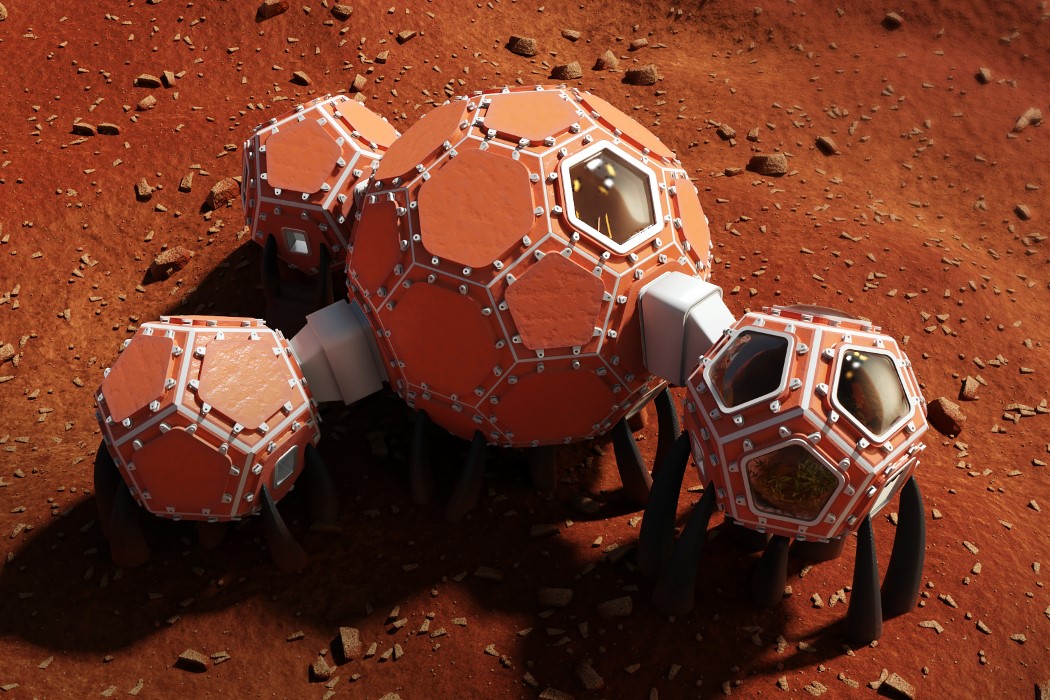

Team Mars Incubator took part in NASA’s 3D-Printed Habitat Challenge with its modular habitat. Each module serves the purpose of a separate room and is connected by a walkway. Smaller modules are made to be dodecahedral (comprising pentagons), while the large, primary module comprises hexagonal and pentagonal pieces.

