If in this era of pollution, chaos, and panic, you aren’t already a bicycle person, it’s high time you convert into one! Bicycles are slowly becoming people’s preferred means of transportation. People are ditching the fossil fuel consuming and air pollution causing automobiles for the more eco-friendly option of bikes. Not only are bicycles a boon to the environment, but they also promote good health and ensure we get our daily dose of physical exercise done. In fact, you can even upgrade and amp up your bicycle with some fun and functional accessories. From the world’s first smart chain lock to the safest cycling helmet for e-bikes – these accessories are the perfect sidekicks to your bicycle!

1. reTyre

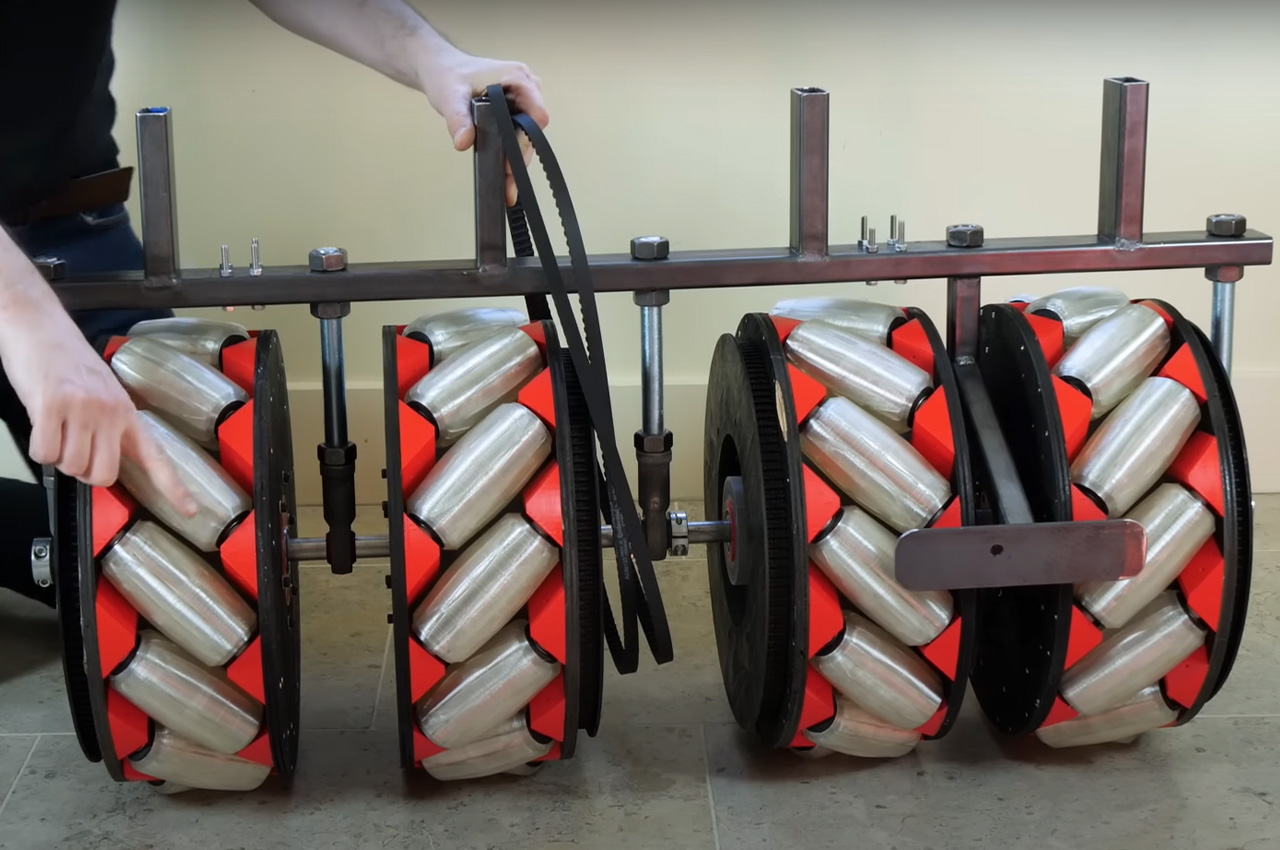

This zippable tire-tread system is called reTyre and it offers your city bicycle the ability and versatility to work off the road too. It features a simple zipping mechanism that adds a secondary and tougher tread on your tires, enabling you to ride on smooth asphalt and tough terrains!

