There’s something refreshing about a company that doesn’t just slap their logo on a tote bag and call it customer appreciation. SWNA Office’s Earth’s Hatch kit for Lotte E&C proves that welcome gifts can be more than forgettable tchotchkes collecting dust in a drawer. This is design that actually thinks about the person receiving it, and what they might genuinely need in their daily life.

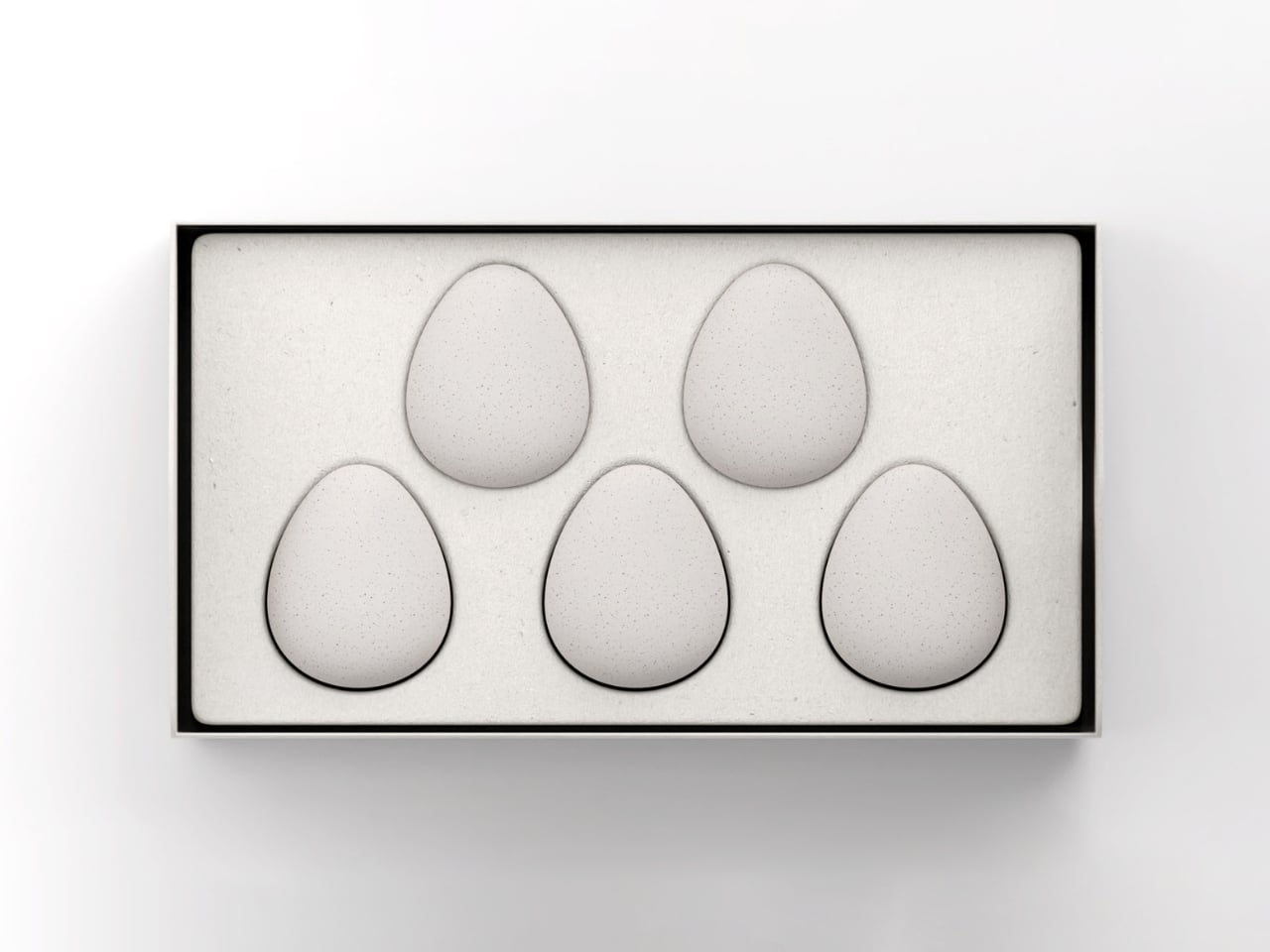

The kit arrives in a birdhouse-shaped package made from pulp paper, the kind that feels substantial in your hands. Strip away the paper band, and inside you’ll find five egg-shaped magnetic objects nestled in protective pulp packaging. The whole experience feels deliberate, like opening something that was designed to be opened, not just shipped.

Designer: SWNA Office

But here’s where it gets interesting. Those five eggs aren’t just decorative items you’ll stash away and forget. Each one serves a specific purpose at the threshold of your home, that chaotic zone where packages pile up and keys mysteriously vanish. One egg contains a ceramic-blade box cutter for safely slicing through Amazon deliveries. Others function as magnetic hooks and holders, perfect for hanging access cards, food waste sorting tags, car keys, or that shoehorn you’re always hunting for when you’re already late.

The egg shape itself is surprisingly smart from a user experience perspective. It’s soft and rounded, fitting comfortably in your palm. The scale feels just right, not so small that it’s fiddly, but not so large that it dominates your door. There’s a gentle familiarity to holding an egg, even one made from recycled plastic. It’s a form we all understand instinctively.

The birdhouse package transforms into a refillable tissue holder after you’ve unpacked everything. The circular opening on the side isn’t just aesthetic; it’s functional, letting you see at a glance when you’re running low. Made from vegan leather, it brings a soft contrast to the stone-like texture of the eggs. The eagle motif threading through both the eggs and the “nest” creates visual continuity that feels intentional rather than gimmicky.

What makes this project worth paying attention to is how it handles sustainability without being preachy. Sure, the eggs are made from recycled plastic and the case uses vegan leather, but the kit doesn’t stop at material choices. It’s designed to make eco-friendly living more manageable. That box cutter with the ceramic blade helps you break down boxes properly for recycling. The sorting tools encourage proper waste management. The kit isn’t just made sustainably; it helps you live more sustainably.

This is where corporate gifting usually fails. Most welcome packages are essentially branded advertising that recipients tolerate. Earth’s Hatch flips that script by centering utility. The magnetic feature is particularly clever because it solves a real problem. How many times have you frantically searched for your keys or access card? Now they have a dedicated spot right by your door, held by these smooth, tactile objects that are actually pleasant to interact with daily.

The name itself, Earth’s Hatch, captures what Lotte E&C seems to be going for with their “safe planet project.” It’s about emergence, about something new coming into being. The eagle egg symbolism reinforces that idea of potential and care. Eagles are protective of their eggs, just as we should be protective of the planet. It’s a bit poetic for a construction company, but that’s precisely what makes it memorable.

SWNA Office managed to create something that works on multiple levels. At first glance, it’s a beautiful object with its muted, speckled surface that photographs gorgeously in that minimalist product photography style we’ve all become accustomed to. But it doesn’t rely solely on aesthetics. The design holds up in actual use, which is rarer than it should be.

What this project really demonstrates is that thoughtful design can elevate even something as mundane as organizational tools and tissue holders. By connecting form, function, and meaning, Earth’s Hatch becomes more than a welcome kit. It’s a physical manifestation of a company’s values, something recipients will actually use and remember. That’s the kind of design that deserves attention.

The post Lotte E&C Just Turned 5 Eggs Into the Welcome Gift You’ll Use first appeared on Yanko Design.