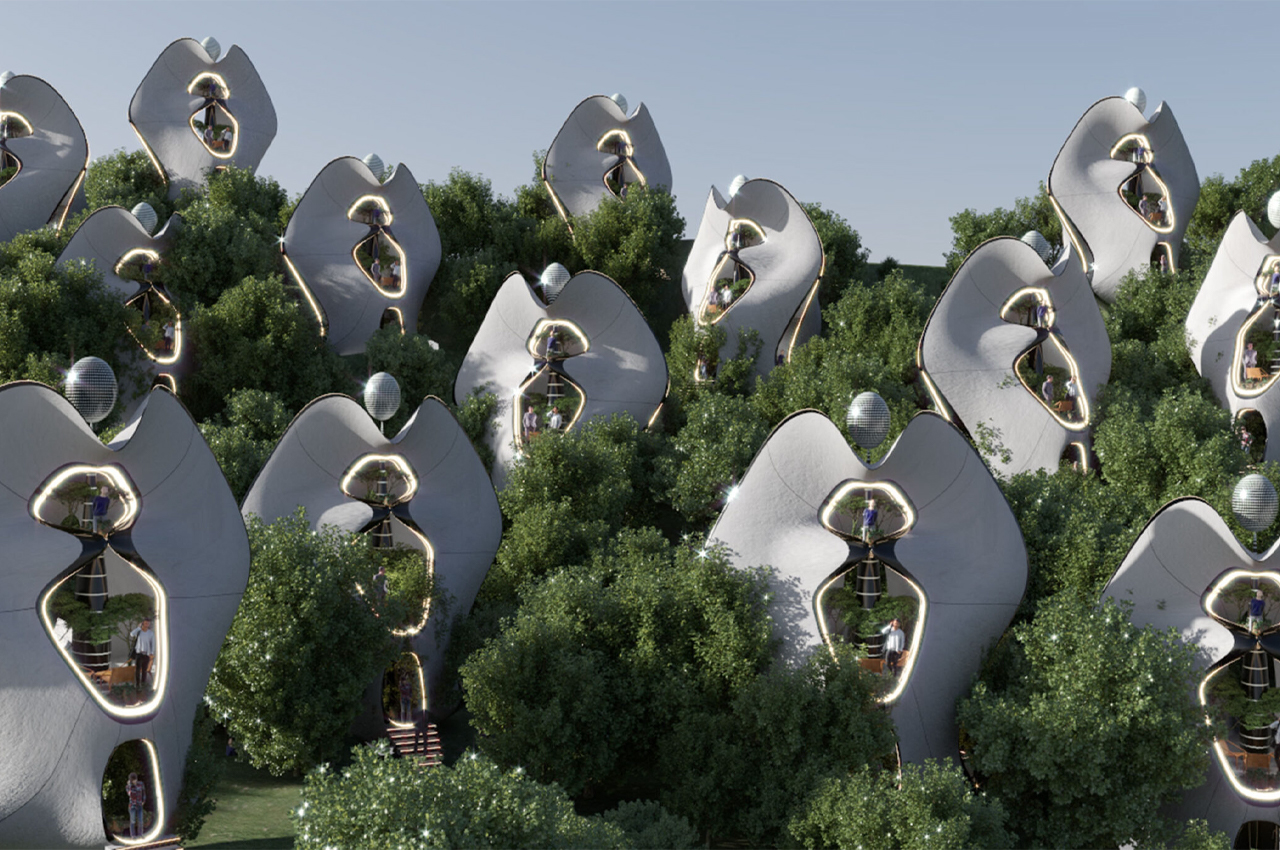

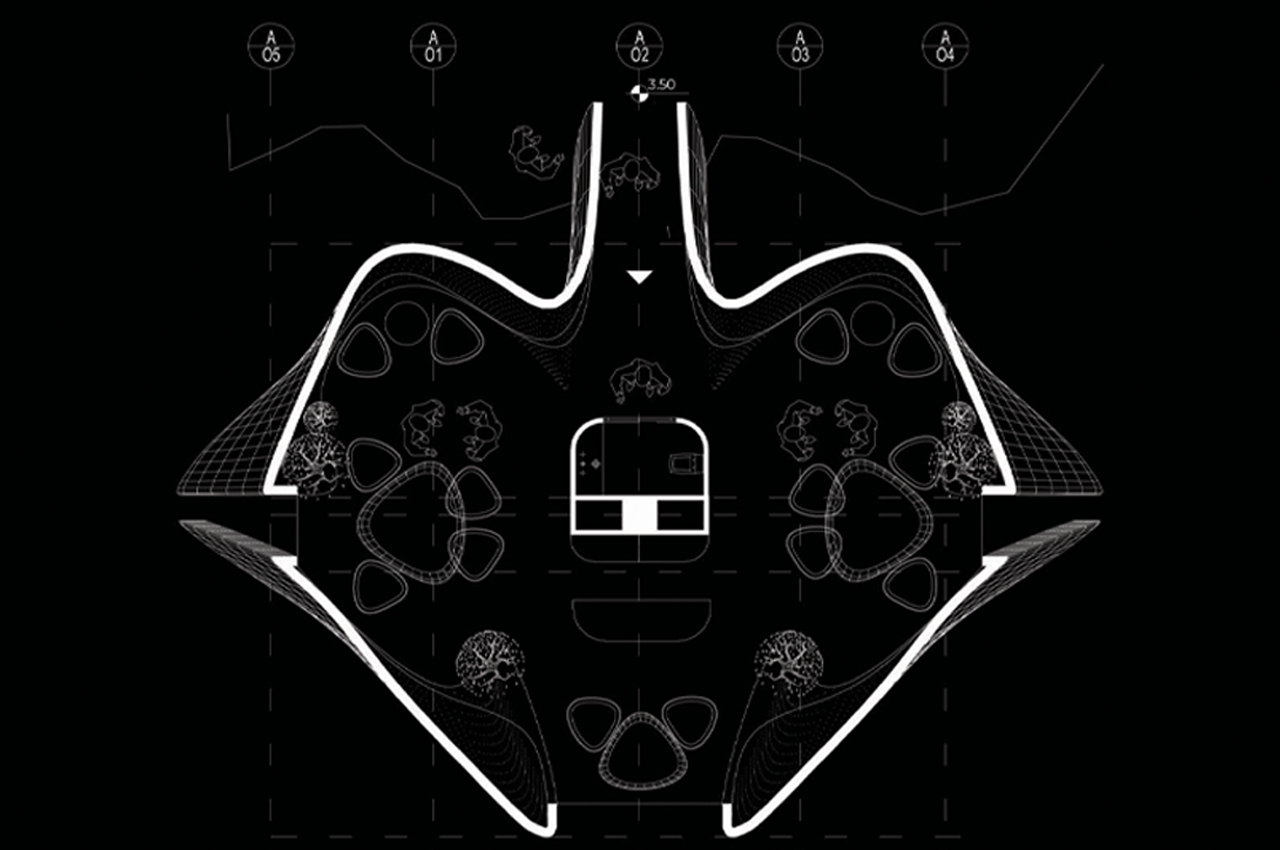

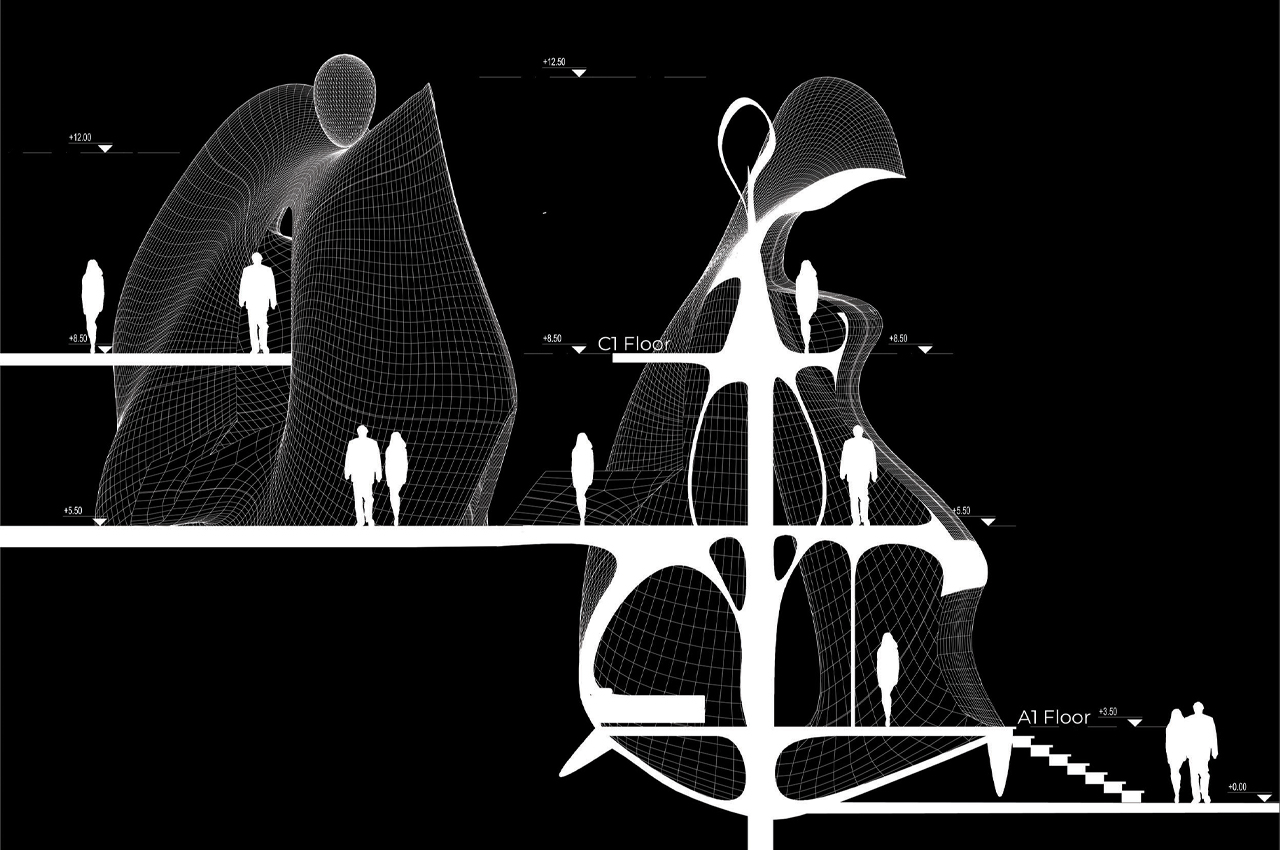

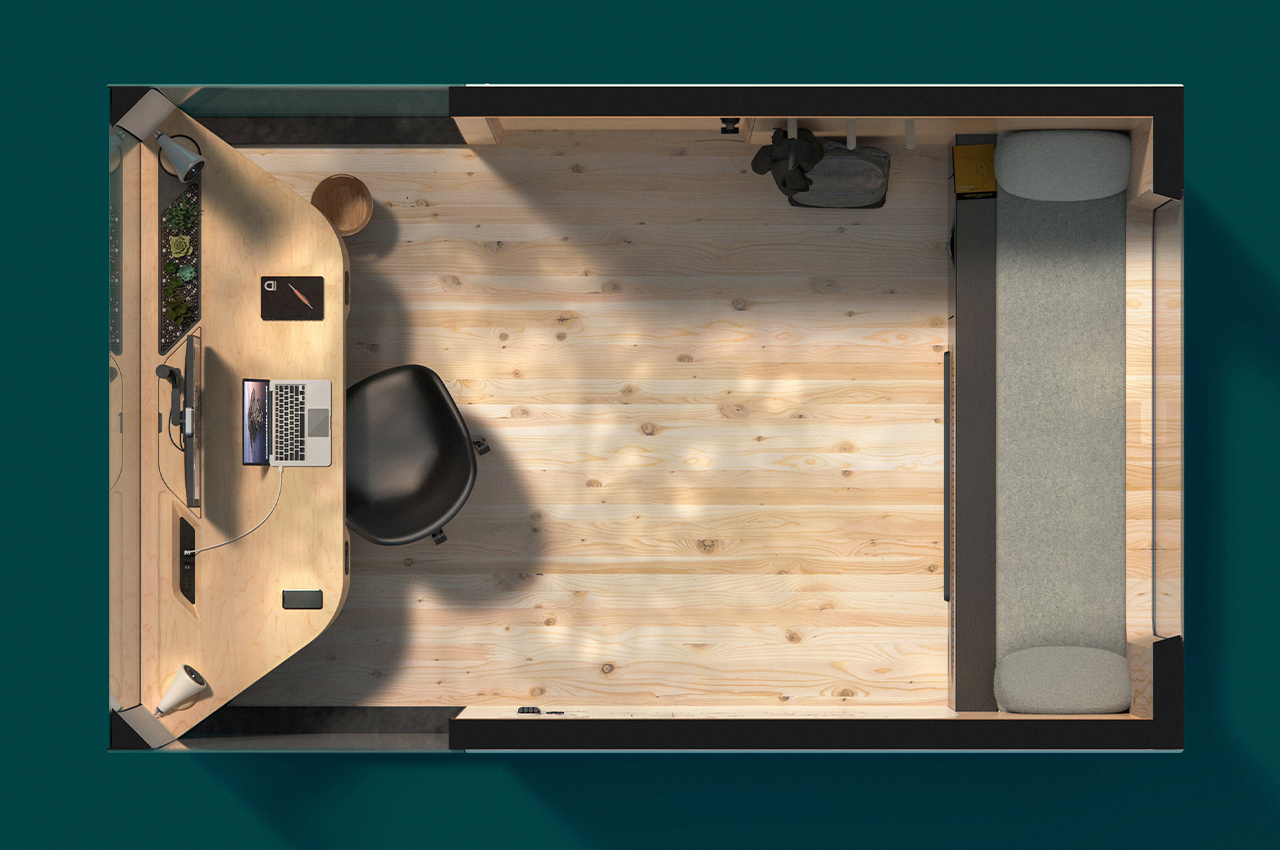

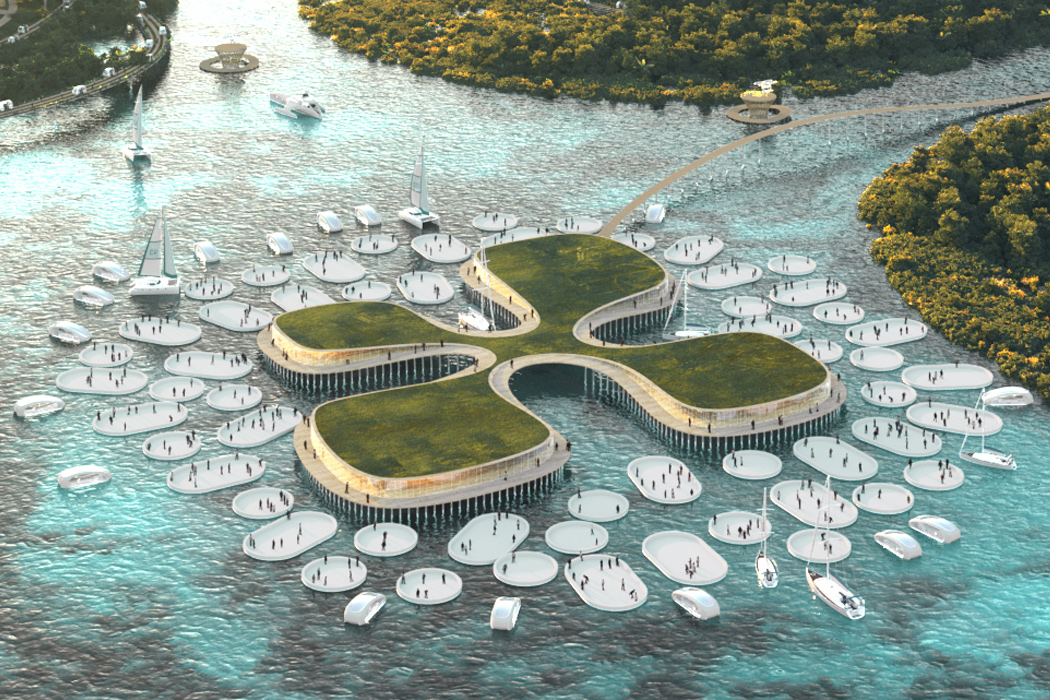

In the future, you will find Enclaves floating on the Vistula River with the Wawel Castle as the backdrop. Designer Agnieszka Białek who made this zen office pod is a graduate of the Academy of Fine Arts in Kraków, Poland which explains the picturesque theme. The architectural structure has soft, curved edges and a contemporary look which is a contrast to the natural setting but still complements it. Since the pods are floating on the river, it reduces utility requirements to almost zero and there is no soil degradation. Enclaves look like bubbles on the river – the natural foam creates floating, geometric shapes that grew into a larger version for the project. Like lily pads, the pods are anchored to the river bed and also attached to each other like a network which makes it modular in nature. The pods can be 3D-printed within a few days using waterproof and recycled/recyclable materials to further reduce their environmental impact. It comes with built-in furnishings that create versatile spaces to suit everyone’s work personality and needs.

