3D Printing is gaining more momentum and popularity than ever! Designers and architects all over the world are now adopting 3D Printing for the creation of almost all types of products and structures. It’s a technique that is being widely utilized in product design, owing to its simple and innovative nature. But designers aren’t employing 3D printing only to create basic models, they’re utilizing this technique in mind-blowing ways as well! From an electric violin with a 3D-printed body to a pair of 3D-printed shoes that’ll make you feel like Bigfoot – the scope of this dependable technique is unlimited! Dive into this collection of humble yet groundbreaking 3D-printed designs.

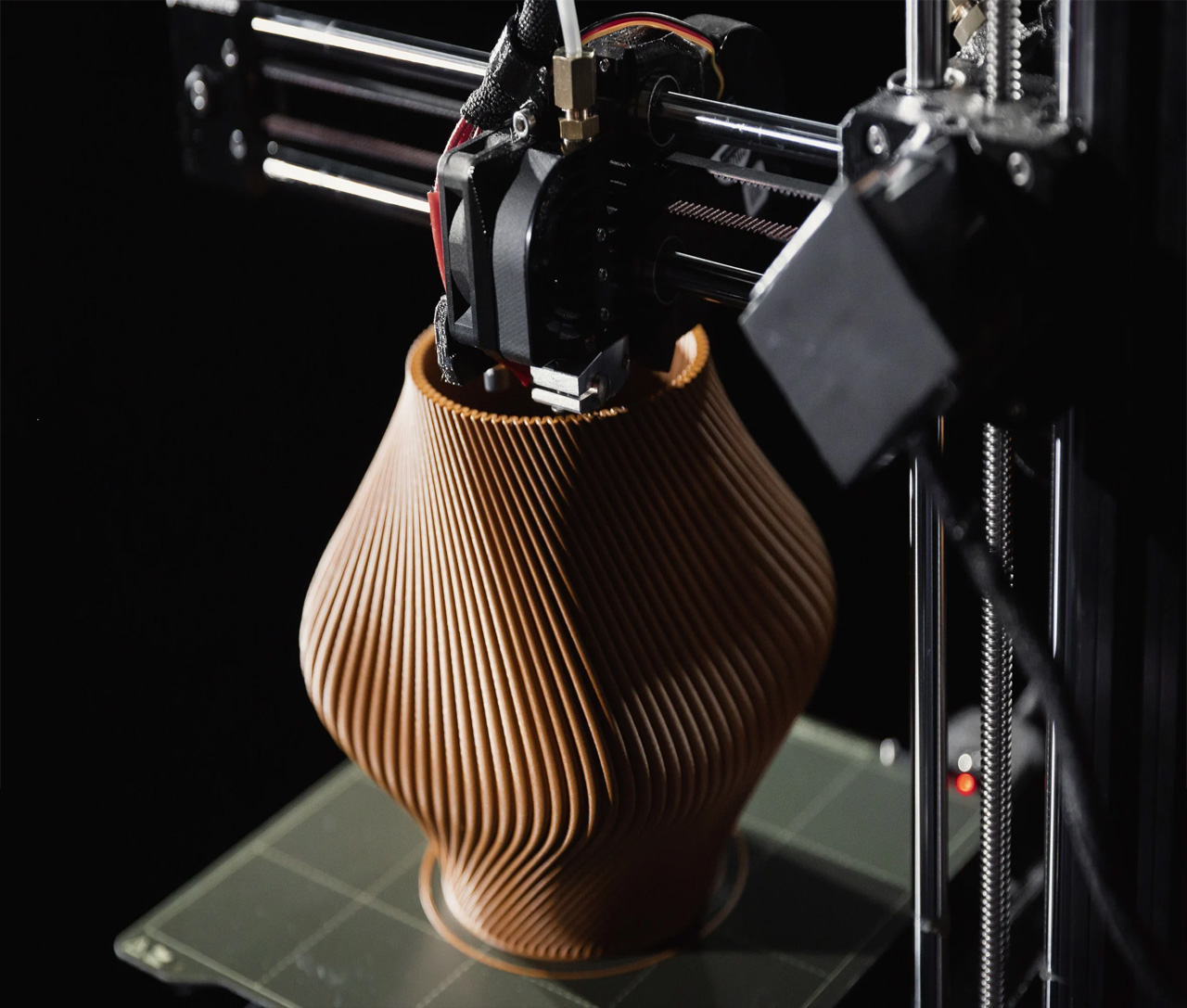

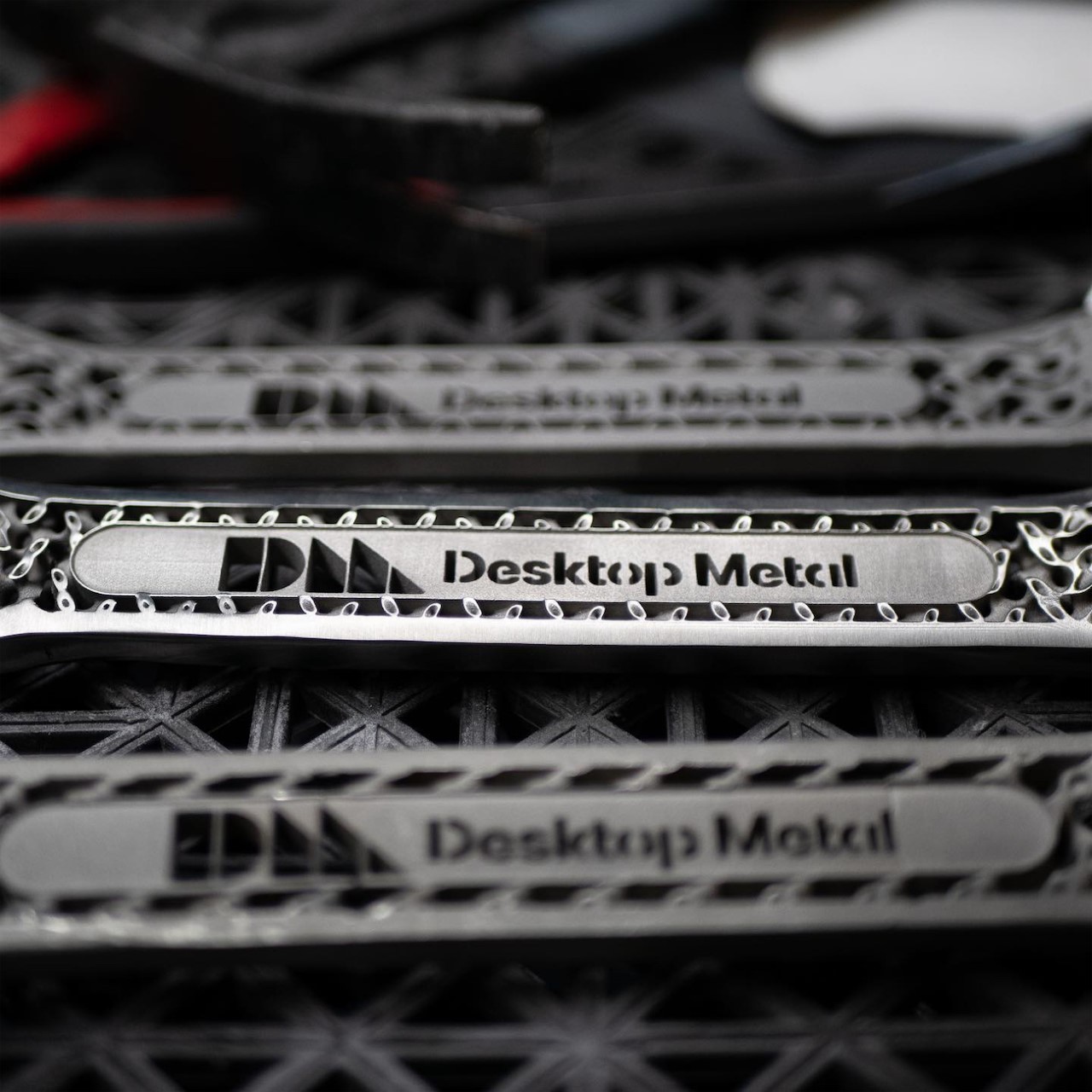

1. 3D-printed Wrench

Look at these wrenches and you’ll almost instantly notice something different about them. Unlike the die-cast wrenches you see with solid metal bodies, these unique tools from Desktop Metal come with a textured inner surface, featuring multiple holes and cavities.

