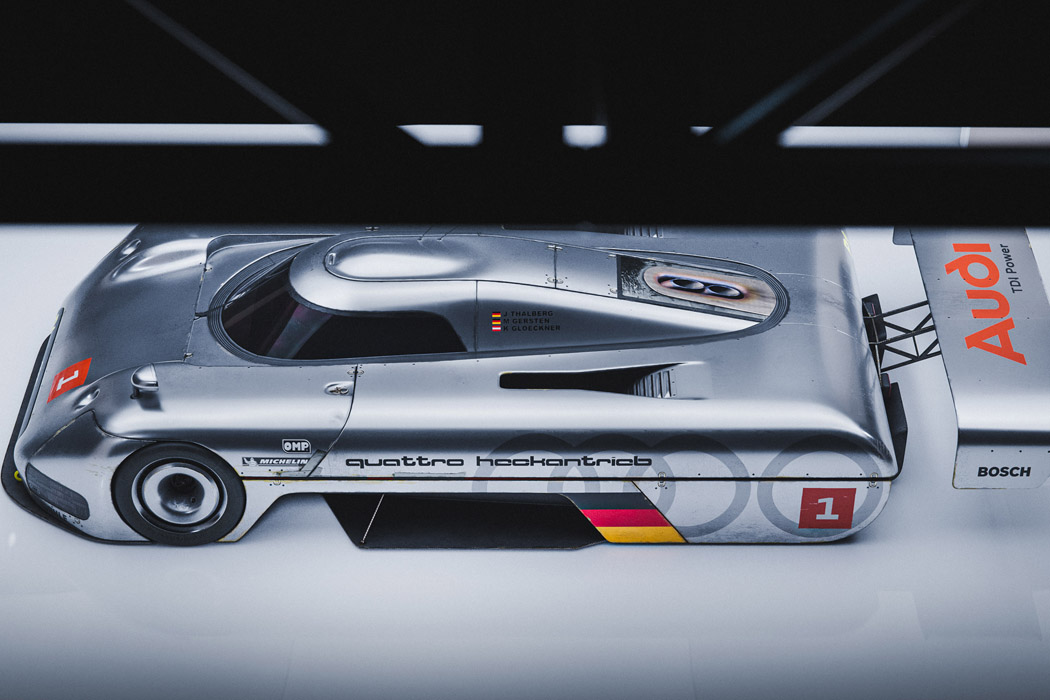

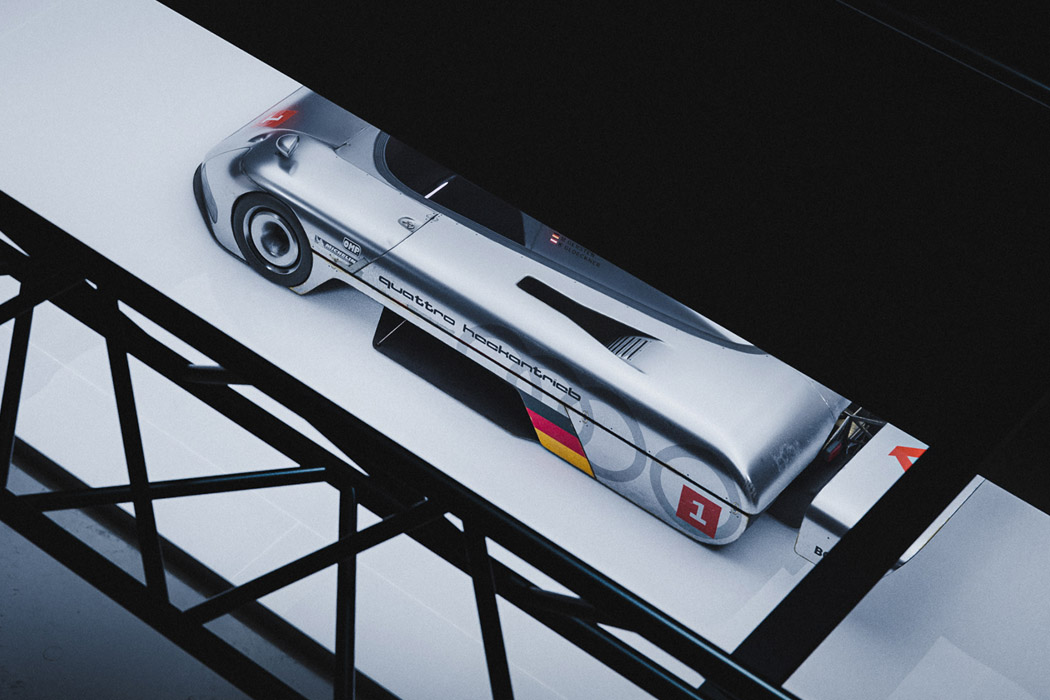

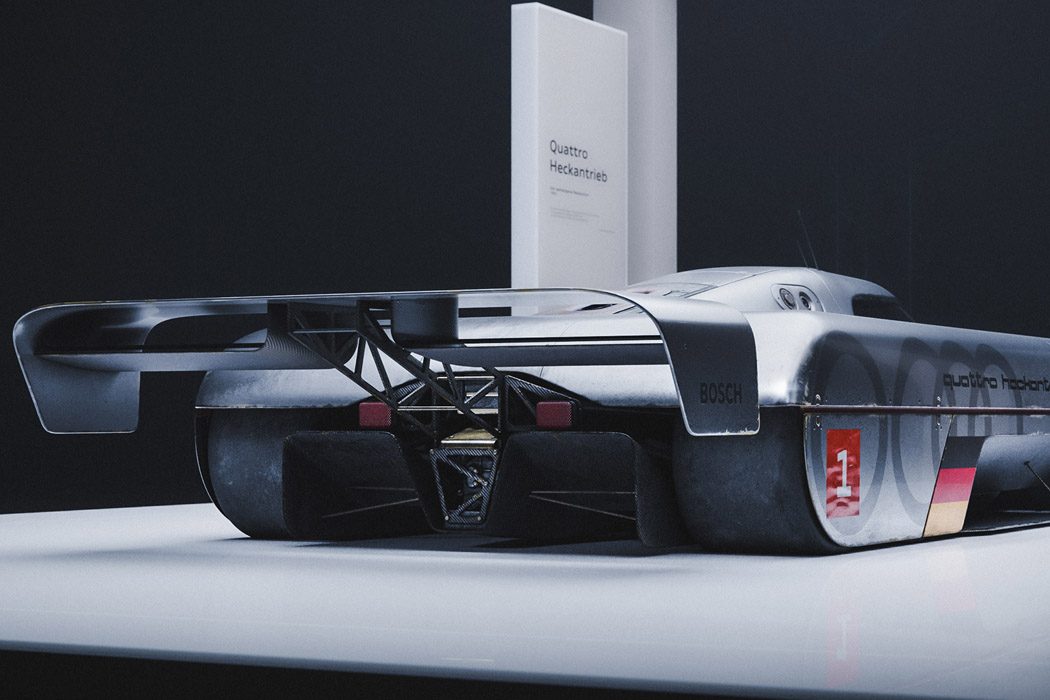

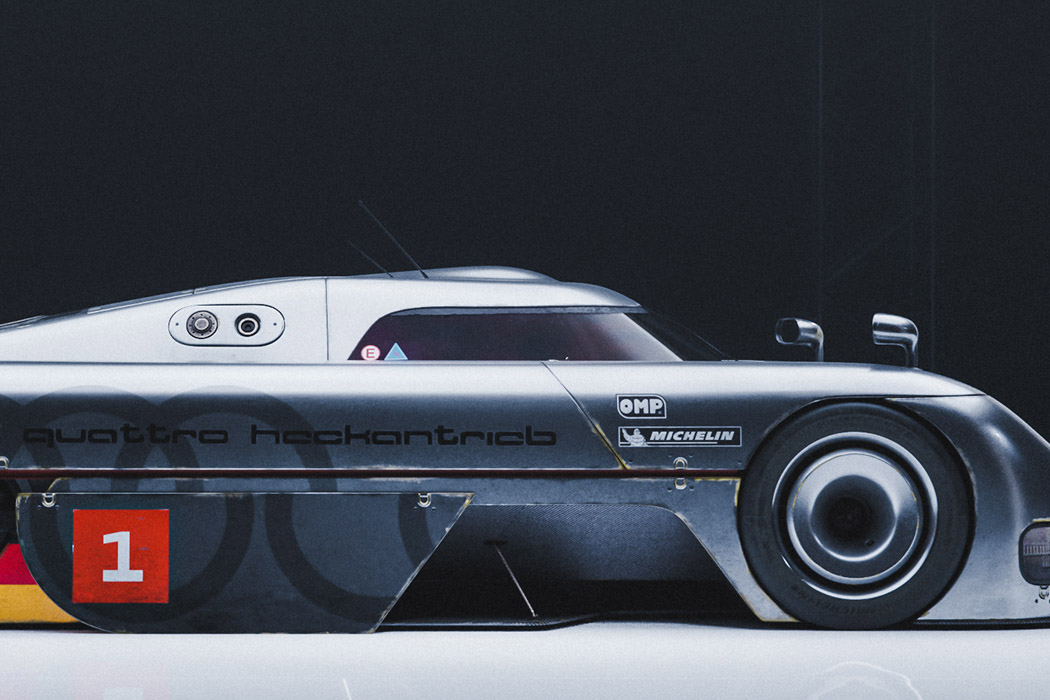

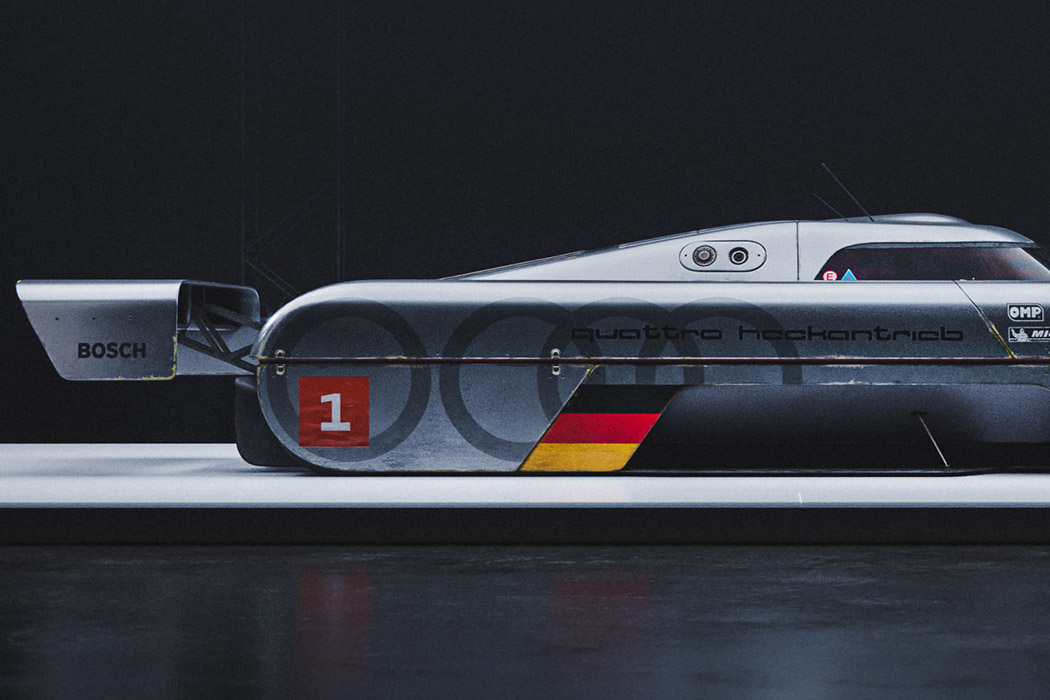

