You’ve heard of Amazon, right? One of the world’s largest retailers? Run by the world’s richest man (even after his divorce settlement!)

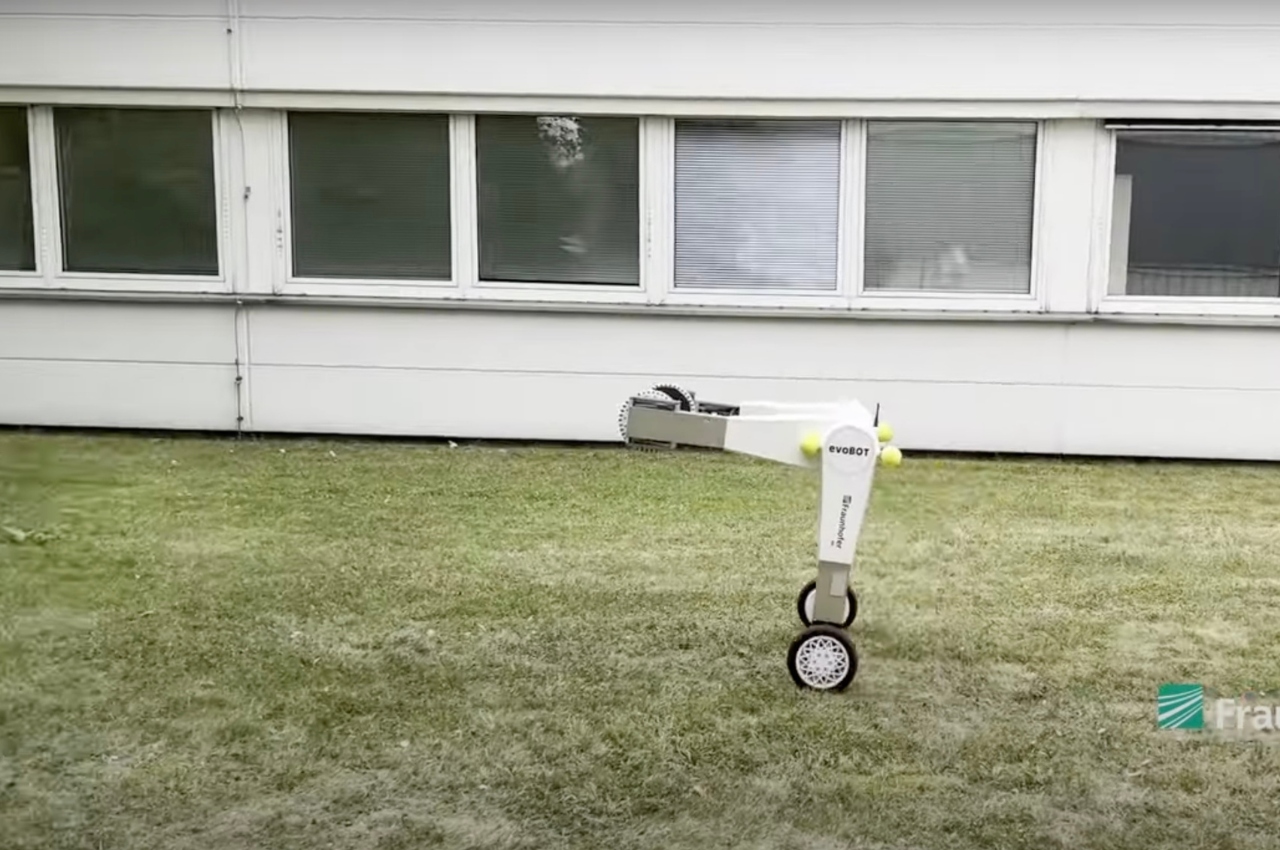

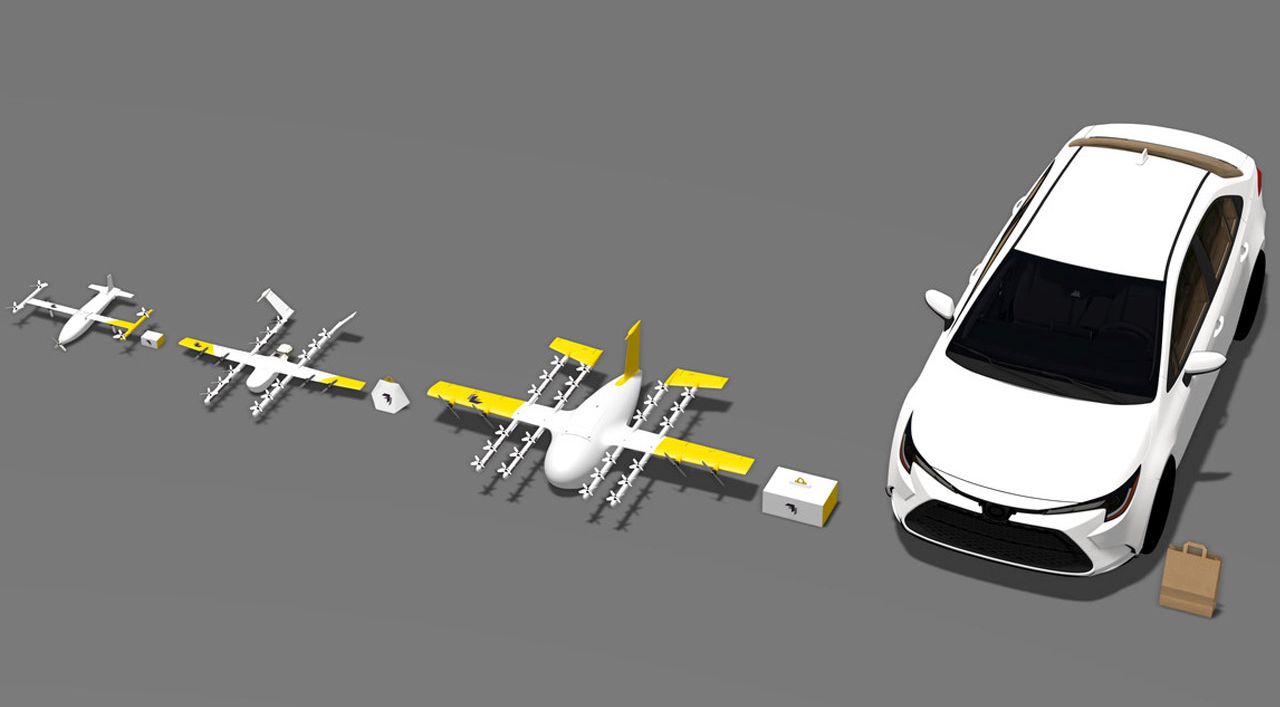

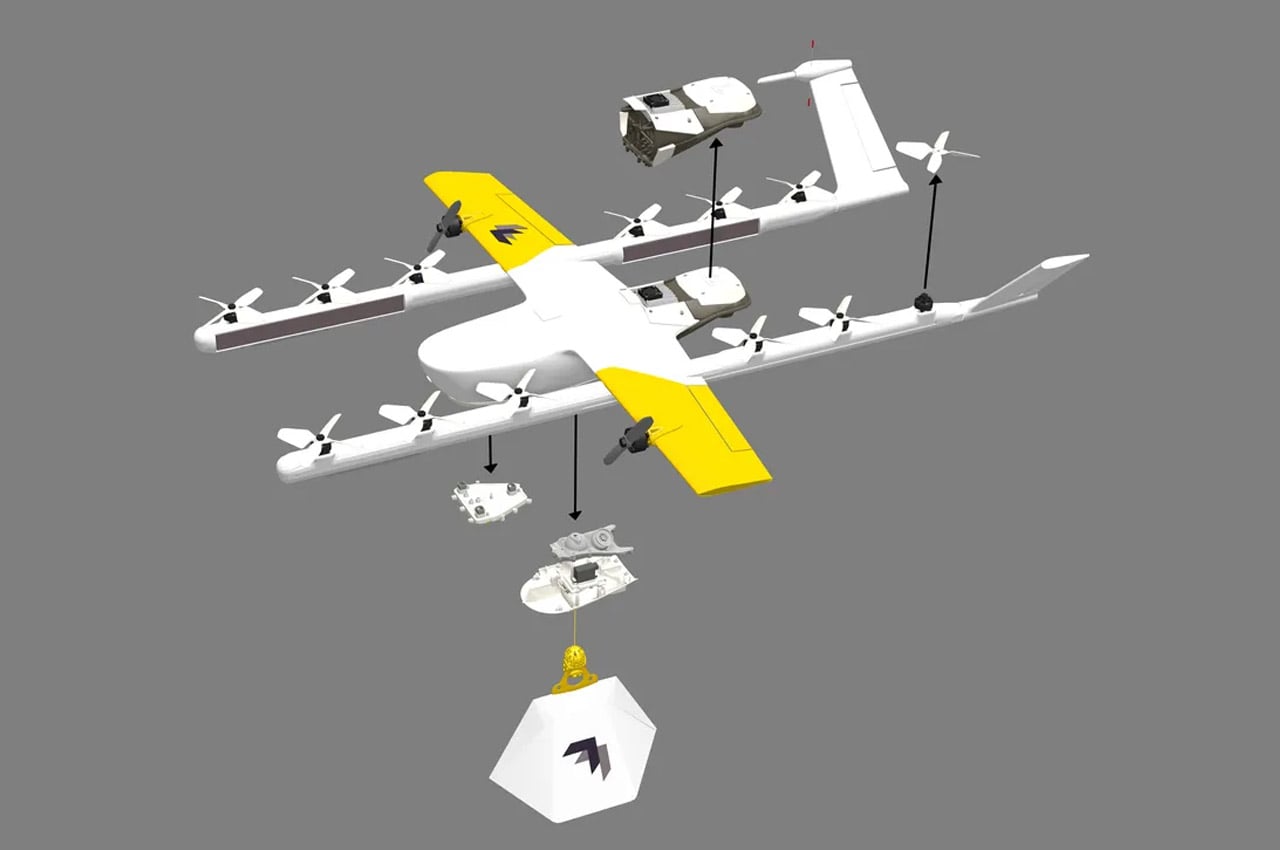