Why is it noteworthy?

The inner surface of these wrenches uses a gyroid-style in-fill, commonly seen in 3D printing to fill up inner spaces with support material while conserving plastic. The gyroid inner mass gives these metal wrenches their strength while simultaneously cutting down on material and weight. The result is the same, functional tool but with nearly 30% less mass and weight.

What we like

- The parts have a much higher and more uniform density (up to 99%) than other metal 3D printing methods while being much faster too

What we dislike

- The prototype wrench is less of an actual product and more of a showcase of Desktop Metal’s capabilities

2. Karen Ultralight Electric Violin

While the name Karen Ultralight Electric Violin may not be the best moniker for this instrument, it’s definitely the kind you won’t be able to ignore. Envisioned by Anima Design for Katahashi Instruments the Karen Ultralight is a dynamic electric violin that ditches conventional wooden acoustic chambers for something more eye-catching.

Why is it noteworthy?

The violin comes with a relatively hollow body made through generative design, which still provides strength with minimal use of material. The 3D-printed generative frame sits on a carbon fiber body, with a birchwood fingerboard for an elevated yet familiar playing experience. Working just like an electric guitar, the Karen Ultralight has a 1/4-inch jack output, but even sports an internal 9V battery and a headphone jack so you can ‘silently’ play music directly into your headphones without disturbing the neighbors!

What we like

- Uses a popular design technique called generative design

- A slot on the back lets you put in a 9V battery and plug your own headphones into the Karen, giving you the ability to play silently, right into your ear

What we dislike

- Without trying this, we cannot say how the music produced will sound like minus the wooden timbre

