"We're not scanning every object in the collection," Adam Metallo tells me, offering up the information almost as soon as we set foot in the Smithsonian's Digitization office. It's an important piece of information he wants to make sure I have, right off the bat. It seems that, when the story of the department's 3D-scanning plans first hit the wire, a number of organizations blew the scope of the project out of proportion a bit. And while the team's project is certainly ambitious, it's not, you know, crazy. It's the work of a three-person team, still in its nascent stages, attempting to prove the value of new technologies to a 167-year-old museum affectionately known as "the nation's attic."

In the fall of 2011, Metallo and fellow Smithsonian 3D scanner Vince Rossi (a duo the institute has lovingly deemed its "laser cowboys") unpacked their equipment in Chile's Atacama Desert. "They were widening the Pan-American Highway, and in doing so, they uncovered about 40 complete whale specimens," Rossi explains. "But it might take decades for them to remove the fossils from the rock, so we were able to capture this snapshot of what that looked like in 3D." The tool of choice for the expedition was a laser arm scanner, which utilizes a process the duo compares to painting an object, moving back and forth across its surface as the device records the relative position of its axes.

Filed under: Science

Comments

Source: Facebook, Twitter

Open Bionics announced today that its 3D-printed Hero Arm prosthetic will be available for purchase in the UK next month. The company's founders started Open Bionics because they were interested in developing prosthetic limbs that were less expensive...

Open Bionics announced today that its 3D-printed Hero Arm prosthetic will be available for purchase in the UK next month. The company's founders started Open Bionics because they were interested in developing prosthetic limbs that were less expensive...

Open Bionics announced today that its 3D-printed Hero Arm prosthetic will be available for purchase in the UK next month. The company's founders started Open Bionics because they were interested in developing prosthetic limbs that were less expensive...

Open Bionics announced today that its 3D-printed Hero Arm prosthetic will be available for purchase in the UK next month. The company's founders started Open Bionics because they were interested in developing prosthetic limbs that were less expensive...

When Sony introduced the Xperia XZ1 at IFA, the Japanese tech giant said it was seeking partnerships with 3D printing services to go with its pre-loaded 3D scanning app. Now, Sony and Sculpteo have revealed that they've teamed up to give people the p...

When Sony introduced the Xperia XZ1 at IFA, the Japanese tech giant said it was seeking partnerships with 3D printing services to go with its pre-loaded 3D scanning app. Now, Sony and Sculpteo have revealed that they've teamed up to give people the p...

In 2014, HP unveiled the original Sprout - a unique all-in-one with a projector and camera extrusion that turns the surface between you and the display into an interactive space. It was designed for creative professionals and hobbyists, and a later v...

In 2014, HP unveiled the original Sprout - a unique all-in-one with a projector and camera extrusion that turns the surface between you and the display into an interactive space. It was designed for creative professionals and hobbyists, and a later v...

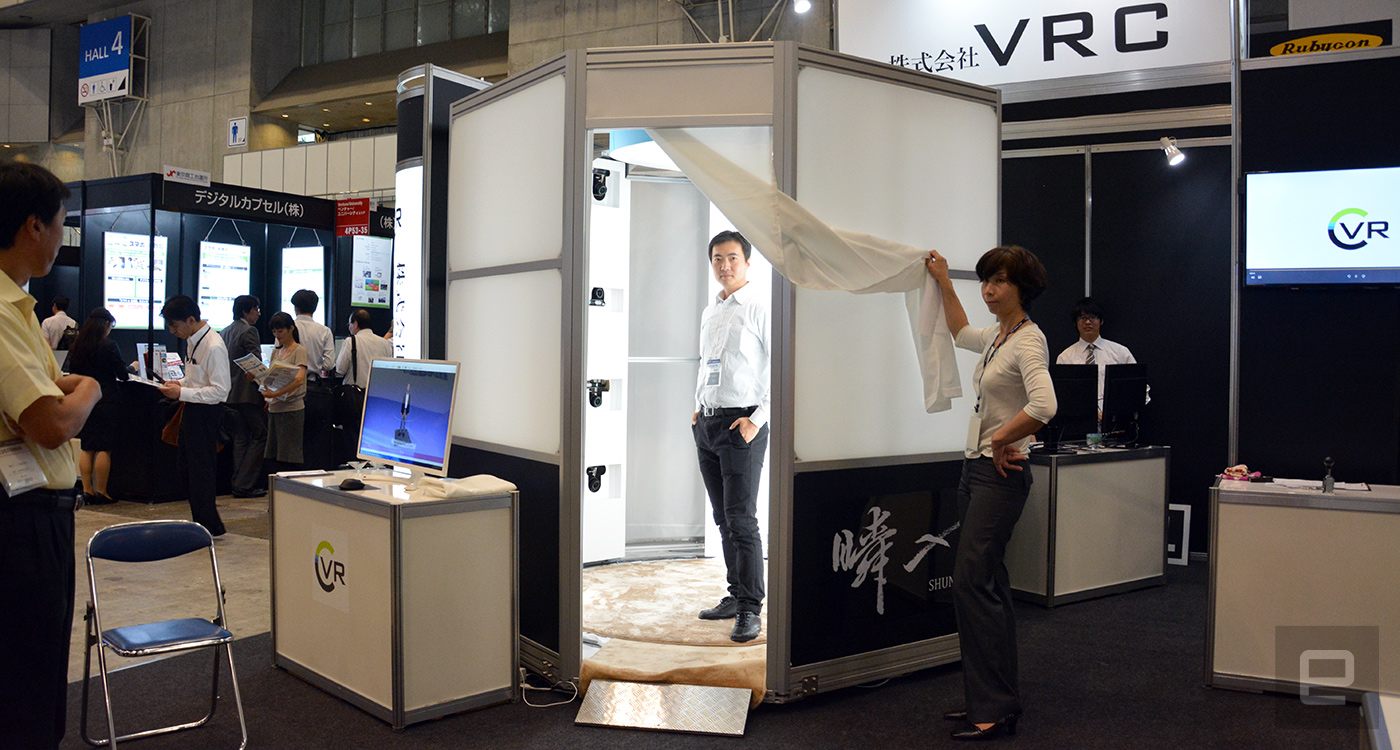

3D scanners come in all shapes and sizes these days, and obviously the bigger you go, the more you have to pay. In the case of full-body scanning, many existing solutions require you to stand still for 12 to 14 seconds which isn't ideal for both the...

3D scanners come in all shapes and sizes these days, and obviously the bigger you go, the more you have to pay. In the case of full-body scanning, many existing solutions require you to stand still for 12 to 14 seconds which isn't ideal for both the...

HP originally pitched its 3D-scanning Sprout computer to creatives and hobbyists, but doesn't it seem like an ideal machine for curious classrooms? The company agrees, apparently. It's introducing the Sprout Pro, a version of the unique all-in-one...

HP originally pitched its 3D-scanning Sprout computer to creatives and hobbyists, but doesn't it seem like an ideal machine for curious classrooms? The company agrees, apparently. It's introducing the Sprout Pro, a version of the unique all-in-one...