Why is it noteworthy?

reTyre’s special bicycle tire comes with a zipper lining and a selection of treads or skins that you can clad on your existing tire. The original tire works great on asphalt, and the wide variety of skins allows you to ride your bicycle on mud, gravel, rocks, or even snow.

What we like

- When not in use, the treads easily fold up and go right into your backpack

What we dislike

- Not sure how long the tire will take to wear down

2. Bumpair 2.0

French company Bumpair partnered up with a scooter share company in France to create a super cool inflatable helmet that you inflate with a hand pump, deflate once you’re done using it, and keep it away for storage!

Why is it noteworthy?

Compared to the first version, Bumpair 2.0 is supposed to be much more comfortable! The surface and shape of the helmet are better controlled, so you don’t feel any discomfort or pressure on your head once you wear the helmet.

What we like

- The straps are better adjusted providing you with a comfortable and reassuring feel

What we dislike

- Some people may prefer the older version which inflates with the press of a button

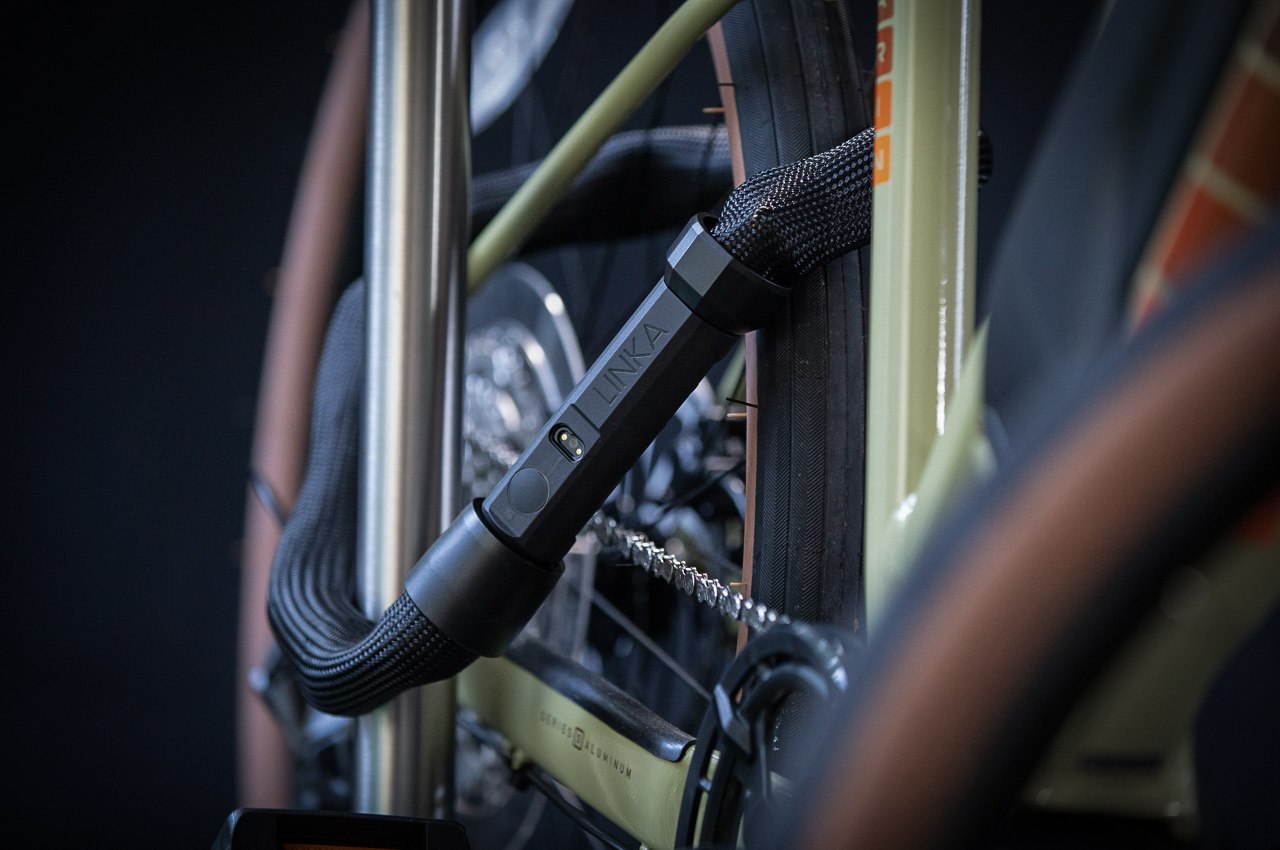

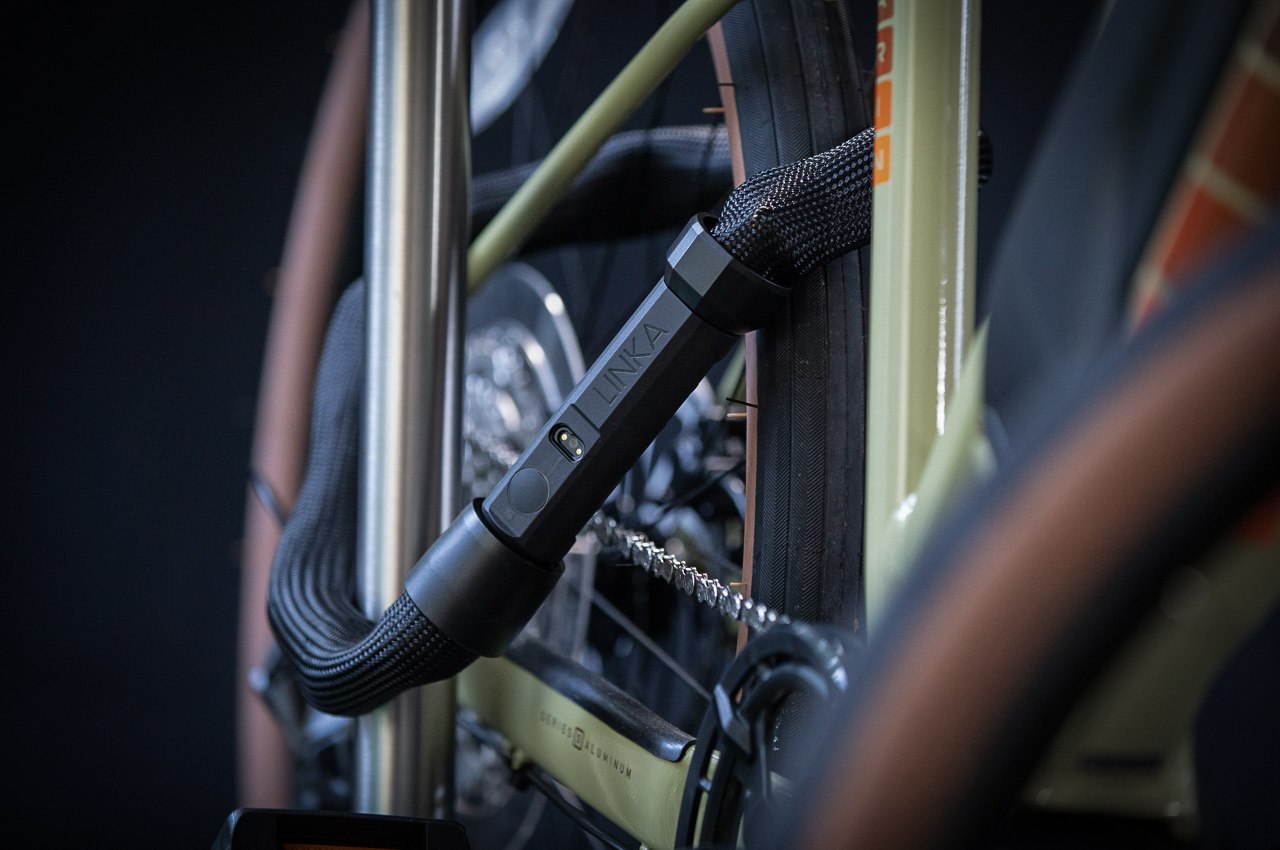

3. LINK LASSO

The ingenious LINK LASSO is engineered to withstand any kind of attack from different tools such as bolt cutters, hammers, or even hacksaws!