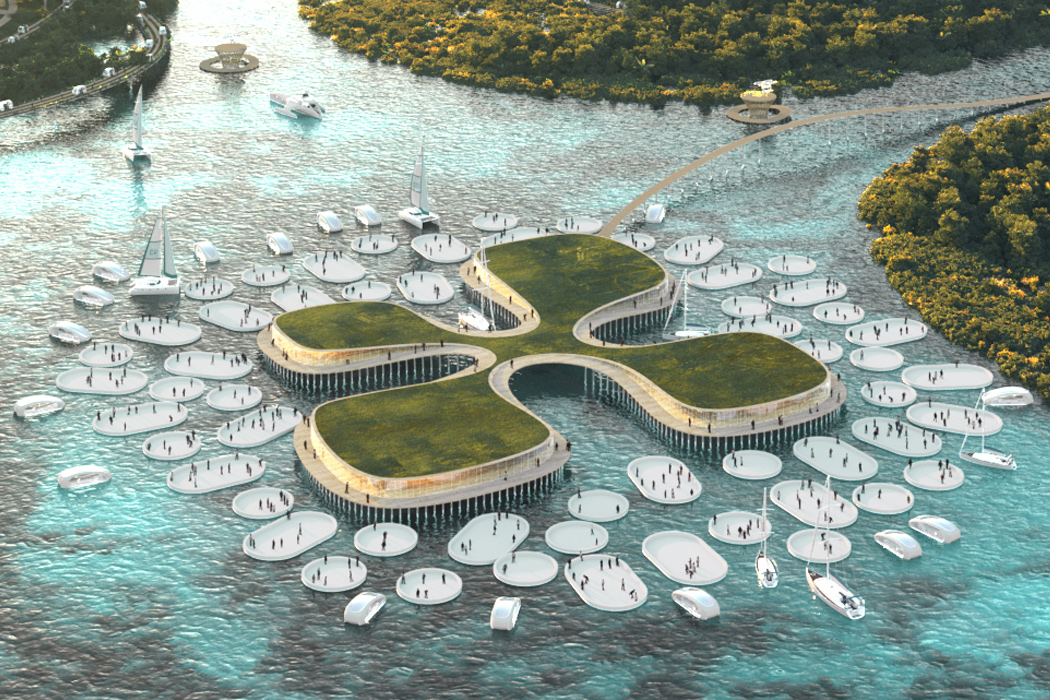

BiodiverCity is one of Bjarke Ingels’ most recent projects, it is a city of three islands connected by autonomous vehicles for land, water, and air to make this a transport emission-free habitat off the coast of Malaysia. Three islands will be built in Penang and will serve as cultural, business, and residential hubs. The most striking thing about the development is that all the transportation on the 4,500 acres will consist of autonomous boats, vehicles, and air travel, making the islands car-free and pedestrian-friendly. Construction is one of the biggest sources of carbon emissions, in fact, even more than the aviation industry. So to reduce the impact on the environment, most buildings will be prefabricated or 3D printed on-site and others will use a combination of bamboo, Malaysian timber, and “green concrete” which is made from recycled materials like aggregate.

Team Zopherus created its rather unique Zopherus habitat for NASA’s 3D-Printed Habitat Challenge. Rather than carrying material to Mars, the Zopherus relies (in part) on materials found on Mars. Essentially a massive interplanetary 3D printer, the Zopherus deploys rovers that collect material and bring it back to the printer, which binds it together with cement, and prints the habitat out. The habitat uses two nozzles that print in HDPE and the Martian concrete. The HDPE forms a base structure as well as an outer cover for the Martian concrete construction, reinforcing it as well as protecting it from the extreme temperatures of the red planet.

Founded by Maggie Grout, the non-profit organization Thinking Huts presented plans for a 3D printed school in Fianarantsoa, a city in Madagascar. The school will be built using locally sourced materials, and while being completely conscious of the surrounding environment. Designed by Studio Mortazavi, the school will feature 3D printed walls, solar panels, a vertical farm, and internet access.

