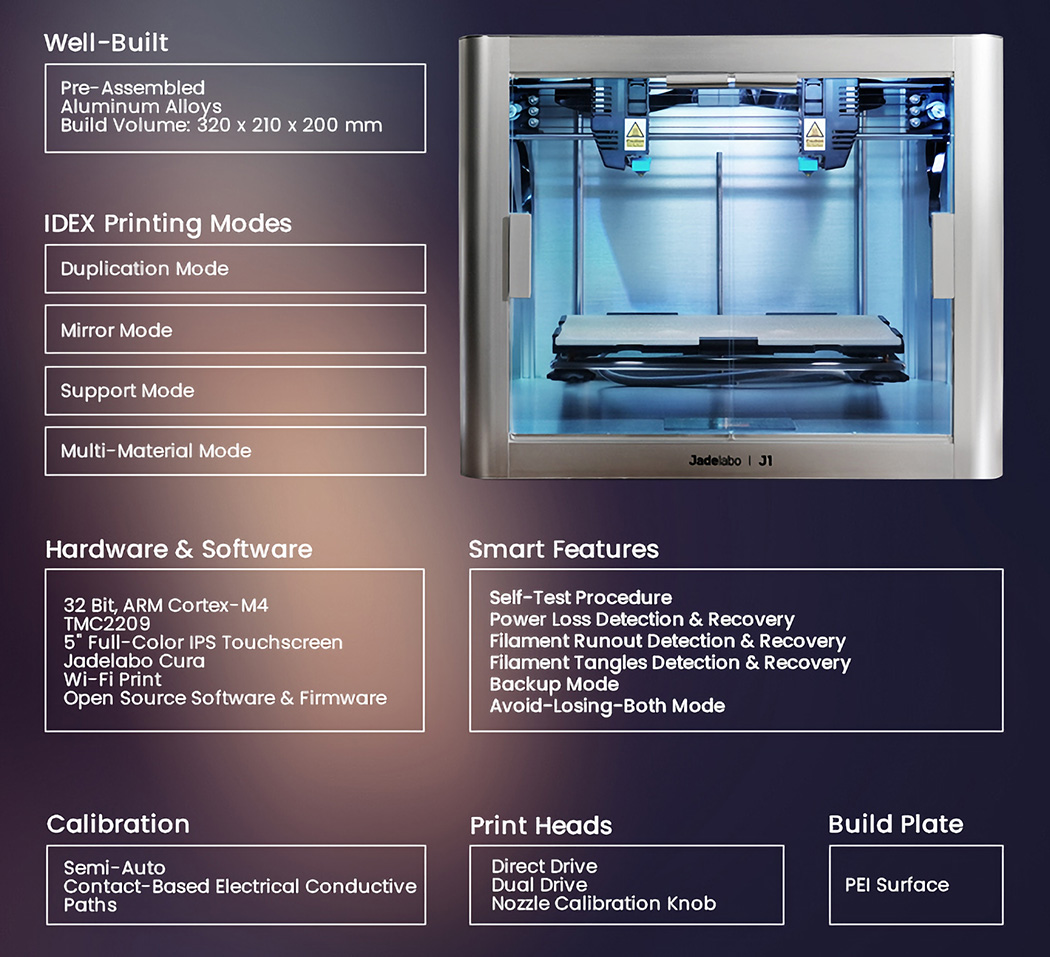

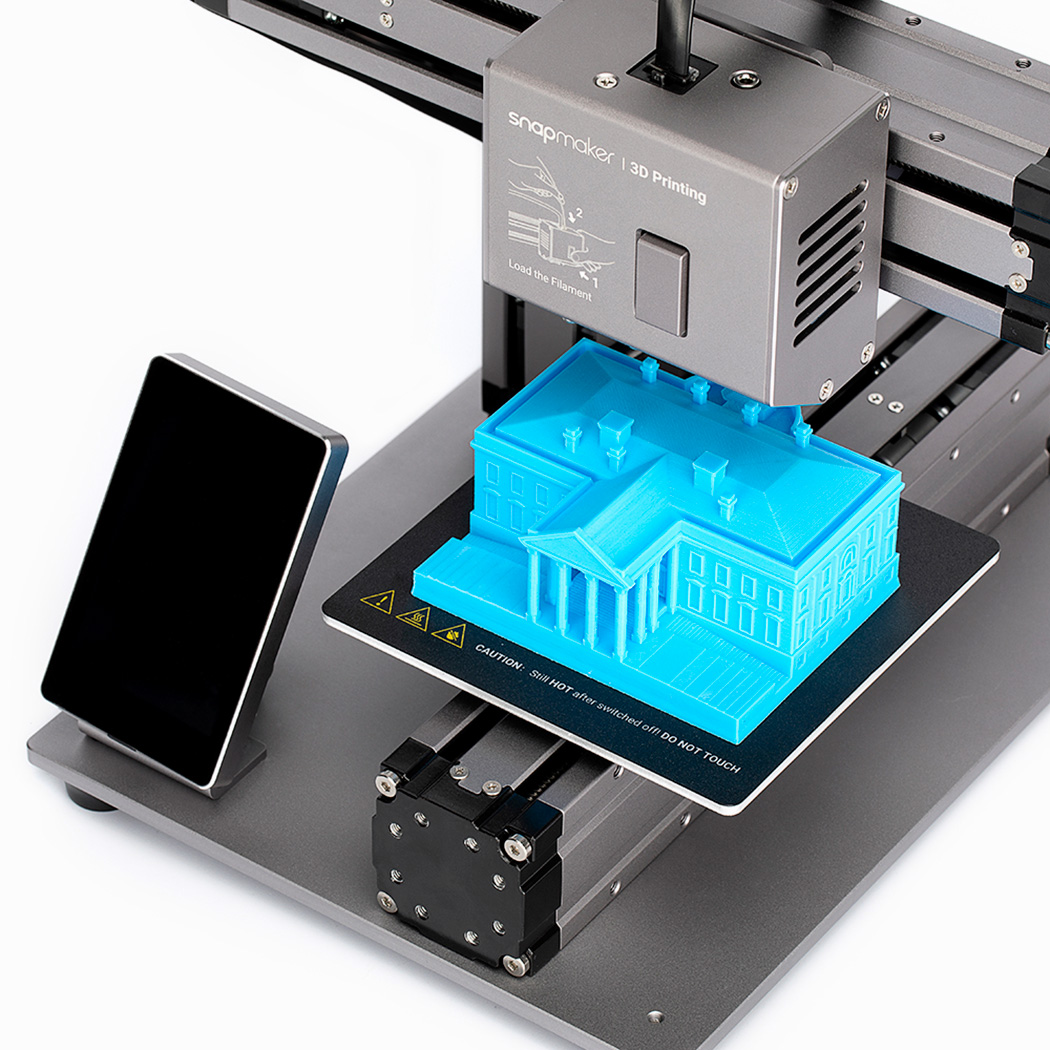

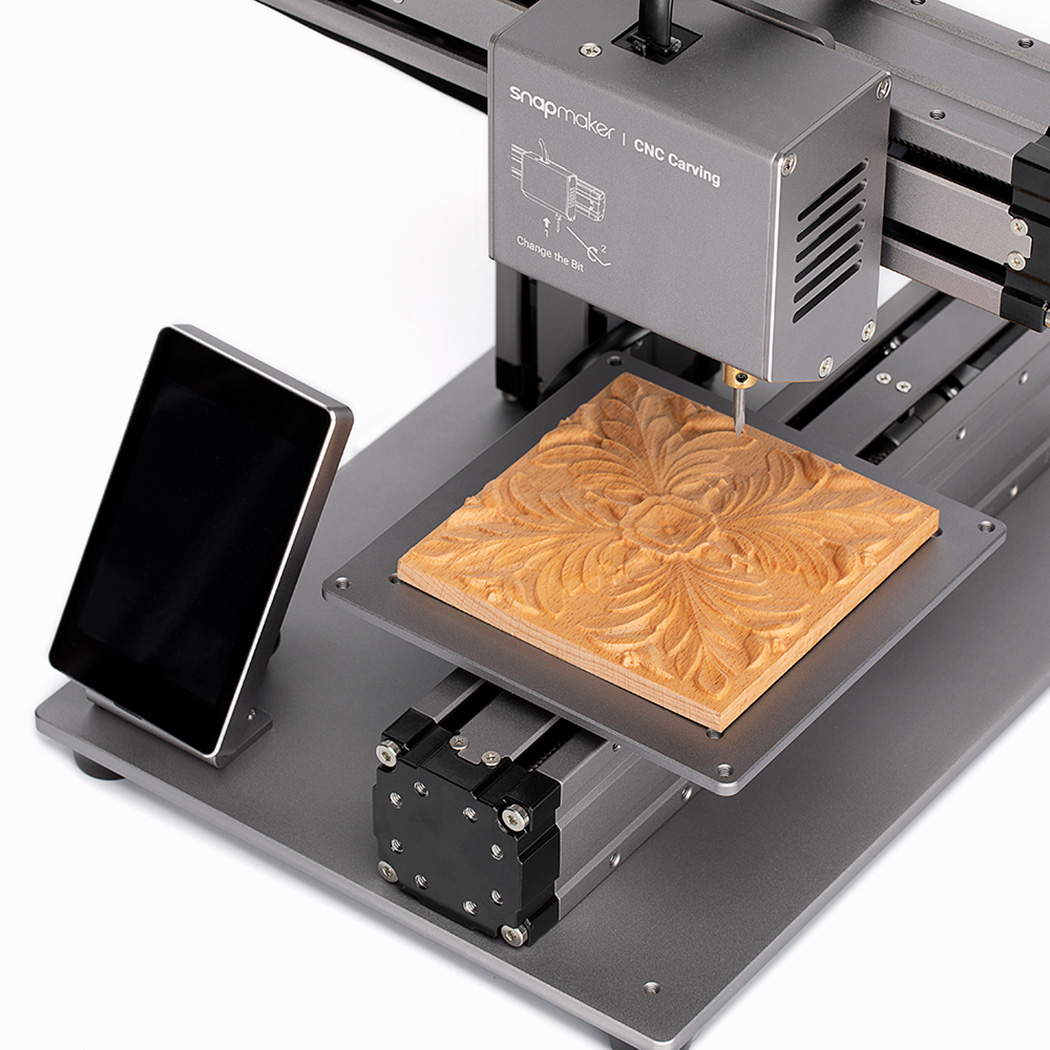

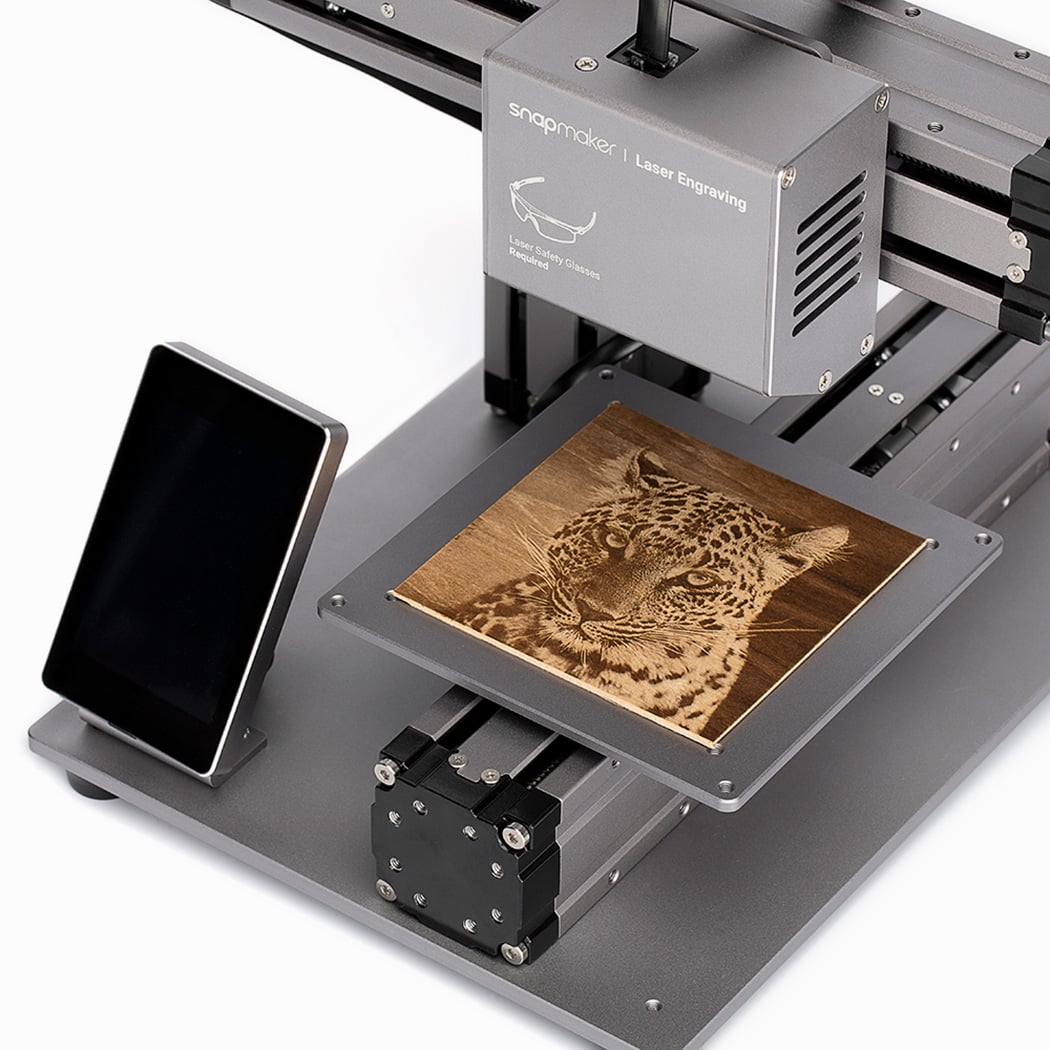

This pandemic has made the office smaller, teams more compact, and has shifted almost every aspect of your regular design studio into the home workspace… even the prototyping station. Sometime in March last week, I predicted that the lockdown would force design studios and companies to bring their prototyping and manufacturing in-house, to avoid logistical barriers and supply chain restrictions. I’d like to think that I was right for the most part. People began diversifying their supply chains, 3D printing saw a bit of a boom (some designers even used it to make cheaper ventilators), and all in all, small-scale production shifted right into tiny offices, garages, and bedrooms. While Jadelabo’s J1 printer isn’t a product of the lockdown and the pandemic, it definitely fits well into the trend that’s been set off over the last year. This independent dual-extruder printer makes manufacturing and prototyping an absolute breeze – it allows you to simultaneously print in multiple materials, multiple colors, and occupies the same amount of desktop space as any 3D printer. Oh, and it probably costs less than your smartphone.