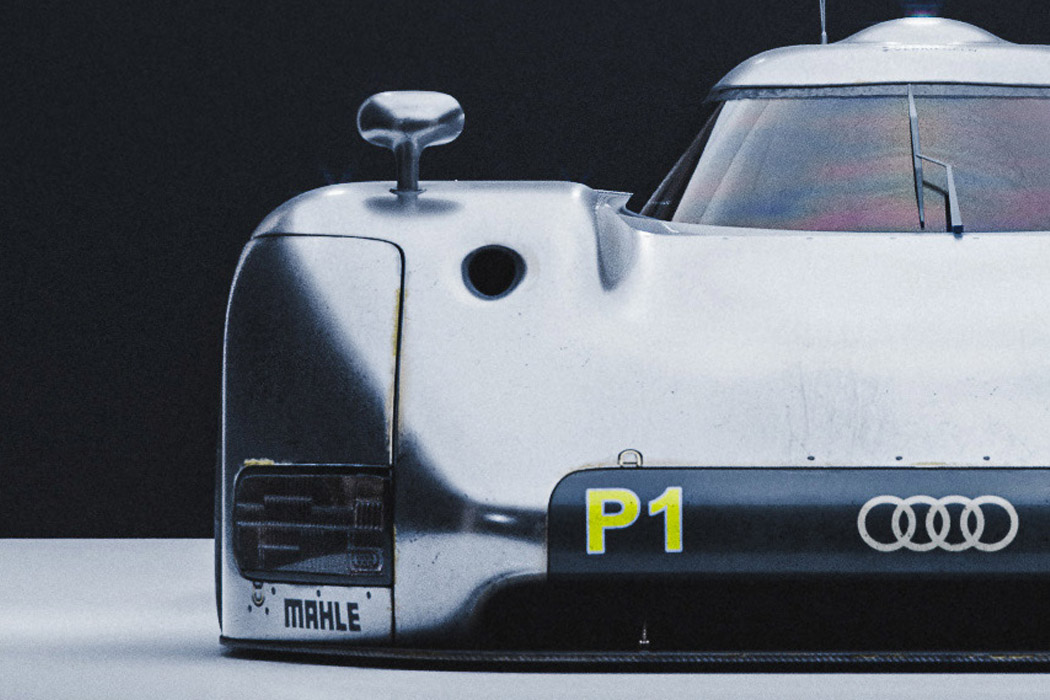

Automotive lovers who are acquainted with Audi surely know about Quattro. The all-wheel-drive road vehicle burst into the scene in 1980, and ten million Quattro (derived from the word four-wheel-drive system) drive cars have hit the road. Based on this adventurous progression, Audi has built the electrified version of the powertrain for future mobility. This Quattro H 1993 concept designed by 3D specialist Federico Ciuffolini superimposes the vision of a dystopian future where Mad Max-like vehicles will fight for domination of resources on the planet. I can’t help but see the racing DNA of the R18 E-Tron Quattro being the inspiration for the design here.