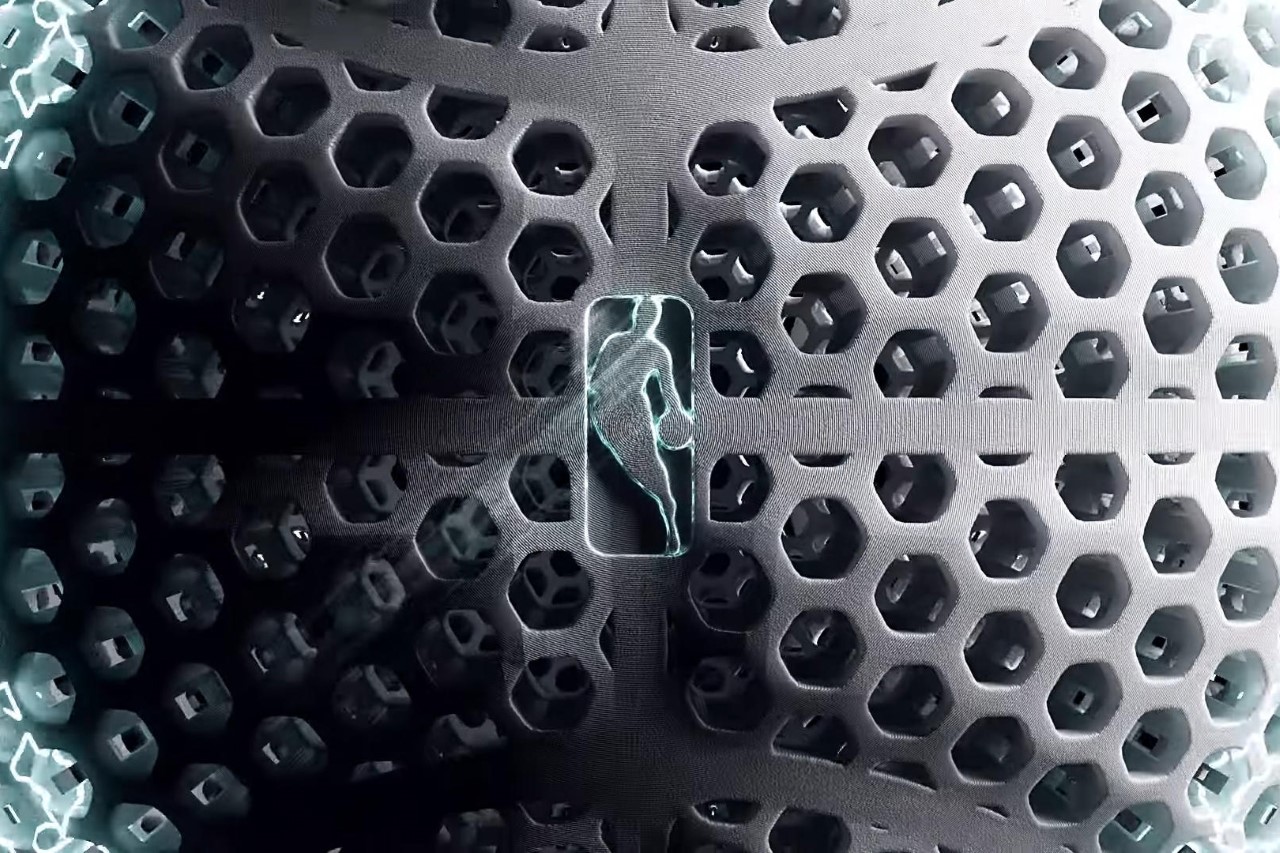

3. Wilson Airless Basketball

Using a format and technique similar to those airless car tire concepts we’ve seen before, Wilson’s latest airless basketball employs a similar see-through 3D-printed mesh to create a ball that bounces just like a basketball… but looks like nothing any basketball you’ve ever seen before.

Why is it noteworthy?

Created as an experimental prototype by Wilson Sporting Goods Co.’s R&D (Basketball) division, the Airless Basketball prototype is a stunning piece of design and engineering that looks, weighs, and bounces just like a basketball, but fundamentally rethinks the ball’s physical structure and underlying physics.

What we like

- The ball employs a 3D hexagonal mesh structure that’s highly elastic, enabling it to bounce just like a pressurized ball

- Doesn’t need pumping for refilling

What we dislike

- A lot of factors remain undetermined, like the ball’s lifespan, resistance to damage, how well players can grip it, whether objects can get stuck inside the ball’s mesh, how it reacts to spin, and what its overall aerodynamics are

4. The PSFF Bench

The PSFF Bench is a prototype and is a furniture piece with a sculptural appeal to it. It is 3D printed using concrete! Besides adding character to the square and enhancing its overall appeal, the bench aims to function as an off-the-shelf solution for providing public skateboard-focused furniture to places all over the world.

Why is it noteworthy?

With this project, Holland hopes to bring iconic sweeping skate landscapes, and minimal concrete design to the skating world of Southampton. It includes a collection of 3D-printed furniture pieces that are wholly focused on skating. The objects are created using concrete, and no other material.