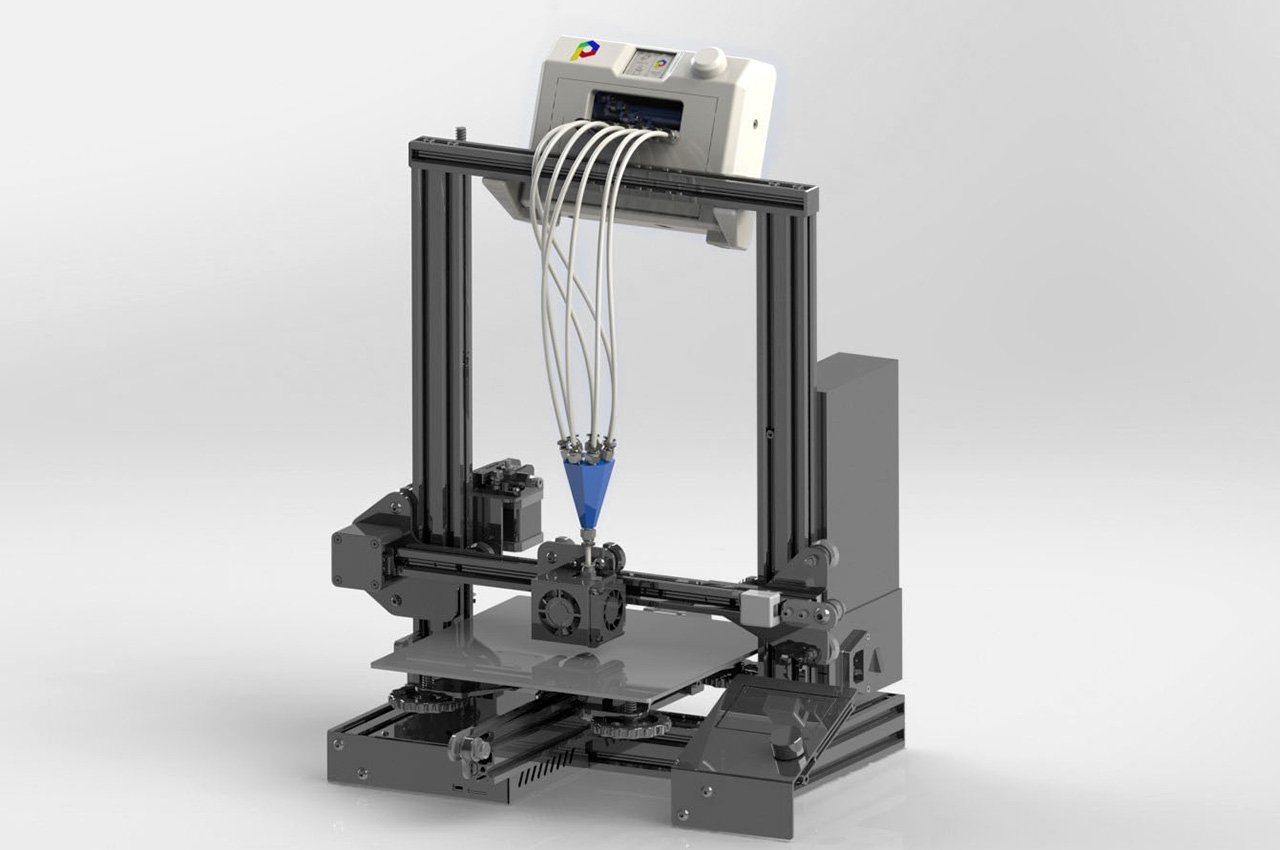

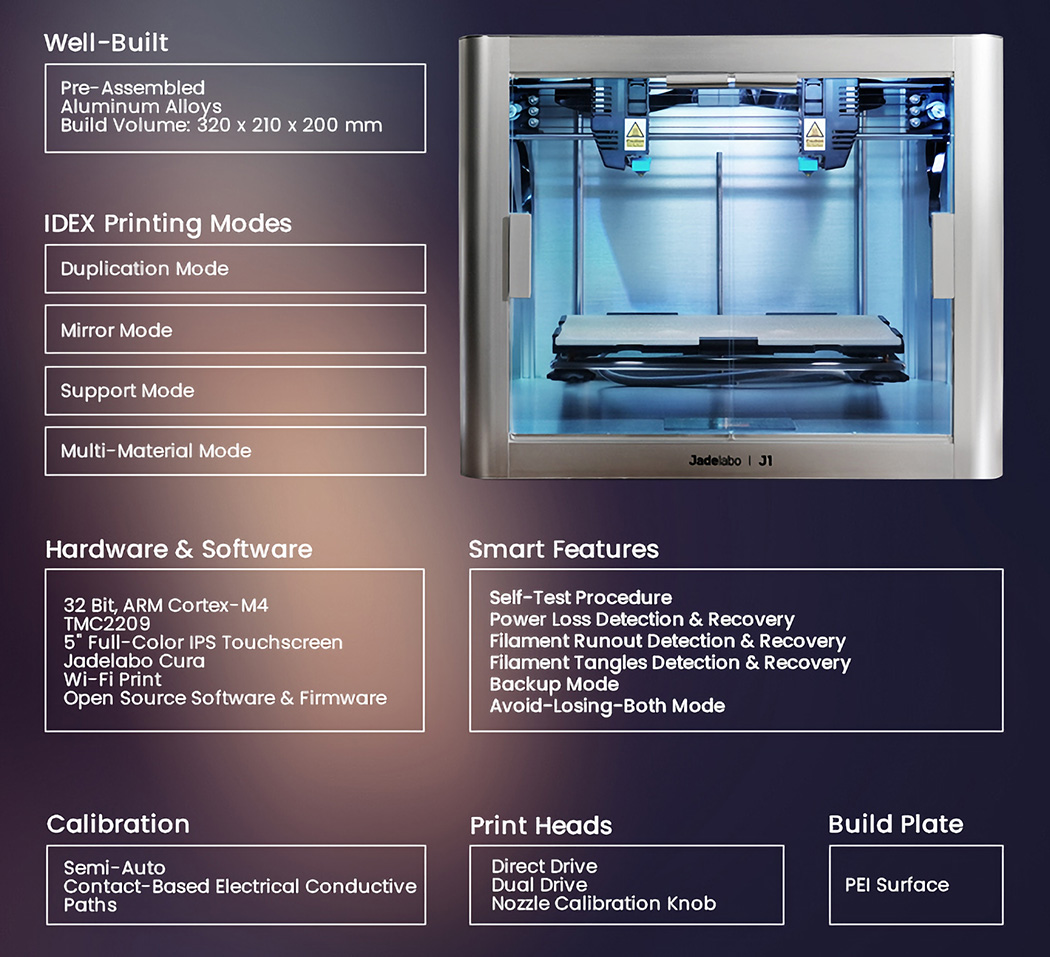

The Jadelabo J1 is quite frankly two 3D printers built into one enclosure. With two extruder heads that can move independently on their own, you can practically print twice as many parts in the same amount of time, speeding up your workflow by 2X. The J1’s dual extruders can work simultaneously, printing two different designs at the same time, or even the same design twice, using its “Duplicate Mode”. If you’ve got a larger, more complex design, you can split it in half and have the J1’s extruders share the workload… and if you’ve got a bilaterally symmetrical print, the J1’s “Mirror Mode” allows you to input one half of a 3D model and have the printer create a mirror image too! Things get even more interesting when you start working with different materials. You can create complex designs by using one extruder to print the main material and the other extruder to print a removable ‘filler’ material in “Support Mode”. Or better still, explore “Multi-Material Mode”, in which the J1 can handle working with two materials simultaneously, allowing you to print in different polymers that have vastly different properties. For example, you could print a plastic part with a rubberized TPU grip, or a rigid part with a flexible hinge made from PLA. J1’s ability to mix and match materials makes it infinitely versatile and twice as fast as your regular desktop printer.