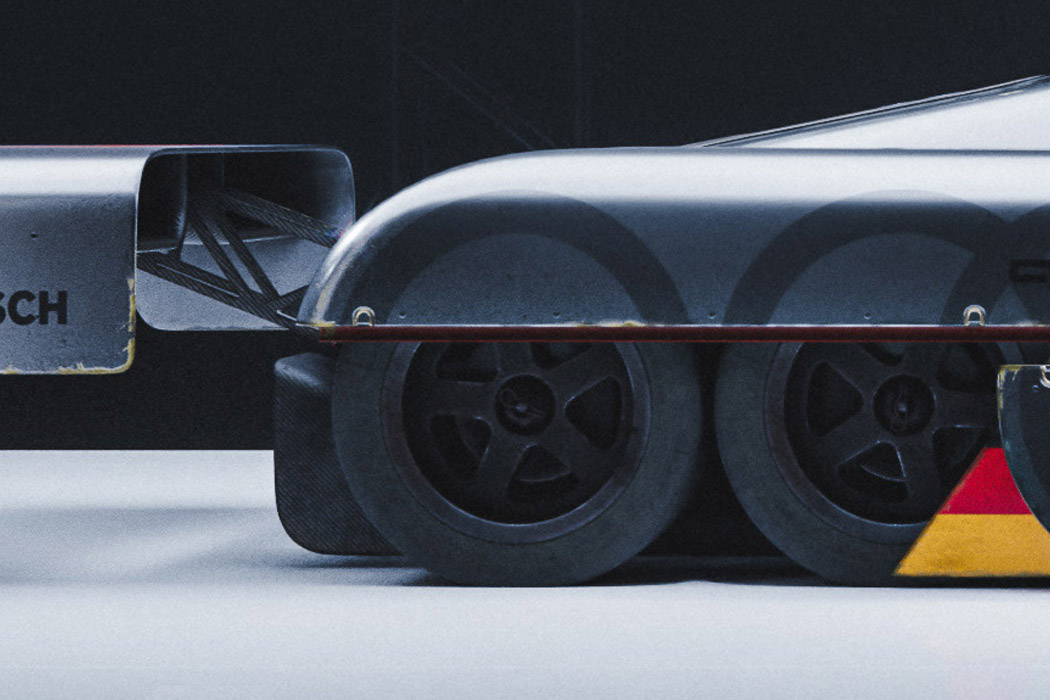

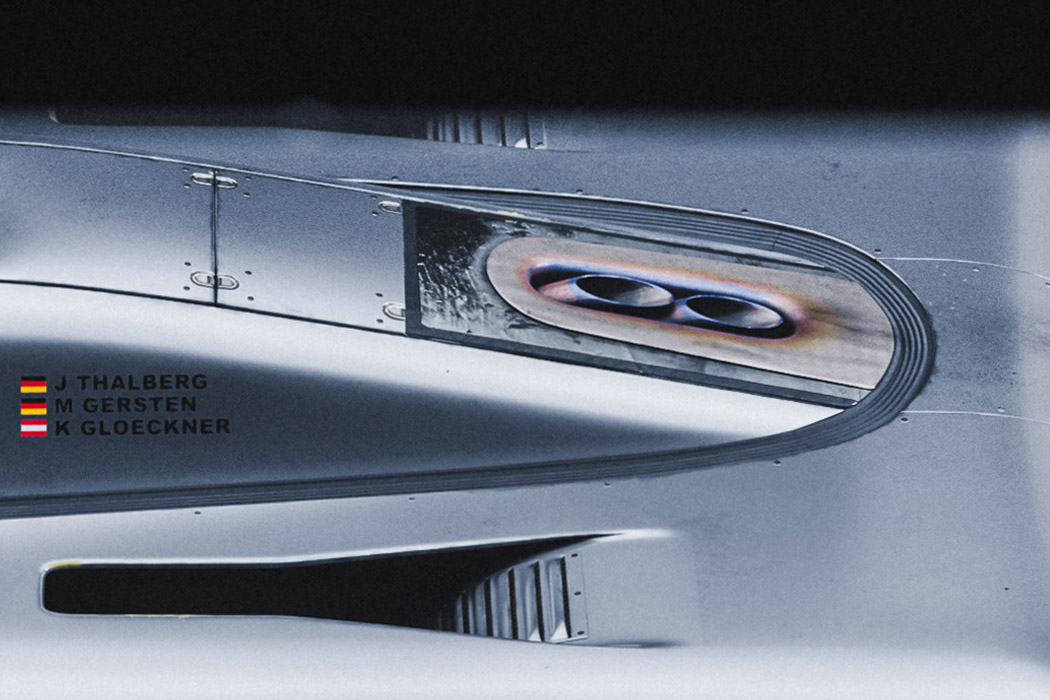

The Quattro H 1993 concept car defines the evolution of racing culture in a world where the dynamics of lifestyle are completely radical from current times. Federico creates the blueprint with fiberglass, Kevlar, and carbon fiber construct for the ideal weight to power ratio. A powerful drivetrain and engine demand good airflow, so the use of naca and ram ducts is truly justified, hence eliminating the need to run the aero. The Quattro’s cell is made out of isolated monocoque for structural integrity and connects to the main chassis with a heavy-duty gasket.

Ballast is used to lower the cockpit barycenter to align the pilot (giving dampened solicitations) when lateral g-forces take effect at high-speed cornering. The result is a car with a very stiff and low-slung positioning on the road for maximum grip. A true racer at heart, the Quattro H 1993 amalgams the past and present racing DNA into a car of the future set in an uncertain world.

Designer: Federico Ciuffolini