2020 was a life-altering and drastic year, and for the past 4 years, we have been redeeming our careless mistakes of the past and living more consciously and sustainably. We cannot ignore the needs of our planet anymore, we need to consider the environment, and what better way to start doing that than from our own homes? Sustainable chairs are taking the design industry by storm, they’re a step towards making our homes and our daily lives more eco-friendly and sustainable. They’re an attempt to cast aside toxic materials, and instead, add furniture designs to our home that won’t rot away on Earth for years once we’re done with them. We’ve curated a collection of furniture products created from cork, 3D printing, and even coffee-based waste! The options are endless, and the end result is the same – a greener, healthier, and happier Mother Earth!

1. 3D-Printed Chair

Created by Johannes Steinbauer Office For Design, these innovative 3D-printed chairs were designed using additive manufacturing, and without utilizing fabrics, springs, and foam. The chair doesn’t include any springs or foam, but it is still super functional and comfortable to sit in.

Why is it noteworthy?

The design of the chair is quite simple with four legs, a round seat, and a single bar at the back. You can add other components like racks and textiles through 3D printing. The various parts can be assembled and disassembled, and once its lifespan ends, you can dispose of the different parts separately, and recycle them.

What we like

- The chair is easy to assemble and disassemble

- Sustainable design that employs 3D printing

What we dislike

- No instruction on how to have a space-saving variant

2. Hemp & Eelgrass Chair

Foersom & Hiort-Lorenzen collaborated with furniture brand Norman Copenhagen to build a collection of plant-based chairs, which were unveiled at the Stockholm Design Week. The collection includes two unique chairs, one made from hemp, and one made from a combination of hemp and eelgrass.

Why is it noteworthy?

Hemp is a type of cannabis plant, while eelgrass is like seaweed. The biomaterials were used to replace injection-molded plastic, which created a shell chair supported by powder-coated steel legs.

What we like

- The material used is recyclable and is an innovative mix of two plants

What we dislike

- Aesthetically the chair isn’t very pleasing and could be an eyesore in homes if not paired properly with the decor

3. VALE Collection

Called the VALE collection, LAYER designed this eco-friendly chair and stool collection for the US furniture brand KFI Studios. It is made from recycled PET bottles and was designed as a protest against the plastic waste that is drowning and polluting the planet’s oceans and landfills.

Why is it noteworthy?

The collection is LAYER and KFI Studio’s eco-friendly solution to the rising issue of plastic waste, It is a refreshing change, and a fine specimen of sustainable furniture, in a day and age where 9 million tons of furniture are found in landfills.

What we like

- Made using an eco-friendly and durable material produced from recycled PET bottles

What we dislike

- The looks of the chairs and stool are a bit boring, more aesthetic details could have been added