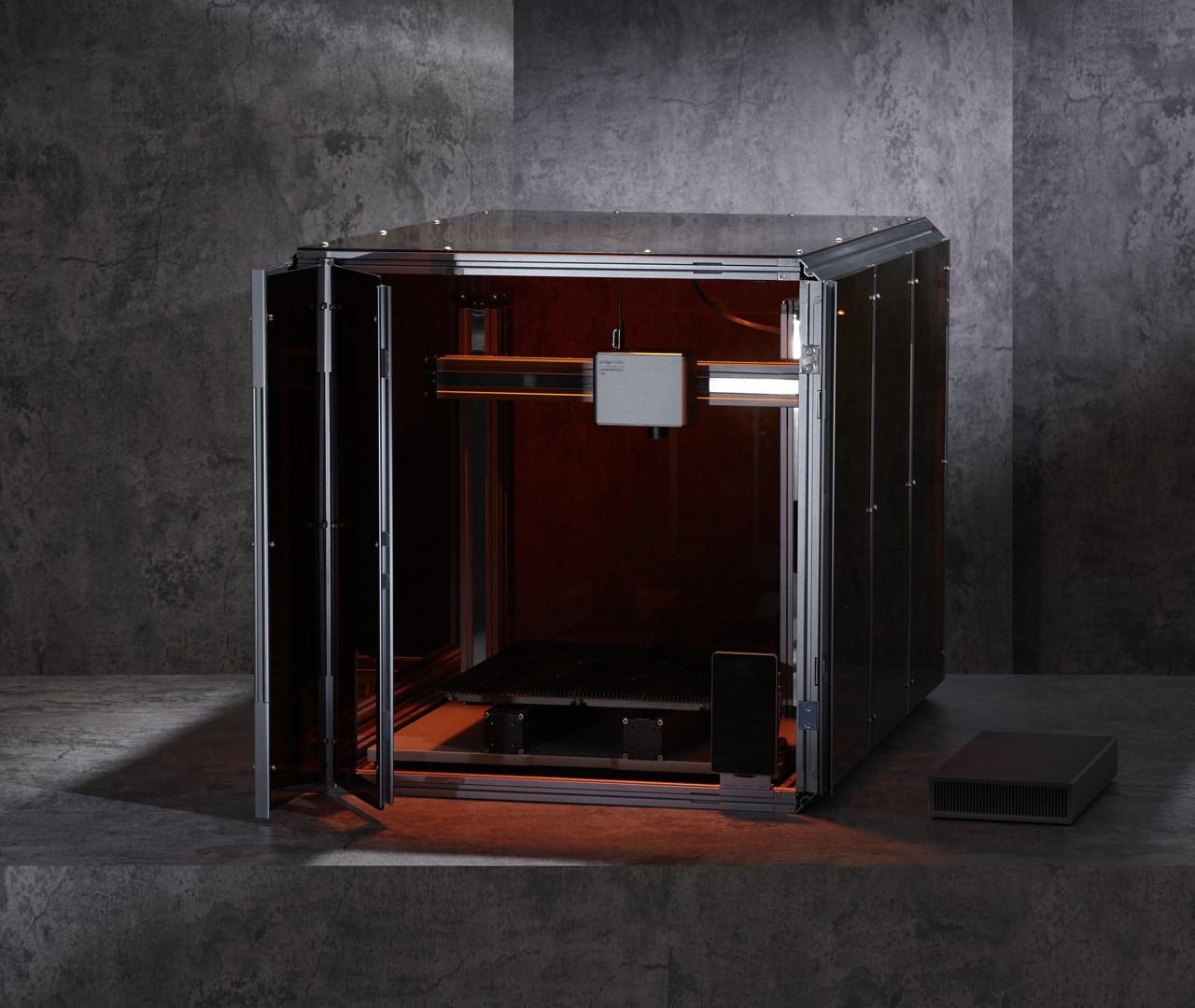

The Jadelabo J1 uses a combination of direct drive and dual drive motors to operate the two extruders. The extruders themselves have nozzles that are easy to remove, clean, and upgrade, and are even outfitted with sensors that can alert you if your filament jams or runs out mid-print. The extruders print onto a special PEI-coated glass surface that allows easy print removals every time, and for higher-temperature prints, glass doors allow you to ‘enclose’ your printing area, preventing wind, drafts, or breeze from your air conditioner from altering the temperature and quality of the print. Even with 2 extruders, using the J1 is much easier than your conventional 3D printer. The J1 comes with an auto-leveling and calibration feature that’s much more accurate than your traditional sensor calibrator. It uses an open electric circuit that gets closed as the nozzle touches the level bed, allowing the printer to calibrate itself with stunning accuracy. It even comes built with its own self-test feature that lets the machine perform a comprehensive check on all its components to let you know if your J1 is running smoothly, and as a standard practice, it has an auto-recover feature for when the power goes out in the middle of a print… something that’s 50% less likely when your printing time gets halved, thanks to two nozzles!