What we like

- The 3D-printing process is supremely optimized and produces premium-quality construction products

What we dislike

- Aesthetics are dull and unassuming

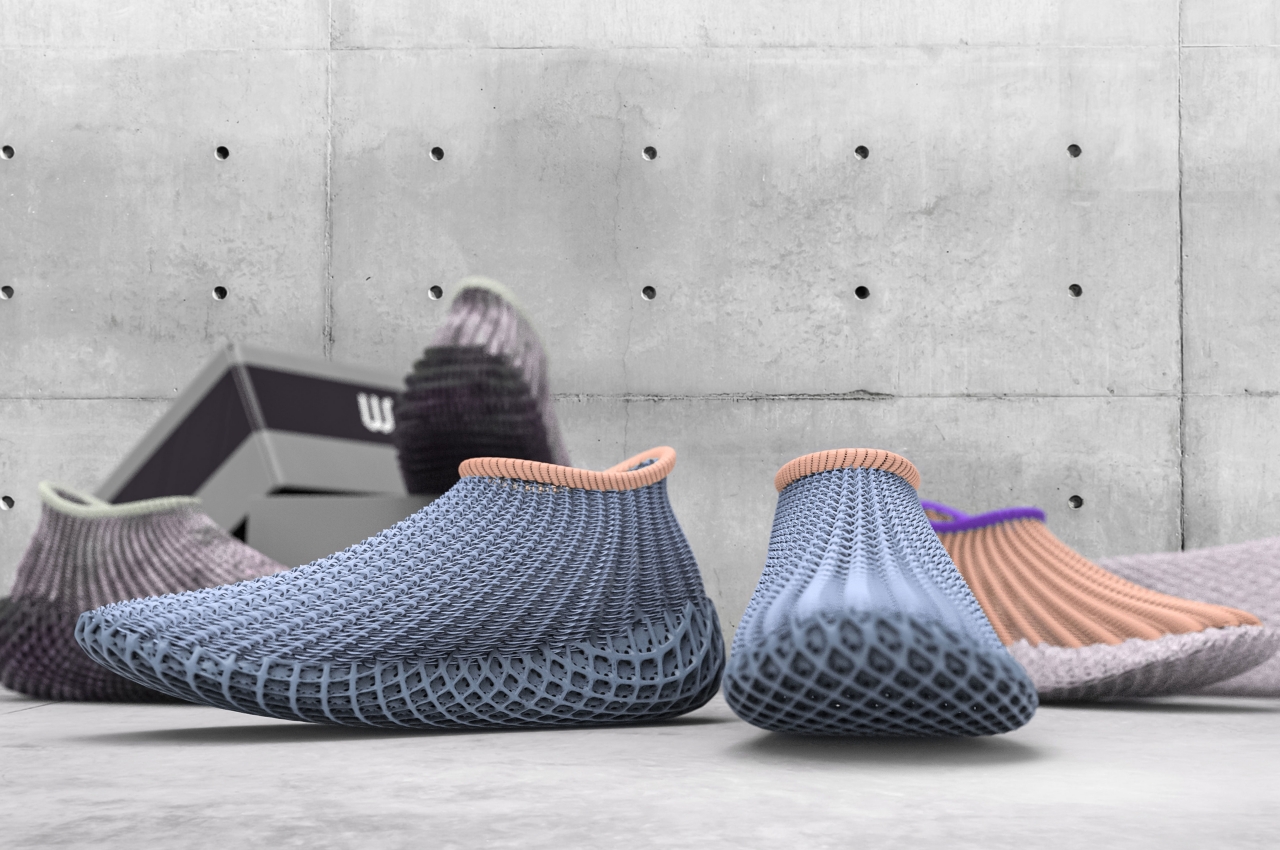

5. The Cryptide Sneaker

The Cryptide Sneaker was designed by Stephan Henrich for Sintratec. The German architect and designer came up with a pair of full 3D shoes meant to be laser sintered with a flexible TPE material. Using a Sintratec S2 System 3D printer, the shoes were formed and printed.

Why is it noteworthy?

The Cryptide features a sole with an open design. The designer said it was made possible by SLS production (Selective Laser Sintering) and a material called Sintratec TPE elastomer. Simply put, SLS is an additive manufacturing that takes advantage of a laser to sinter particles into a more solid 3D structure. Henrich and Sintratec worked together to bring the sneaker design into reality.

What we like

- The size and shape can adapt to the foot of the wearer

- They remind us of the Adidas Futurecraft 4D!