Why is it noteworthy?

The LINK LASSO is a square manganese hardened steel chain that offers toughness on the inside, and a 100% recyclable polyethylene sleeve protects it from the outside. It has been “obsessively engineered” to provide the most security for your bicycles!

What we like

- Protected by a corrosion-resistant stainless steel 304 frame

What we dislike

- You need to buy the SmartMotion Key separately

4. VIRGO

Meet VIRGO – the safest cycling helmet for e-bikes. VIRGO is engineered to provide an optimal balance of safety and performance with its cutting-edge design.

Why is it noteworthy?

VIRGO is designed not only for e-bike riding but for regular bike rides as well. It provides full protection in a lightweight and compact form to people who value safety and performance. The design is a skillful blend of lightweight construction, optimal ventilation, and full facial protection in case of a head-on collision.

What we like

- Built of a polycarbonate shell with a protective layer of EPS

- Provides you with a combination of protection and lightness

What we dislike

- It can get a bit hot and heavy to wear for longer periods of time

5. Lockinvisible

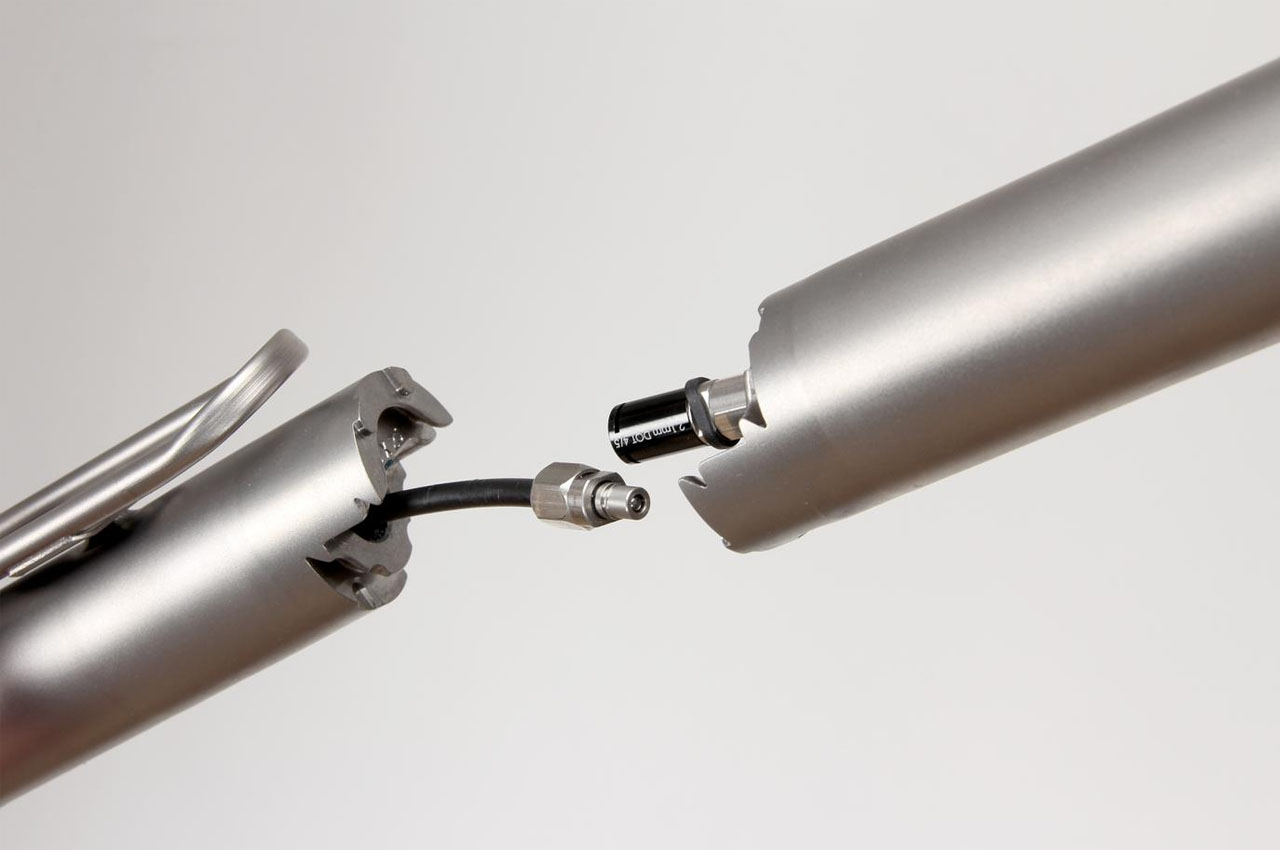

The Lockinvisible fully integrated bicycle lock secures your ride safely and in style! It has a seamless design, excellent security, and great convenience. It features a stylish integration, that enables the lock to smoothly integrate into the bike’s seat post!