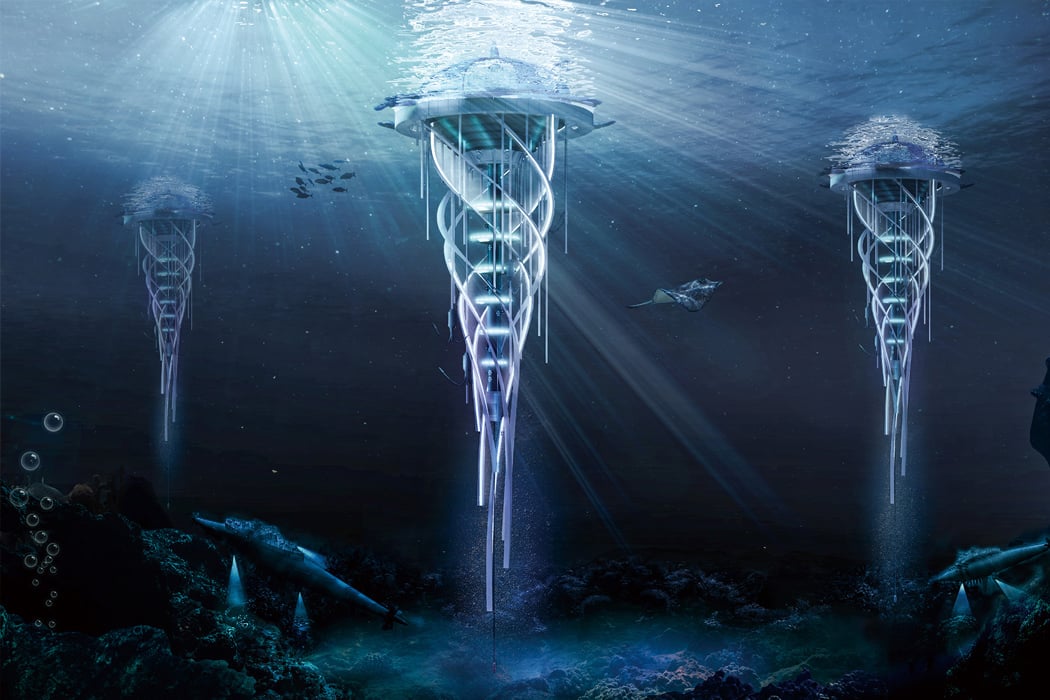

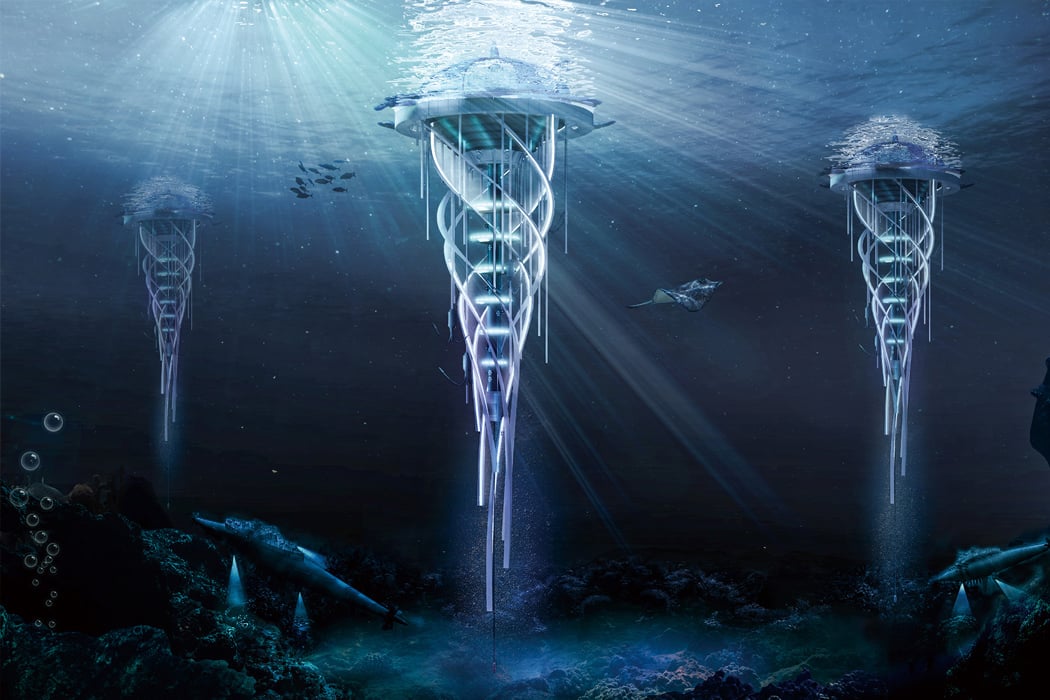

How many of you are aware of combustible ice? Typically a frozen mixture of water and concentrated natural gas, it can be lit on fire in its frozen state and is believed to comprise one of the world’s most abundant fossil fuels. While we dig into the seas to fuel our consumption, the problem of marine garbage is becoming more and more serious. Because of plastic’s structural characteristics, it will not be easily corroded by seawater. Therefore, designers Xuejun Bai, Chucheng Pang, Lei Zhai, Yuyang Sun, Dianao Liu came up with the idea of using local materials, turning plastic waste into 3d-printed materials, as our own building materials, and filling cracks in the seabed caused by combustible ice mining to prevent secondary disasters. “In order to solve the energy and environmental problems to the greatest extent, we install the location with the highest coincidence of combustible ice and marine waste as the building site. There are two main moving lines in the building, the downward materials, and the upward energy. Among them, the energy tower transforms the plastic waste on the sea into 3D printing materials, and prints the building and energy tank down along the core cylinder, turning itself into a building with growth.

For more such innovative and mesmerizing 3D printed architectural designs, check out Part 1 of this post!