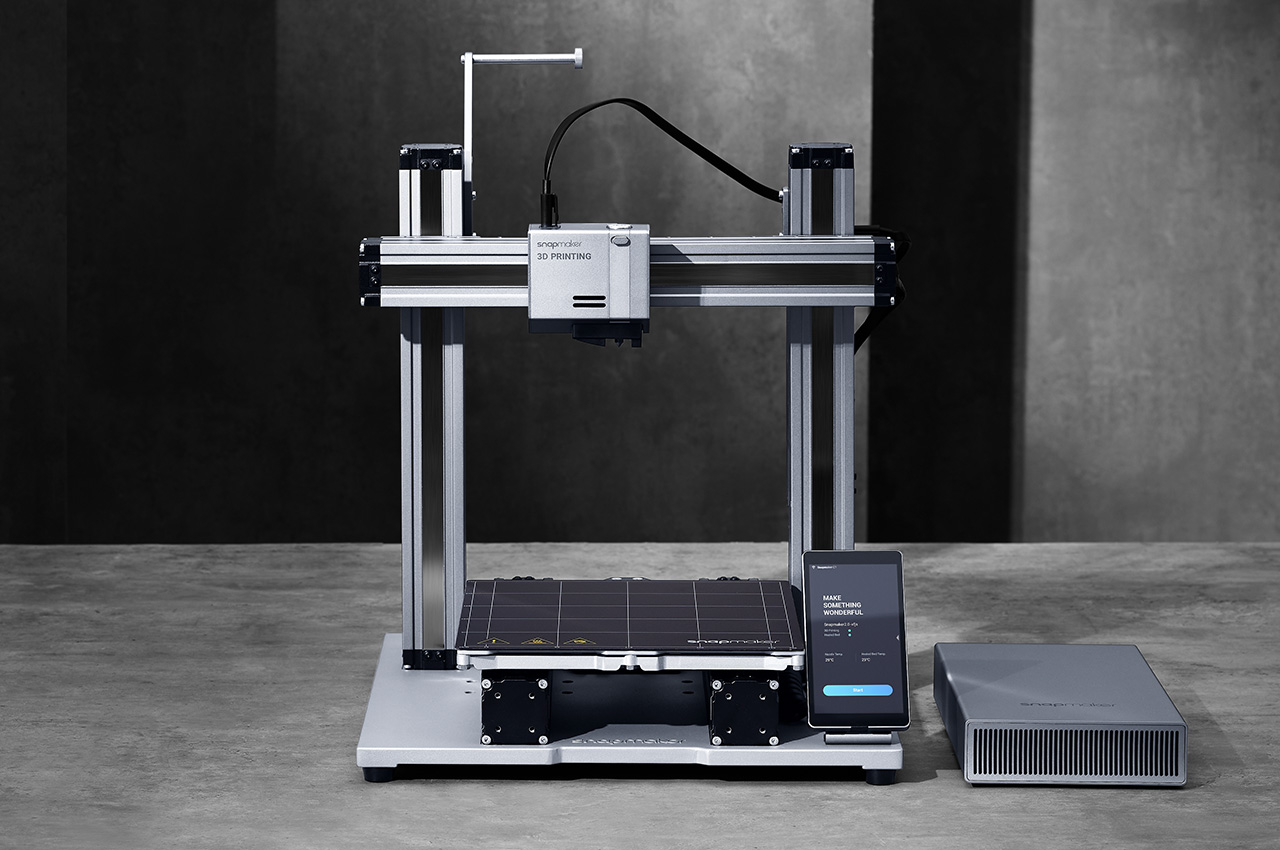

What’s truly impressive about the J1 is that even in its most expensive configuration, the Jadelabo J1 costs well under $1000 ($849 to be precise). It runs like most state-of-the-art printers, with built-in WiFi that lets you trigger prints remotely or send files wirelessly to the device. An intuitive touchscreen lets you control the printer more intimately, and while the J1 works with most third-party 3D printing applications, it comes bundled with Jadelabo Cura, which gives you complete control over IDEX (independent dual extruder) 3D printing. Each J1 comes with a remarkably sleek design enclosed within a metal frame. The product occupies about the same amount of space as a large microwave oven, making it perfect for any tabletop in the corner of your room, workshop, or studio. Whether you’re working in an office or still operating out of your home, the J1 gives you complete control over fabrication and prototyping. You can use its dual extruder features to make incredibly detailed prototypes, craft projects or personal designs with multiple parts and materials… or you could just use it to run two simultaneous prints at the same time, sort of like a factory line! That’s two printers for the price of one!

Designer: Jadelabo

Click Here to Buy Now: $659 $1199 ($540 off). Hurry, only 32/100 left! Raised over $160,000.

Jadelabo J1 – Smart IDEX 3D Printer for Everyday Makers

Designed for beginners to the most demanding makers, the Jadelabo J1 redefines what’s possible with an Independent Dual Extruder (IDEX) 3D printer.

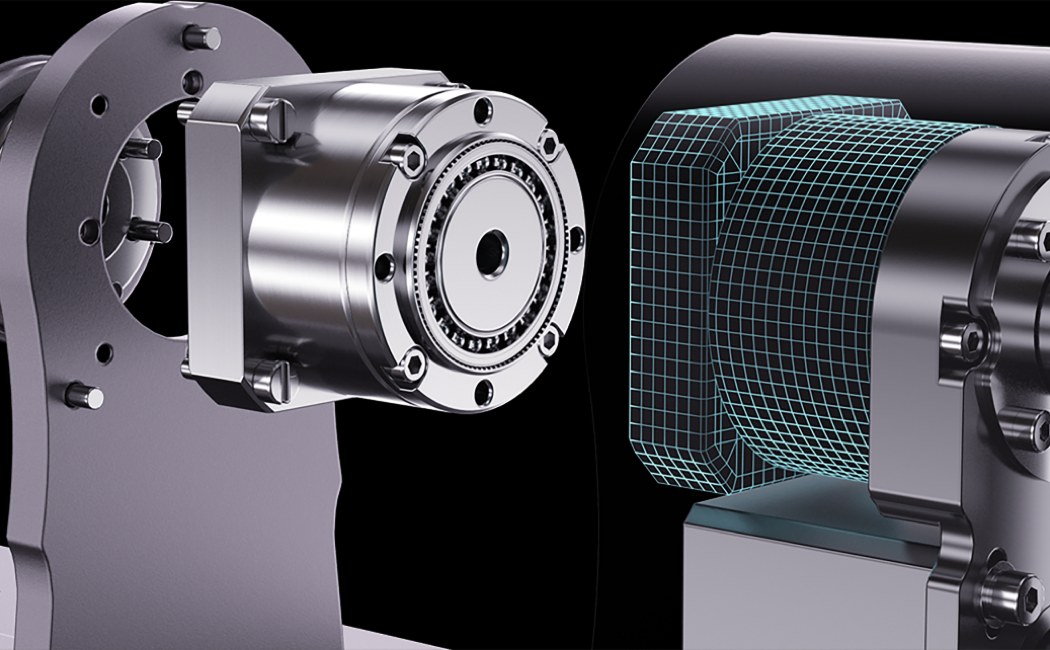

Independent Dual Extruder System

Support removal has never been easier. The dissolvable support structures make post-processing much easier, leading to a better surface quality for your parts, and let you print complex geometries that would otherwise be impossible. In addition, when printing premium materials, you can save money by printing the supports with a less expensive material.