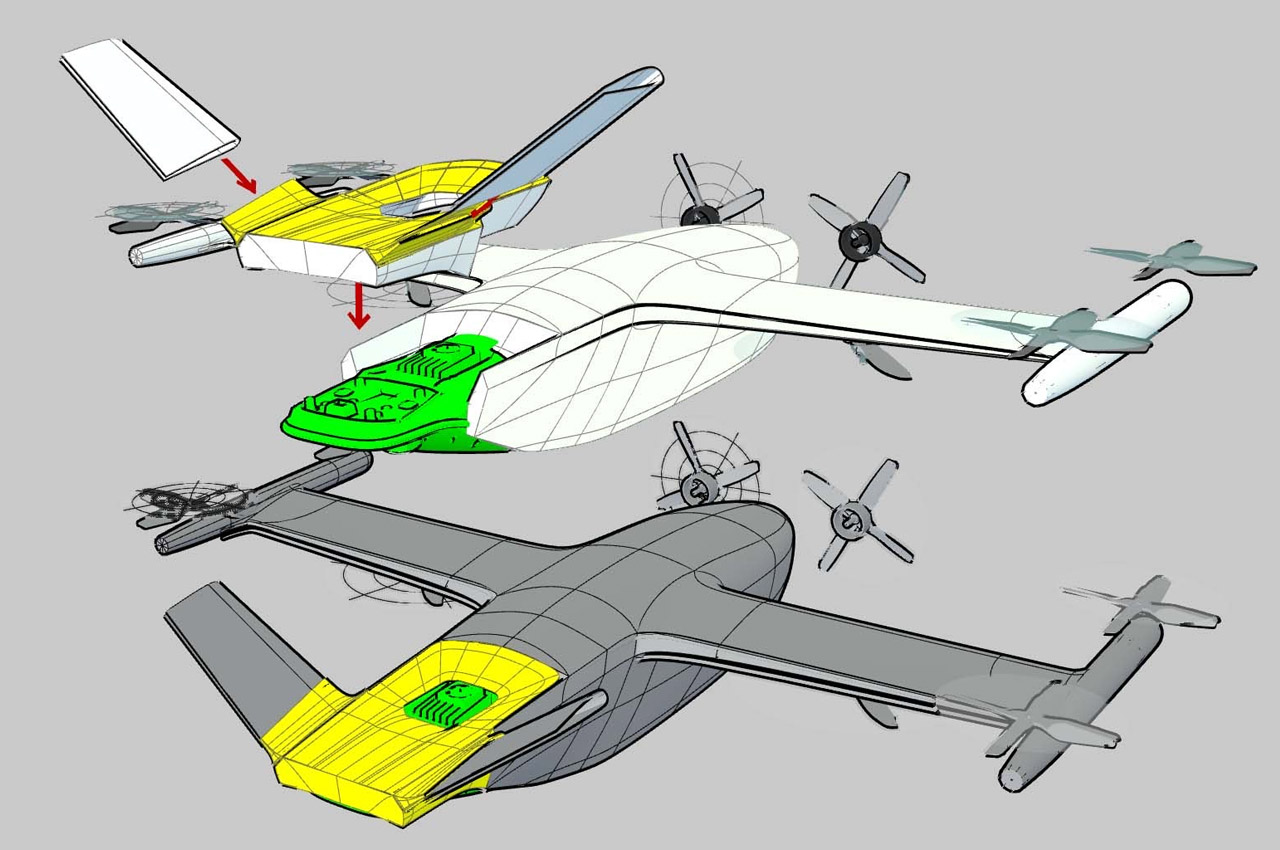

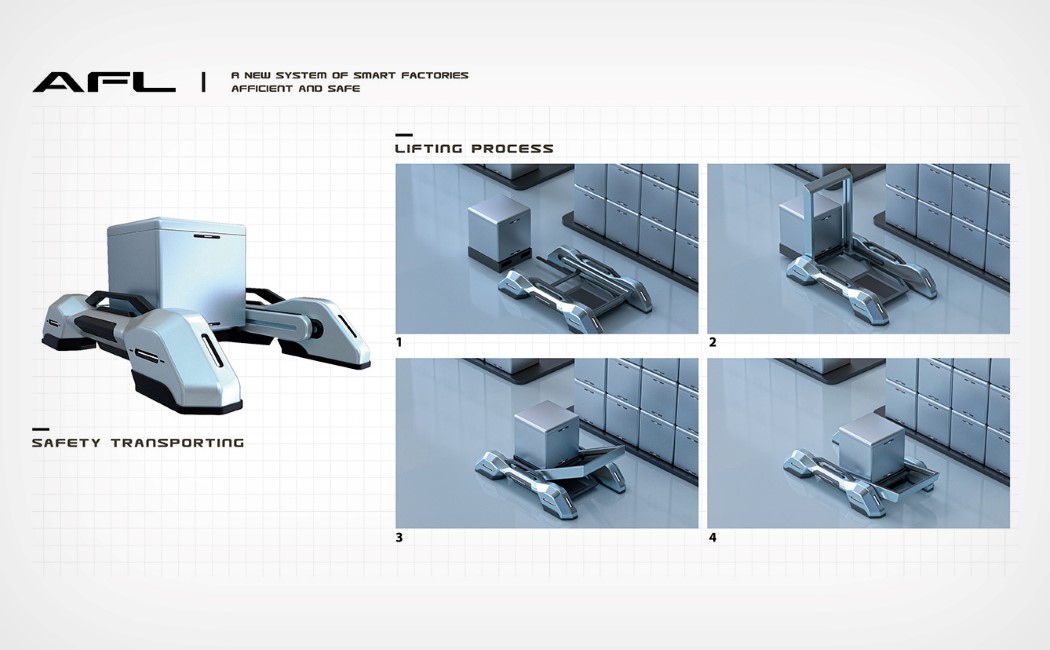

Amazon is an absolute behemoth. Going from being a book-selling service in 1995, to being one of the biggest names in online retail, and even reaching a trillion dollar valuation along the way, Amazon is famous for investing heavily in research and development. For the longest time, all of Amazon’s profits went right into their research and development team, allowing it to become the immovable force it is today. While Amazon’s most profitable service is its web-server service, Amazon is most well known for its e-commerce, logistics and delivery. Having experimented extensively with unmanned delivery methods, including drones as well as self-driving robots, Amazon is looking for a Lead Industrial Design Engineer to join their Robotics team in North Reading, Massachusetts.