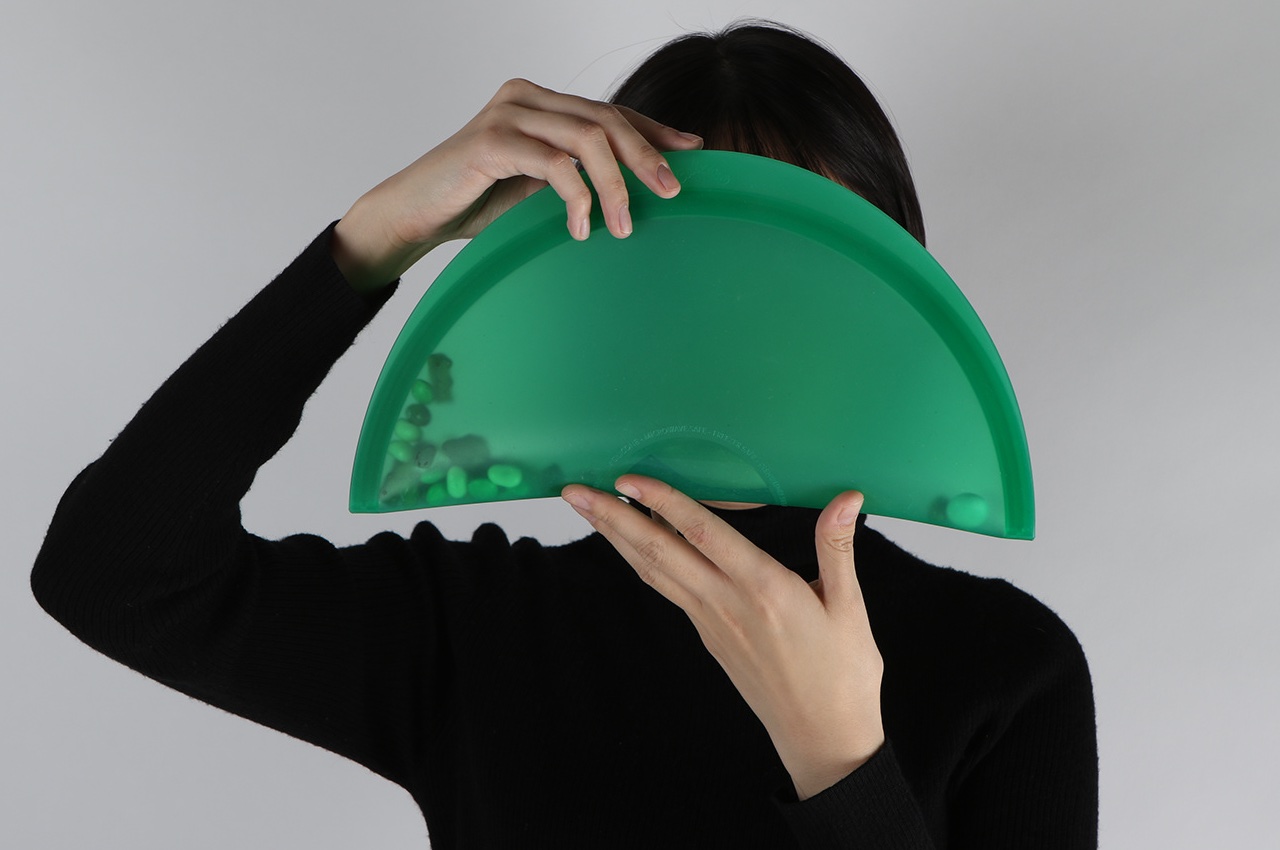

4. OTO Chair

Called the OTO Chair, and designed by Alessandro Stabile and Martinelli Venezia, this chair is designed to be a “manifesto for circular design”. The chair is a recycled plastic chair that aims to achieve a goal of full sustainability, in materials choices and supply chain – as a complete whole.

Why is it noteworthy?

It has a clean, minimal, and simple form, and comes in a bunch of fun colors to pick from – onyx, fog, mustard, coral, forest, and eucalyptus. You can choose the color that best suits your personality and interior decor style.

What we like

- The production of each OTO chair removes almost 500 grams of plastic from the sea

What we dislike

- Its hard, flat surfaces look a little too rigid for comfort

5. Gago Rocking Chair

Portuguese design brand Dam just released a cork-clad rocking chair to celebrate 10 years of the brand’s existence. The innovative-looking chair is inspired by seaplanes.

Why is it noteworthy?

When you look at the Gago rocking chair, it brings to mind the image of the rounded shape of an aviator’s helmet, which is an ode to the first successful crossing of the South Atlantic Ocean by a Portuguese pilot in 1922. The label of every chair says “1922, *8383km”. The number represents the milestone journey between Lisbon and Rio de Janeiro.

What you like

- The chair is made from cork, making it sustainable and durable

What we dislike

- Being a rocking chair, it is a niche furniture design and doesn’t hold utility for everyone