IDEX Multi-material Mode

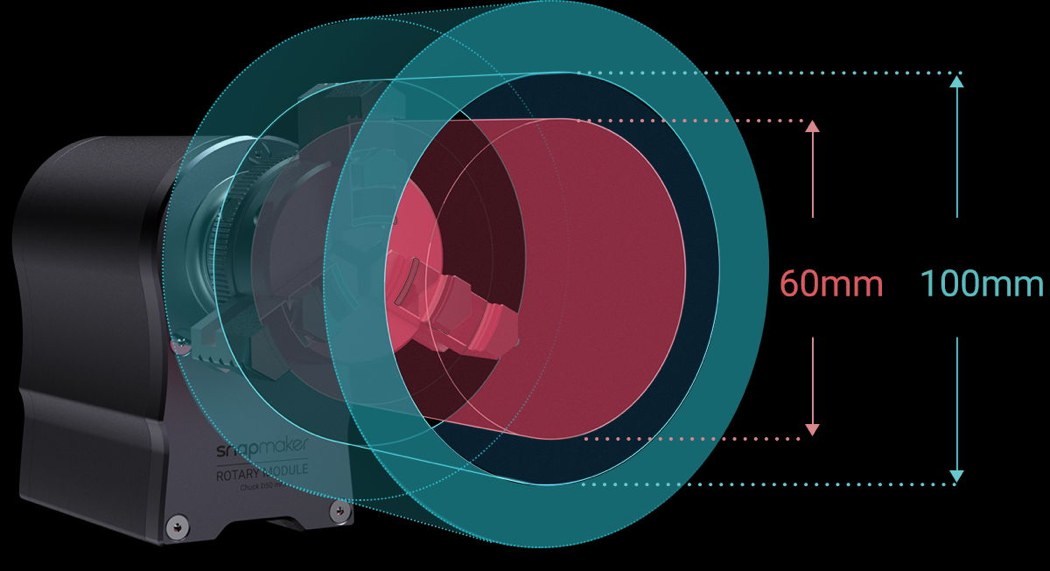

Unlike the conventional dual extruder 3D printer that places two nozzles in a single print head, Jadelabo J1 features an Independent Dual Extrusion System (IDEX) that can allow the two nozzles to have a large temperature difference, which greatly enhances performance when combining different materials in one single print. It also reduces contamination of materials or colors, giving you a neat and clean multi-material print.

IDEX Duplication Mode

Jadelabo J1’s IDEX system allows you to print two identical parts simultaneously. This is a unique and advanced feature compared to single/dual extruder 3D printers. You will find it very useful for modular design projects. Double productivity, without extra cost. It will help you halve the cost of machinery and setup time.

IDEX Mirror Mode

Jadelabo J1 enables faster and more efficient symmetric object printing. Cut your wait time in half, without sacrificing print quality.

A Wide Range of Materials

From commonly used materials like PLA, PETG, to advanced materials like TPU, ABS, ASA, PVA, HIPS, PC, and Nylon (PA), Jadelabo J1 can print them all. From the print heads, heated bed, motion mechanism, and an enclosure add-on, all the components and structures in Jadelabo J1 are carefully designed to work with a wide range of materials.

Various Material Combinations

Jadelabo J1 features an IDEX system that allows various combinations of different materials. Think outside the box, and make something new, creative, and inspiring.