THE OPPORTUNITY

Are you inspired by invention? Is problem solving through teamwork in your DNA?

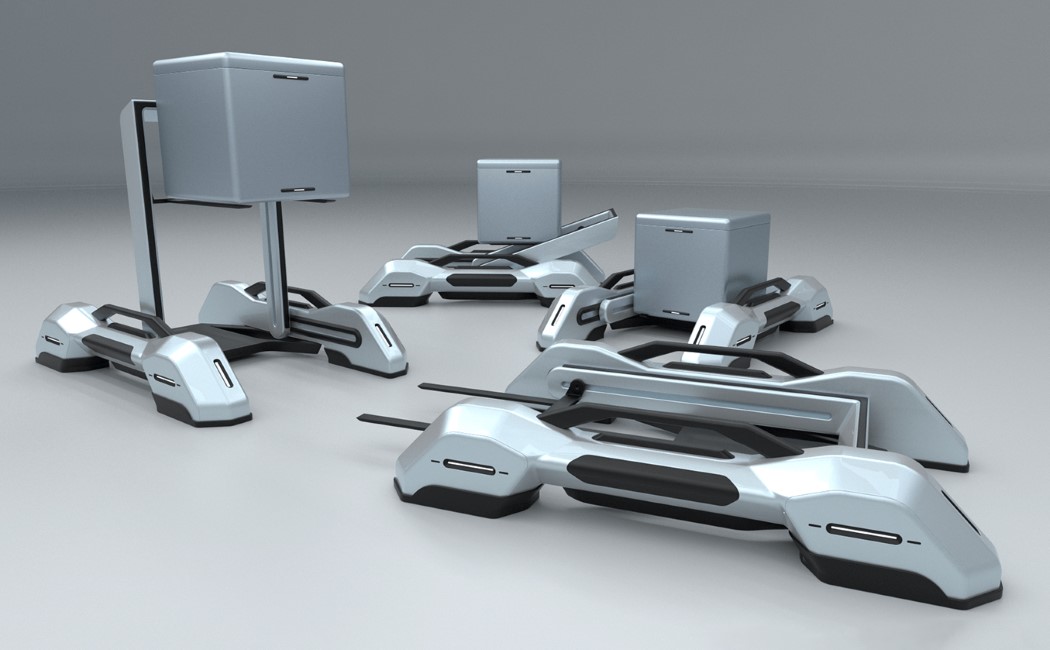

Do you like the idea of seeing how your work impacts the bigger picture? Answer yes to any of these and you’ll fit right in here at Amazon Robotics. We are a smart team of doers that work passionately to apply cutting edge advances in robotics and software to solve real-world challenges that will transform our customers’ experiences in ways we can’t even imagine yet.

We invent new improvements every day. We are Amazon Robotics and we will give you the tools and support you need to invent with us in ways that are rewarding, fulfilling and fun.

The Global Fulfillment and Transportation Solutions Team seeks a customer obsessed and innovative Lead Engineer to lead in the designs for our next generation Robotic Operations. The Lead Engineer provides technical, operational and analytical design leadership for a multi-disciplinary team. This role requires you to scope and design highly automated operations and supply chain workflows that scale, provide technical guidance on current generation designs and technologies that step towards the future vision, influence our technology R&D roadmap, and deliver on significantly complex programs often starting before the problem is well understood.

WHO ARE YOU AND WHAT YOU WILL DO

As a successful candidate you will have a passion for designing high-performance digital-physical systems leveraging your background developing industrial automation solutions and/or leading highly automated high-volume, high-mix, and short lead time operations. You will lead, develop, and/or contribute to cross-functional teams of passionate engineers to conceptualize, design and implement robotics technologies in next generation facilities and network designs all the way through facility construction and startup. You must have strong fundamentals in Industrial Engineering, Lean systems, technical problem solving ability, financial acuity, and the ability to effectively communicate with and influence decision makers at all levels.