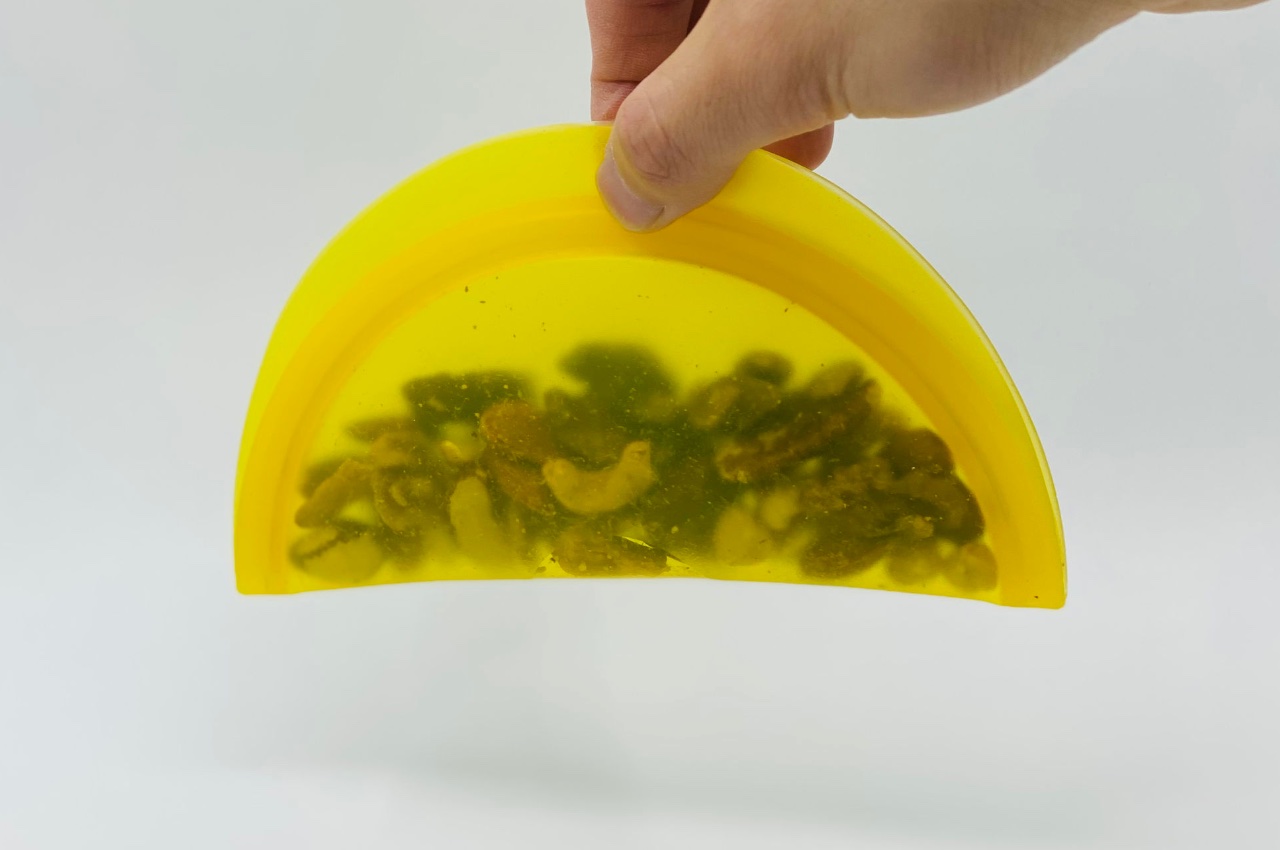

6. Bend Chair

Created by the Thai design brand Waste is More, the Bend Chair is made using coffee-based waste, wood, and recycled plastic. The minimalist-looking and simple chair is made from More’s signature PlasCoff materials, which is an eco-friendly and durable alternative to other materials.

Why is it noteworthy?

The unique material merges recycled plastic with waste from coffee bean processing, creating a design that is pretty sustainable for your home. What makes the furniture design even more interesting is that the deeper the shade, the higher is the content of coffee waste.

What we like

- Constructed using a locally sourced rubber tree timber and coffee-based waste

- It is the ultimate mix of ergonomics, sustainability, functionality and good looks

What we dislike

- Aesthetics are a bit unassuming and simple

7. Tellus Bench

Called the Tellus Bench, this innovative seating design was created by the street furniture brand Vestre and designer Emma Olbers. It is made using fossil-free steel, and no carbon sessions are created during its manufacturing process.

Why is it noteworthy?

The steel used to build the Tellus Bench was manufactured by Swedish steelmaker SSAB in its converted blast furnace, which uses green hydrogen instead of coal for heat, and emits no carbon dioxide.

What we like

- The bench features wide armrests and offers comfort to the user, while also providing sufficient space to place a coffee or tea cup

What we dislike

- Aesthetics are a bit dull and unassuming

8. Liberty Ocean Chair

The Liberty Ocean Chair is designed by the office furniture brand Humanscale and was made using one kilogram of abandoned fishing nets found in the ocean. It is said to be the first task chair made from recycled fishing nets and is a commendable effort on Humanscale’s behalf to tackle the issue of ocean plastic.

Why is it noteworthy?

The Liberty Ocean Chair is a successor of the original Liberty chair, which is quite ergonomic and minimal as well. But the Liberty Ocean Chair takes it one step further with an eco-friendly and sustainable ethos which is highly valuable in today’s times.

What we like

- Features a form-sensing mesh back

What we dislike

- There seems to be no option for customization

9. Stack Chair

The innovative Stack chair features a compass-like four-legged base, where you can stack the chair almost to infinity. But of course, you’ll be limited by how much vertical space there is, and how high you can safely reach.

Why is it noteworthy?

The design has two parts, the base and the shell, and the parts can be connected by simply snapping the base underneath the shell’s designed rim. The two become a single and stable piece of furniture, which completely simplifies the manufacturing process, as well as assembly and shipping.

What we like

- You can mix and match different base and shell colors or even materials

What we dislike

- The chair doesn’t look too comfy to sit on for long durations of time

10. Fuld

Called Fuld, this nesting chair by Herman Miller is a unique and one-of-a-kind innovation with a sustainable twist. It’s an efficient and effective solution that will reconfigure your workspace without compromising on sleekness, minimalism, and style.

Why is it noteworthy?

It is a revolutionary one-piece construction equipped with an inverted Y shape, which makes the production process reduce the water creation. The back is equipped with elasticity, to provide the utmost comfort as you shift and move around.

What we like

- Made from 50 percent post-consumer recycled content

What we dislike

- There isn’t much head support if you’re quite tall

The post Top 10 Sustainable Chair Designs For An Eco-Friendly Home first appeared on Yanko Design.