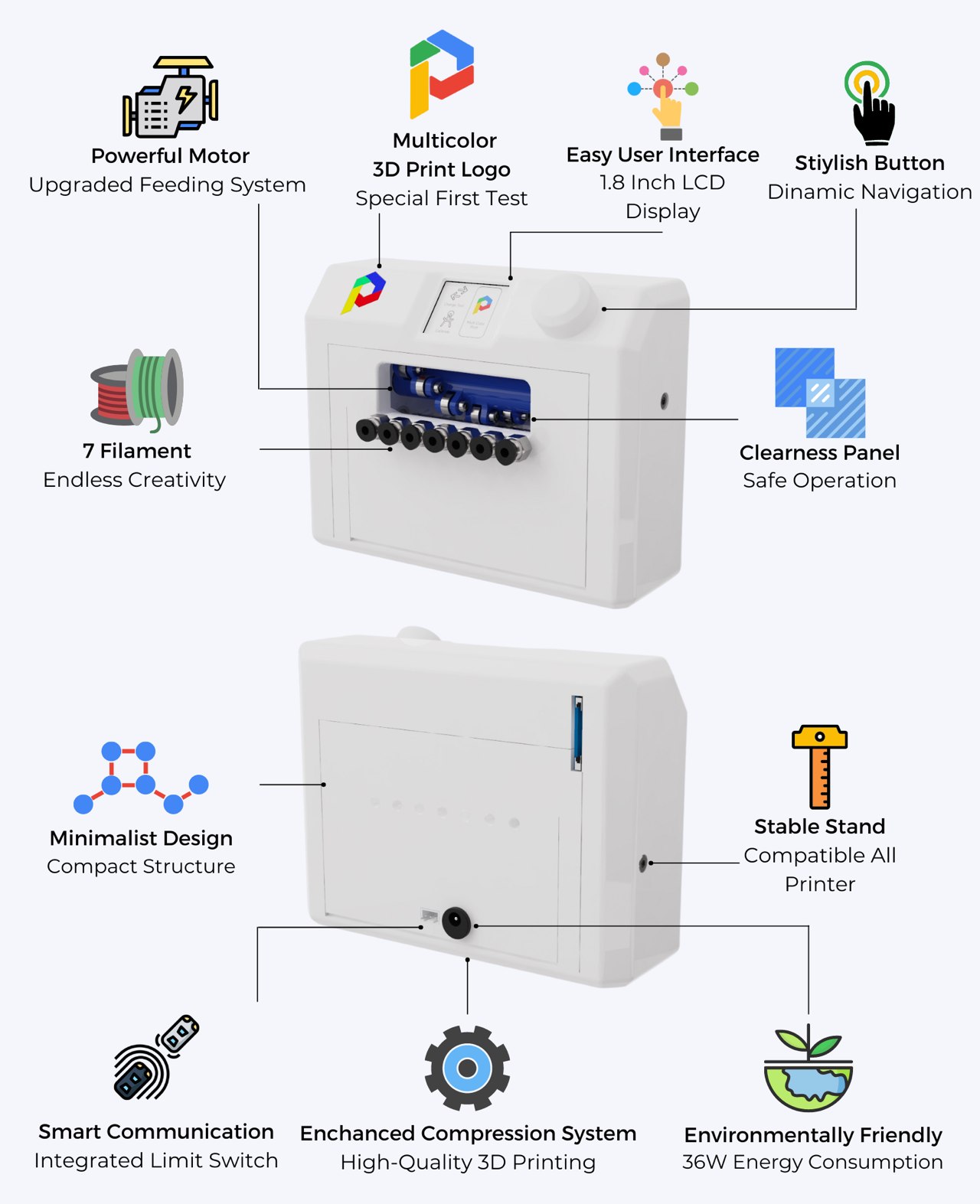

Pro Print Heads

Jadelabdo J1 uses a combination of a direct drive and a dual drive setup. This highly responsive extrusion system enables greater grip strength and better filament flow control, leading to the best possible printing performance, even with highly flexible materials. Jadelabo J1 also features filament sensors to detect, auto-pause, and alert you to filament runout and jams.