You are eager to get into the weeds to deeply understand your customer’s driving metrics using a variety of financial and data analytics techniques. You’re able to pull yourself out of the weeds to provide a holistic vision and cohesive strategy for next generation designs and network strategies. You have an intrinsic motivation and innate ability to simplify problems to deliver results in a fast-paced and often ambiguous environment. Amazon’s culture encourages innovation and expects engineers and managers alike to take a high level of ownership in solving problems.

You will build a network of relationships with business, technology, and engineering leaders, product managers and systems architects across Amazon to align towards simple and coherent designs. At the same time you will bridge gaps you find between partner teams in order to build holistic integrated systems and architectures crossing multiple technology teams. You’ll advise executives and the broader tech community on solutions that resolve global system architecture opportunities that trade-off robustness, stability, scalability, cost-effectiveness, complexity and business value. You will lead and implement mechanisms to “force multiply” yours and the team’s collective technical knowledge, provide technical guidance, and be a resource for technical review across Robotics.

This role is located in North Reading, Ma. Expect to travel up to 10%.

REQUIREMENTS

Basic Qualifications

• Proven outcomes of your socially responsible business knowledge and strong technical insight to address customer challenges. Ability to anticipate and develop business priorities for future action. Ability to assess broader and deeper impact of decisions on the business.

• Proven experience with Design for Operations and process design based on Lean Principles. Mastery of fundamentals in Industrial Engineering including Lean/Toyota Production Systems (TPS), value stream engineering, statistical process control (SPC), business case analysis, and ergonomic and safety assessment.

• Demonstrated understanding of supply chain strategy, network architecture and business planning. Have detailed knowledge of global supply chain infrastructure and how different architectures scale.

• Minimum of 10 years of relevant experience with a Bachelor’s degree in engineering, operations, or a related field required; MBA or advanced degree preferred. Alternatively 2+ years of Amazon experience as a Principal Engineer preferred for internal transfer.

• Minimum of 5 years of experience leading and managing relevant cross-functional programs.

• Experience using CAD and commercial off the shelf data manipulation technologies.

Preferred Qualifications

• Experience working with the designs of complex automated material handling systems including robotics and high-speed manufacturing in high mix and short lead time environments.

• Experience working with Architects, General Contractors, and Engineers on greenfield and brownfield construction projects to integrate life safety, regulatory, structural, mechanical, electrical, plumbing, and low voltage requirements into the full project lifecycle.

LOCATION

North Reading (Massachusetts), USA.

Visit the YD Job Board to view similar jobs or to post a Job Opening.

Volvo Trucks' autonomous vehicle Vera is ready to hit the road. In collaboration with ferry and logistics company DFDS, Vera will begin transporting goods between a logistics center and a port terminal in Gothenburg, Sweden. The vehicle will haul shi...

Volvo Trucks' autonomous vehicle Vera is ready to hit the road. In collaboration with ferry and logistics company DFDS, Vera will begin transporting goods between a logistics center and a port terminal in Gothenburg, Sweden. The vehicle will haul shi...

While Boston Dynamics' robots make for fascinating -- sometimes disturbing -- internet videos, they haven't quite crossed into everyday life. That could change sooner rather than later. Boston Dynamics took a big step toward bringing its box-moving (...

While Boston Dynamics' robots make for fascinating -- sometimes disturbing -- internet videos, they haven't quite crossed into everyday life. That could change sooner rather than later. Boston Dynamics took a big step toward bringing its box-moving (...

The Tesla Semi already has one very large guinea pig for an electric fleet: Walmart. The retail juggernaut has some 6,000 trucks and moves merchandise all over the country and as of last May, it was the world's largest retailer. The company eyeing EV...

The Tesla Semi already has one very large guinea pig for an electric fleet: Walmart. The retail juggernaut has some 6,000 trucks and moves merchandise all over the country and as of last May, it was the world's largest retailer. The company eyeing EV...