What we dislike

- They don’t rate high on aesthetics + style

6. Cozy Cleo

Based in Germany, the design studio EveryOtherDay designed this 3D-printed table lamp. It was created using recycled plastic bottles and cardboard. This sustainable product is a fine specimen of circular design and wholly embodies minimalistic design principles.

Why is it noteworthy?

The table lamp is Rasenberger’s innovative attempt to tackle the excessive wastage of cardboard, and instead incorporate it in a circular design process, providing the material with a new and redefined identity. In this entire process, almost 200g of cardboard, and 10 plastic bottles are recycled.

What we like

- Once the lifecycle of the lamp has ended, it can be recycled, allowing the materials to once again be utilized in a completely new and different manner

What we dislike

- Not sure if the lamp will have a long lifespan

7. The Blizzfosser

Customized to each person’s interdental crevasses, the Blizzflosser is the brainchild of Chris Martin who has already made us fans with the weirdly productive toothbrush-sponge.

Why is it noteworthy?

The Blizzflosser comes with soft floss lined according to an individual’s denture. It is washable and reusable. The floss aligned on the contraption is thin to glide through into the gaps between the teeth and does not hurt the gums. Getting one of these tailored for you is simple; Blizzbrush sends a double-sided special paste tray to you that you bite into to leave about 5mm deep impressions of your upper and lower dentures. You then snap pictures of your production and send them to the company that based on the images customizes and 3D prints a complete denture flosser for you.

What we like

- Replicates the manual flossing techniques

What we dislike

- People accustomed to flossing, may not like this new technique

8. Wabo

Wabo is a collection of hand boards that are created from plastic waste produced from 3D-printed prototyping. Eight million pieces of plastic make their way into the ocean on a daily basis. That’s a lot of plastic. While some brands commit themselves to gimmicky sustainable practices that have more to do with marketing than carbon-neutral manufacturing, other brands learn how to make something out of the plastic waste they produce.

Why is it noteworthy?

The multidisciplinary design studio Uido Design is a studio known for its catalog of 3D printable product designs and its team is doing something about the waste they produce during the design process. Shredding the plastic waste produced from 3D printing into bits and pieces, Uido Design uses the waste to create hand boards for users to ride the ocean waves.

What we like

- The hand boards are handcrafted

What we dislike

- Not a necessary product, but still fun!