Why is it noteworthy?

You can effortlessly install it by simply replacing your bike’s seatpost with Lockinvisible, and adjusting the seat height by using a height-fixing adapter. It’s a quick, easy, and efficient process.

What we like

- It’s a part of your bike, so you never end up losing it, it effortlessly merges with it

What we dislike

- We’re not sure how sturdy it is!

6. The AirBell

Although this looks like your average everyday bicycle bell, it is in fact a smart anti-theft device for your bicycle called the AirBell! The AirBell features a tiny holding space for an Apple AirTag!

Why is it noteworthy?

The AirBell allows you to track your bicycle without anyone getting to know. It helps you locate your bicycle if it’s missing or lost, and also notifies you about its location if it ever gets stolen. Since it has a universal and versatile design, you can attach it to your existing bicycle.

What we like

- Utilizes Apple’s ultrawide-band chip, and ‘Find My’ tracking abilities to give you tabs on your bike

- Impossible to figure out if there’s an AirTag hidden inside

What we dislike

- There aren’t any different color/style options

7. Slapstick Smart Bicycle Lock

Inspired by the popular children’s toy – the slap-band, the Slapstick Smart Bicycle Lock completely reinvents a bike lock with its fun, playful, and fast-deploying design. The lock snaps around your bicycle frame with a belt-like locking mechanism that easily adjusts to match the size of your frame.

Why is it noteworthy?

Affixing the lock is as easy as just snapping it in place and watching the band automatically wrap around your bicycle. The lock’s smart hub helps you secure and remove the Slapstick without needing a key, making the entire process simple, fast, and intuitive!

What we like

- Inspired by a popular children’s toy

- Can use your smartphone to lock and unlock it

What we dislike

8. FR-1 Bike Saddle

This revolutionary bike seat is called the FR-1 Bike Saddle, and it is built from cork. It is a sustainable solution for bikes and bike parts, and it is a radical design that utilizes a material that is not usually chosen for bike parts.

Why is it noteworthy?

At first, you would think this is not a sturdy and comfortable material for something that you will be sitting on probably for a long period. But cork is actually pretty durable and lightweight so it should be something that can last a long time and not hurt your tushy that much. It is also water-resistant and can offer better cushioning compared to other materials.

What we like

- Stronger but also more lightweight compared to the more common steel that a lot of bike seats utilize

- Sustainable design that supports the historic local cork farming

What we dislike

9. The LIVALL LTSW21

Designed by the same company that brought us the LIVALL EV021 smart helmet with built-in safety lights, the LIVALL LTSW21 are wireless earphones that are specially created for cyclists.

Why is it noteworthy?

With a unique design that allows you to wear most cycling helmets along with the earphones, the LTS21 gives you the ability to listen to music/podcasts, answer calls, and talk to fellow riders while still providing situational awareness through its open-ear design.

What we like

- The wireless earphones can be worn regularly as well as with your cycling helmet!

What we dislike

- Color options are limited to black and white – more variations would be appreciated!

10. Hiplok SWITCH Folding Bike Lock

The Hiplok SWITCH folding bike lock is designed to help you carry your bicycle lock everywhere with you with ease! It’s also super light and weighs just over a kilogram, making it easy to strap to your backpack.

Why is it noteworthy?

The bike lock features a SWITCH clip carry system that makes it easy to carry on yourself or your bike. It has an easy-to-install bracket and SWITCH plate that fits the lock or a water bottle.

What we like

- Made using 6 premium hardened steel bars that link up to create its total strength

What we dislike

- Available in two color options only, we would love to see more variants

The post Top 10 Clever Accessories To Give Your Bicycle A Level-Up Makeover first appeared on Yanko Design.