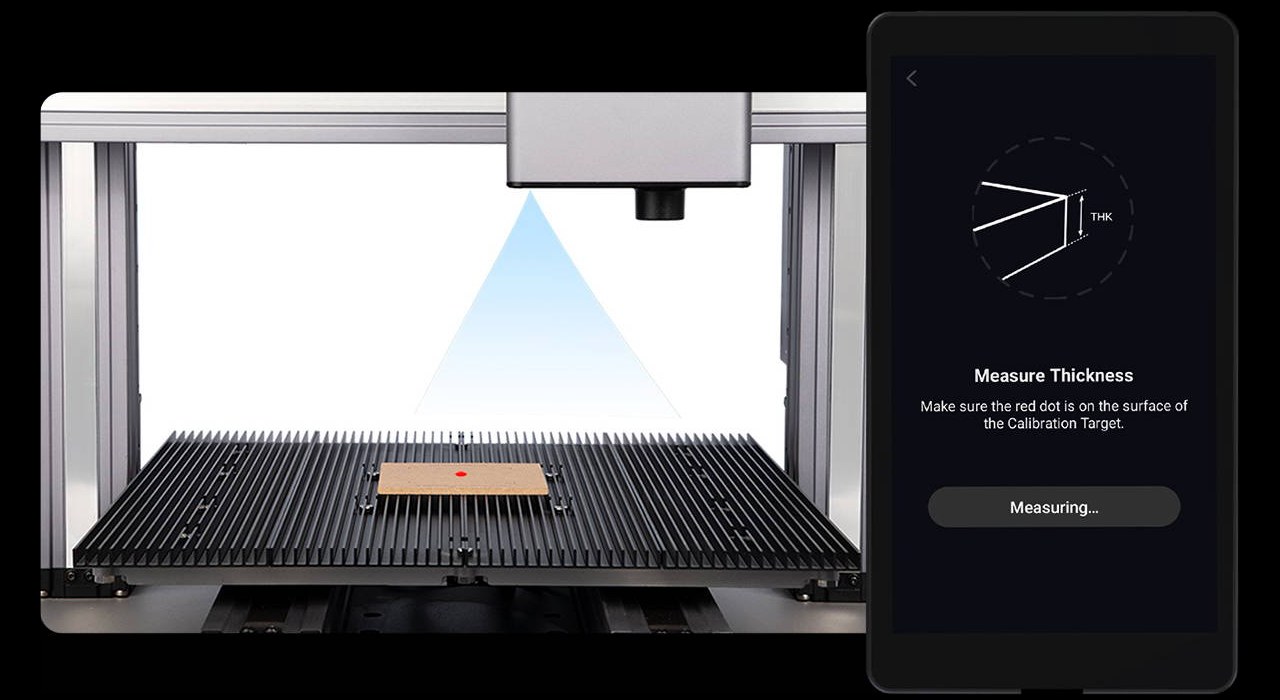

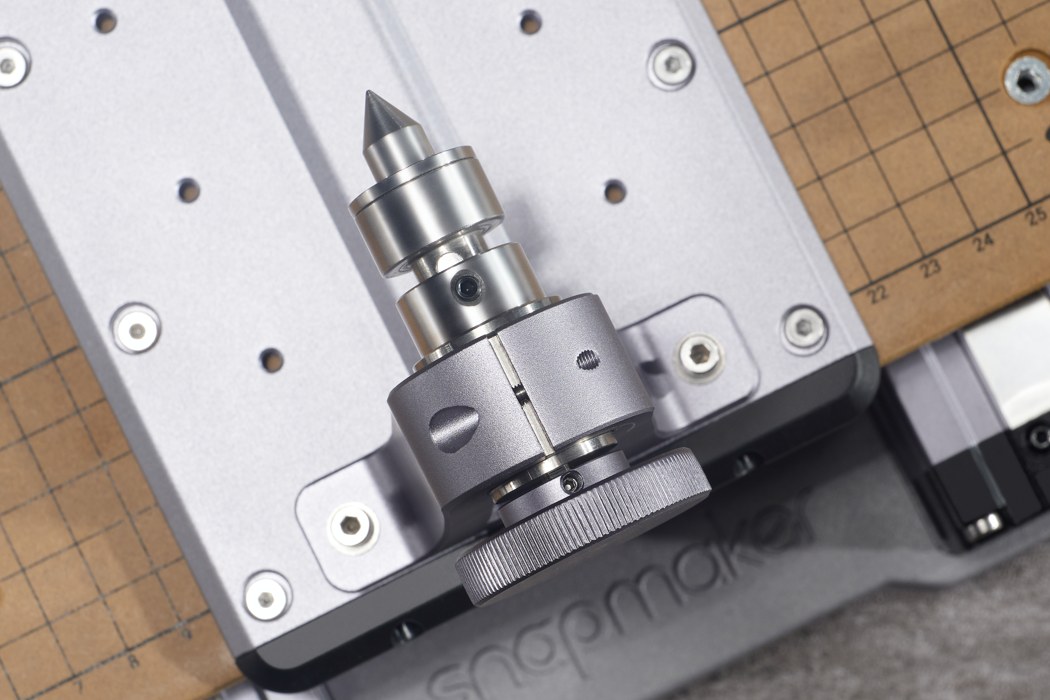

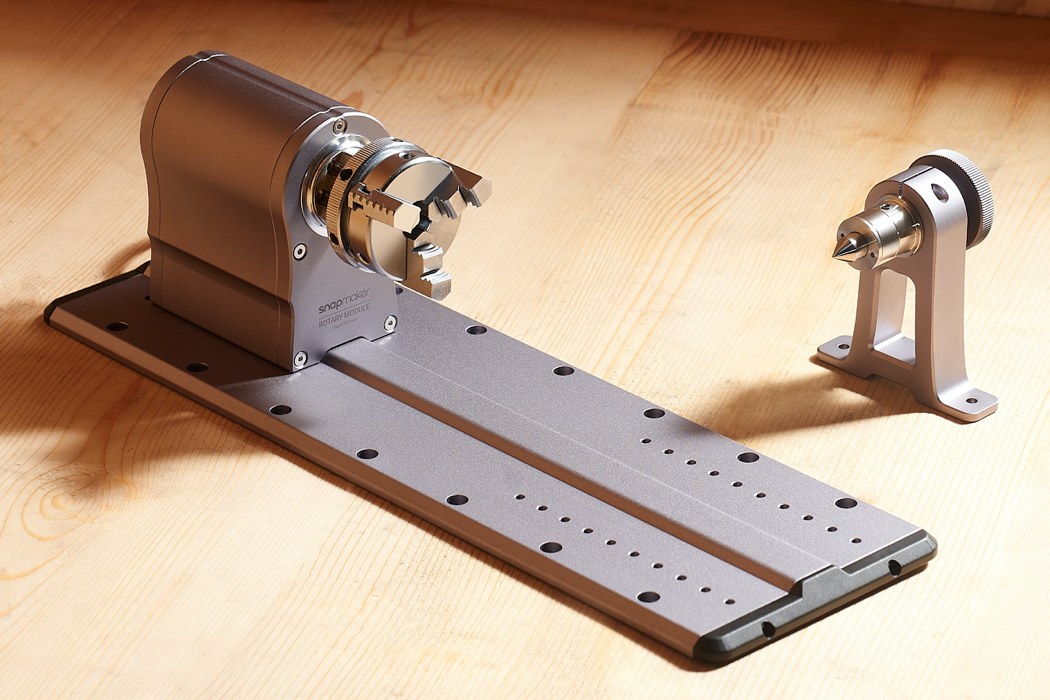

Unique Nozzle Height Calibration

You can precisely adjust the nozzle height by following the instructions on the touchscreen to turn the knob to a specific value. Jadelabo J1 also incorporates easy-to-replace hotends, and supports multiple nozzle diameters.

Preventing Oozing

Reliable Build Plate

Featuring a glass plate with a Polyetherimide (PEI) print surface, Jadelabo J1 offers an ideal build plate for 3D printing with a wide range of materials. The glass plate is reliably flat, thermally stable, and extremely durable. The PEI surface offers both excellent adhesion and easier print removal.

More Precise and Quicker Calibration

Most IDEX 3D printers are difficult to calibrate; Jadelabo J1 is different. For the first time in IDEX calibration, an innovative solution of contact-based electrical conductive paths are applied to achieve unparalleled accuracy in both platform calibration and dual extruder calibration for an IDEX 3D printer.

Dual Extruder Calibration

XY Calibration: Jadelabo J1’s calibration is more accurate than any sensor based system. The nozzle closes an electric circuit as it touches metal spots on the bed, triggering a calculation of specific position. This simplified signal conversion process. In addition, it eliminates issues like sensor drift and inconsistencies in manufacturing to ensure you get the best possible calibration.

XY Calibration Comparison

Z Calibration – Even for experienced users, conventional dual extruder Z calibration can be intimidating. That’s why Jadelabo J1 comes with a novel calibration method with a unique nozzle height calibration knob design. Just follow the instructions on the touchscreen and turn the knob to a specific value, then fasten the nozzle. And that’s it. Easy, fast, and reliable.

Enhanced Smart Features – Self Test Procedure

Every Jadelabo J1 arrives pre-assembled and pre-tested to guarantee a high-quality machine. In addition, you can run the self-test procedure to automatically test the most important components of the machine whenever you need.

Power Loss Detection and Recovery

Jadelabo J1 features power loss detection and recovery. It will save the extruder’s last position when it loses power and continue from that point once power is restored and you resume the print.

Filament Runout Detection and Recovery

Jadelabo J1’s filament sensor can detect, auto-pause, and alert you to filament run outs and jams. This can help prevent failed prints along with reducing material waste and power. In the case of filament running out, J1 lets you resume the print after the problem is fixed.

Filament Tangles Detection and Recovery

Jadelabo J1 has a filament tangle detection and recovery feature that helps you prevent failed prints. It will auto pause the print when there’s a tangle, and let you resume the print after you fix the problem.

Backup Mode

Unlike a single extruder 3D printer, Jadelabo J1 features a Backup Mode that can automatically switch from one print head to a standby print head if it detects a filament run out or clog. This means it will continue to print instead of waiting for you to fix the problem, saving you time.

Avoid-Losing-Both Mode

To avoid “all or nothing” in duplication and mirror printing, Jadelabo J1 features Avoid-Losing-Both that lets you stop the failed print but continue printing the good one. You can now print with multiple parts without fear.

Powerful Controller Board

A 32-bit ARM Cortex-M4 microprocessor provides fast motion and quick processing. Pair that with TMC2209 drivers which are both extremely quiet and precise (capable of up to 256 microstepping).

Intuitive Touchscreen

Jadelabo J1 features a large 5″ full-color capacitive IPS touchscreen that lets you easily manage all your prints. You will enjoy an easy-to-use IDEX printing experience with its initial setup wizard, well-organized navigations, instant notifications, and much more. Equipped with an ARM Cortex-A53 processor, 1GB RAM, 8GB EMMC, running on Linux, it’s a seriously powerful touchscreen.

Software: Jadelabo Cura

Jadelabo Cura lets you use IDEX to its fullest. It features an easy workflow, custom printing modes, validated printing profiles, and hundreds of settings for in-depth control. It’s free, open-source, and tailor-made for Jadelabo J1 with ongoing updates and support.

Third-party Compatibility

Feel free to use the third-party software that you’re used to. You can prepare G-code in third-party slicers, and set up printing modes directly from the touchscreen.

Wi-Fi Connectivity

You can connect your Jadelabo J1 via Wi-Fi or USB. Setup is quick and easy. You can send files over Wi-Fi and control your print in the local area network (LAN).

OctoPrint Compatibility

Jadelabo J1 is compatible with OctoPrint, which is a free and open source software for remote control and monitoring of your print jobs right from your browser.

Excellent Build Quality

From electronics manufacturing and components mounting, to inspection, testing, and precision parts manufacturing, everything is driven by automated systems and the spirit of craftsmanship. All structural parts have good process-ability, durability, and surface quality.

Click Here to Buy Now: $659 $1199 ($540 off). Hurry, only 32/100 left! Raised over $160,000.