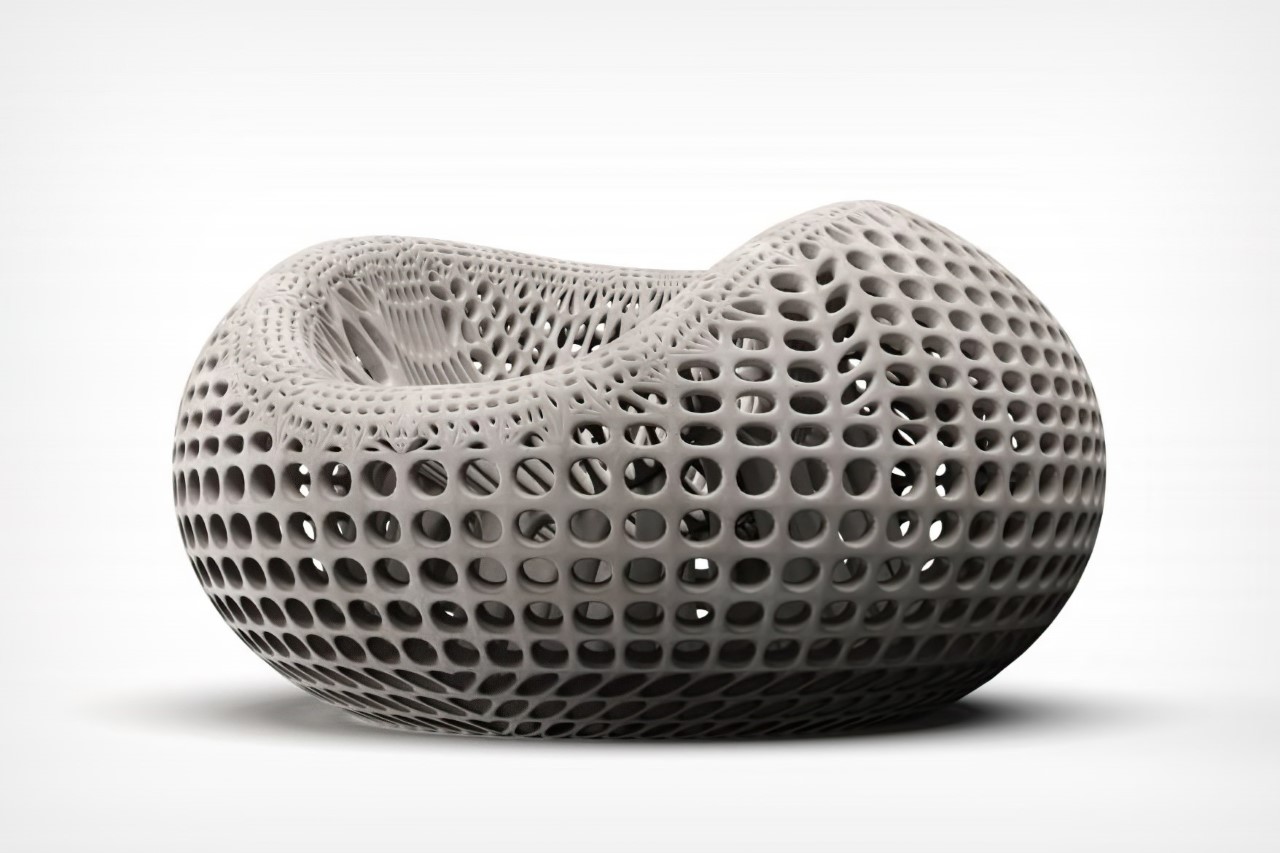

9. 3D-printed Chairs

Designed by Johannes Steinbauer Office For Design, these 3D-printed chairs are produced using additive manufacturing and are created without using fabrics, springs, and foam! And they still manage to be super functional and comfortable. These chairs utilize rigid parts, instead of the typical racks from chairs.

Why is it noteworthy?

The design is simple enough with four legs, a round seat, and a single bar at the back. But if you want to add other components like more racks or even textiles, these can also be added through 3D printing. The different parts are easy to assemble and disassemble and once it reaches the end of life, you can dispose of the different parts separately and recycle them accordingly.

What we like

- Super easy to assemble and disassemble

- Sustainable design

What we dislike

- No instruction on having a space-saving version of this design

10. Cullan’s 3D-printed Shoes

Designed in the metaverse by Cullan Kerner, the shoes embody an aesthetic that’s best described as ‘oddly refreshing’ and the reason is because it doesn’t stick to the constraints of regular shoe design intended for mass production. The process with shoe design is standardized to a great degree – you’ve got pre-set sizes, materials that are readily available, dies for cutting/molding these materials, and processes like stitching or gluing that bring them together

Why is it noteworthy?

Cullan’s design process, however, is completely different. For starters, the shoes were made entirely in Gravity Sketch, a free VR software that allows you to design directly in a 3D space. Cullan designed the shoes almost like a sculptor makes an art piece, creating in 3D space. The shoes are made for 3D printing – a process that still hasn’t been mass-accepted by the shoe industry. The idea is simple – Cullan’s model gets imported into a 3D printing software, and the printer meticulously builds the design layer by layer using a single flexible elastomeric material.

What we like

- Each shoe can be designed to fit you perfectly, and they’re all made to order

- Available as NFTs

What we dislike

- Without an actual shoe model, we can’t say how the feet support will be and the durability of the shoe once in use

The post Top 10 3D printed products designed to make sustainability a part of your everyday life first appeared on Yanko Design.